Low-density superhigh-strength corrosion-resistant propping agent and preparation method thereof

An ultra-high-strength, corrosion-resistant technology, used in chemical instruments and methods, earth-moving drilling, mining fluids, etc., which can solve problems such as reducing overall strength, low bonding efficiency, and resistance to pressure differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

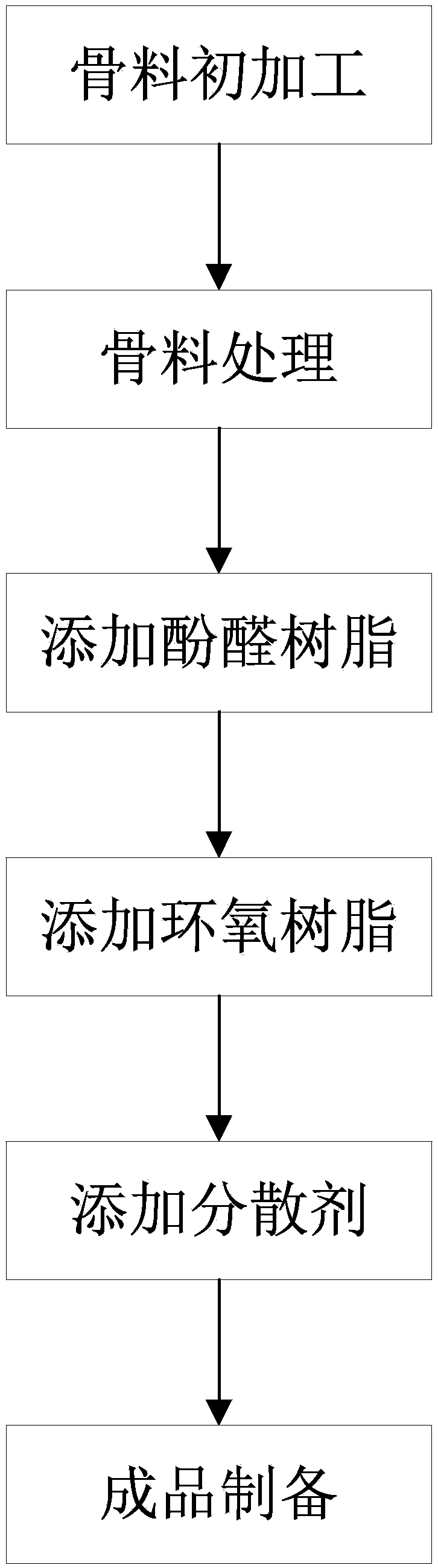

[0028] See attached figure 1 , Grind 85% bauxite, 12% coal gangue, and 3% clay respectively into powders larger than 325 meshes, mix the powders evenly according to the proportion, put them into a disc granulator for spray granulation, and add the materials to granulate The order of the machine is to first add two-thirds of the total amount of bauxite and half of the amount of clay, stir evenly, so that the bauxite and clay are fully mixed and adhered, and then the remaining bauxite and coal gangue are evenly sprinkled into the making machine. Granulator, and add water appropriately, once agglomeration occurs, add clay and stir until all the bauxite and coal gangue are added, then add the remaining clay at one time, stir evenly, and after sieving, dry until the moisture is less than 3 %, put it in a resistance furnace for calcination at 1350°C for 3 hours, heat the temperature up to 300°C / h, keep it for 1 hour, and then cool and sieve to get 30-50 mesh aggregates, put 2kg of a...

Embodiment 2

[0030] Grind bauxite 90%, coal gangue 9%, and clay 1% respectively into powders larger than 325 mesh, mix the powders evenly according to the proportion, put them into a disc granulator for spray granulation, and sieve, Dry until the water content is less than 3%, put it into a resistance furnace for calcination at 1450°C for 3 hours, and then cool and sieve to obtain aggregates of 30-50 meshes. Put 2kg of aggregate in a resistance furnace and heat it to 280°C, then add it to the sand mixer Cool down to 230°C, add 30g of thermoplastic phenolic resin and stir for 30s, then add 10.5g of 40% urotropine aqueous solution and stir for 30s, then add 20g of epoxy resin (epoxy value 0.09-0.14mol / 100g) and stir for 30s, then Add 3g of epoxy resin curing agent (amine value 305KOHmg / g) and stir for 15s. Finally, add 2g of silicone oil and stir for 20s. After crushing, cooling and sieving, a 30-50 mesh low-density ultra-high-strength corrosion-resistant proppant is obtained. The detected b...

Embodiment 3

[0032] Put 2kg of the aggregate in Example 1 in a resistance furnace and heat it to 260°C, put it into a sand mixer and cool it down to 230°C, add 40g of thermoplastic phenolic resin and stir for 30s, then add 14g of 40% urotropine aqueous solution and stir for 30s , followed by adding 20g of epoxy resin (epoxy value 0.04-0.065mol / 100g) and stirring for 30s, then adding 2g of epoxy resin curing agent (amine value 430KOHmg / g) and stirring for 15s, and finally adding 2g of liquid paraffin and stirring for 20s, after crushing and cooling The 30-50 mesh low-density ultra-high-strength corrosion-resistant proppant can be obtained by sieving. The detected bulk density is 1.61g / cm3, the apparent density is ≤2.75g / cm3, the crushing rate is 1.74% under the closing pressure of 130MPa, and the acid solubility is ≤1.29%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com