PDC drill bit using optimized side rake distribution that minimized vibration and deviation

a fixed cutter and drill bit technology, applied in the direction of instruments, analogue processes for specific applications, electric/magnetic computing, etc., can solve the problems of significant expense involved in the design and manufacture of drill bits and in the drilling of wells, and achieve the effect of optimizing the performance of fixed cutter drill bits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

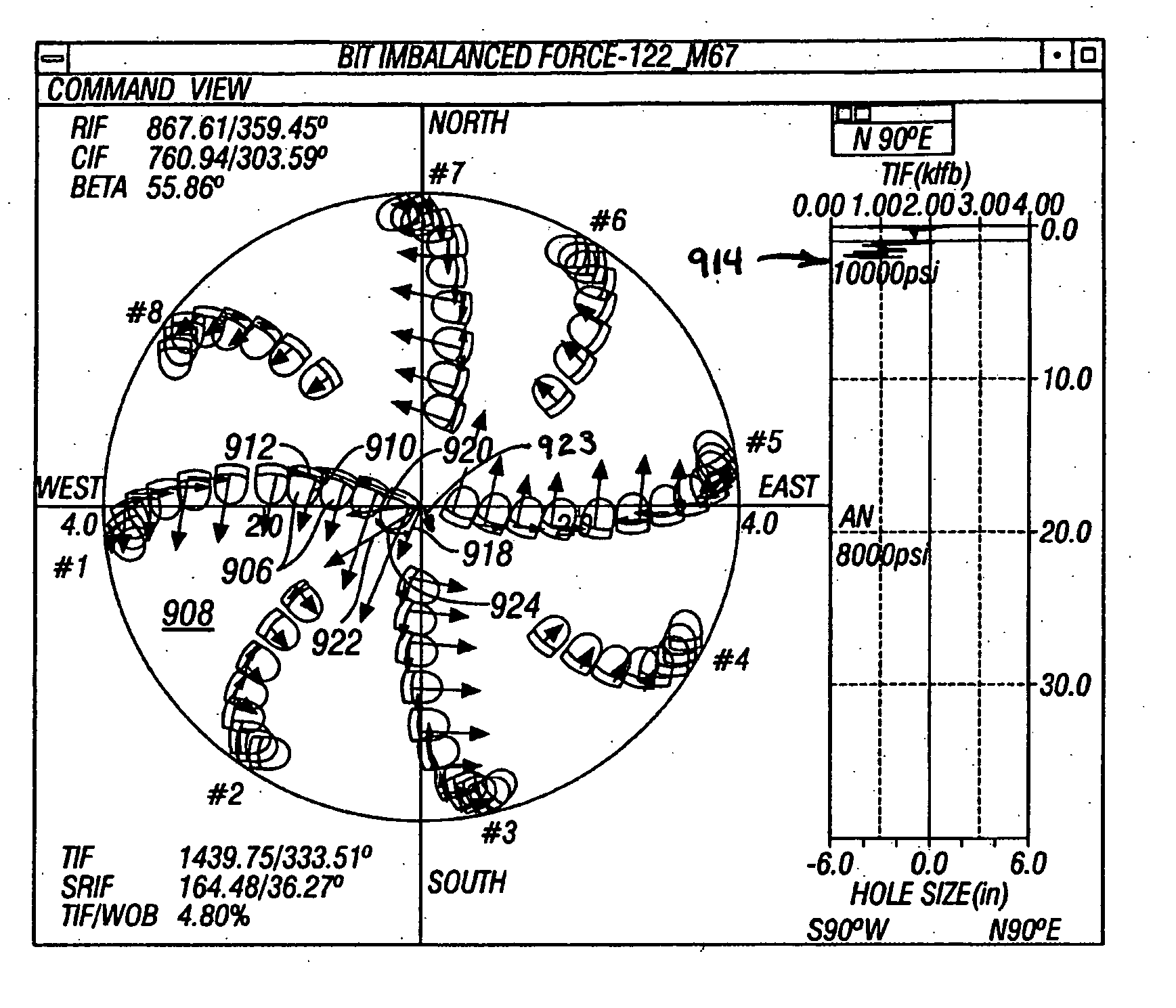

Image

Examples

example alternative embodiments

[0196]FIG. 30 shows a partial end view of a fixed cutter bit 1200 with an alternative modification of the distribution of side rake angles along one exemplary blade 1202 having cutters 1204, 1206, 1208, 1210, and 1212 in a cone region 1214 that are positioned with their faces 1216 parallel to a radial plane 1220 through the centerline 1222 of the bit 1200. By moving the cutters 1204, 1206, 1208, 1210, and 1212 forward of the radial plane 1220 without tilting the cutters, the faces 1216 continue to be parallel to the radial plane 1220. However the offset distance 1218 causes the tangent lines 1224, 1226, 1228, 1230 and 1232 at the face of each cutter 1204, 1206, 1208, 1210, and 1212 to be at a different side rake angle 1234, 1236, 1238, 1240 and 1242, respectively, relative to the centerlines of each cutter. Thus, the side rake angle for each cutter is different and relatively larger at the center cutter 1204 and relatively smaller at cutter 1212. This shows an alternative way to mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com