Preparation method of high-density aramid insulating hardboard

A technology of insulating cardboard and cardboard, which is applied in papermaking, papermaking machines, textiles and papermaking, etc., can solve the problems of few research reports, high strength and high difficulty of aramid fibers, reduce production costs, protect the ecological environment, and improve reliability. compressibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

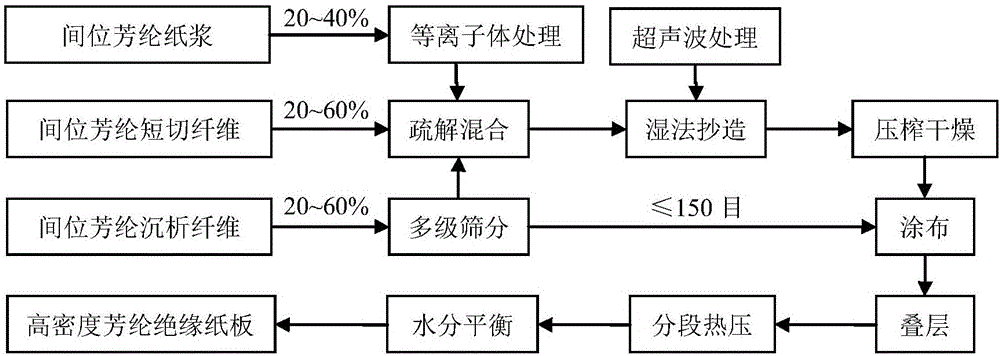

[0038] A method for preparing high-density aramid insulating cardboard, characterized in that the aramid insulating cardboard has a thickness of 1.0-10mm and a density of 1.1-1.2g / cc, comprising the following steps:

[0039](1) In terms of mass fraction, 20-60% meta-aramid chopped fibers, 20-60% meta-aramid fibrids and 20-40% meta-aramid pulp are mixed in water after dissolving, and the middle The meta-aramid fibrid fiber passes through multi-stage screening, and the size combination mass ratio of the meta-aramid fibrid fiber is ≤30 mesh: 30~50 mesh: 50~100 mesh: 100~150 mesh=0~2:1 ~3:3~7:1~5, meta-aramid pulp is made by mechanically cutting aramid paper, aramid waste silk and aramid scraps, and then hydraulic beating. The average length is 0.1-0.4mm. And the meta-aramid pulp is treated with low-temperature plasma, the processing power is 70-120W, the pressure is 50-100Pa, and the surface O / C ratio of meta-aramid pulp is 150-250% after low-temperature plasma treatment;

[004...

Embodiment 1

[0048] Select meta-aramid chopped fibers with a relative absolute total mass of 60%, meta-aramid fibrid fibers with a relative absolute total mass of 20%, and meta-aramid pulp with a relative absolute total mass of 20% to be fluffed in water; Among them, the meso-aramid fibrids are sieved in multiple stages and combined according to the size of ≤30 mesh: 30-50 mesh: 50-100 mesh: 100-150 mesh=0:1:7:2; Aramid pulp is made by mechanically cutting aramid paper, aramid waste silk, aramid scraps, etc., and then hydraulic beating. The average length is 0.4mm. It is treated with low-temperature plasma, with a power of 70W and a pressure of 50Pa. Make the surface O / C ratio reach 150%; mix the fiber slurry evenly, use the inclined wire former to carry out wet copy forming, the concentration of the netting is 0.005%, and use ultrasonic treatment in the former with a frequency of 50kHz; press and dry in the aromatic The surface of the fiber paper is coated with a layer of pure meta-aramid...

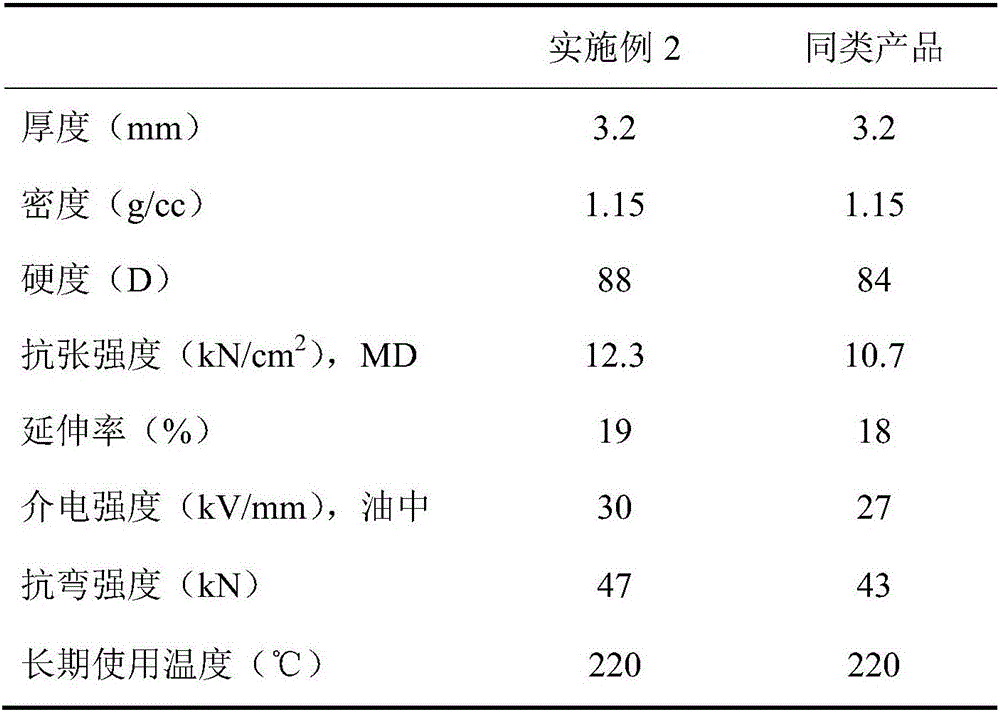

Embodiment 2

[0050] Select meta-aramid chopped fibers with a relative absolute total mass of 20%, meta-aramid fibrid fibers with a relative absolute total mass of 60%, and meta-aramid pulp with a relative absolute total mass of 20% to be fluffed in water; Among them, after the meta-aramid fibrids are screened in multiple stages, they are combined according to the size of ≤30 mesh: 30-50 mesh: 50-100 mesh: 100-150 mesh=2:3:4:1; Aramid pulp is made by mechanically cutting aramid paper, aramid waste silk, aramid scraps, etc., and then hydraulic beating. The average length is 0.3mmmm. It is treated with low-temperature plasma, with a power of 90W and a pressure of 80Pa. Make the surface O / C ratio reach 200%; mix the fiber slurry evenly, use the inclined wire former to carry out wet copying forming, the online concentration is 0.005%, and use ultrasonic treatment in the forming device with a frequency of 80kHz; press and dry in the aromatic The surface of the fiber paper is coated with a layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com