Patents

Literature

43results about How to "Stable cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Insert-exchangeable, rotary tool and throwaway insert

InactiveUS6884006B2High operating requirementsStable cuttingMilling cuttersShaping cuttersPositive typeEngineering

Owner:HITACHI TOOL ENG LTD

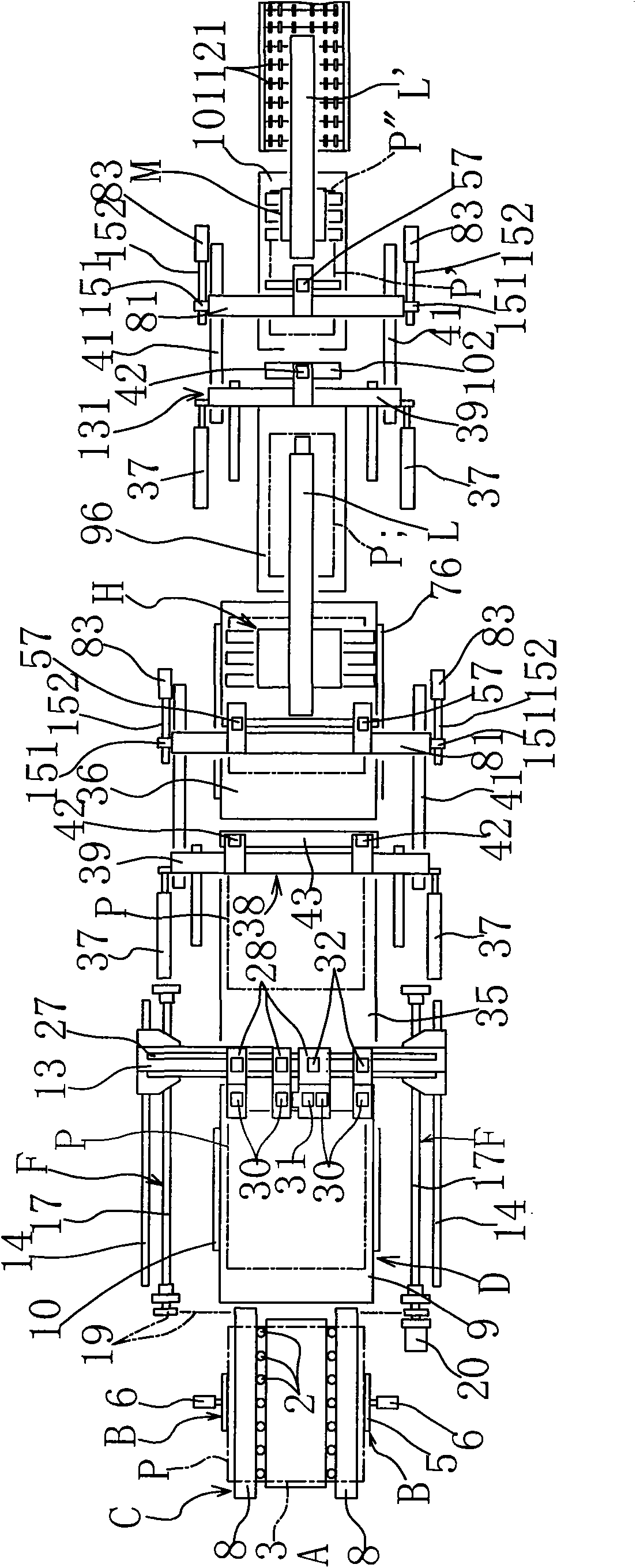

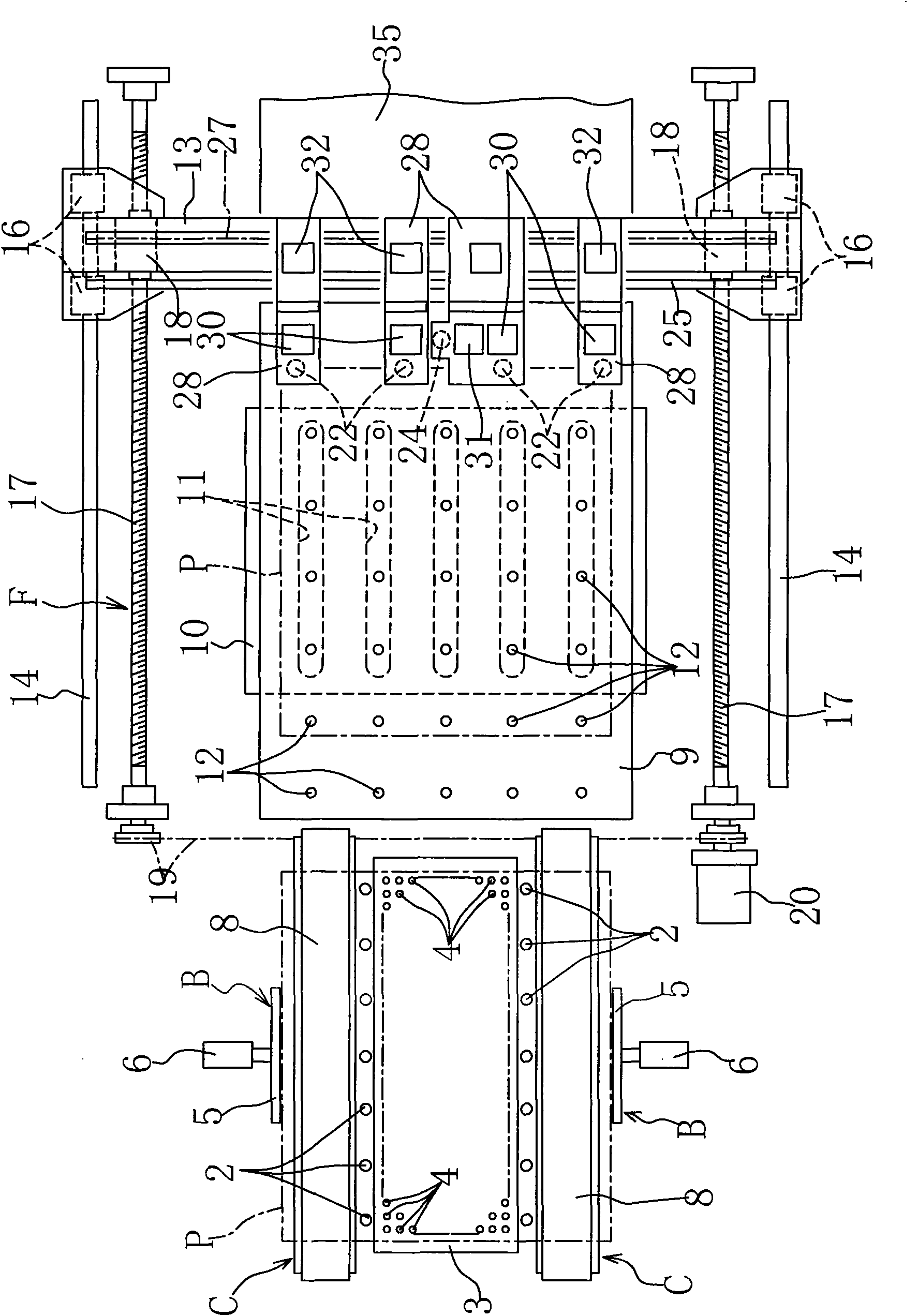

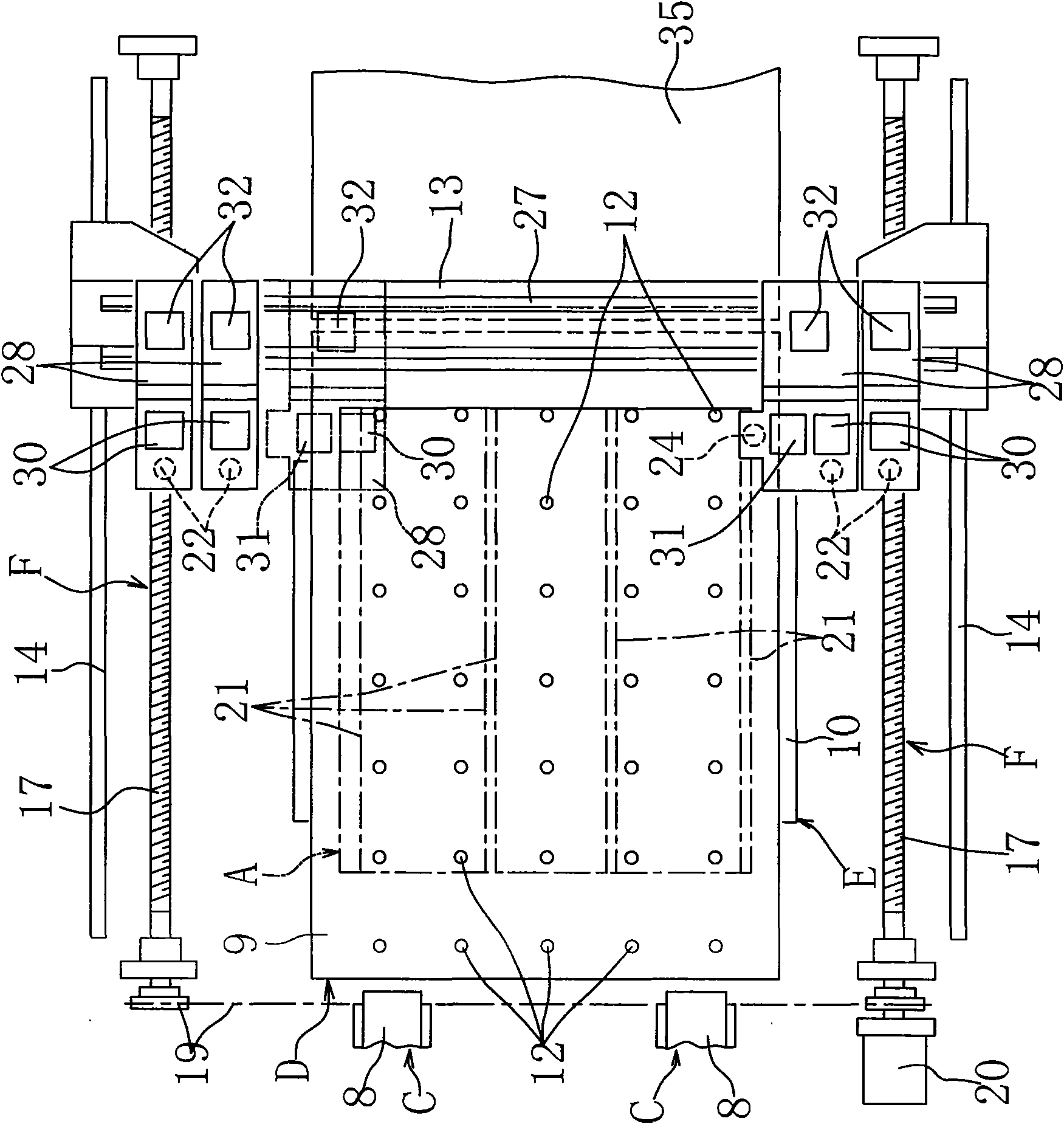

