Dual-frequency integrated ultrasonic transducer based on piezoelectric composite film

An ultrasonic transducer and piezoelectric composite technology, applied in the field of micro-electromechanical, can solve problems such as poor performance, limited piezoelectric performance of composite materials, insufficient polarization of composite materials, etc., and achieve wide frequency application range and low acoustic impedance , the effect of good piezoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

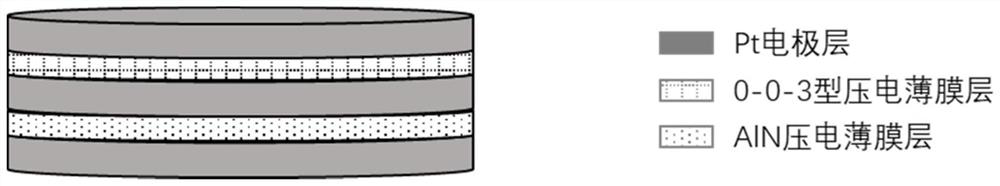

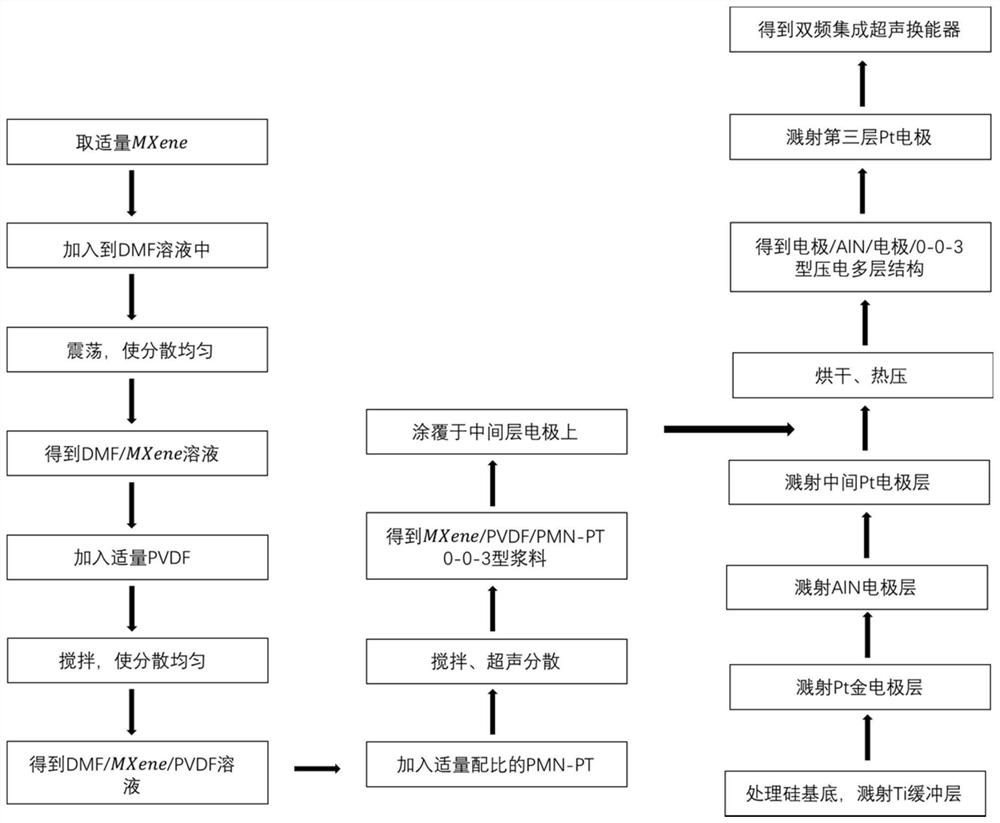

[0019] The present invention is a dual-frequency integrated ultrasonic transducer based on a piezoelectric composite film, and its basic structure is a multilayer structure composed of a 0-0-3 type piezoelectric composite film, an ultra-high frequency piezoelectric film and three layers of electrodes; Among them, the 0-0-3 type piezoelectric composite film and the ultra-high frequency piezoelectric film are two types of piezoelectric film layers, which correspond to two types of ultrasonic transducer layers with different center frequencies, thereby realizing a dual-frequency integrated ultrasonic transducer. Specifically, as figure 1 As shown, the structure of the present invention from top to bottom is a metal upper electrode layer, a 0-0-3 type composite piezoelectric film (high-frequency ultrasonic transducer layer), an intermediate metal electrode layer, an ultra-high frequency piezoelectric film layer, and a lower electrode layer. In the present invention, the two ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com