Sleeving splicing type full-metal screw stator and machining method thereof

A technology of metal stator and screw stator, which is applied in earth square drilling, rotary piston engine, driving device for drilling in borehole, etc. It can solve the problems of low working performance, difficult processing control and difficult surface strengthening of metal screw drilling tools, etc. problem, to achieve the effect of solving the stator fixing problem, solving the stator sealing problem, and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with embodiment the present invention is described in further detail, following embodiment is only descriptive, not restrictive, can not limit protection scope of the present invention with this.

[0051] A method for processing a set spliced all-metal screw stator, comprising the following steps:

[0052] S1, determine the initial parameters of the stator;

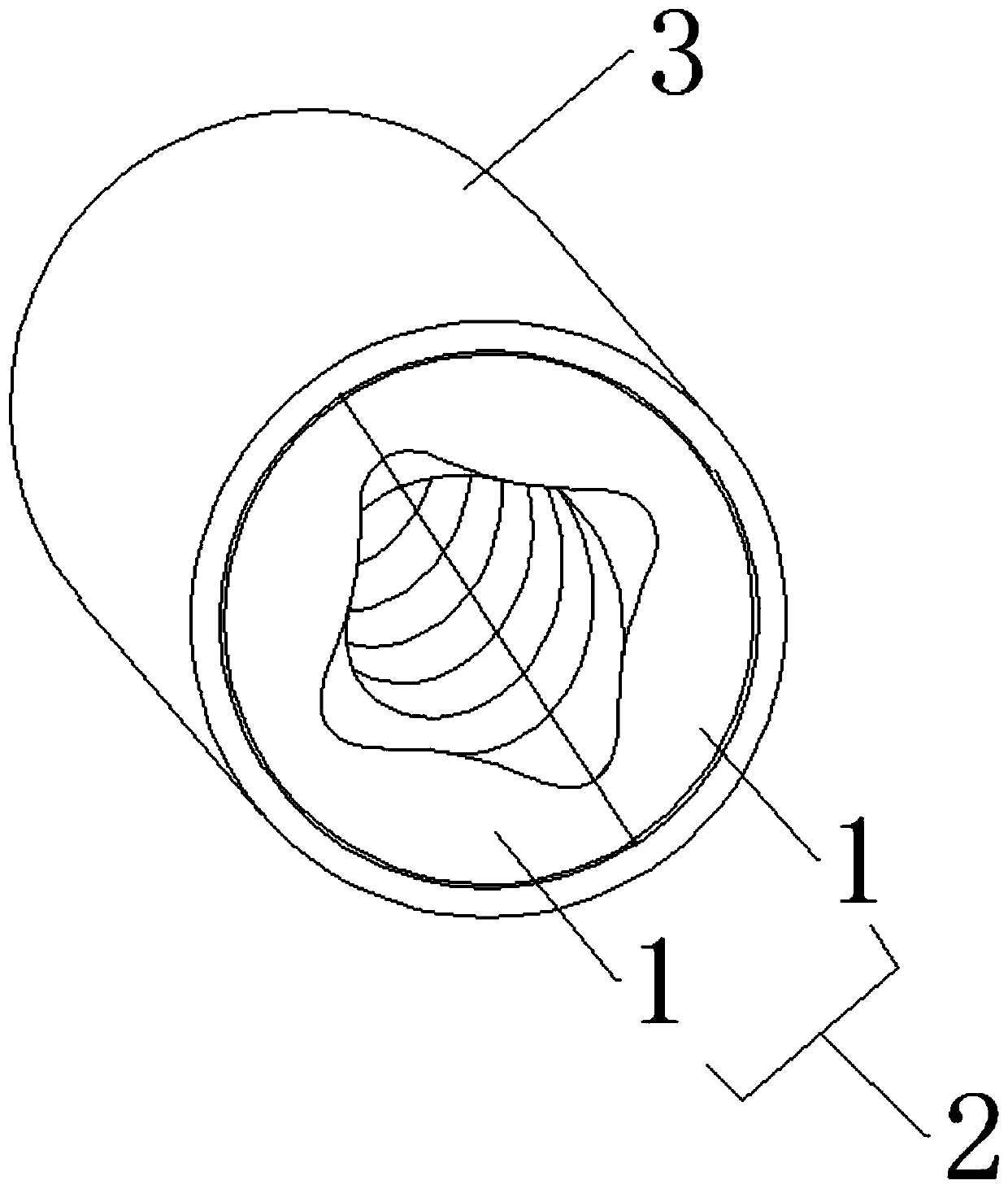

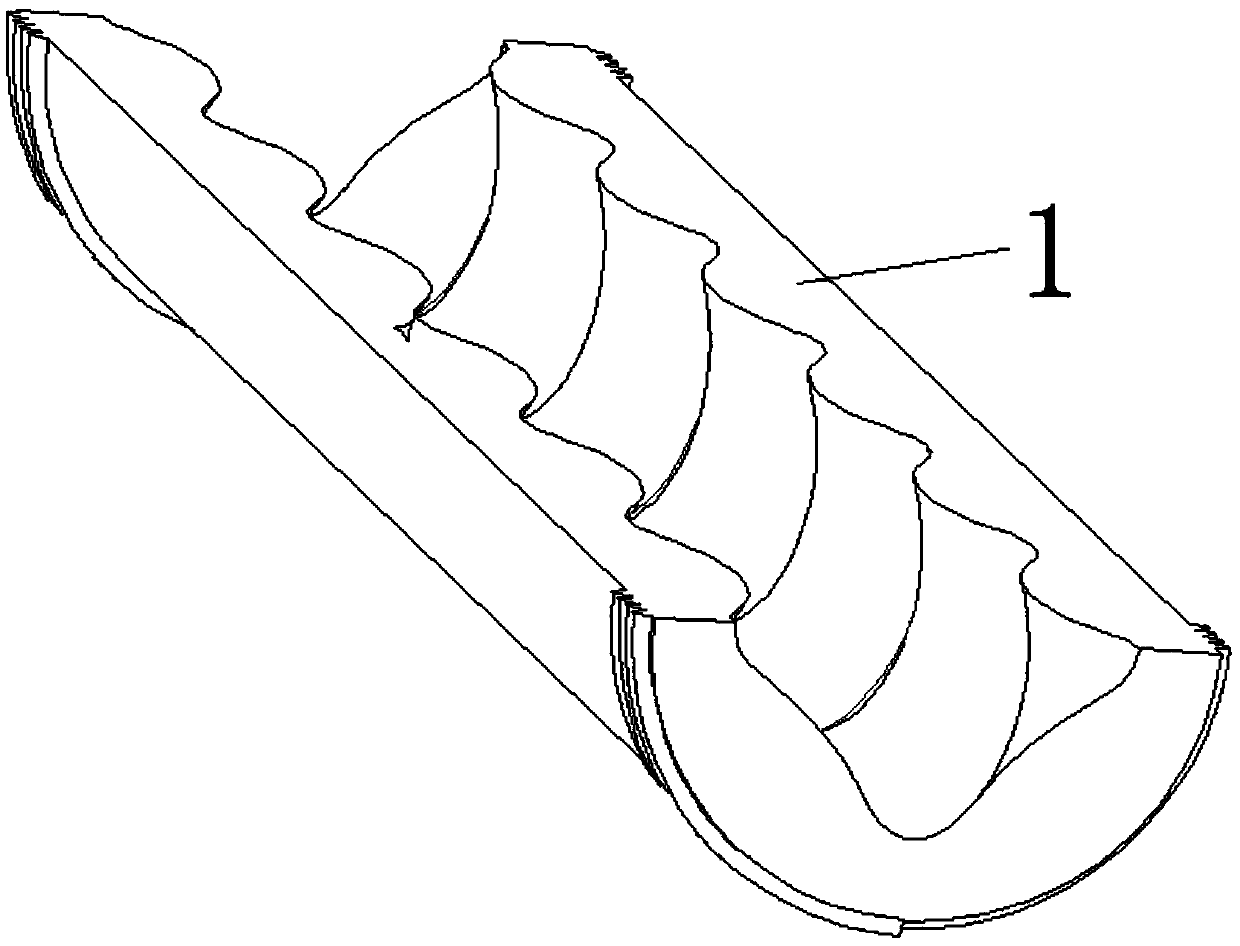

[0053] S2, generating a stator bone line diagram according to the stator bone line equation;

