Bipolarity current collector and preparation method

A current collector and bipolar technology, which is applied in the field of bipolar current collector and its preparation, can solve the problems of battery short circuit, copper foil negative electrode oxidation, and increased safety hazards of high-voltage batteries, so as to increase safety and prevent short circuit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

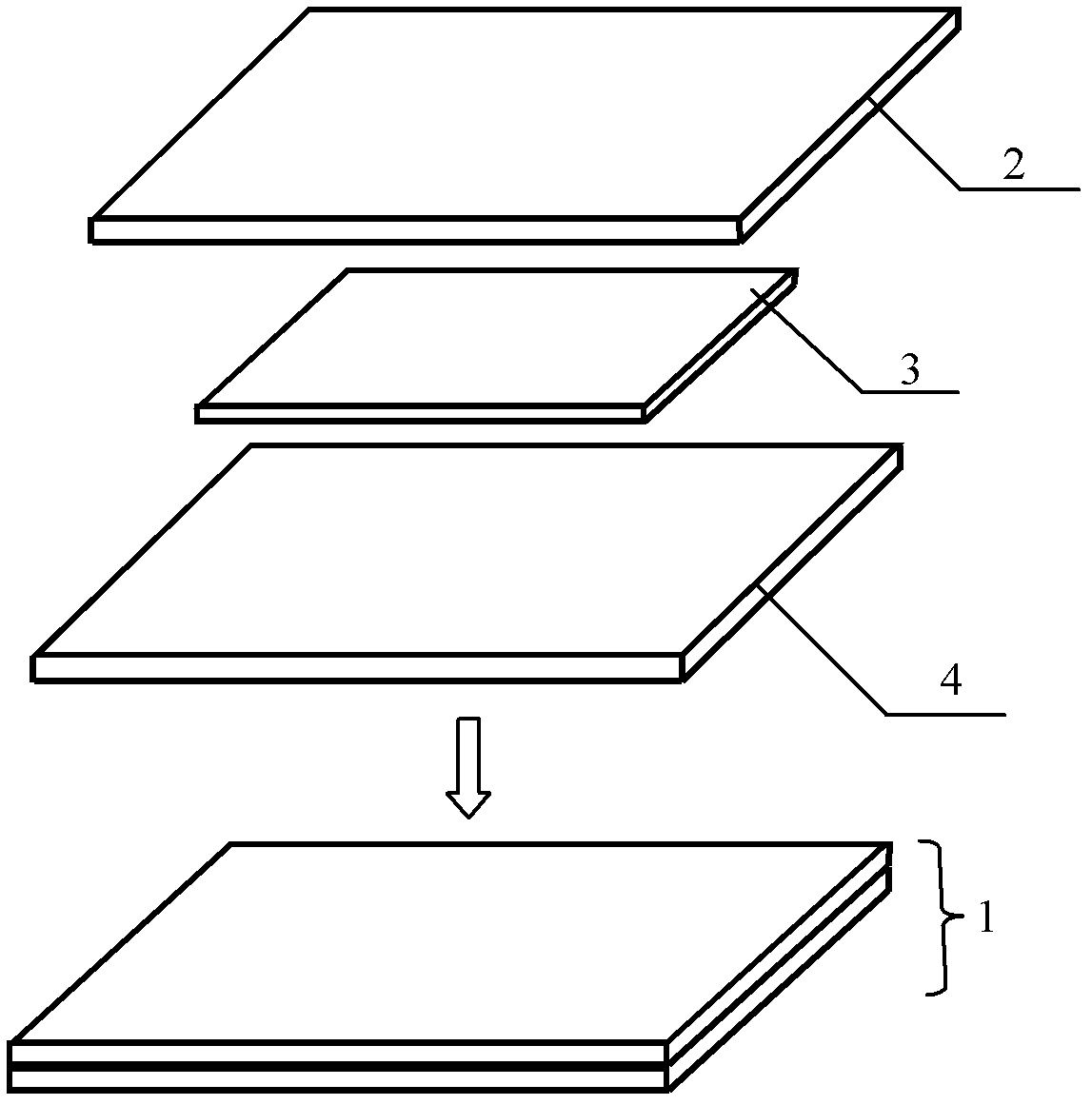

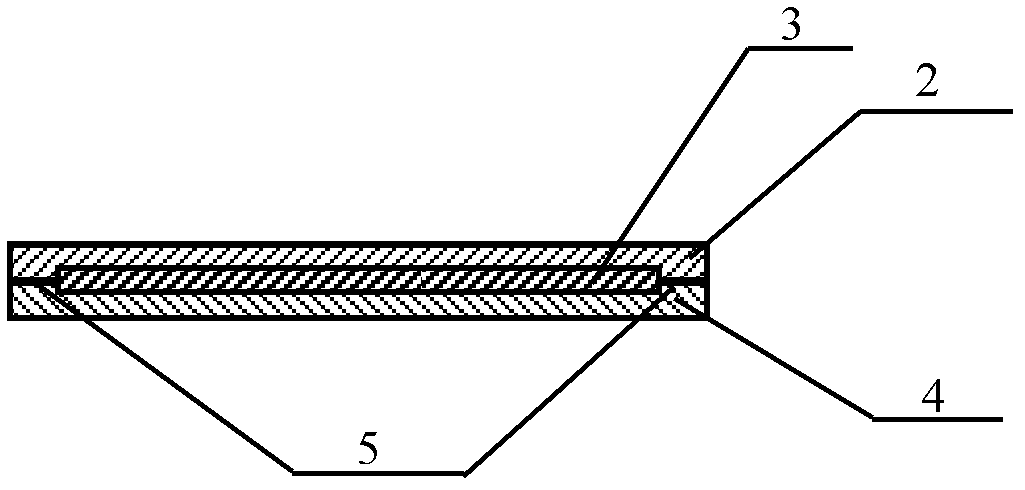

[0037]Preparation of bipolar current collector: pre-treat the surface of the copper foil, and then coat the surface of the copper foil with an electrolyte-resistant polyurethane adhesive coating with a width smaller than that of the copper foil, dry it, and then compound on the surface of the polyurethane adhesive coating A layer of polyethylene film to prepare a polymer barrier layer with a thickness of 0.05 to 5 microns; then vacuum-evaporate aluminum to obtain an aluminum foil with a thickness of 0.01 to 30 microns on the copper foil surface with a polymer barrier layer. The obtained bipolar current collector is cut into square or circular small pieces, and the copper foil and aluminum foil on the edge of the small pieces are in conductive contact;

