Waterproof and moisture permeable membrane, preparation method of waterproof and moisture permeable membrane, waterproof and moisture permeable fabric and preparation method of waterproof and moisture permeable fabric

A waterproof and moisture-permeable film and fabric technology, which is applied to the waterproof and moisture-permeable film, its preparation, and the field of waterproof and moisture-permeable fabrics, can solve the problems of reducing the comfort level of clothing and waterproof articles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a method for preparing a waterproof and moisture-permeable membrane, comprising the following steps:

[0050] Dissolving the hydrophobic polymer in the first solvent to obtain a hydrophobic spinning solution;

[0051] Dissolving the hydrophilic polymer in the second solvent to obtain a hydrophilic spinning solution;

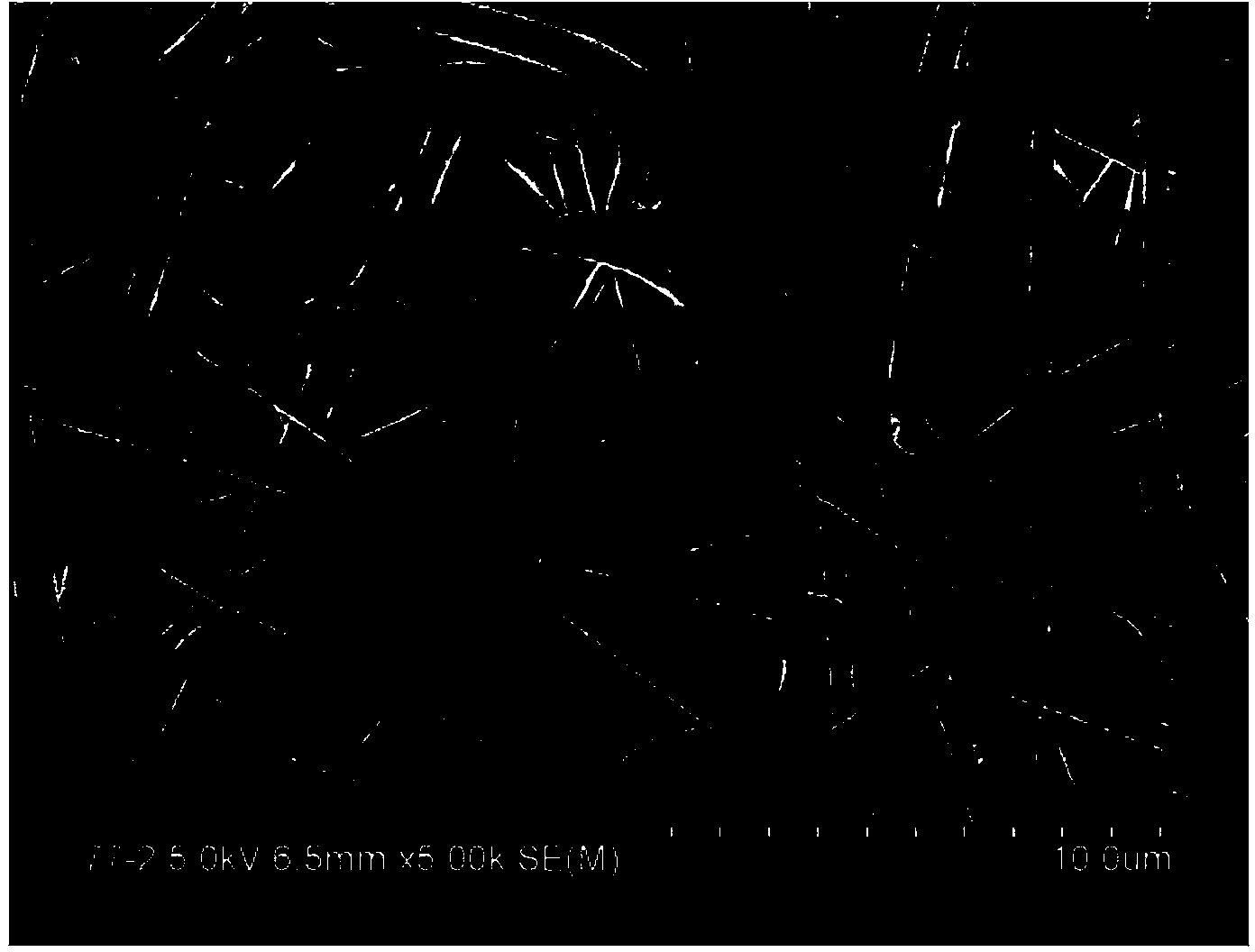

[0052] Carrying out the first electrospinning of the hydrophobic spinning solution to obtain a nanofiber hydrophobic layer;

[0053] Carrying out the second electrospinning of the hydrophilic spinning solution to obtain a nanofiber hydrophilic layer;

