Treatment method of fracturing backflow fluid

A technology of fracturing flowback fluid and treatment method, which is applied in the fields of filtration treatment, water/sewage treatment, mining wastewater treatment, etc., which can solve the problems of increased cost, environmental damage, and high content of suspended solids, so as to reduce the water consumption of fracturing , Reduce fracturing costs, reduce treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1, specifically, the method for treating fracturing flowback fluid provided by the present invention includes the following steps:

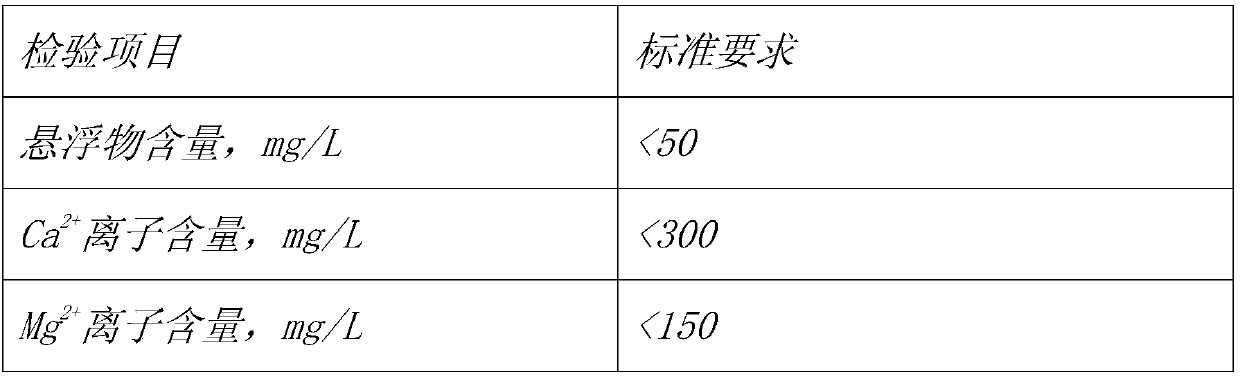

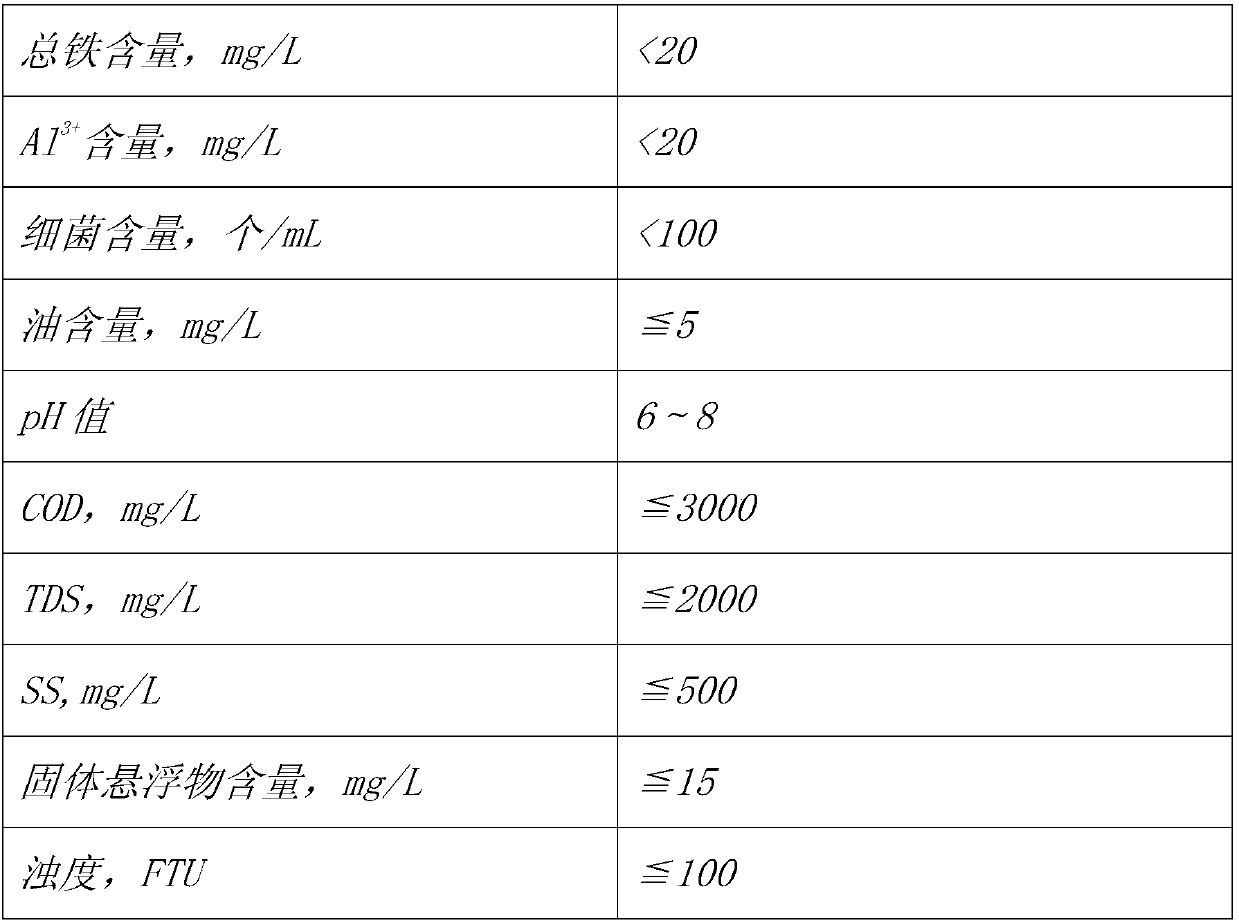

[0049] (1) Perform physical treatment on the flowback fluid to remove impurities such as mechanical impurities, suspended solids and oil stains in the fracturing flowback fluid, and conduct preliminary water quality testing and analysis;

[0050] Among them, including: pH value (measured by PH meter), turbidity (turbidimeter), residual additive concentration (water quality detection analyzer), salinity (gravimetric method), sediment (gravimetric method), total hardness ( EDTA complexometric titration or water hardness tester), total alkalinity (acid-base neutralization titration method), COD value (COD rapid tester), BOD value (BOD tester), oil content determination (automatic oil tester) , Determination of various ion content (water quality detection analyzer, automatic ion analyzer) to obtain the initial value of each componen...