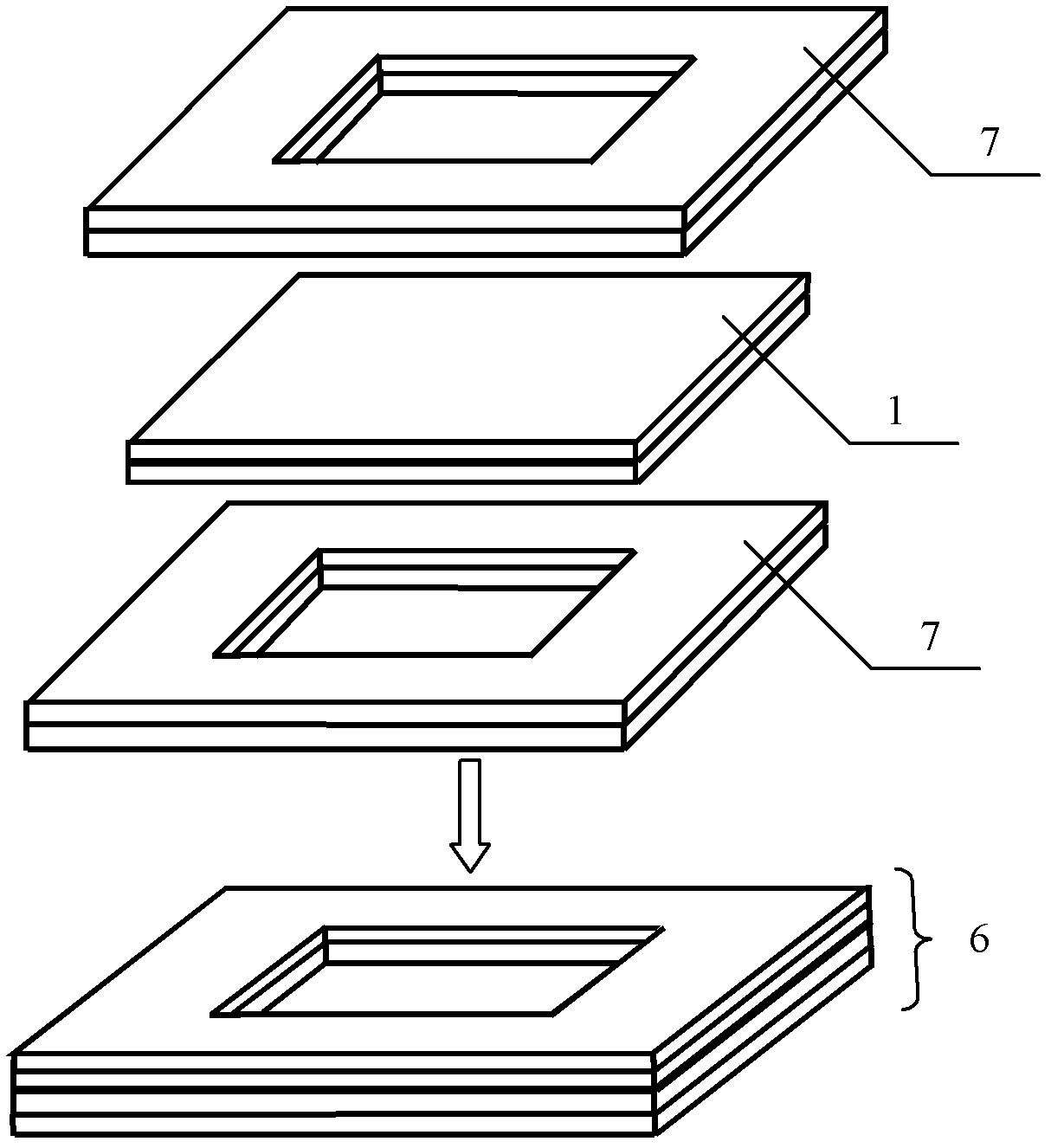

[0038] Preparation of insulating frame: co-extrude polyethylene terephthalate and maleic acid grafted polypropylene to obtain a double-layer film with a thickness of 10-500 microns, and open a square hole or a round hole in the ...

Embodiment 2

[0044] Prepare a high-voltage battery in the same manner as in Example 1, except that a layer of modified polyethylene with an area smaller than that of the bipolar current collector is coated on the surface of the aluminum foil during the preparation of the bipolar current collector, and dried; The polyethylene surface is coated with polyvinylidene fluoride coating containing carbon black conductive particles, dried and pressed into tablets.

Embodiment 3

[0046] A high-voltage battery was prepared in the same manner as in Example 1, except that the materials used for the insulating frame during the preparation of the composite bipolar current collector were biaxially stretched nylon and cast polypropylene, and the adhesive of the lining during the preparation of the high-voltage battery was Frame material is cast polypropylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com