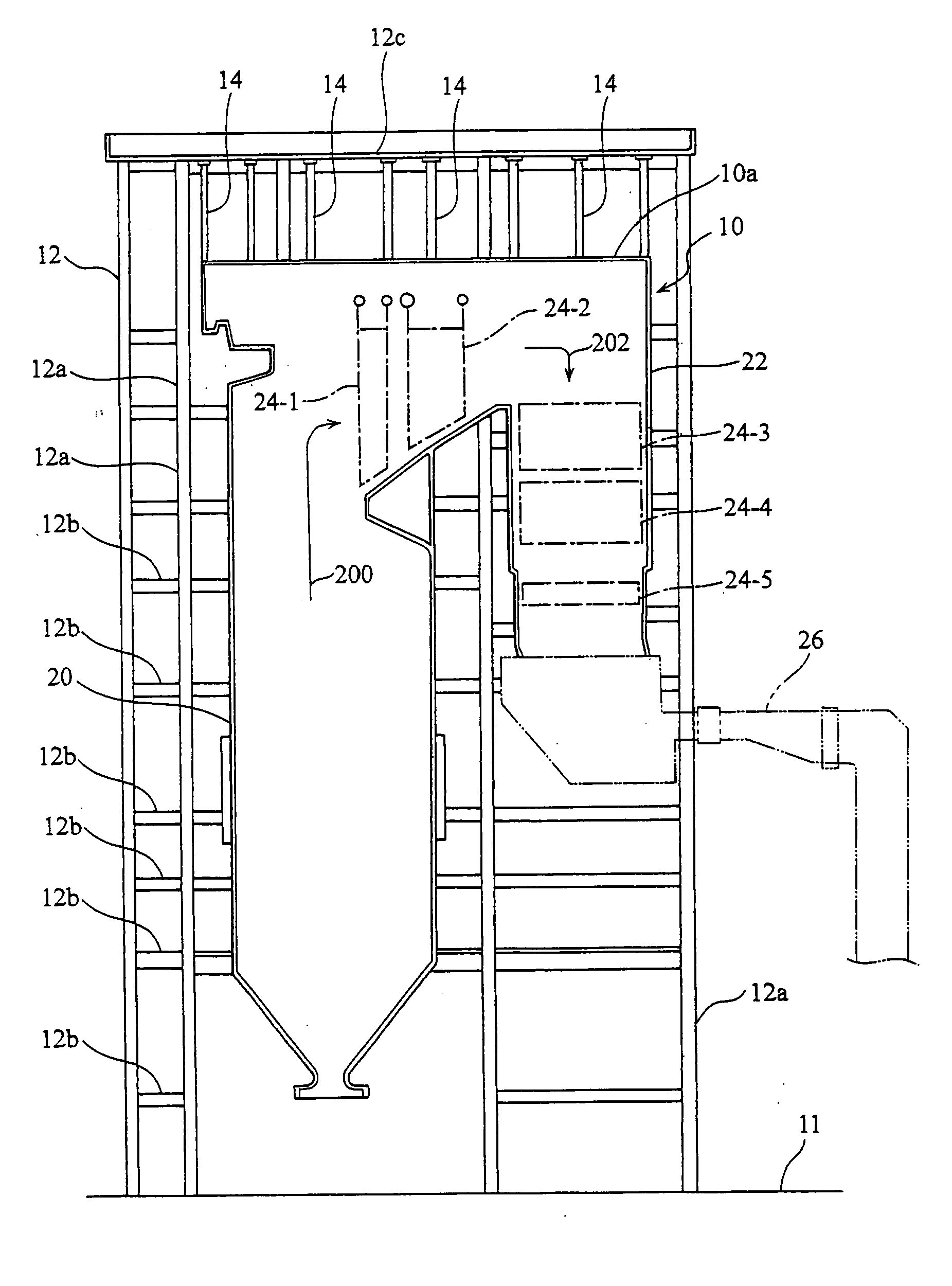

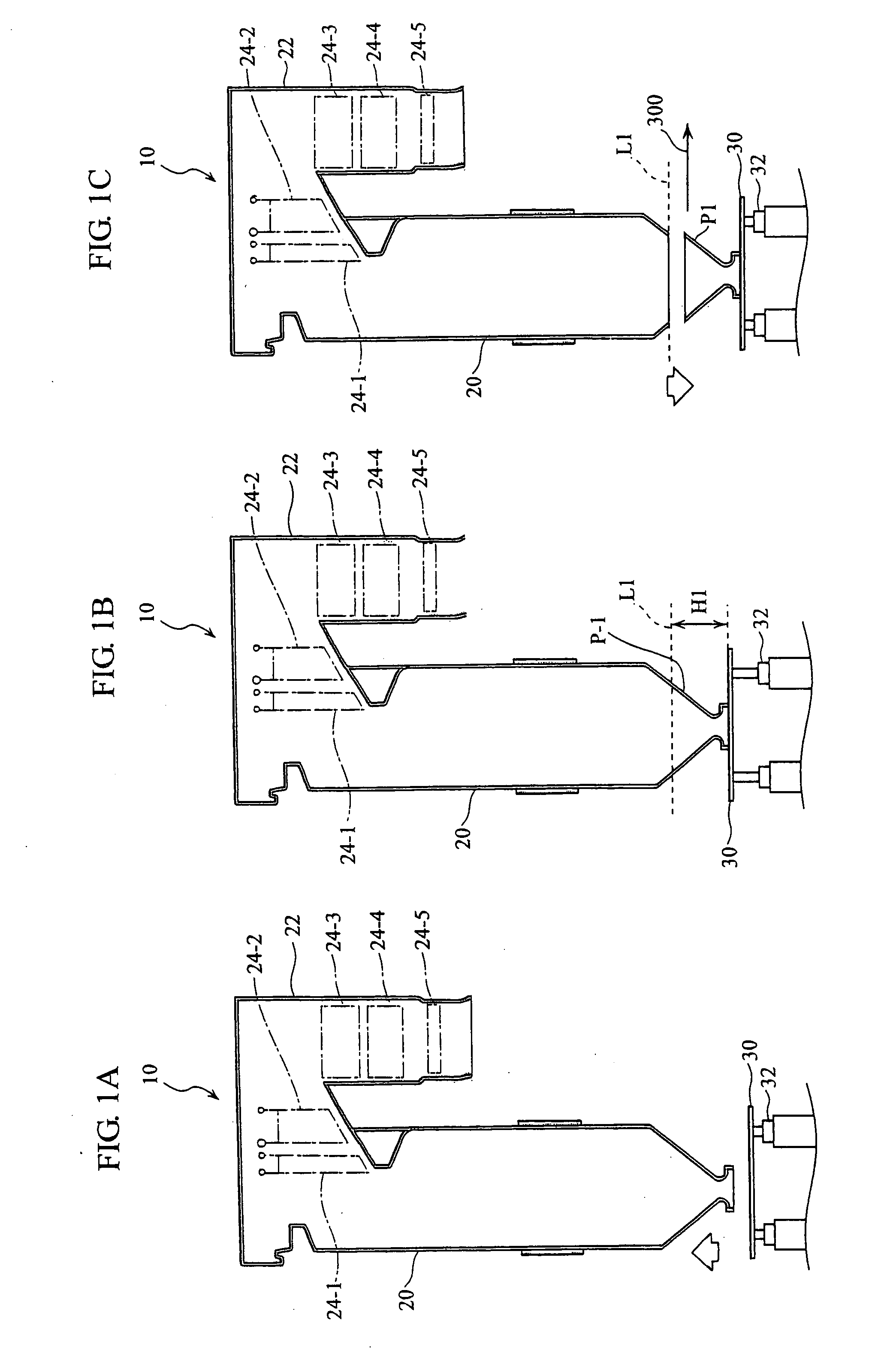

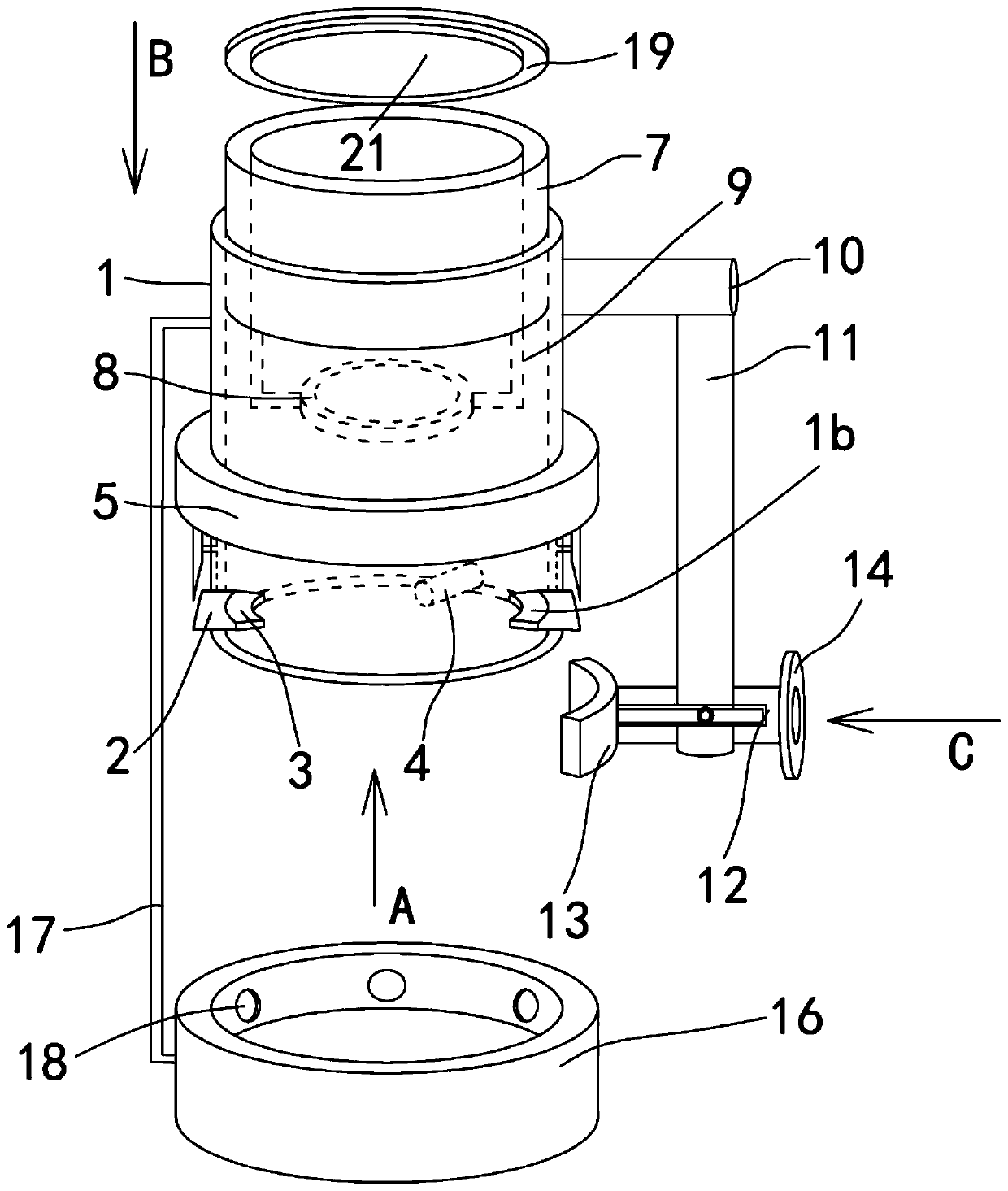

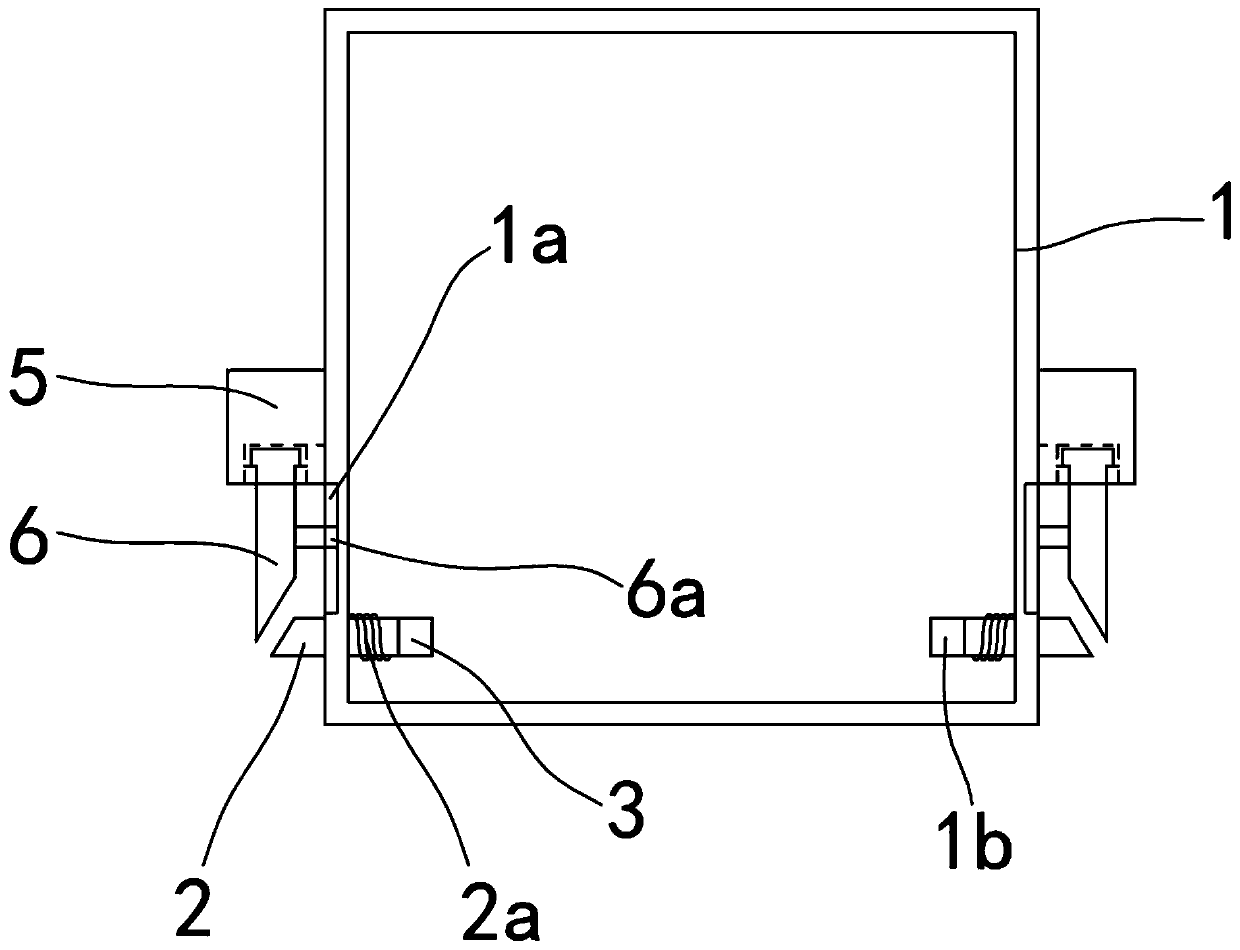

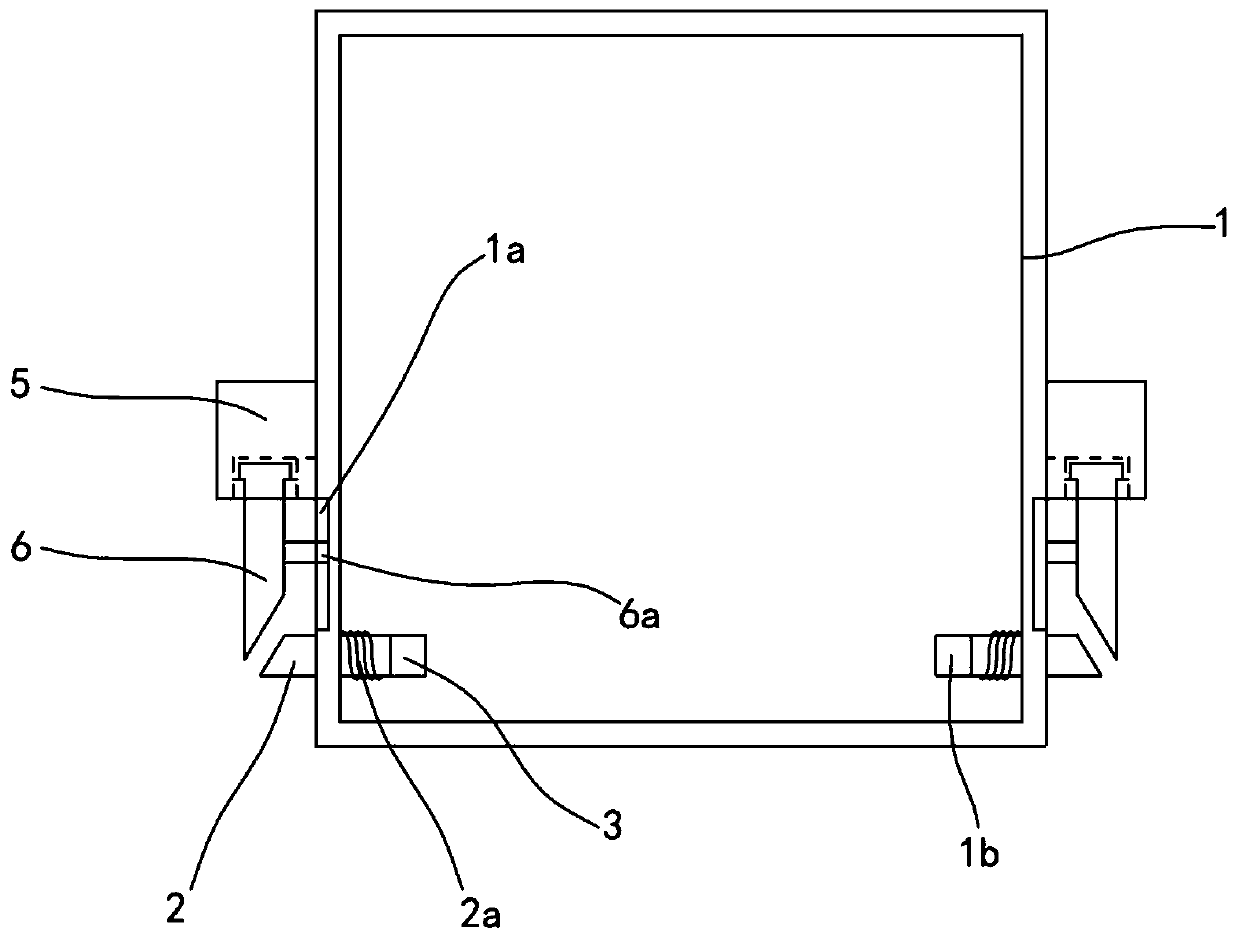

