Sleeve-pressure-type grinding device for inverted-conical-surface sealing ring

A technology of sealing ring and inverted cone surface, which is applied in the direction of grinding workpiece supports, grinding/polishing equipment, grinding machines, etc., can solve the problem of difficulty in effectively obtaining sealing rings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

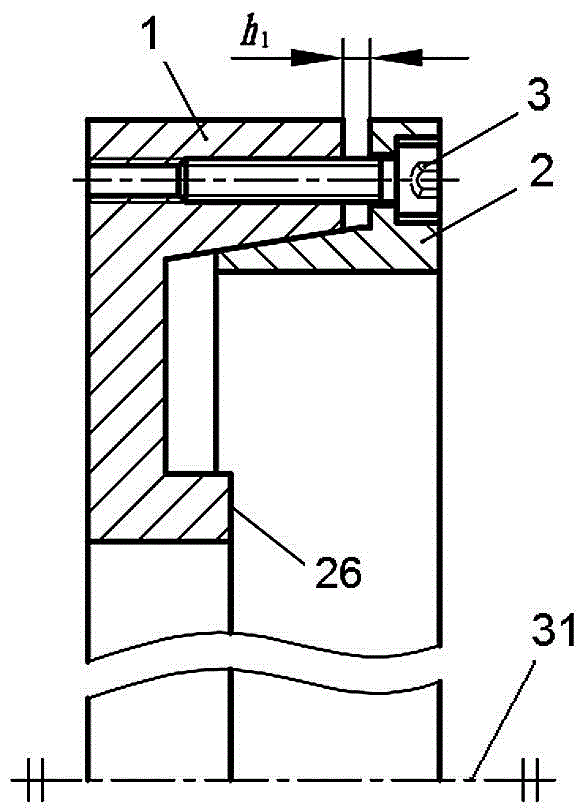

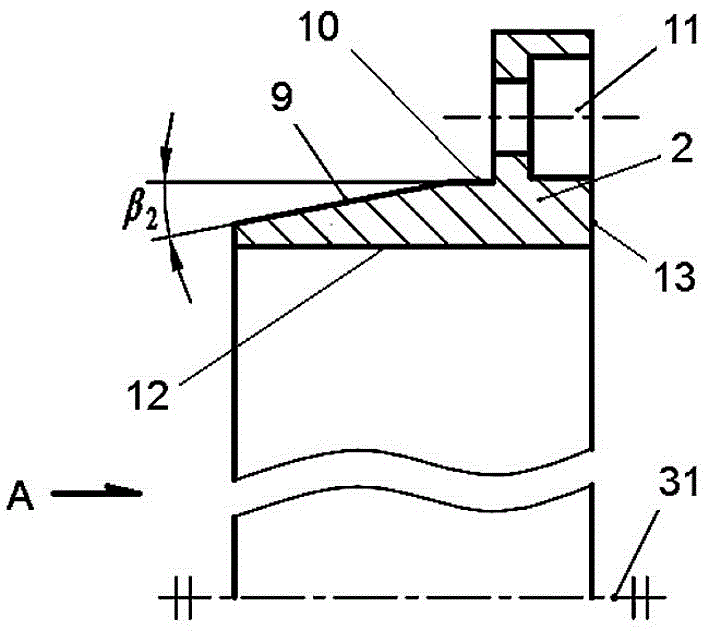

[0026] figure 1 Shown is the basic form of an overall structure of the taper sleeve grinding device for processing inverted cone sealing rings according to the present invention, which includes a set of outer sleeve structures 1 that are axially socket-fitted with opposite ends respectively having concave-convex structures and interpolation structure 2, which can be distributed uniformly along the circle by 18 ( Figure 4 The connecting structures 3 in the form of 6) screws or bolts and nuts are connected and fastened to each other. in,

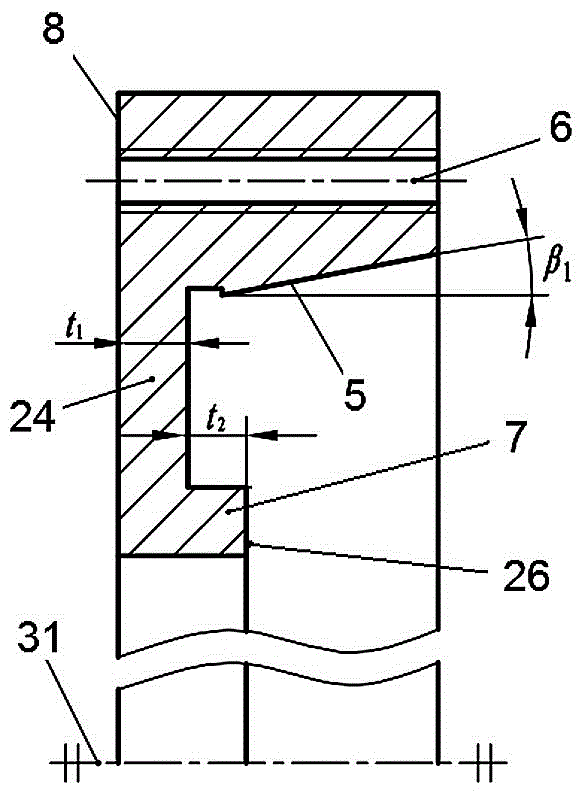

[0027] Jacket structure 1 such as figure 2 As shown, it is a cylindrical structure, on the radially outer side of the radially outwardly expanded cylindrical wall structure at one axial end, there is a concave hole surface for interfitting with the interpolation structure 2 Structure 5. The concave surface structure 5 is centered on the central axis 31 and has a cone angle. β 1 cone surface, cone angle β 1 The size of 2′≤ β 1≤300′....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com