Method for producing ecological plate floor substrate

A production method and technology of ecological boards, which are applied in wood processing utensils, household components, applications, etc., can solve the problem of less base material, and achieve the effect of high surface quality requirements and simple production technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

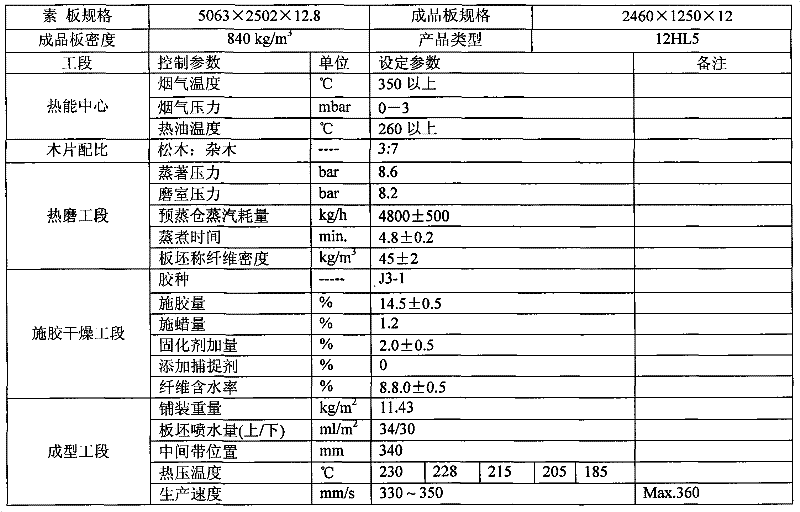

[0021] Describe in detail below in conjunction with embodiment:

[0022] In the process of implementing the plan, we only explained the production of the ecological board floor substrate of this product and the process of other products with special requirements, and the operation process is to produce according to the requirements of the process.

[0023] 1. Raw material preparation: The requirements for woody raw materials are the same as those of other varieties and specifications, and there are no special requirements. They are all mechanically peeled by a peeling machine, and then cut into wood chips according to the specifications and processes after removing impurities from the book cover. Wood chips are stacked in different wood chip bins according to coniferous wood and broad-leaved wood, so as to meet the requirement of uniform proportioning of wood chips through the metering screw. The ratio of softwood to broadleaf is 3:7.

[0024] 2. After water washing, fiber ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com