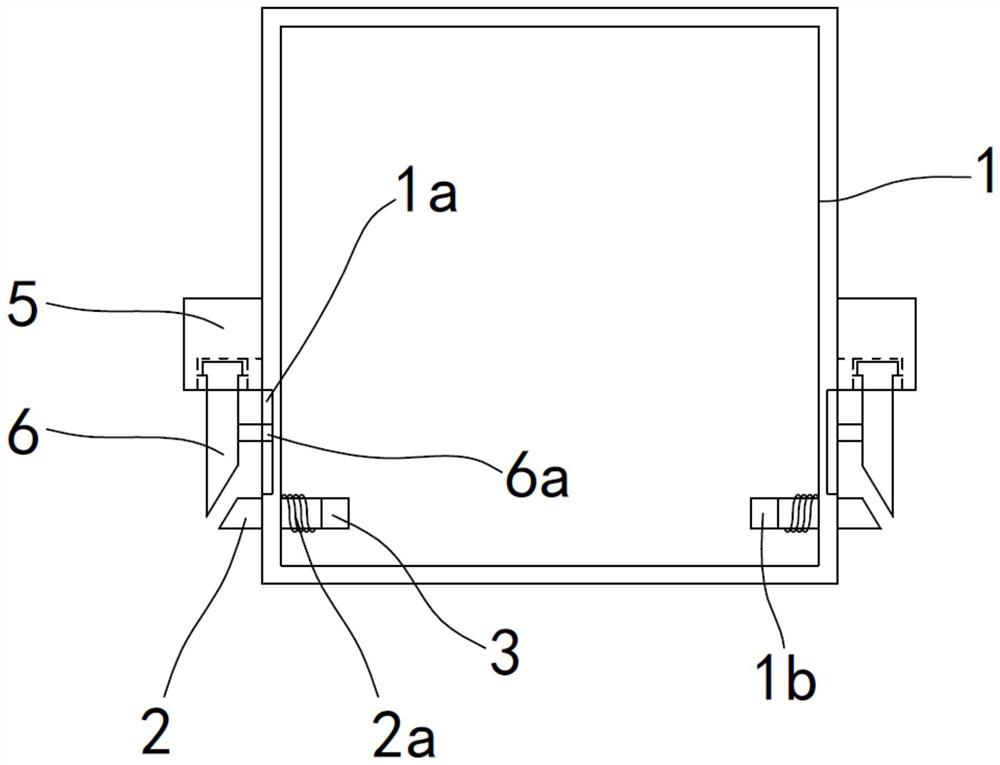

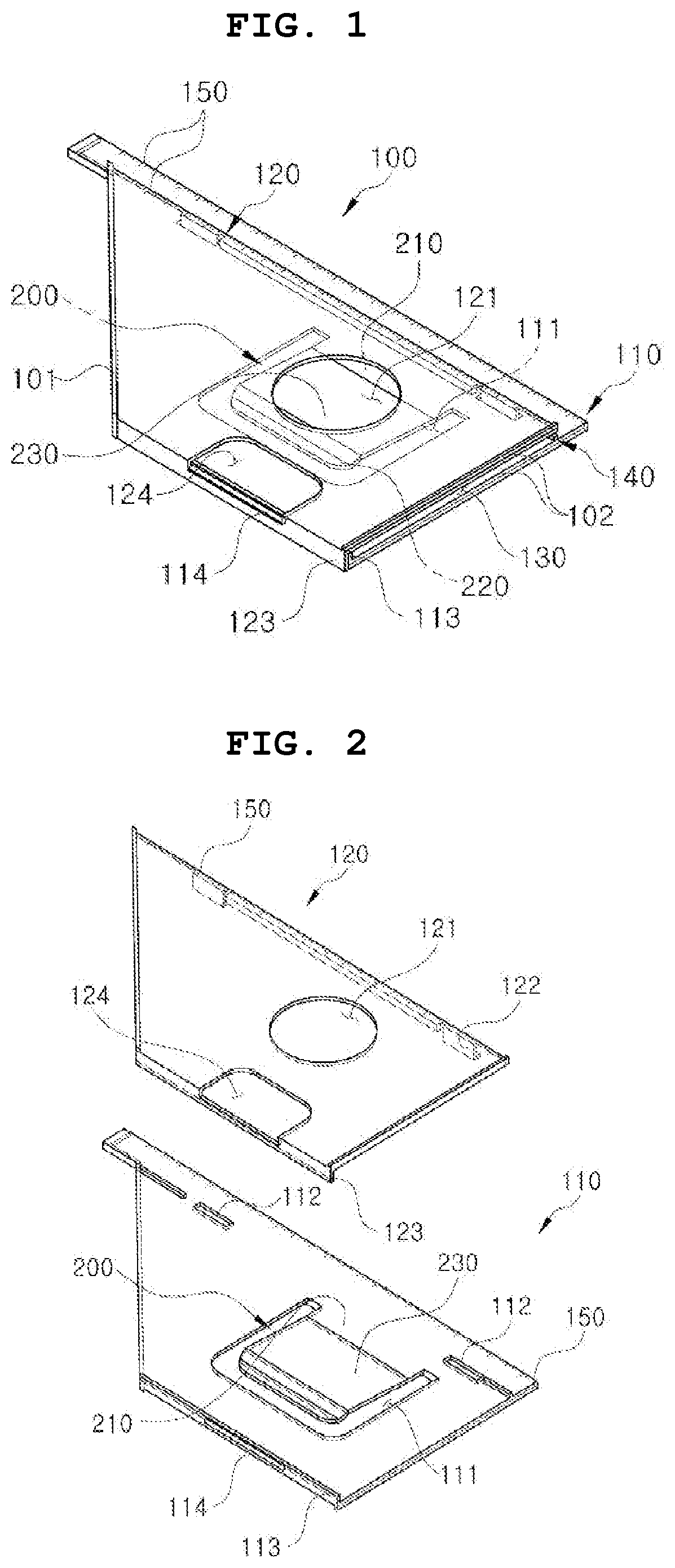

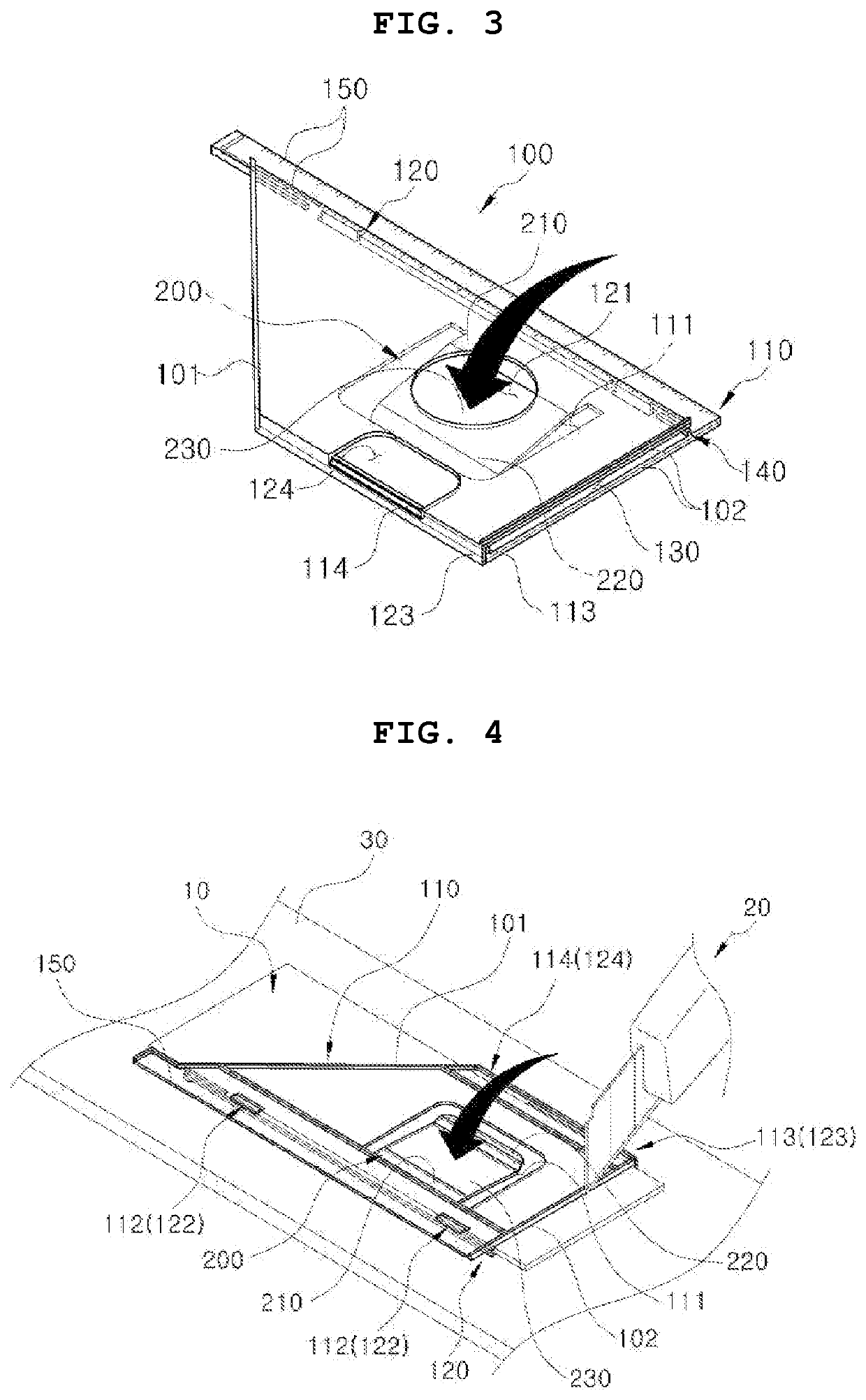

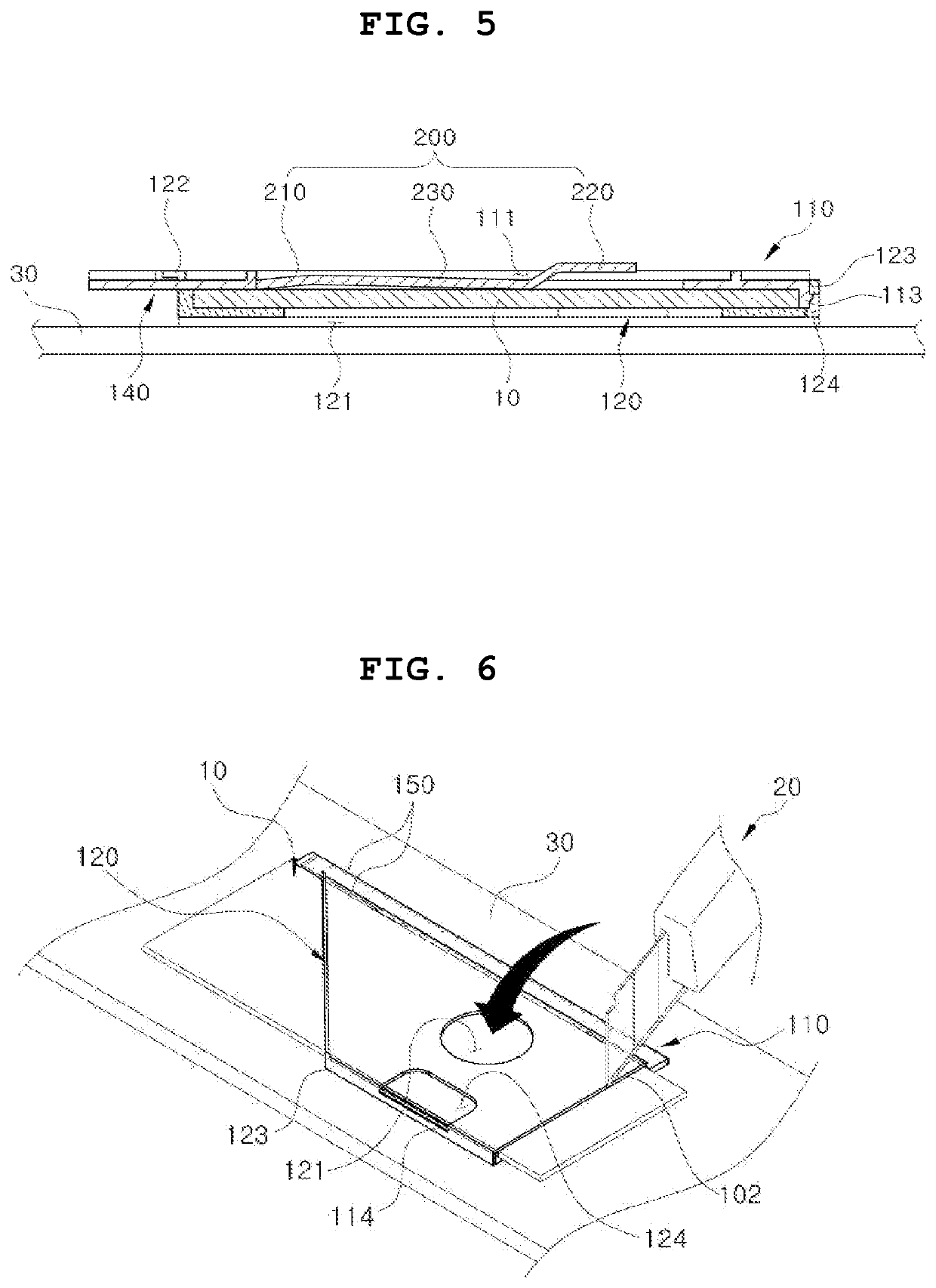

