bi1-xsbx thermoelectric material and preparation method thereof

A technology of thermoelectric materials and powder materials, which is applied in the field of Bi1-xSbx thermoelectric materials and their preparation, can solve the problems of limited improvement of thermoelectric material performance, difficult to control product composition, and inability to be widely used, so as to reduce lattice thermal conductivity. , easy to operate, the effect of increasing the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

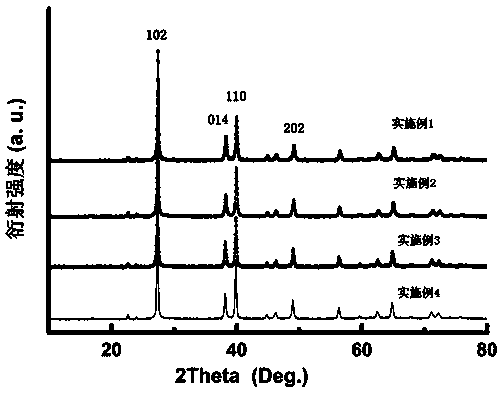

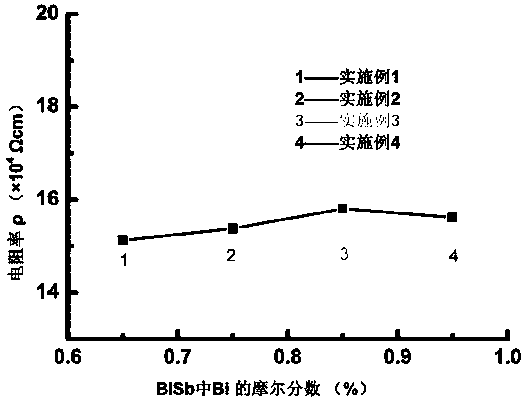

[0029] This embodiment prepares Bi 1-x Sb x The method for thermoelectric materials includes the following steps:

[0030] 1) Weigh 0.65mol of raw material Bi and 0.35mol of raw material Sb respectively; put them into an agate ball mill jar, carry out mechanical alloying in a high-energy ball mill, add 50ml of absolute ethanol as a dispersant, use nitrogen protection during ball milling, and the ball-to-material ratio is 10:1, the stirring speed was 300r / min, and the grinding time was 100h; the ground material was vacuum-dried to obtain Bi 0.65 Sb 0.35 powder material;

[0031] 2) Take the Bi obtained in step 1) 0.65 Sb 0.35 Put the powder material into the mold, put it into the magnetic field for orientation, the magnetic field strength is 1800KA / m, the mold vibrates slightly during the orientation process, and the orientation time is 0.5h;

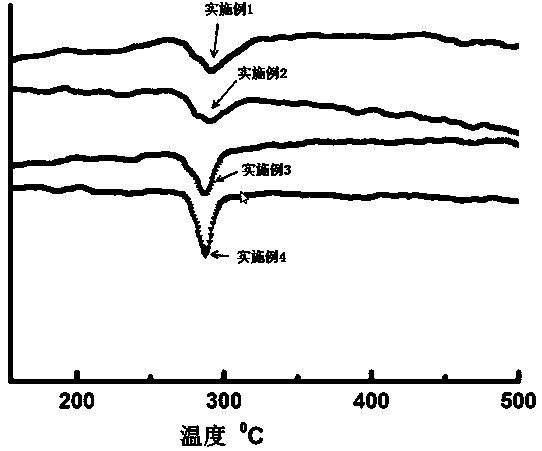

[0032] 3) Put the mold after the orientation operation in step 2) into a vacuum hot press, evacuate to -0.1MPa, and then pressuri...

Embodiment 2

[0035] This embodiment prepares Bi 1-x Sb x The method for thermoelectric materials includes the following steps:

[0036] 1) Put Bi 0.75 Sb 0.25 Put the powder material into the mold, put it into the magnetic field for orientation, the magnetic field strength is 2100KA / m, the mold vibrates slightly during the orientation process, and the orientation time is 0.6 h;

[0037] 2) Put the mold into a vacuum hot press, evacuate to -0.1MPa, and then pressurize and heat for sintering. The sintering temperature is 280 °C, the pressure is 50 MPa; the holding time is 150 s; a disc sample is made, with a diameter of 10mm and a thickness of 2 mm, that is.

[0038] Bi of this embodiment 1-x Sb x The thermoelectric material is Bi obtained directly according to the above method 1-x Sb x thermoelectric materials.

Embodiment 3

[0040] This embodiment prepares Bi 1-x Sb x The method for thermoelectric materials includes the following steps:

[0041] 1) Weigh 0.85mol of raw material Bi and 0.15mol of raw material Sb respectively; put them into an agate ball mill jar, carry out mechanical alloying in a high-energy ball mill, add 100ml of absolute ethanol as a dispersant, and use argon protection during ball milling. 15:1, the stirring speed was 500r / min, the grinding time was 120 h; then vacuum-dried to obtain Bi 0.85 Sb 0.15 powder material;

[0042] 2) put Bi 0.85 Sb 0.15 Put the powder material into the mold, put it into the magnetic field for orientation, the magnetic field strength is 2000KA / m, the mold vibrates slightly during the orientation process, and the orientation time is 1.0 h;

[0043] 3) Put the mold into a vacuum hot press, evacuate to -0.1MPa, and then pressurize and heat for sintering. The sintering temperature is 270 ℃, the pressure is 60 MPa; the holding time is 240 s; the waf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com