Liquid and supercritical carbon dioxide tackifying switch surfactant and compounding system thereof

A technology of surfactant and switch surface, applied in the field of switch surfactant and its compound system, can solve the problems of low efficiency of tackifier, great formation damage, environmental pollution, etc., and achieve the effect of improving tackifier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The switch surfactant polyoxyethylene alkylamine is used as the tackifier, and the structural formula of the polyoxyethylene alkylamine is as follows:

[0034]

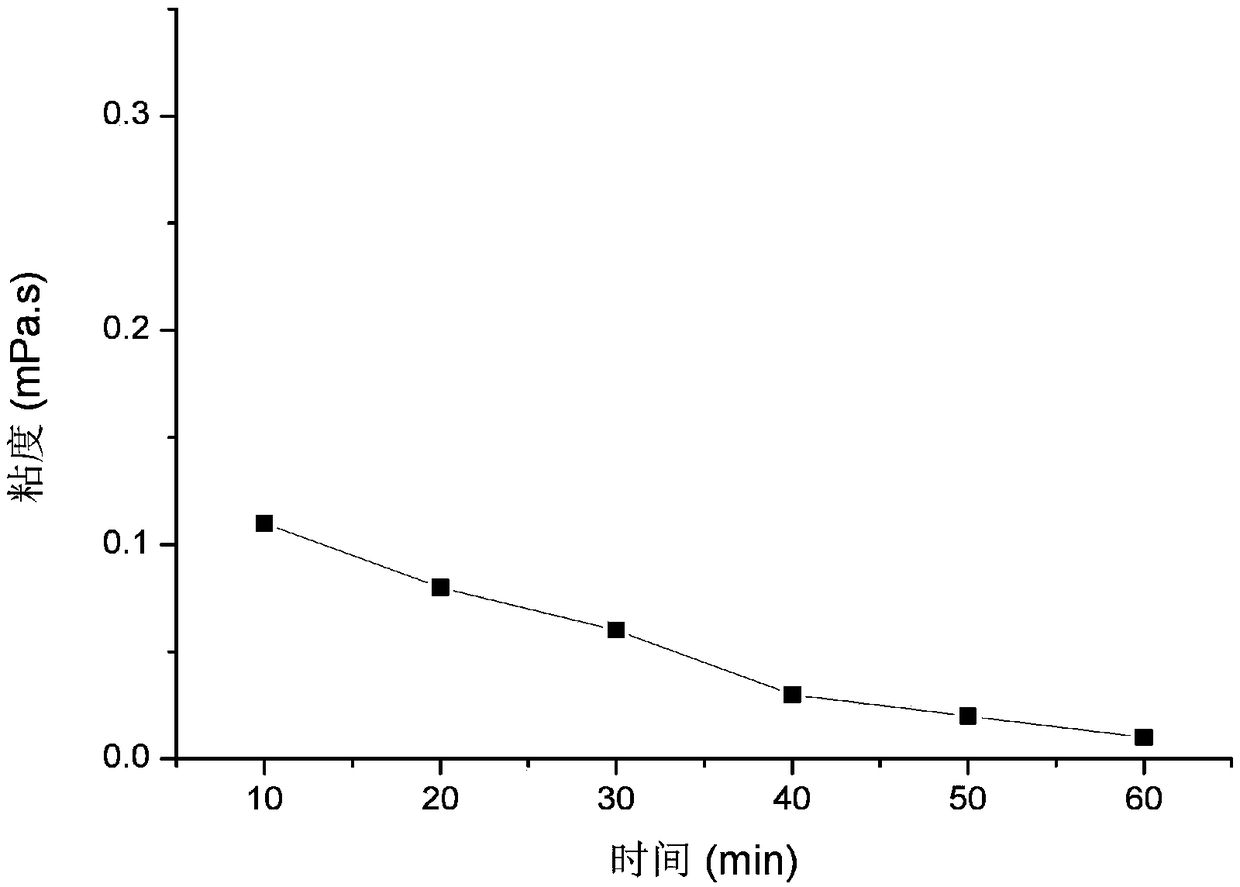

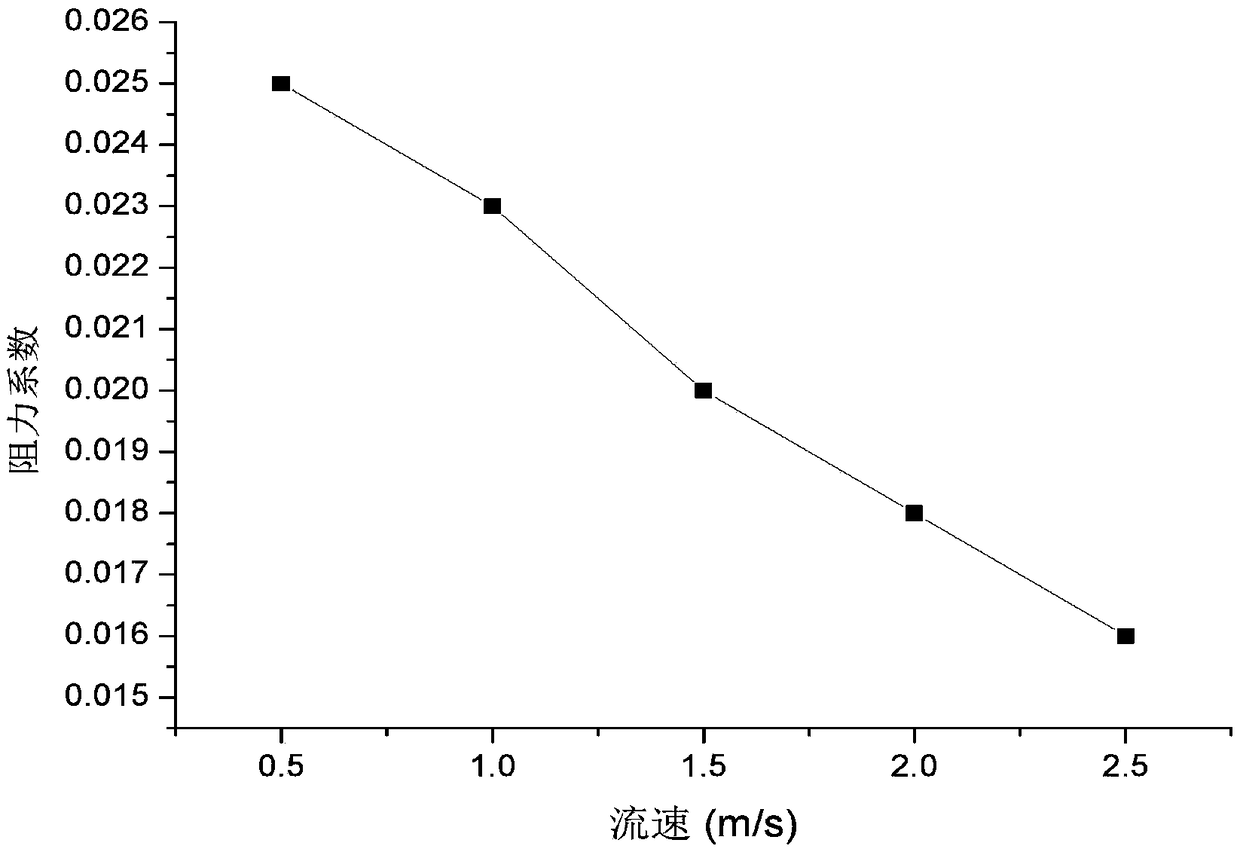

[0035] Among them, R 2 , R 3 It is a long-chain alkyl group containing 10 carbon atoms, and y is 3. The polyoxyethylene alkylamine is added into liquid carbon dioxide to obtain a fracturing fluid system. In the fracturing fluid system, the mass percentage of polyoxyethylene alkylamine is 5%, and the rest is liquid carbon dioxide. The desired viscosification effect can be obtained after the fracturing fluid system is fully stirred. At room temperature, the viscosity reaches 0.11mPa.s at 7MPa. figure 1 is the change curve of the viscosity of the liquid carbon dioxide system with the shear time in this embodiment. figure 2 It is the relationship diagram between the displacement of the liquid carbon dioxide system and the drag coefficient in this embodiment. It can be seen from the figure that the viscosi...

