Method for enhancing electrostatic spinning nanofiber membrane

A nanofiber membrane and nanofiber technology, applied in electrospinning, fiber processing, textiles and papermaking, etc., can solve the problem that the strength of electrospun membranes does not increase substantially, does not have universal applicability, and fibers cannot be effectively bonded, etc. problems, to achieve the effect of meeting the requirements of low-carbon production, improving the overall mechanical properties, and facilitating industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] PAN and 21216 PVDF produced by Solvay were used as two polymers for mixed electrospinning. Among them, PAN, as a high-melting point component, can still maintain thermal stability at 220 °C. The nanofiber membrane obtained by electrospinning has a large tensile modulus after hot rolling, but the elongation at break and the strength at break are low ( see Figure 14 ); PVDF21216 is a thermoplastic low-melting polymer component with a melting point of 135°C and an initial melting temperature of 110°C. The tensile modulus of the fiber membrane obtained by its single-component electrospinning is small, but the elongation at break and the strength at break are relatively large (see Figure 12 ).

[0054] Pre-dried PAN and PVDF21216 under the condition of 80 for 2 hours, weighed PAN and solvent according to the mass fraction ratio of PAN / acetone / DMF=15 / 20 / 65, weighed according to PVDF21216 / acetone / DMF=10 / 20 / 70 Take PVDF21216 and solvent, and dissolve it with magnetic stirrin...

Embodiment 2

[0059] The 6020 and 21216 PVDF thermoplastic polymers produced by Solvay in the United States were used as the two components of the solution electrospinning mixed spinning. As a high melting point component, PVDF6020 has a melting point of 175°C, and the fiber membrane obtained by electrospinning has relatively high breaking strength and moderate elongation at break; PVDF21216, as a low melting point component, has a melting point of 135°C and an initial melting temperature of 106°C. The tensile modulus of the fiber membrane obtained by electrospinning is small, but the elongation at break is large (see Figure 12 with 15 ).

[0060] Pre-dry PVDF6020 and PVDF21216 at 80°C for 2 hours, weigh PVDF6020 and solvent according to the mass fraction ratio of PVDF6020 / acetone / DMF=10 / 20 / 70, and weigh according to PVDF21216 / acetone / DMF=10 / 20 / 70 Take PVDF and solvent, stir and dissolve at 45°C until a transparent mixed solution is formed, and cool to room temperature to obtain PVDF6020...

Embodiment 3

[0065] The 6020 and 21216 PVDF thermoplastic polymers produced by Solvay in the United States were used as the two components of the melt electrospinning mixed spinning. As a high melting point component, PVDF6020 has a melting point of 175°C, and the fiber membrane obtained by electrospinning has relatively high breaking strength and moderate elongation at break; PVDF21216, as a low melting point component, has a melting point of 135°C and an initial melting temperature of 106°C. The fiber membrane obtained by electrospinning has a smaller tensile modulus, but a larger elongation at break.

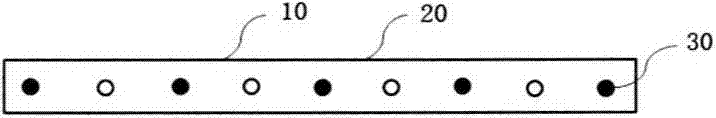

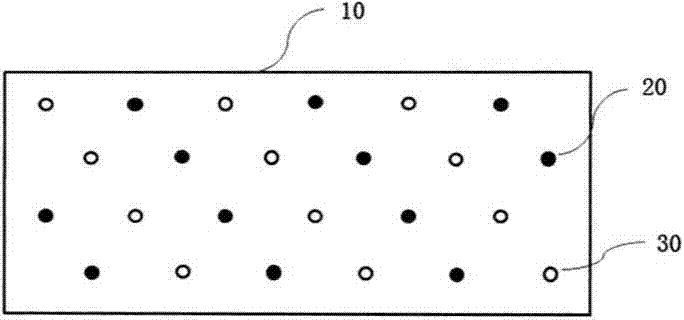

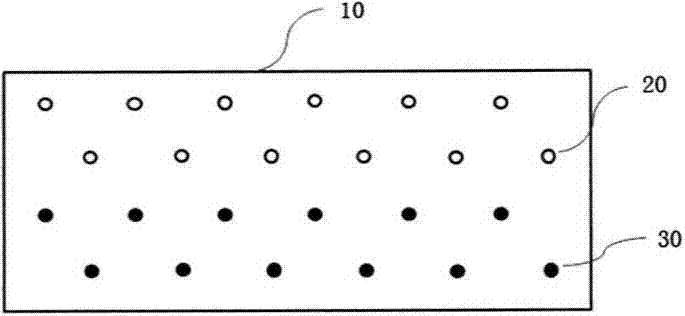

[0066] Pre-dry PVDF6020 and PVDF21216 at 80°C for 2 hours to obtain dry polymers of PVDF6020 and PVDF21216. Two rows of spinneret holes are staggered (see figure 1 : figure 1 Four rows of spinning needles or spinneret holes are shown; this example uses a meltblown device with two rows of spinneret holes) for hybrid electrospinning. The spinning plate is grounded, the web curtain is mad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com