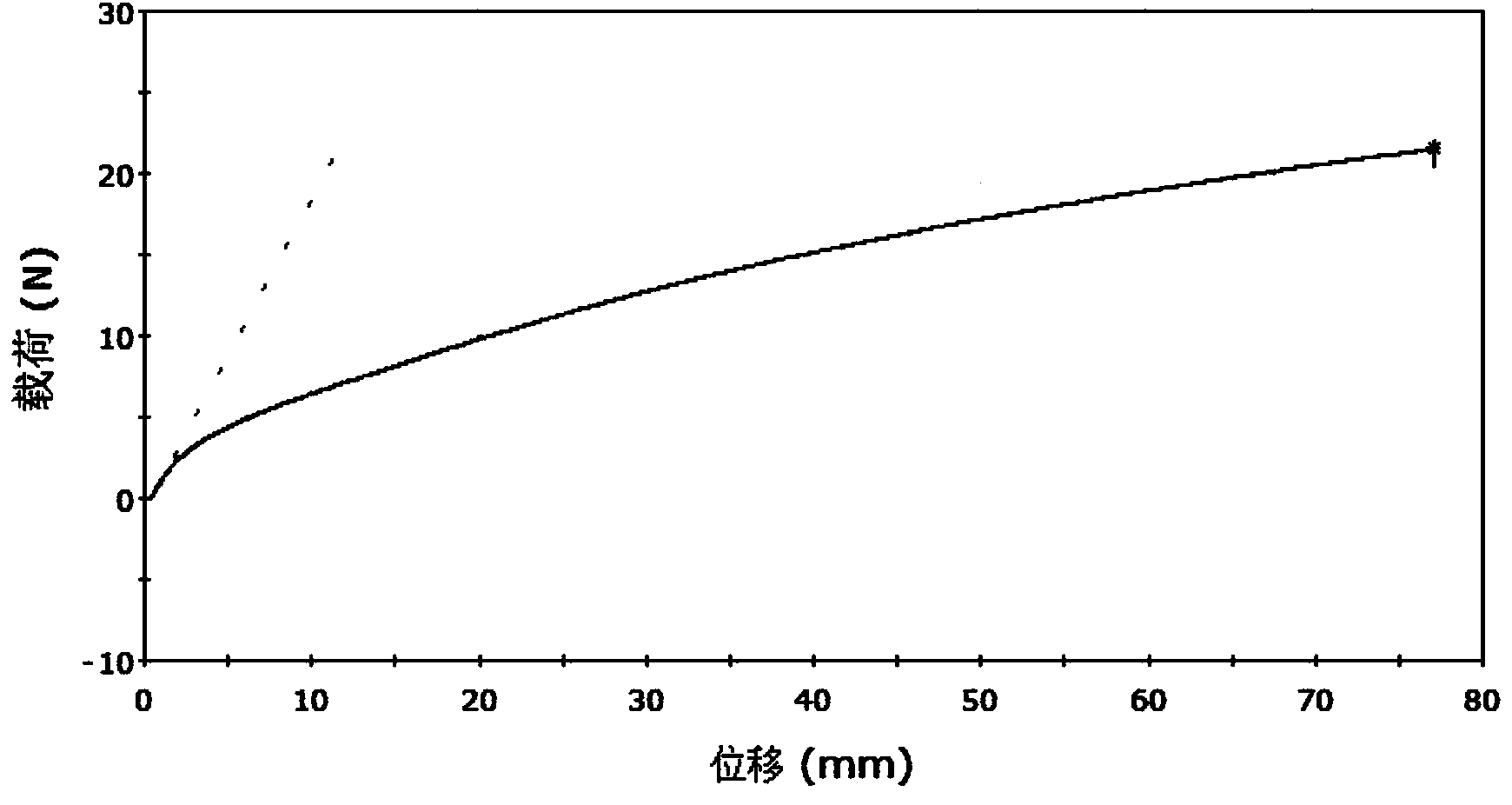

[0054] The nanofiber hydrophilic layer and the nanofiber hydrophobic layer are hot-compressed to obtain a waterproof and moisture-permeable membrane.

[0055] In the invention, the hydrophobic polymer is dissolved in the first solvent to obtain the hydrophobic spinning solution. In the present invention, the hydrophobic polymer is preferably first dried to obtain a drie...

Embodiment 1

[0090] Dry polyethylene terephthalate (PET) particles and polyamide-66 (PA-66) particles in a vacuum oven at 110°C for 12 hours, and polyvinylidene fluoride-perfluoropropylene (PVDF-HFP) powder 1. Thermoplastic polyurethane (TPU) particle powder was dried in a vacuum oven at 100° C. for 12 hours, cooled to room temperature and placed in a desiccator for use.

[0091] Weigh 200g of dry PET particles and dissolve in 1400g of trifluoroacetic acid and dichloromethane mixed solvent, stir at room temperature for 12h to obtain a transparent PET organic spinning solution; weigh 150g of dry PVDF-HFP powder and dissolve in 850g of DMF In the mixed solvent of acetone, stir 12h at room temperature, obtain transparent PVDF-HFP organic spinning solution;

[0092] Weigh 150g of dry PA-66 particles and dissolve them in a mixed solvent of 850g of formic acid and chloroform, stir at room temperature for 12h to obtain a transparent PA-66 organic spinning solution; weigh 120g of dry TPU particles...

Embodiment 2

[0103] Dry polyvinylidene fluoride (PVDF) powder and polyamide-6 (PA-6) particles in a vacuum oven at 110°C for 12 hours, and dry polyvinylidene fluoride-perfluoropropylene copolymer (PVDF-HFP) powder, thermoplastic polyurethane (TPU) particle powder was dried in a vacuum oven at 100°C for 12 hours, cooled to room temperature and placed in a desiccator.

[0104] Weigh 200g dry PVDF powder and dissolve it in a mixed solvent of 1800g DMF and acetone, stir at room temperature for 12h to obtain a transparent PVDF organic spinning solution; weigh 200g dry PVDF-HFP powder and dissolve it in a mixed solvent of 1400g DMF and acetone solvent, stirred at room temperature for 12h to obtain a transparent PVDF-HFP organic spinning solution;

[0105] Weigh 150g of dry PA-6 particles and dissolve them in a mixed solvent of 850g of formic acid and chloroform, stir at room temperature for 12h to obtain a transparent PA-66 organic spinning solution; weigh 120g of dry TPU particles and dissolve th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com