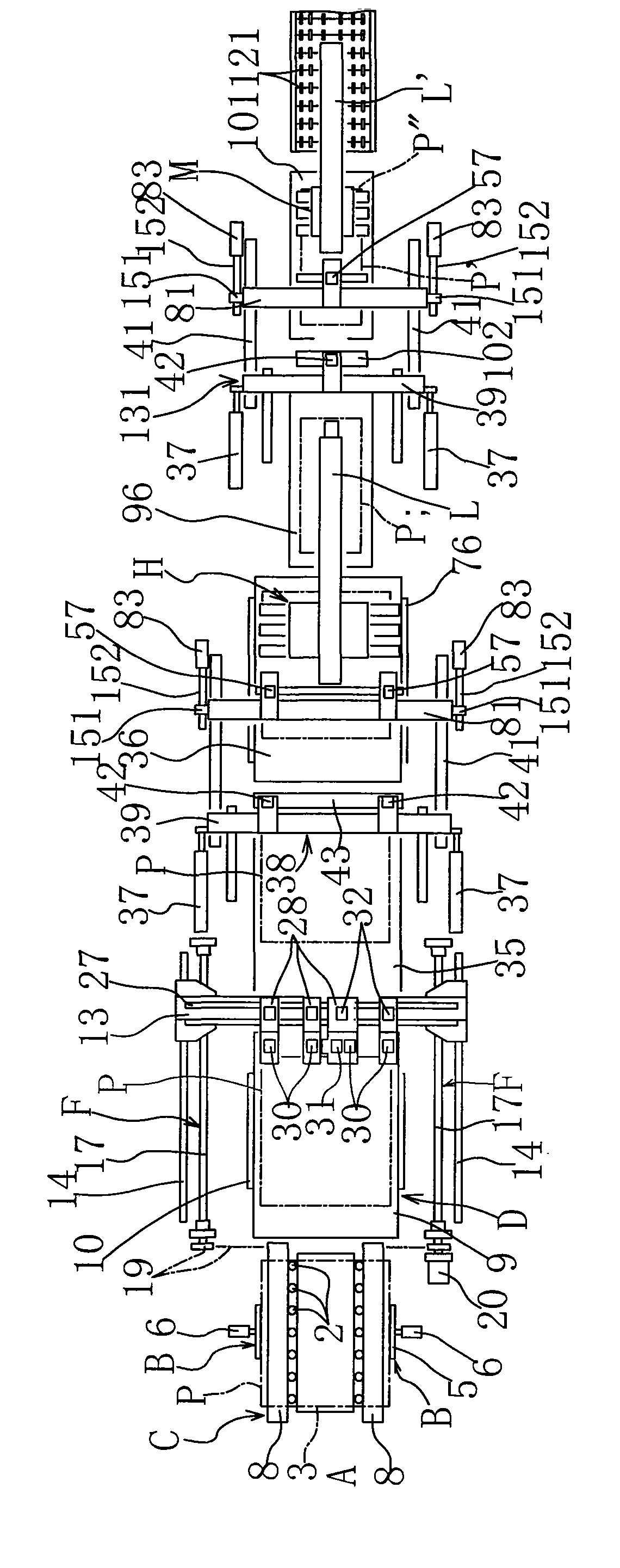

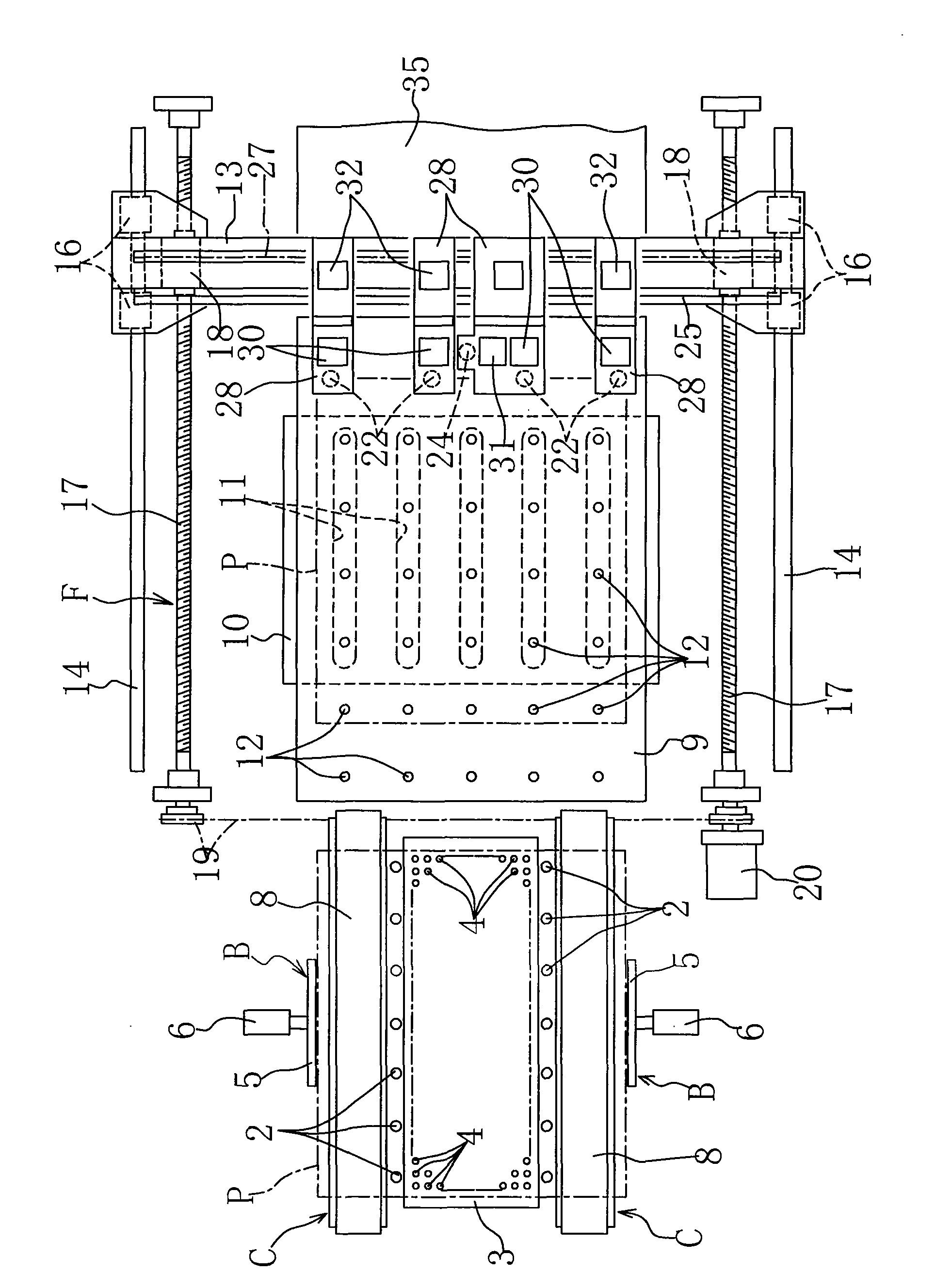

Cutting device of LCD panel

ActiveCN101628784AReduced installation areaStable cuttingGlass severing apparatusManufacturing lineLiquid crystal

