Composite film-based frequency-adjustable surface acoustic wave gyro

A technology of surface acoustic wave and composite film, which is applied in the direction of speed measurement by gyro effect, gyroscope/steering induction equipment, measuring device, etc. It can solve the problem that the actual frequency of the oscillator and the detector is difficult to be consistent, so as to increase the strength and overcome the Effects of low sensitivity and increased sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

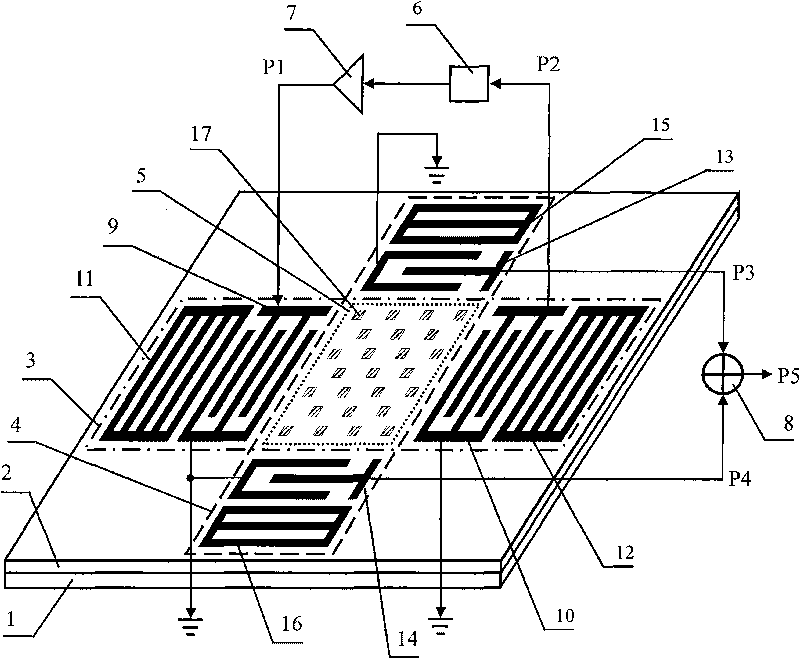

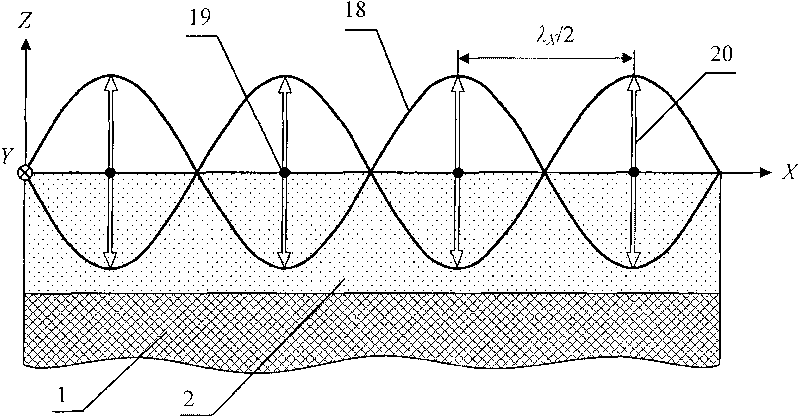

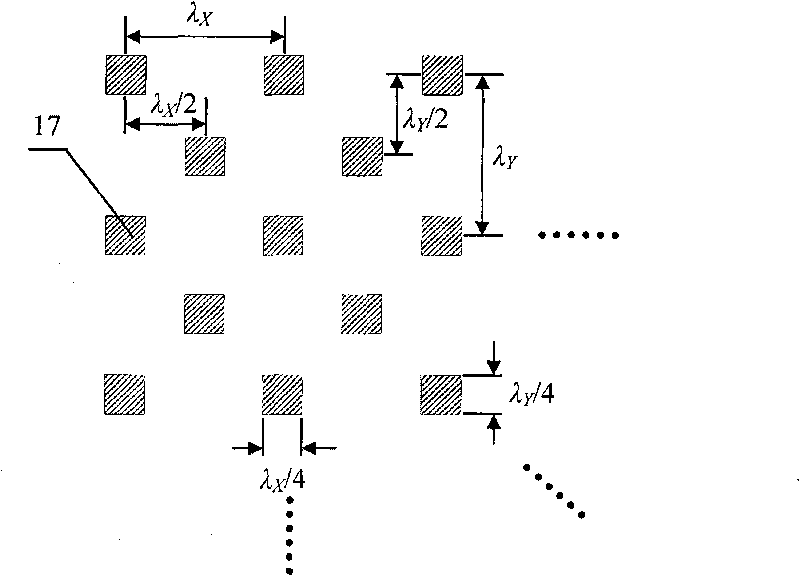

[0023] Such as figure 1 As shown, the frequency-tunable surface acoustic wave gyro based on the composite film of the present invention includes a magnetostrictive substrate 1, a piezoelectric film 2, a surface acoustic wave resonator 3, a surface acoustic wave detector 4, a metal lattice 5, a phase shifter The network 6 and the radio frequency amplifier 7, the piezoelectric film 2 is covered on the magnetostrictive substrate 1, the surface acoustic wave resonator 3, the surface acoustic wave detector 4 and the metal lattice 5 are arranged on the surface of the piezoelectric film 2, the surface acoustic wave The resonator 3 and the surface acoustic wave detector 4 are arranged perpendicular to each other, and the surface of the piezoelectric film 2 at the intersection of the surface acoustic wave resonator 3 and the surface acoustic wave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com