UV laser drilling hole method

A technology of laser drilling and laser beam, which is applied in the direction of removing conductive materials by mechanical methods, can solve problems such as cracking and falling off of the electroplating layer, fracture of the electroplating copper layer, and poor electroplating, so as to increase processing flexibility and improve processing Quality, simple effect of optical path system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

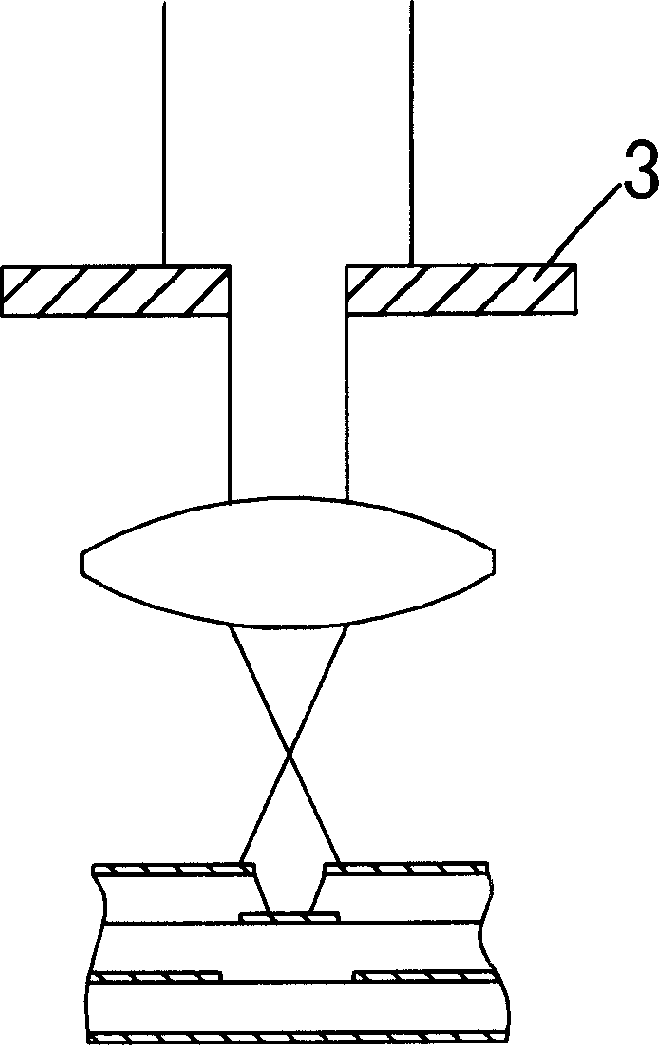

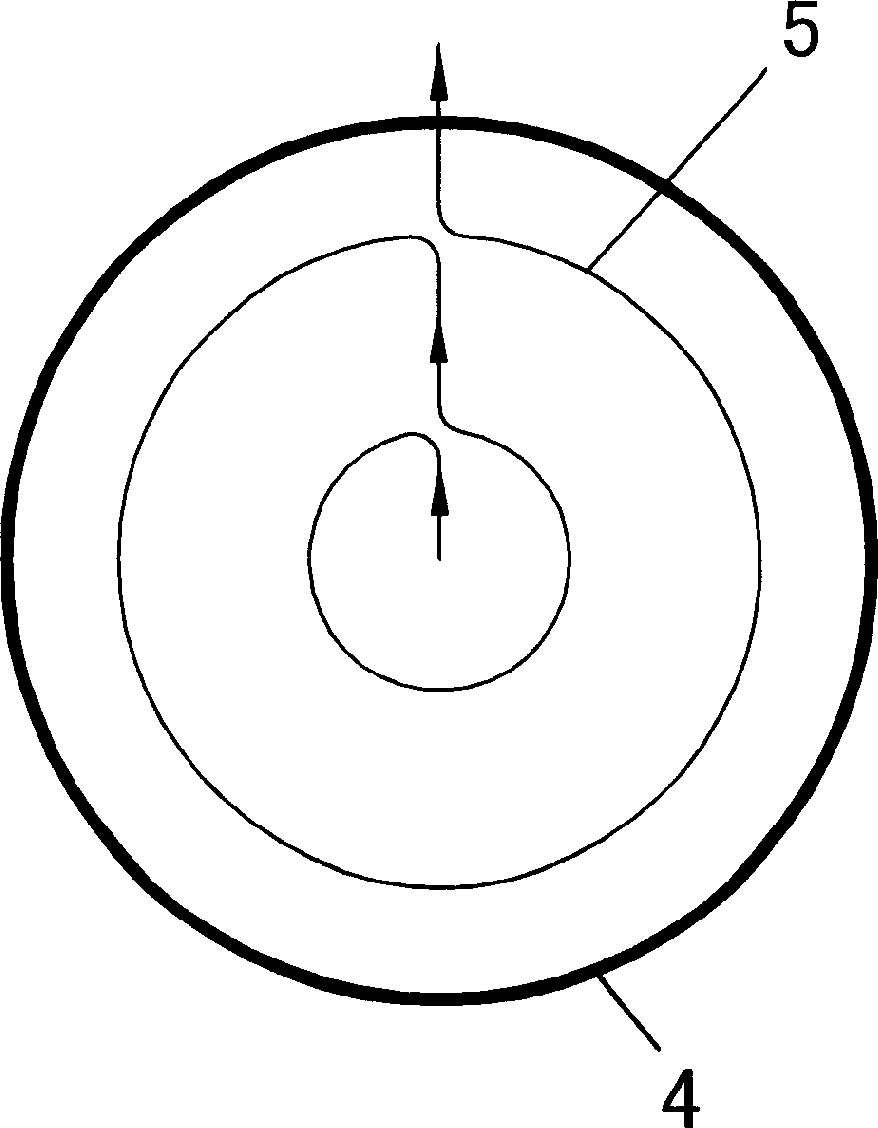

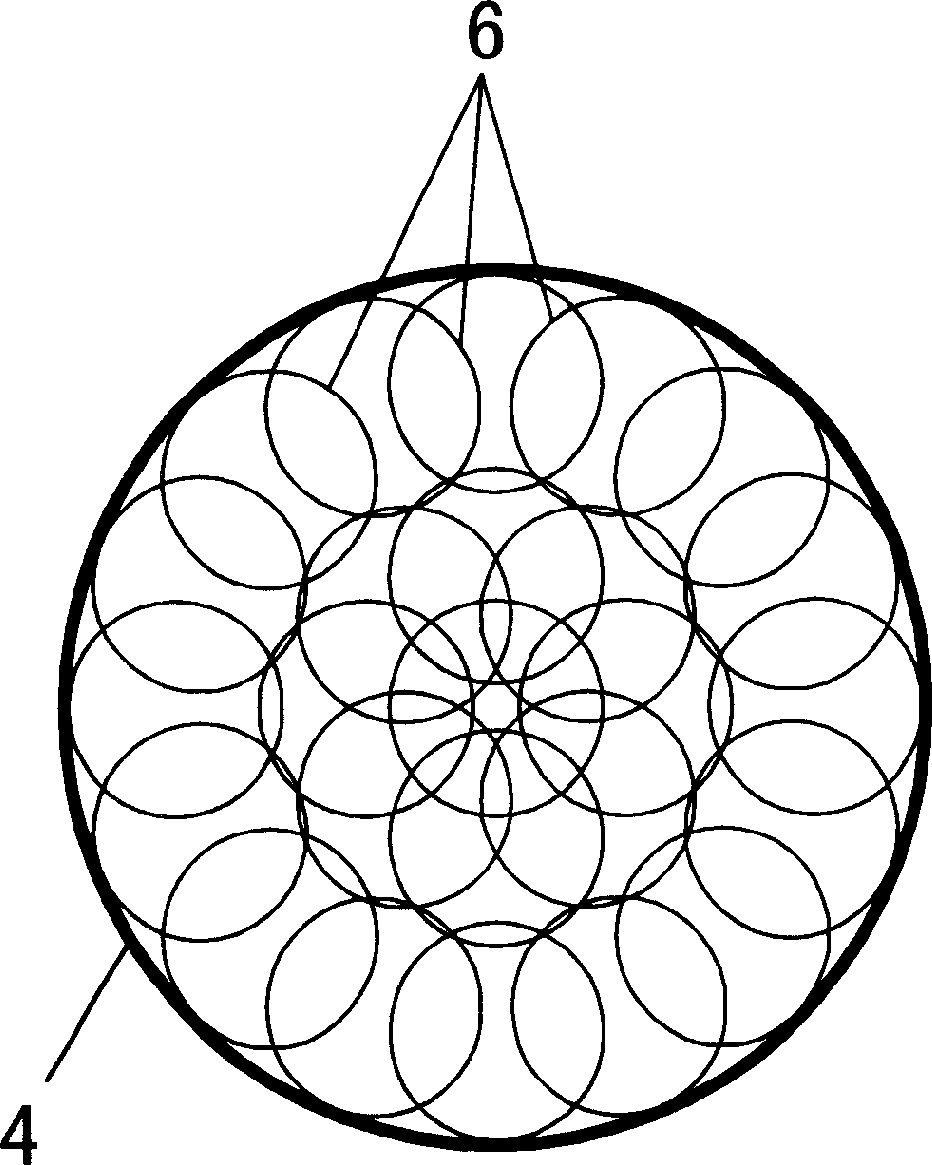

[0021] see Figure 3a , Figure 3b , Figure 4 , Figure 5a , Figure 5b and Figure 6 , the present invention adopts the method of UV laser drilling to process the micro via hole 4 on the high-density interconnection printed circuit substrate. As we all know, the wavelength of UV laser is very short (less than 400nm), the energy density after focusing is extremely high, and most materials have a relatively high absorption rate for UV laser. After absorbing UV laser, various materials will destroy the molecular bonds of organic matter, metals, etc. The metal bond of the crystal and the ionic bond of the inorganic matter make it form suspended particles or atoms, molecular groups, etc. to escape, thereby forming a blind hole for connectivity between the inner and outer copper pattern layers of the multilayer printed circuit board. After the hole wall is cleaned and copper-plated, the copper pattern layer 1 of the inner layer and the outer layer can be connected together to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com