Embodiment 2

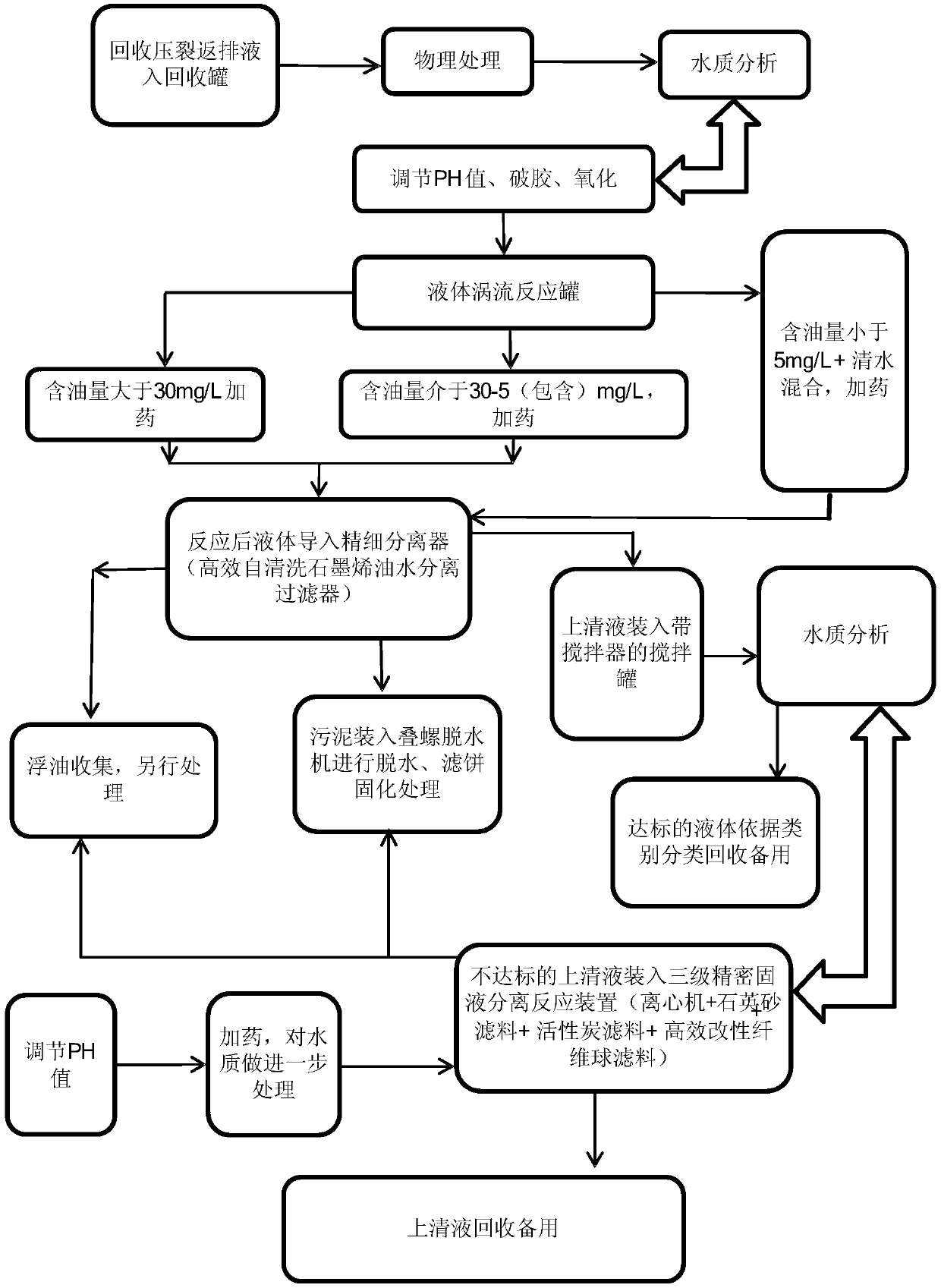

[0114] Example 2, see figure 1 , a treatment method for fracturing flowback fluid, comprising the following steps:

[0115] 1) Recover the fracturing flowback fluid into the recovery tank, perform physical treatment on the fracturing flowback fluid recovered in the recovery tank, remove mechanical impurities, suspended solid impurities and oily impurities in the fracturing flowback fluid, and conduct a preliminary physical treatment of the fracturing flowback fluid. Water quality detection and analysis of the treated fracturing flowback fluid; among them, water quality detection and analysis include: pH value, turbidity, residual additive concentration, salinity, sediment, total hardness, total alkalinity, COD value, BOD value , oil content determination and various ion content determination to obtain the initial value of each component in the fracturing flowback fluid;

[0116] 2) According to the pH value obtained in step 1), use 0.01mg / L pH regulator to adjust the pH value...

Embodiment 3

[0133] see figure 1 , a treatment method for fracturing flowback fluid, comprising the following steps:

[0134] 1) Recover the fracturing flowback fluid into the recovery tank, perform physical treatment on the fracturing flowback fluid recovered in the recovery tank, remove mechanical impurities, suspended solid impurities and oily impurities in the fracturing flowback fluid, and conduct a preliminary physical treatment of the fracturing flowback fluid. Water quality detection and analysis of the treated fracturing flowback fluid; among them, water quality detection and analysis include: pH value, turbidity, residual additive concentration, salinity, sediment, total hardness, total alkalinity, COD value, BOD value , oil content determination and various ion content determination to obtain the initial value of each component in the fracturing flowback fluid;

[0135] 2) According to the pH value obtained in step 1), adjust the pH value to 8-9 with a 150mg / L pH regulator, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com