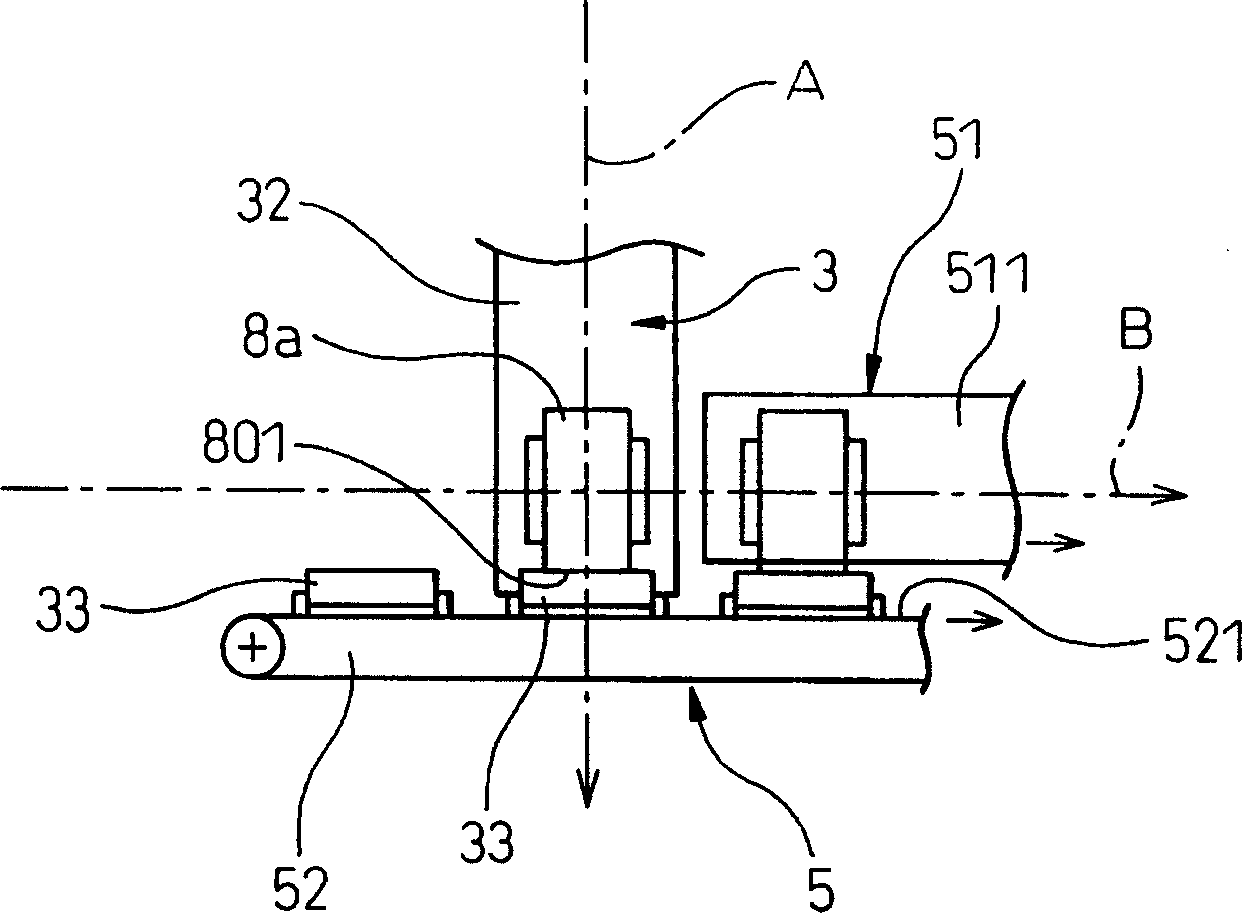

The invention provides a cutting device of LCD panel marking the cutting lines on the A surface in the X and Y axe, marking the cutting lines for rough cutting and precious cutting on the B surface, and cutting each cutting line of a large LCD panel on a marking table of one production line. First and second cutters for marking in the X and Y axes are arranged on the marking table, in front of which a cutter of the cutting line for rough cutting, a cutting roller for cutting the cutting line, a cutter of the cutting line for precious cutting, and a cutting roller for cutting the cutting line are provided, and a first supplement table and a second supplement table for forward delivery are arranged above the cutters and cutting rollers, moreover, a cutting device is arranged in front of each supplement table.

