Composite piezoelectric ceramic fiber membrane for road power generation and preparation method

A piezoelectric ceramic, road power generation technology, applied in the direction of fiber chemical characteristics, conjugated synthetic polymer rayon, conjugated rayon, etc., can solve the problem of poor dispersion of nano piezoelectric ceramic fibers, composite piezoelectric ceramic fiber membrane High mechanical strength, poor compatibility between piezoelectric ceramic fibers and polymers, etc., to achieve good power generation effect, eliminate polarization steps, and solve the effect of poor dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

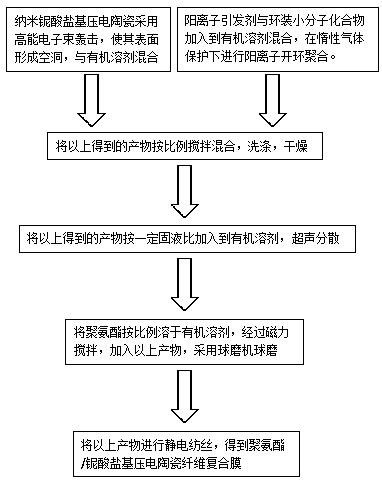

Method used

Image

Examples

Embodiment 1

[0033] (1) K with a diameter of 200nm 0.5 Na 0.5 NbO 3 The piezoelectric ceramic material is bombarded with a high-energy electron beam, the energy of the high-energy electron beam is 1.9MeV, the irradiation dose is 250kGy, and the irradiation time is 23min, so that holes are formed on the surface of the niobate-based piezoelectric ceramic material. The void rate on the surface of the piezoelectric ceramic material is 21%, and it is weighed and added to high-purity water for 3 hours to form a dispersion liquid according to the weight ratio of 1:15, and the solution containing the active group is mixed with the dispersion liquid according to the molar ratio of 0.4:1. Make the surface of the niobate-based piezoelectric ceramic material have an active group -COOH, and mix it with an organic solvent ether according to a solid-to-liquid ratio of 1g:15mL to obtain an organic solvent dispersion of the initial niobate-based piezoelectric ceramic material;

[0034] (2) The cationic i...

Embodiment 2

[0042] (1) K with a diameter of 800nm 0.5 Na 0.5 NbO 3 The piezoelectric ceramic material is bombarded with a high-energy electron beam, the energy of the high-energy electron beam is 1.9MeV, the irradiation dose is 250kGy, and the irradiation time is 25min, so that holes are formed on the surface of the niobate-based piezoelectric ceramic material. The void rate on the surface of the piezoelectric ceramic material is 23%. Weigh it and add it into high-purity water for 2 hours to form a dispersion liquid according to the weight ratio of 1:14. Mix the solution containing the active group with the dispersion liquid according to the molar ratio of 0.3:1. Make the surface of the niobate-based piezoelectric ceramic material have an active group -SH, and mix it with the organic solvent diphenyl ether according to the solid-to-liquid ratio of 1g: 12mL to obtain the organic solvent dispersion of the initial niobate-based piezoelectric ceramic material. liquid;

[0043] (2) The cati...

Embodiment 3

[0050] (1) K with a diameter of 40nm 0.5 Na 0.5 NbO 3 The piezoelectric ceramic material is bombarded with a high-energy electron beam, the energy of the high-energy electron beam is 1.9MeV, the irradiation dose is 250kGy, and the irradiation time is 12min, so that holes are formed on the surface of the niobate-based piezoelectric ceramic material. The void rate on the surface of the piezoelectric ceramic material is 14%, and it is weighed and added to high-purity water for 6.5 hours to form a dispersion liquid according to the weight fraction ratio of 1:22, and the solution containing the active group is added to the In the dispersion liquid, the surface of the niobate-based piezoelectric ceramic material has -NH 2 , according to the solid-to-liquid ratio of 1g: 20mL and then mixed with the organic solvent toluene to obtain the organic solvent dispersion of the initial niobate-based piezoelectric ceramic material;

[0051] (2) The cationic initiator CF 3 SO 3 OCH 3 , Te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com