Small-aperture high-density drilling method of printed circuit board

A technology of printed circuit board and drilling method, which is applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc. It can solve the problems of PCB factory production capacity bottleneck and huge investment in drilling rigs, so as to avoid partial holes and broken drills, and reduce broken drills , Improve the effect of drilling rig productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The small-aperture high-density drilling method of the printed circuit board of the present invention, its specific steps are as follows:

[0024] (1) With Hitachi ND-6Ni210E / ND-6Ne210E CNC drilling machine, the maximum spindle speed is 180krpm. Press the HOME key to return the working surface to the mechanical zero position and then lock the machine. The copper presser foot gasket under the spindle presser foot is made of soft rubber plastic presser foot gasket.

[0025] (2) Open the F2 drill bit ranking interface to set the position of each specification drill bit (0.2mm~6.35mm);

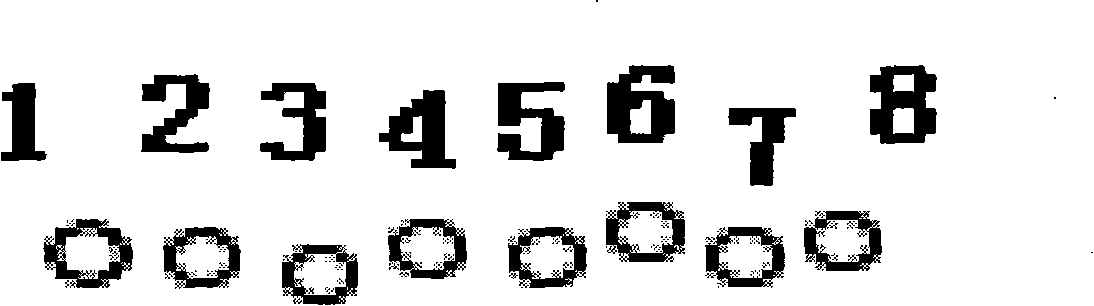

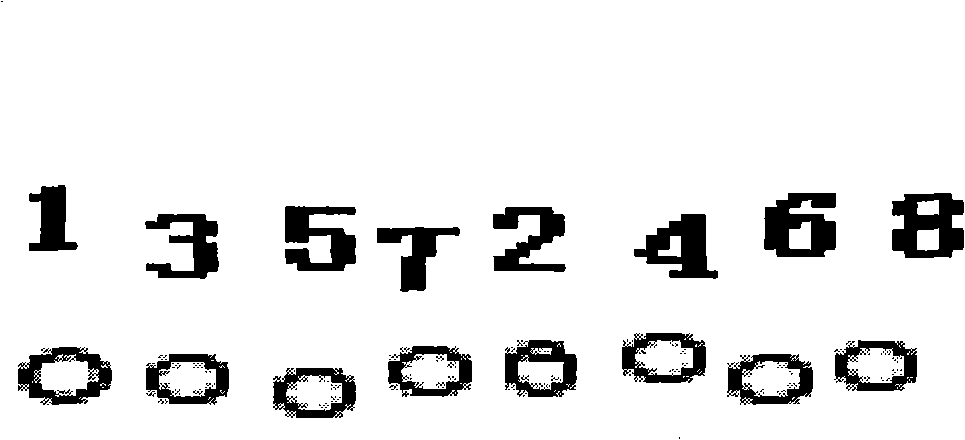

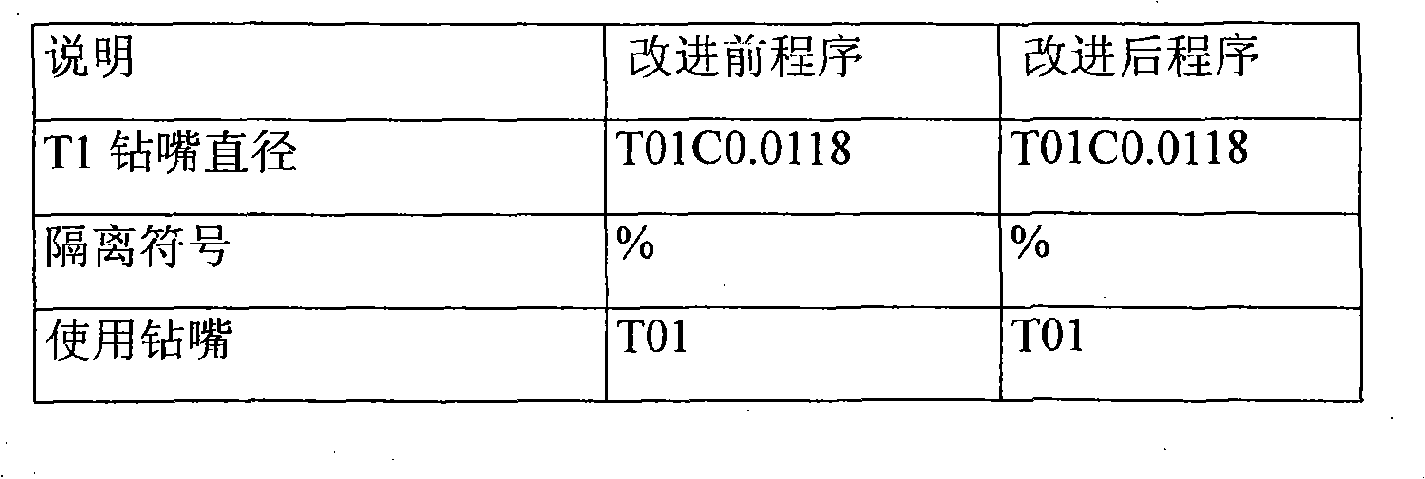

[0026] (3) Open the F3 drill bit parameter interface to set the drill bit parameters of each specification, for example, the Φ0.3mm / Φ0.35mm drill bit parameters are set as follows:

[0027]

Drill specification

Speed S

(thousand revolutions / minute)

Feed speed F

(in / min)

Retraction speed U

(in / min)

Pore limit H

(indivu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com