Embodiment 2

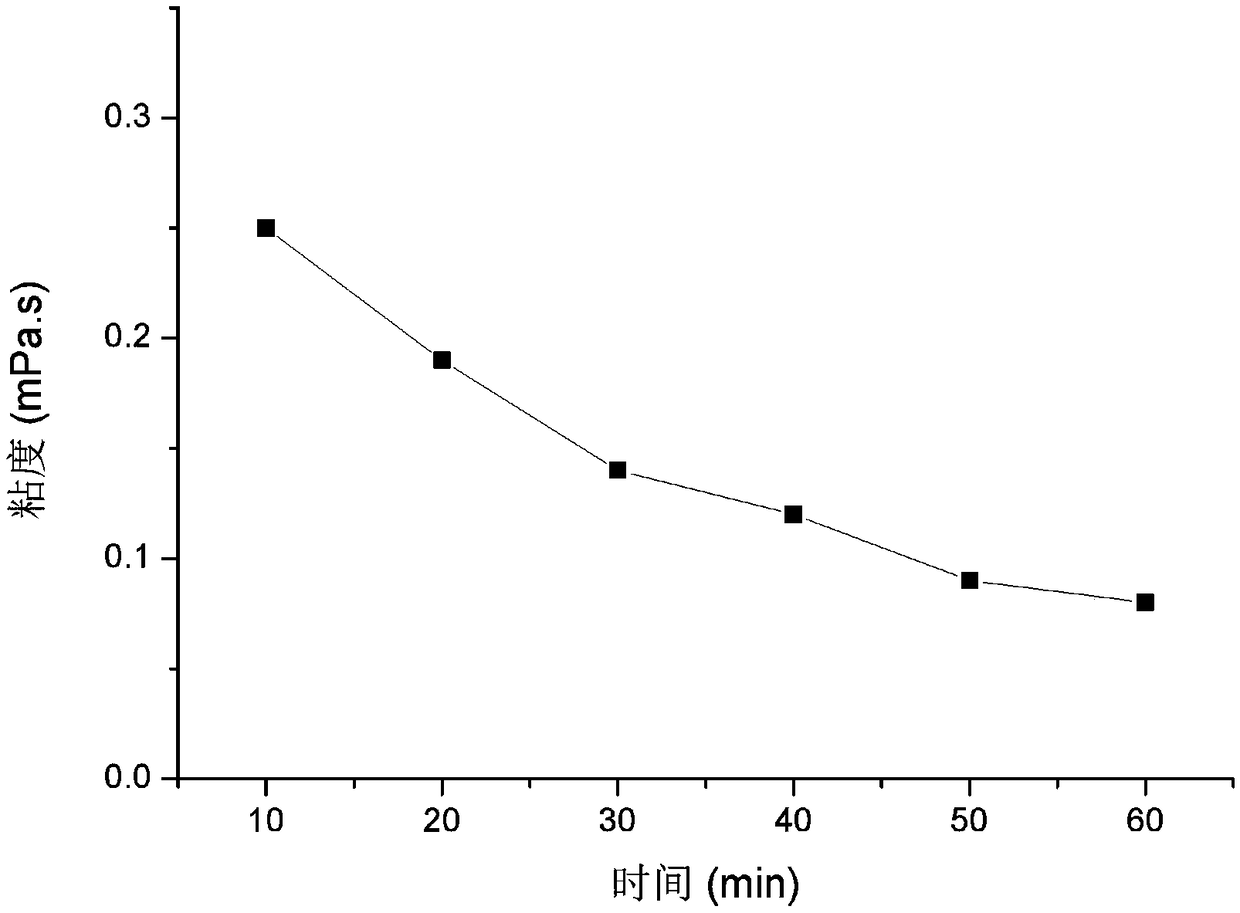

[0037]In this embodiment, a complex system of switching surfactant polyoxyethylene alkylamine and tackifying polymer is used as the tackifier, wherein the specific structure of polyoxyethylene alkylamine is the same as in Example 1, and the tackifying polymer It is polyether modified polysiloxane. The compound system is added into liquid carbon dioxide to obtain a fracturing fluid system. In the fracturing fluid system, the mass percentage of polyoxyethylene alkylamine is 2%, the mass percentage of viscosifying polymer is 0.5%, and the rest is liquid carbon dioxide. The desired viscosification effect can be obtained after the fracturing fluid system is fully stirred. At room temperature, the viscosity reaches 0.27mPa.s at 7MPa. image 3 is the change curve of the viscosity of the liquid carbon dioxide system with the shear time in this embodiment. Figure 4 It is the relationship diagram between the displacement of the liquid carbon dioxide system and the drag coefficient i...

Embodiment 3

[0039] In this embodiment, a complex system of switching surfactant polyoxyethylene alkylamine and tackifying polymer is used as the tackifier, wherein the specific structure of polyoxyethylene alkylamine is the same as in Example 1, and the tackifying polymer It is polyether modified polysiloxane. The compound system is added into liquid carbon dioxide to obtain a fracturing fluid system. In the fracturing fluid system, the mass percentage of polyoxyethylene alkylamine is 2%, the mass percentage of viscosifying polymer is 2%, and the rest is liquid carbon dioxide. The desired viscosification effect can be obtained after the fracturing fluid system is fully stirred. At room temperature, the viscosity reaches 0.48mPa.s at 7MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com