[0054] S3, make an equidistant curve on the stator bone line, and make an equidistant curve with an equidistant radius on the stator bone line outward, to obtain the end surface profile of the motor stator;

[0055] S4, according to the initial parameter value of the motor stator, calculate the outer circle radius and lead of the stator;

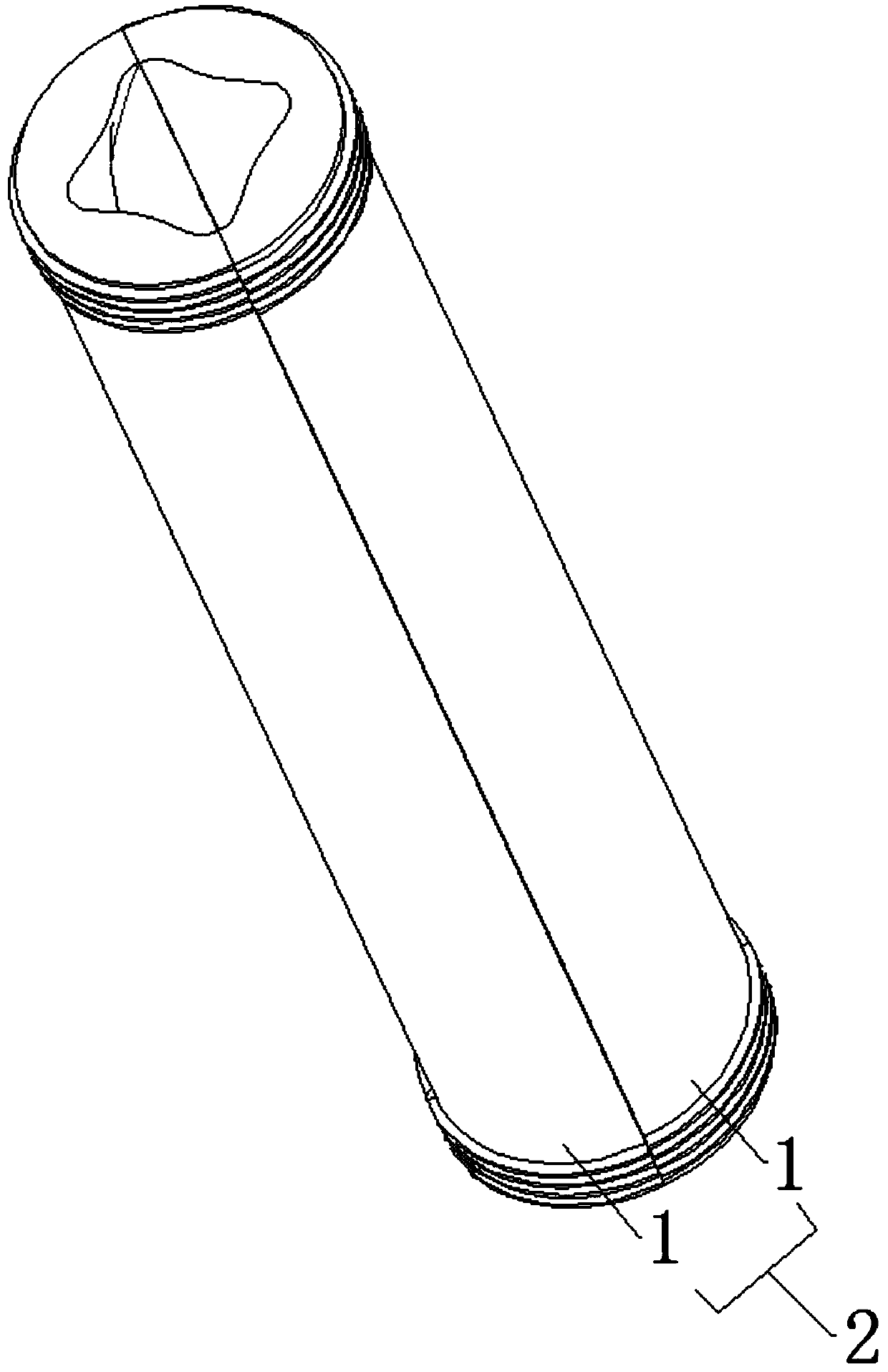

[0056] S5, generate a three-dimensional stator model from the stator end surface profile, outer contour radius, lead and initial parameters of the stator;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com