Truss type intelligent drilling device and arc plate drilling method

A drilling equipment, truss-type technology, used in drilling/drilling equipment, boring/drilling, metal processing equipment, etc. Personal injury and other problems, to achieve the effect of reducing processing costs, improving work efficiency, and improving drilling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

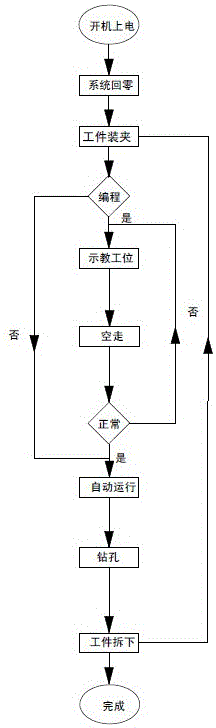

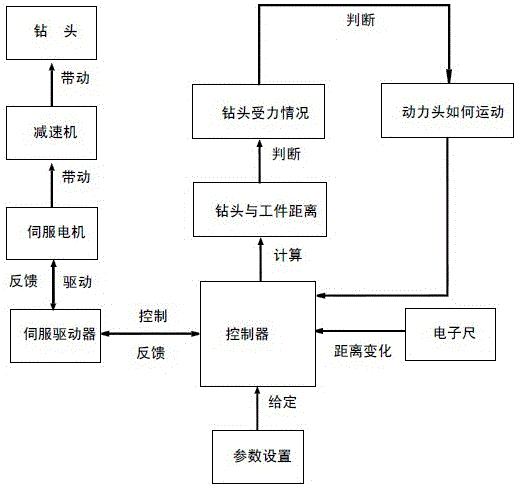

[0044] Figure 1~12 It is the best embodiment of the truss-type intelligent drilling equipment and the drilling method for arc-shaped plates. Figure 1~12 The present invention will be further described.

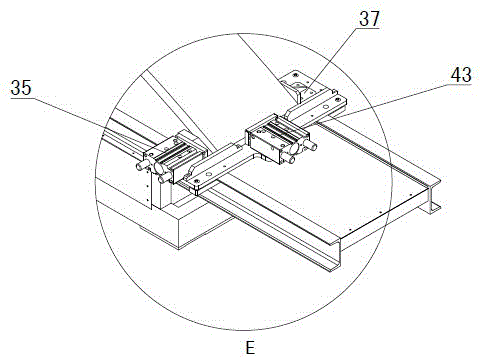

[0045] refer to figure 1 , the truss-type intelligent drilling equipment includes a gantry frame, a mechanical arm and a workpiece fixing mechanism, the upper part of the gantry frame has a Y-axis beam 2, the mechanical arm 9 is arranged on the Y-axis beam 2, and the lower end of the mechanical arm 9 is provided with a drilling hole Mechanism and drilling positioning device, a mechanical arm swing mechanism that drives the mechanical arm 9 to swing is provided between the mechanical arm 9 and the Y-axis beam 2, and the mechanical arm swing mechanism drives the mechanical arm 9 to swing around the axis parallel to the Y-axis beam 2, mechanically The arm 9 is also connected with a drill lifting mechanism that drives the drilling mechanism to lift. An X-axis track device that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com