High-modulus asphalt paving material and preparation method thereof

A technology of asphalt mixture and high modulus, which is applied in the field of asphalt pavement pavement materials, can solve the problems of high cost and high viscosity of the mixture, save pavement materials, reduce the thickness of the asphalt surface layer, and prolong the compaction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

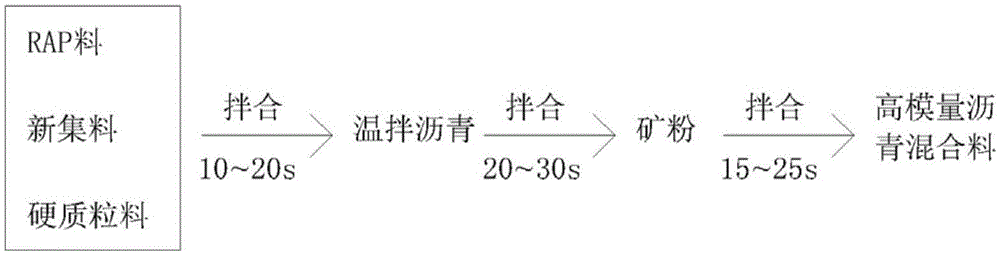

Method used

Image

Examples

Embodiment 1

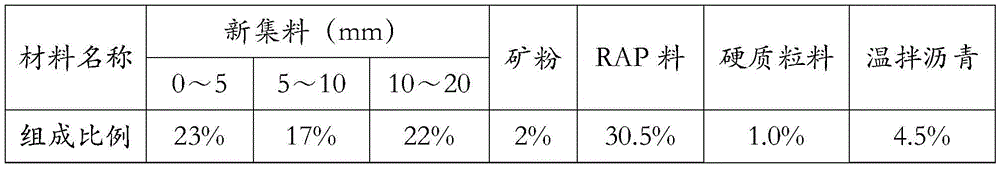

[0032] Embodiment 1, prepare a kind of high modulus asphalt mixture, the raw material that adopts is: the asphalt is heavy handover No. 70, the RAP material is the milling material of the upper layer in the expressway, the aggregate is high-quality limestone, and the hard granular material is Sinopec Production of hard aggregates, mineral powder is limestone ground fine mineral powder.

[0033] The above raw materials should be made into high modulus asphalt mixture as shown in Table 1:

[0034] Table 1 Composition ratio of high modulus asphalt mixture materials

[0035]

[0036] To prepare the high modulus asphalt mixture shown in Table 1, follow the steps below:

[0037] Step 1: Preheat the double-drum hot recycled asphalt mixing plant to ensure the accuracy of temperature control during production, then put the new aggregate into the first drum, heat the new aggregate to 180°C, and put Put the RAP material into the second drum and heat it to 110°C;

[0038] Step 2: Pe...

Embodiment 2

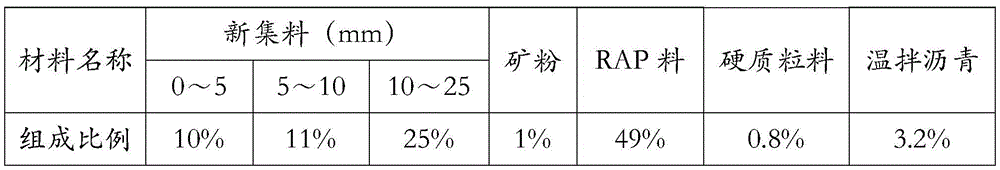

[0046] Embodiment 2, prepare a kind of high modulus asphalt mixture, the raw material that adopts is identical with embodiment, and the ratio of raw material that adopts is as shown in table 3:

[0047] Table 3 Composition ratio of high modulus asphalt mixture materials

[0048]

[0049] To prepare the high modulus asphalt mixture shown in Table 3, the process steps are basically the same as those in Example 1, and the temperature and time in the process steps have been adjusted accordingly:

[0050] Step 1: Preheat the double-drum hot recycled asphalt mixing plant, put the new aggregate into the first drum and heat it to 190°C, put the RAP material into the second drum and heat it to 120°C;

[0051] Step 2, secondary sieving of the new aggregate in the first drum to obtain the proportioning ratio of the sieved new aggregate material composition as shown in Table 3;

[0052] Step 3, weigh 2300kg of the new aggregate sieved in step 2, put it into the mixing tank, weigh 2450...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com