Method for improving coal seam gas permeability through high energy acoustoelectric composite technology

A composite technology and permeability technology, applied in the energy field, can solve problems such as frequent coal mine accidents, and achieve the effects of removing coal seam blockage, improving seepage capacity, and taking a short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

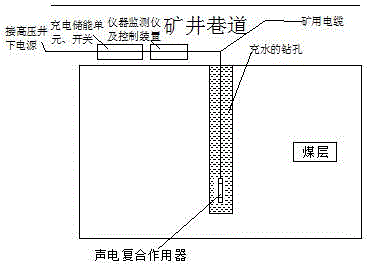

[0015] Before the implementation of this technology, the geological structure of the implemented coal seam, the physical and mechanical properties of the coal seam, and the historical methods of increasing production should be fully investigated. At the same time, the parameters of the high-voltage electric pulse and the function parameters of the acoustic wave probe should be adjusted to adapt to the coal seam conditions.

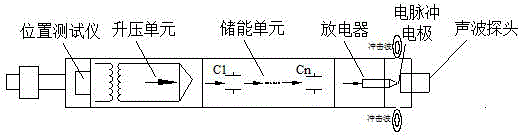

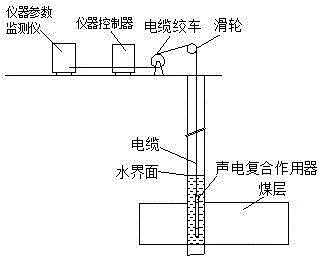

[0016] refer to figure 1 , the high-power acoustic-electric composite effector used in this invention is mainly composed of a booster unit, an energy storage unit, a discharger and an energy converter, etc., wherein the booster unit is composed of a transformer, etc., and the energy storage unit is composed of a plurality of capacitors connected in parallel. The electrical appliance mainly provides the electric energy required for the electrodes and the acoustic wave probe, and the energy converter mainly consists of the electrode and the acoustic wave prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com