Method for preparing graphene-like two-dimensional laminar titanium carbide nanoplate

A two-dimensional titanium carbide and two-dimensional layered technology, which is applied in the field of synthesizing graphene-like two-dimensional layered titanium carbide nanosheets, can solve problems that affect the application of two-dimensional titanium carbide nanosheets, the layer is not smooth enough, and the layer conductance Reduced efficiency and other issues, to achieve the effect of low cost, controllable process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

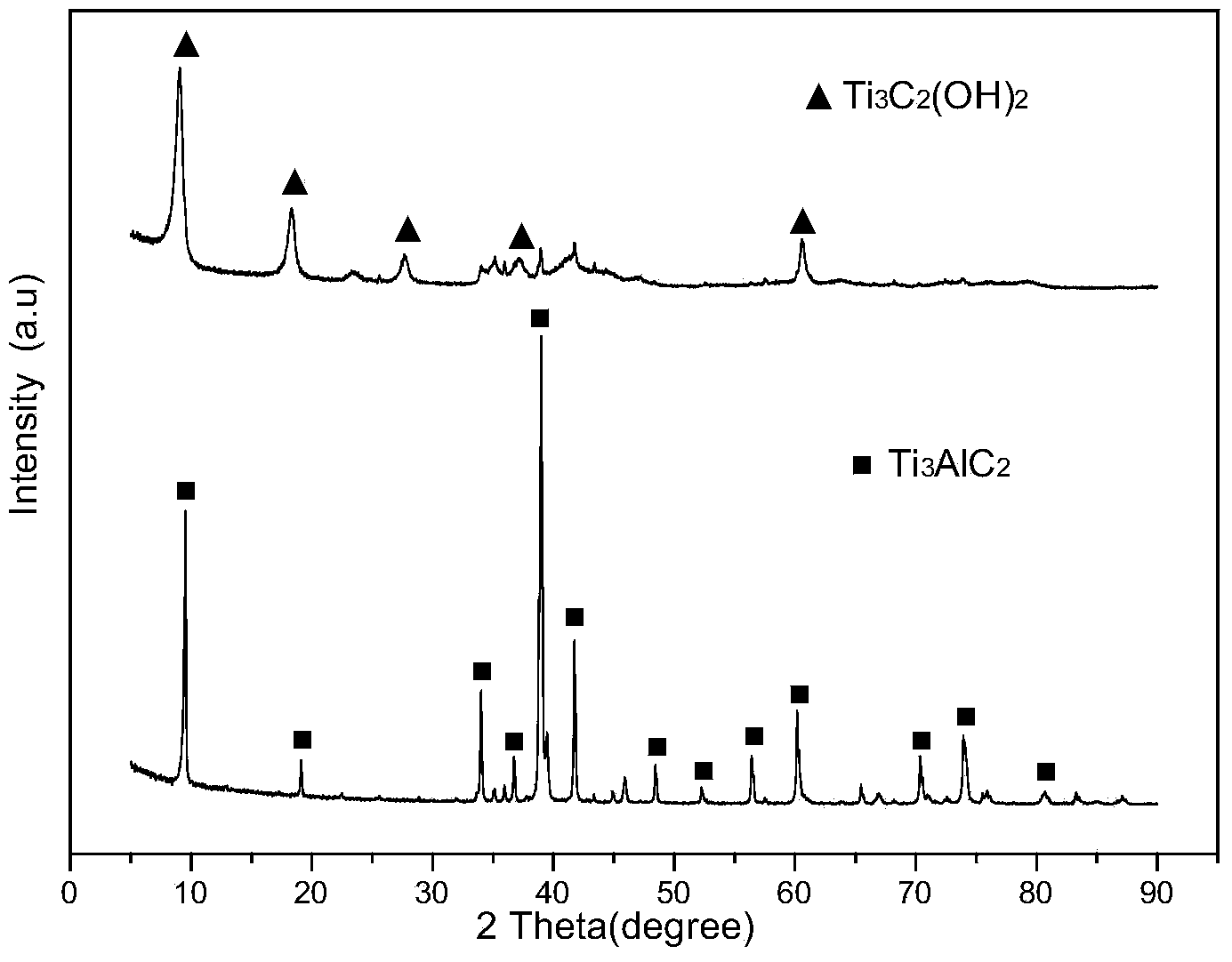

[0025] By Ti: Al: C = 3: 1: 2 molar ratio batching, its mixture and agate balls are dry-mixed in a ball mill tank for 10 hours at a ball-to-material ratio of 2: 1; put the uniformly mixed batching into a graphite mold Compact under a pressure of 5MPa, then place it in an argon-protected hot-press furnace, raise the temperature of the hot-press furnace to 1350°C at a rate of 15°C / min, then keep it at a pressure of 25MPa for 25 minutes, and cool to 60°C After getting loose bulk Ti 3 AlC 2 , after being crushed and ground through a 200-mesh sieve, Ti 3 AlC 2 powder. 8 g of Ti 3 AlC 2 Soak the powder in 100mL of 50wt% HF aqueous solution at room temperature, and react with magnetic stirring at a speed of 1500r / min for 20 hours to obtain a suspension; Wash with ethanol several times, then centrifuge at 5000r / min for 20 minutes to remove larger particles, then centrifuge at 8000r / min for 10 minutes and dry in a vacuum dryer at 40°C for 24 hours; place the vacuum-dried powder i...

Embodiment 2

[0027] According to the molar ratio of Ti: Al: C = 3: 1: 2, dry mix with agate balls in the ball mill tank for 8 hours according to the ball-to-material ratio of 2: 1; put the evenly mixed ingredients into the graphite mold under the pressure of 10MPa Compacted under the pressure, then placed in an argon-protected hot-press furnace, heated to 1300°C at a rate of 10°C / min, kept at a pressure of 30MPa for 20 minutes, and cooled to 60°C to obtain loose block Ti 3 AlC 2 , after being crushed and ground through a 200-mesh sieve; 6 grams of Ti 3 AlC 2 Soak the powder in 100ml of 50wt% HF aqueous solution at room temperature, and react with magnetic stirring at a speed of 2000r / min for 40 hours; the obtained suspension is filtered and washed repeatedly until the pH value is neutral, and then washed with absolute ethanol several times , and then centrifuged at 4000r / min for 30 minutes to remove larger particles, then centrifuged at 8000r / min for 10 minutes and then dried in a vacuum...

Embodiment 3

[0029] According to the molar ratio of Ti: Al: C = 3: 1: 2, dry mix with agate balls in a ball-to-material ratio of 2: 1 in a ball mill for 12 hours; put the uniformly mixed ingredients into a graphite mold under a pressure of 5 MPa Compacted under the pressure, then placed in an argon-protected hot-press furnace, heated to 1400°C at a rate of 20°C / min, kept at a pressure of 20MPa for 30 minutes, and cooled to 55°C to obtain loose block Ti 3 AlC 2 , after being crushed and ground through a 200-mesh sieve; 10 grams of Ti 3 AlC 2 The powder is soaked in 100 ml of 50wt% HF aqueous solution at 50°C, and reacted with magnetic stirring at a speed of 1000r / min for 6 hours; the obtained suspension is filtered and washed repeatedly until the pH value is neutral, and then washed with absolute ethanol several times , and then centrifuged at 5000r / min for 20 minutes to remove larger particles, then centrifuged at 10000r / min for 10 minutes and then dried in a vacuum dryer at 60°C for 24 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com