High-frequency ultrasonic phased array for ophthalmology and preparation method thereof

An ultrasonic phased array and ultrasonic phased control technology, which is used in eye testing equipment, eye examination, blood flow measurement devices, etc. The effect of blood flow condition, improved resolution ability, good beam deflection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

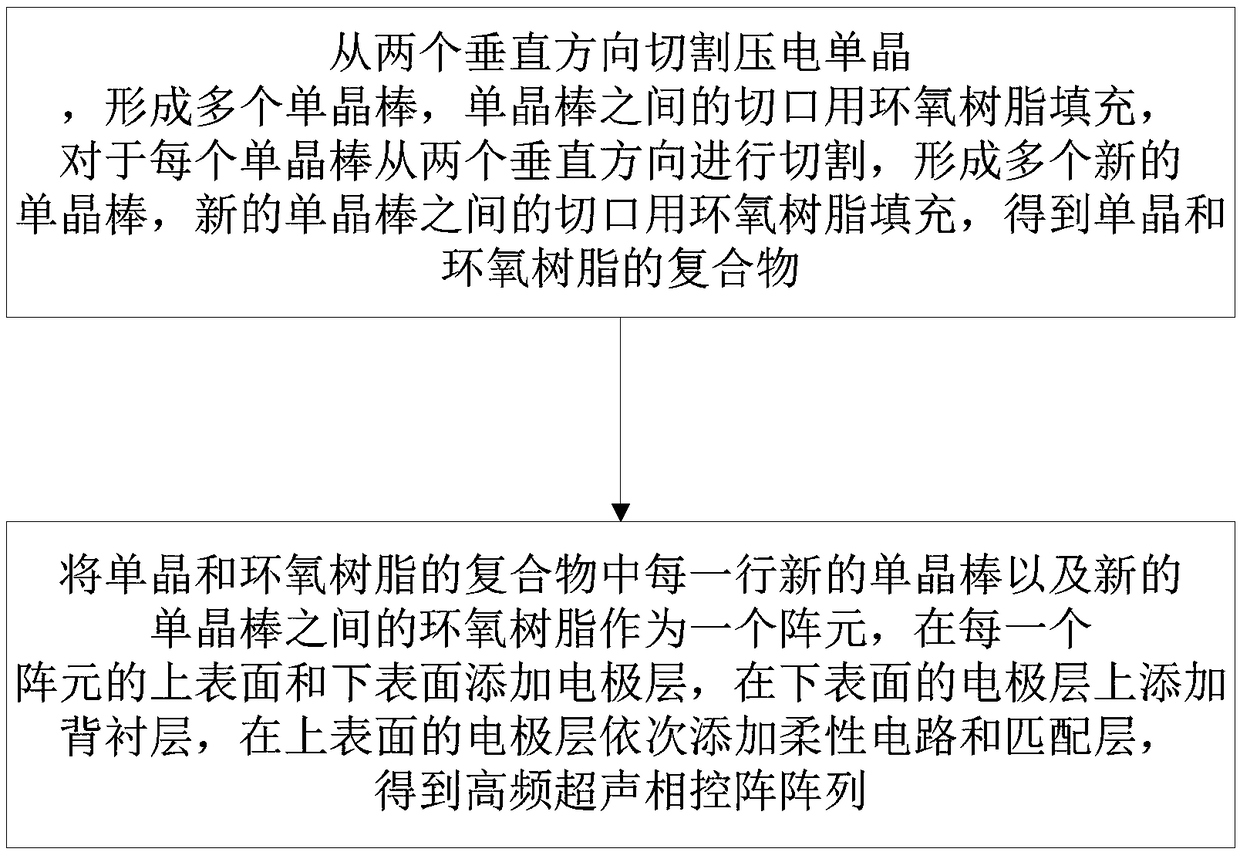

[0023] like figure 1 Shown, a kind of preparation method of the high-frequency ultrasonic phased array array that is used in ophthalmology, comprises:

[0024] (1) Utilize dry etching or laser cutting to cut the piezoelectric single crystal from two vertical directions to form a plurality of single crystal rods, the incisions between the single crystal rods are filled with epoxy resin, and the gaps between the single crystal rods The center distance is 70 μm-140 μm, and the width of the slit between the single crystal rods is 10 μm-15 μm; after the epoxy resin is cured, the air bubbles in the slit between the single crystal rods are removed in vacuum, and then for each single crystal The rods are cut from two vertical directions by dry etching or laser cutting to form multiple new single crystal rods, the cuts between the new single crystal rods are filled with epoxy resin, and the gaps between the new single crystal rods are filled with epoxy resin. The distance between the ...

Embodiment 1

[0027] A method for preparing a high-frequency ultrasonic phased array for ophthalmology, comprising:

[0028] (1) Utilize dry etching to cut PIN-PMN-PT from two perpendicular directions, form a plurality of PIN-PMN-PT sticks, the incision between PIN-PMN-PT sticks is filled with epoxy resin, described PIN- The center distance between the PMN-PT rods is 70 μm, and the width of the incision between the PIN-PMN-PT rods is 10 μm; when the epoxy resin is cured, remove the incision between the PIN-PMN-PT rods in vacuum The air bubbles, and then use dry etching to cut from two perpendicular directions for each PIN-PMN-PT rod, forming multiple new PIN-PMN-PT rods, and the cuts between the new PIN-PMN-PT rods Fill with epoxy resin, the center distance between the new PIN-PMN-PT rods is 35 μm, the width of the slit between the new PIN-PMN-PT rods is 10 μm, when the epoxy resin is cured, Remove air bubbles from the cut between the fresh PIN-PMN-PT rods in vacuo to obtain a 1-3 composit...

Embodiment 2

[0031] A method for preparing a high-frequency ultrasonic phased array for ophthalmology, comprising:

[0032] (1) Utilize laser cutting to cut PMN-PT from two vertical directions, form a plurality of PMN-PT rods, the otch between PMN-PT rods is filled with epoxy resin, and the center distance between described PMN-PT rods is 140 μm, the width of the kerf between the PMN-PT rods is 15 μm; when the epoxy resin is cured, remove the air bubbles of the kerf between the PMN-PT rods in vacuum, and then use a dry method for each PMN-PT rod Etching cuts from two perpendicular directions, forms a plurality of new PMN-PT rods, the incision between the new PMN-PT rods is filled with epoxy resin, and the center distance between the new PMN-PT rods is 70 μm, the width of the slit between the new PMN-PT rods is 15 μm, after the epoxy resin is cured, remove the air bubbles in the slit between the new PMN-PT rods in vacuum to obtain PMN-PT and epoxy 1-3 complexes of resins.

[0033](2) In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com