Solar battery back panel film and preparation method thereof

A technology for solar cells and backsheet films, applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., can solve the problems of poor barrier performance, difficult to repair, and high hardness of composite films, and achieve excellent weather resistance, strong shock resistance, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

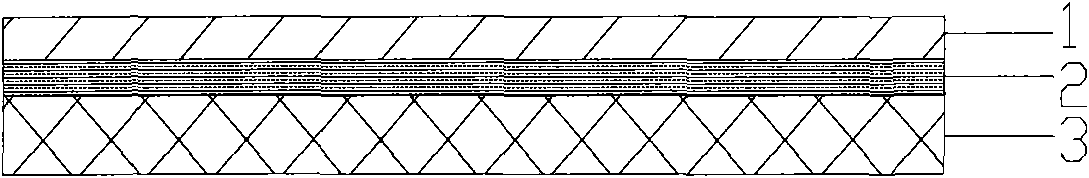

[0034] see figure 2 , a solar cell backsheet film, which is a three-layer structure, including a PVDF layer 1, an adhesive layer 2 and a PET film base layer 3 in sequence.

[0035] Wherein, the PET film base layer 3 has a thickness of 75 μm; the PVDF layer 1 has a thickness of 37 μm; and the adhesive layer 2 has a thickness of 3 μm.

[0036] The PET film base layer 3 adopts a biaxially stretched polyethylene terephthalate magnetic white film.

[0037] The PVDF layer 1 is mixed and granulated by polyvinylidene fluoride resin, pigments and various additives in parts by weight of 100g, 2g, and 5g, melt-extruded at 240°C, cast and stretched in at least one direction 10-1000%, and then prepared by trimming and winding.

[0038] Described polyvinylidene fluoride resin melting index is 10g / 10min; Described pigment comprises titanium dioxide, zinc oxide and carbon black; Described auxiliary agent comprises whitening agent (PEB), dispersant (stearic acid), solvent (phosphoric acid ...

Embodiment 2

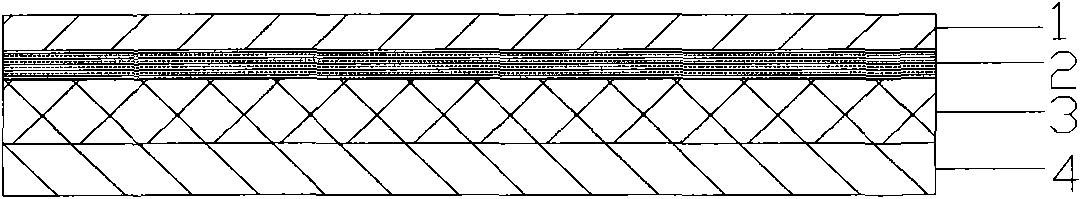

[0045] see image 3 , a solar battery back sheet film, which is a four-layer structure, including a PVDF layer 1, an adhesive layer 2, a PET film base layer 3 and an EVA film layer 4.

[0046] Among them, the thickness of the PET film base layer 3 is 75 μm; the thickness of the PVDF layer 1 is 37 μm; the thickness of the EVA film layer 4 is 250 μm; the thickness of the adhesive layer 2 is 3 μm.

[0047] The PET film base layer 3 adopts a biaxially stretched polyethylene terephthalate magnetic white film.

[0048]The PVDF layer 1 is mixed and granulated by polyvinylidene fluoride resin, pigments and various additives in parts by weight of 100g, 2g, and 5g, melt-extruded at 240°C, cast and stretched in at least one direction 10-1000%, and then prepared by trimming and winding.

[0049] Described polyvinylidene fluoride resin melting index is 10g / 10min; Described pigment comprises titanium dioxide, zinc oxide and carbon black; Described auxiliary agent comprises whitening agent...

Embodiment 3

[0058] see Figure 4 , a solar battery back sheet film, which is a five-layer structure, including a PVDF layer 1, an adhesive layer 2, a PET film base layer 3, an adhesive layer 2 and a PVDF layer 1.

[0059] Wherein, the PET film base layer 3 has a thickness of 250 μm; the adhesive layer 2 has a thickness of 3 μm; and the PVDF layer 1 has a thickness of 25 μm.

[0060] The PET film base layer 3 adopts a white film of biaxially stretched polyethylene terephthalate.

[0061] The PVDF layer 1 is mixed and granulated by polyvinylidene fluoride resin, pigments and various additives in parts by weight of 100g, 5g, and 10g, melt-extruded at 180°C, cast and stretched in at least one direction 10-1000%, and then prepared by trimming and winding.

[0062] Described polyvinylidene fluoride resin melting index is 8g / 10min; Described pigment comprises titanium dioxide, zinc oxide and carbon black; Described auxiliary agent comprises whitening agent (OB-1), dispersant (sodium stearate),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com