Taper sleeve type grinding device for machining inverted cone sealing ring

A technology of sealing ring and inverted cone surface, which is used in grinding workpiece supports, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as difficulty in effectively obtaining sealing rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

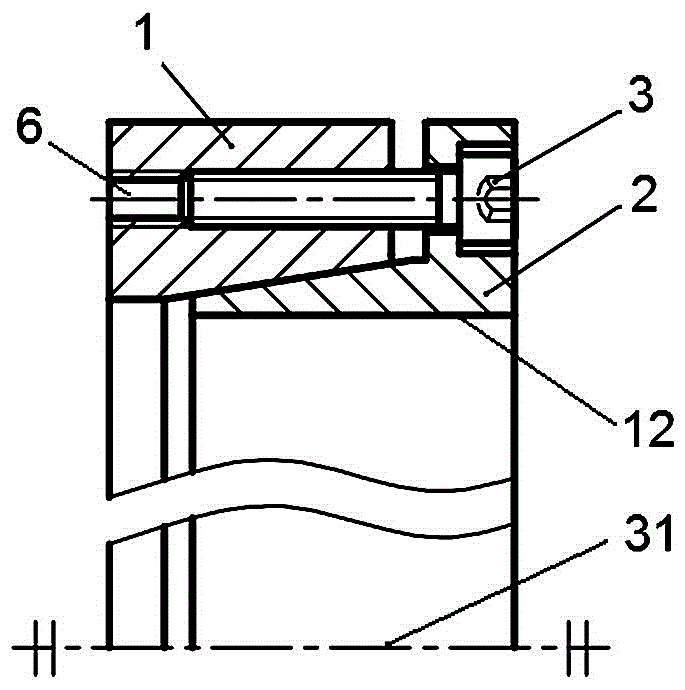

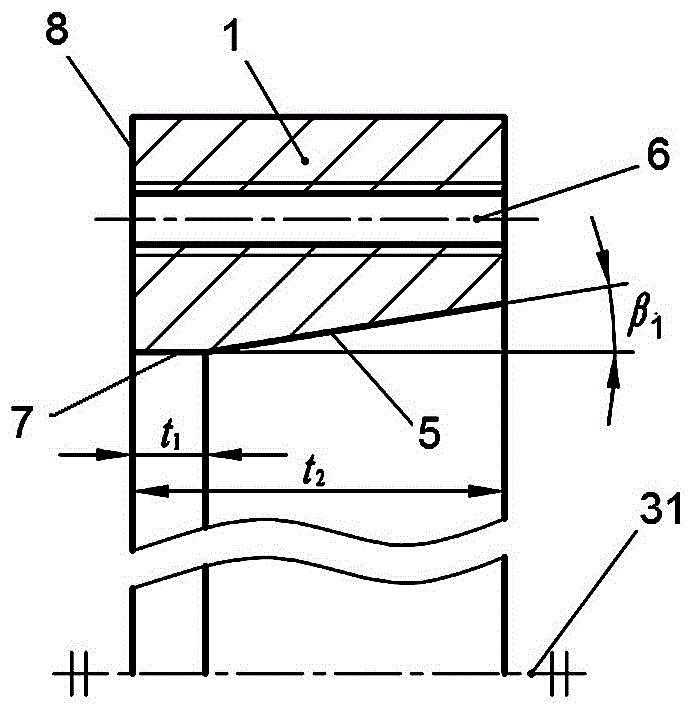

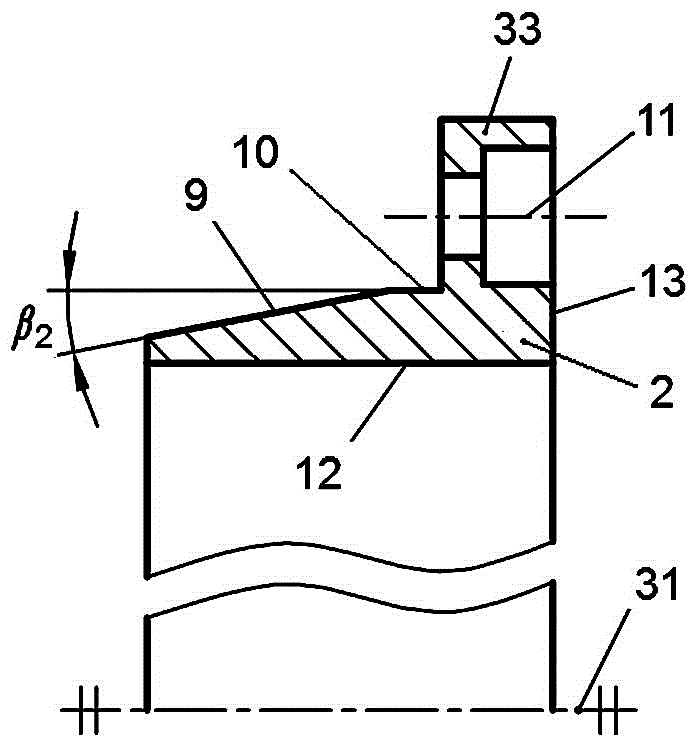

[0021] figure 1 Shown is the basic form of an overall structure of the tapered sleeve grinding device for processing inverted cone sealing rings according to the present invention, including an outer casing structure 1 and an inner insertion structure 2 that can be mated with opposite ends in the axial direction. And can be mutually connected and fastened by connecting structures 3 arranged at equal intervals along the circumference. in:

[0022] The outer casing structure 1 is a cylindrical structure, and its radial outer side is provided with 18 threaded through holes or light holes 6 that can be matched with the connection structure 3 such as screws or bolts and nuts at equal intervals along the circumference, for interpolation structure 2 interconnected tightly.

[0023] The socket-fitting parts of the outer casing structure 1 and the insertion structure 2 take the central axis 31 as the center of rotation and have taper angles respectively. β 1 The working surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com