Owner:SHIRAI IRON WORKS

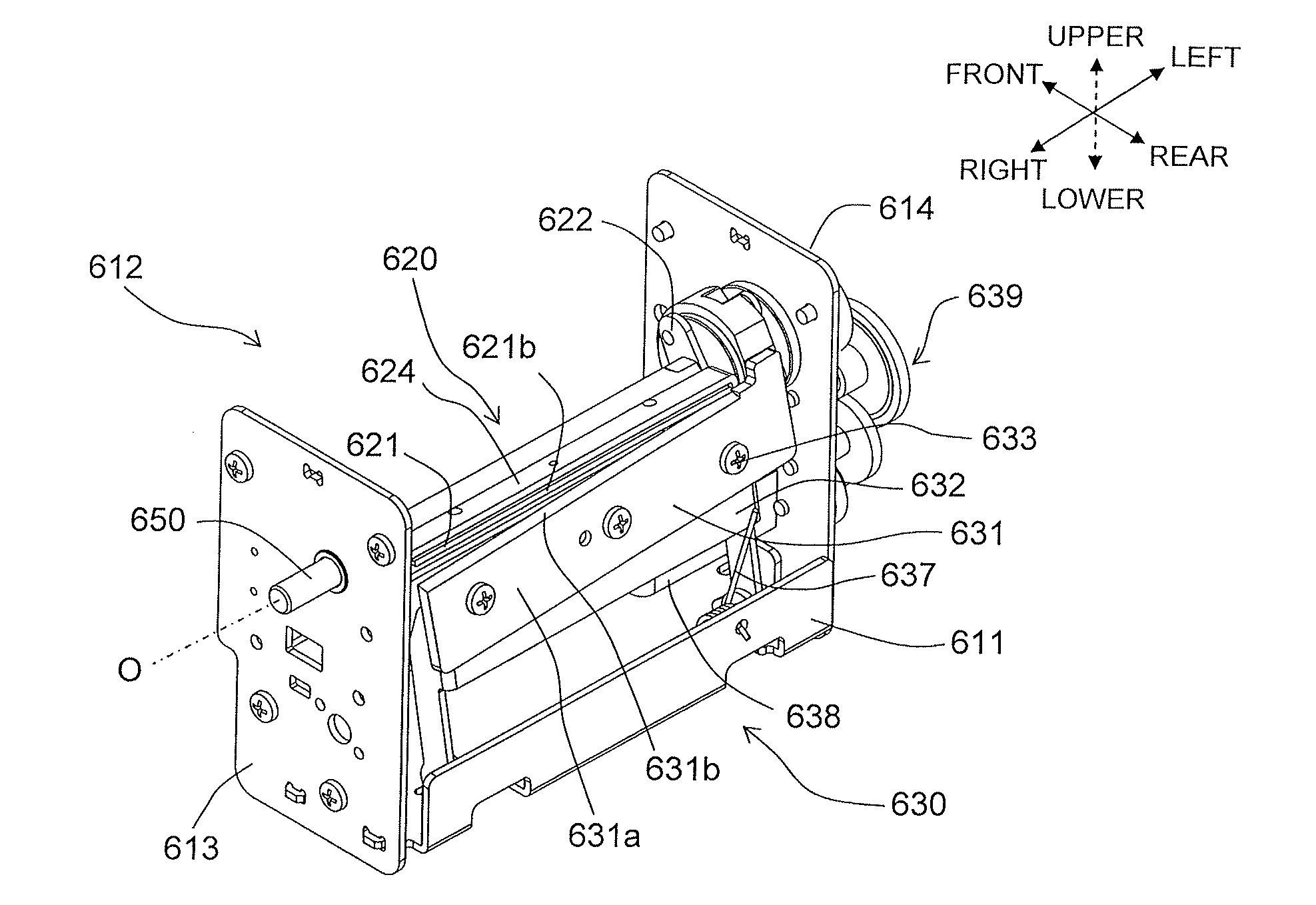

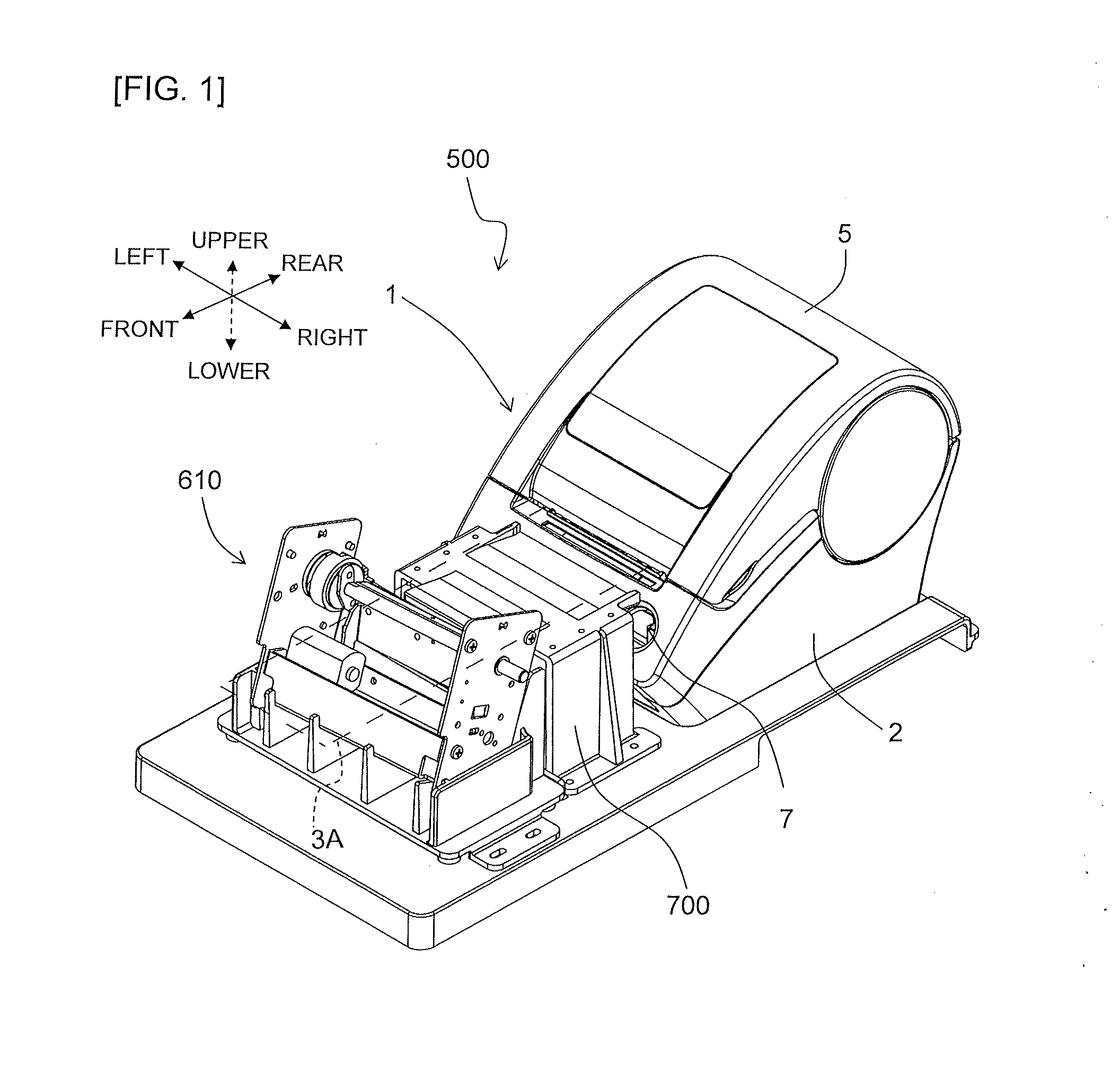

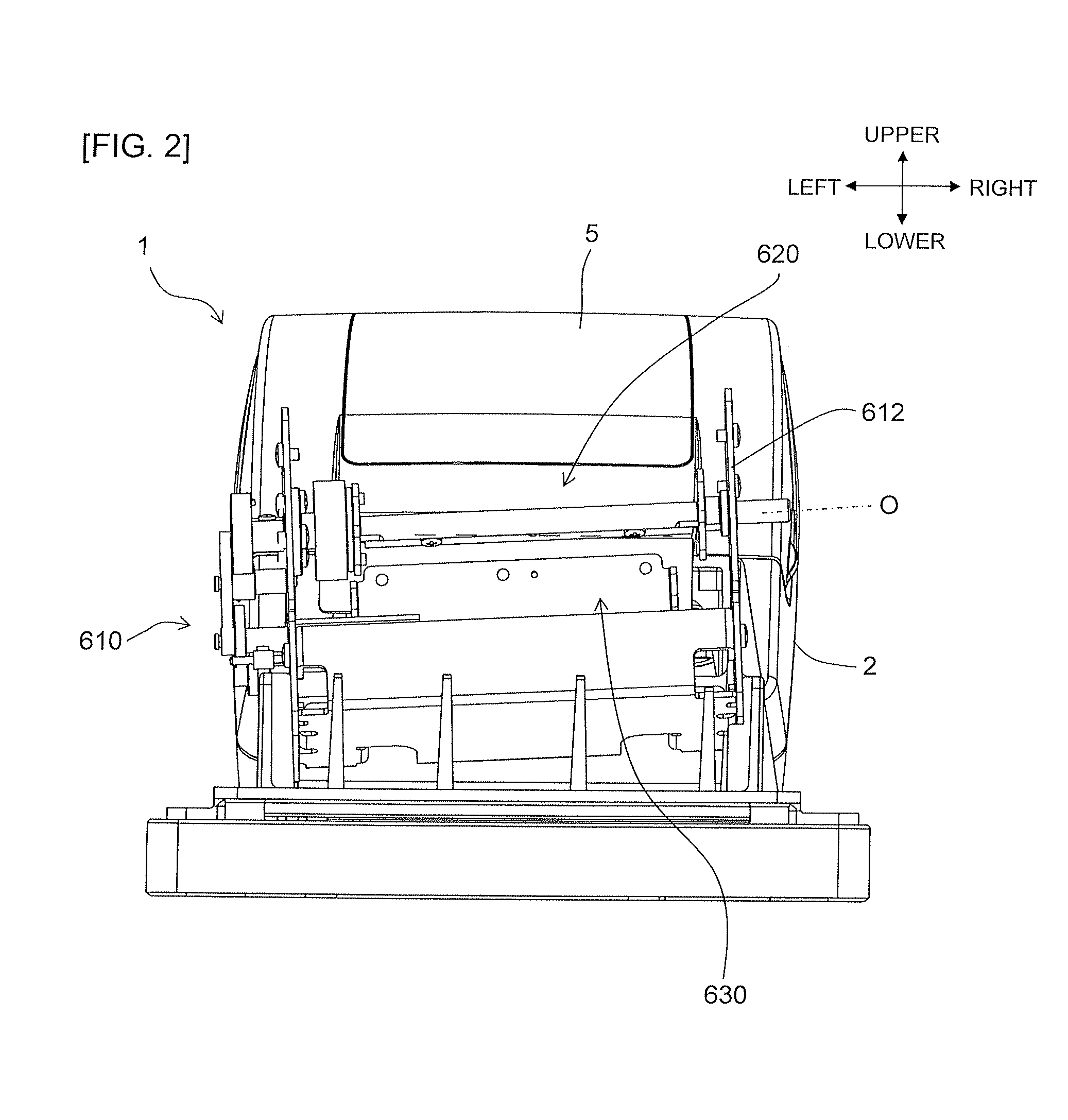

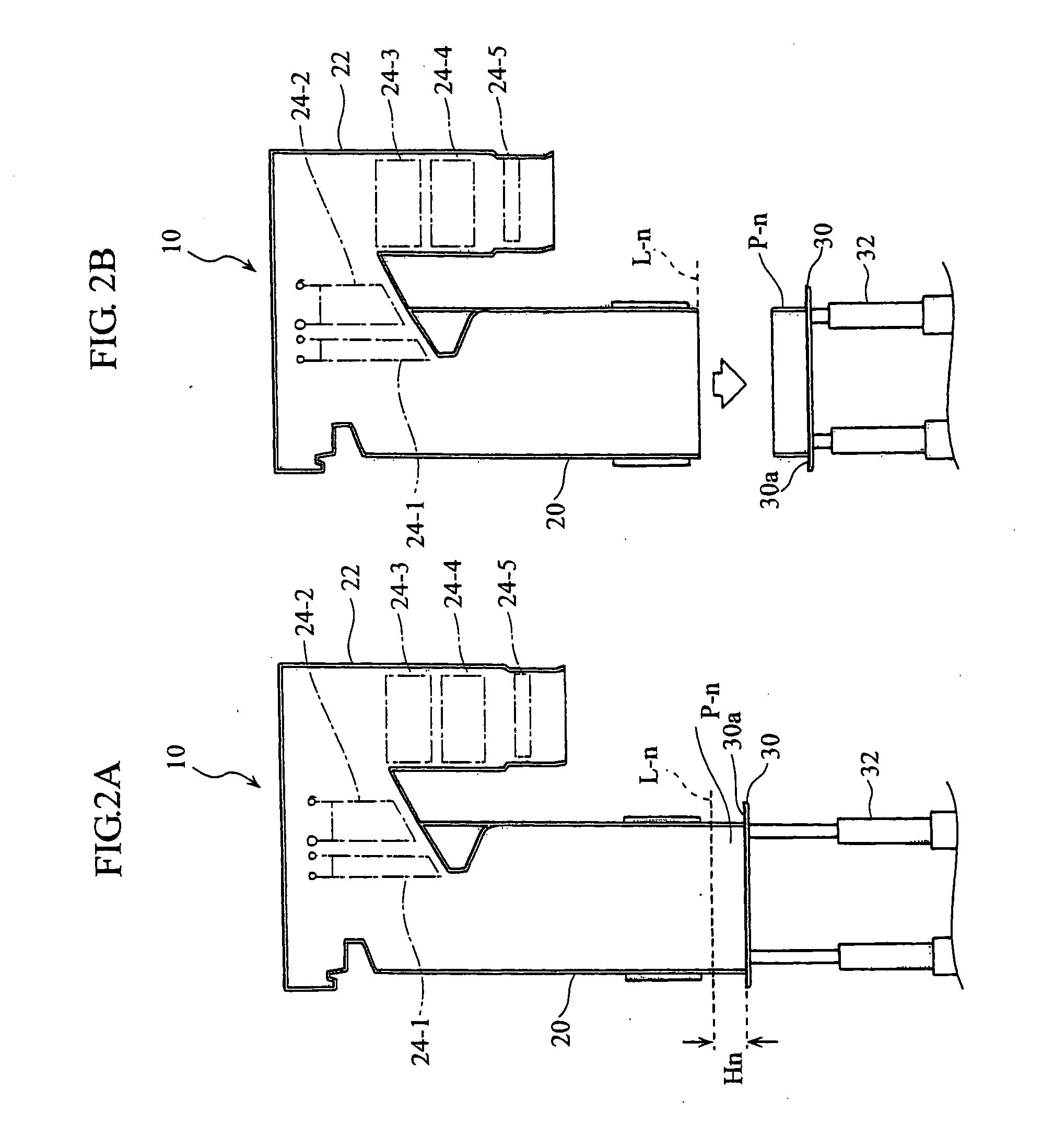

Rotary cutter apparatus and printer

ActiveUS20140126947A1Stable cuttingOther printing apparatusMetal working apparatusComputer printingStructural engineering

A rotary cutter apparatus comprises a rotary body and a holding body. The rotary body is supported by a housing so as to rotate along a rotating direction. The holding body is supported by the housing. The rotary body has a rotary blade including a first edge portion. The holding body has a fixed blade including a second edge portion. The first edge portion is configured to be in contact with the second edge portion and to be rubbed with the second edge portion. The first edge portion and the second edge portion are configured to perform cutting of an object to be cut. The object is located in an introduction path. The rotary cutter apparatus further comprises a guide member configured to be in contact with the object and to guide it when the object is fed to an inside of a rotation trajectory of the rotary body.

Owner:BROTHER KOGYO KK

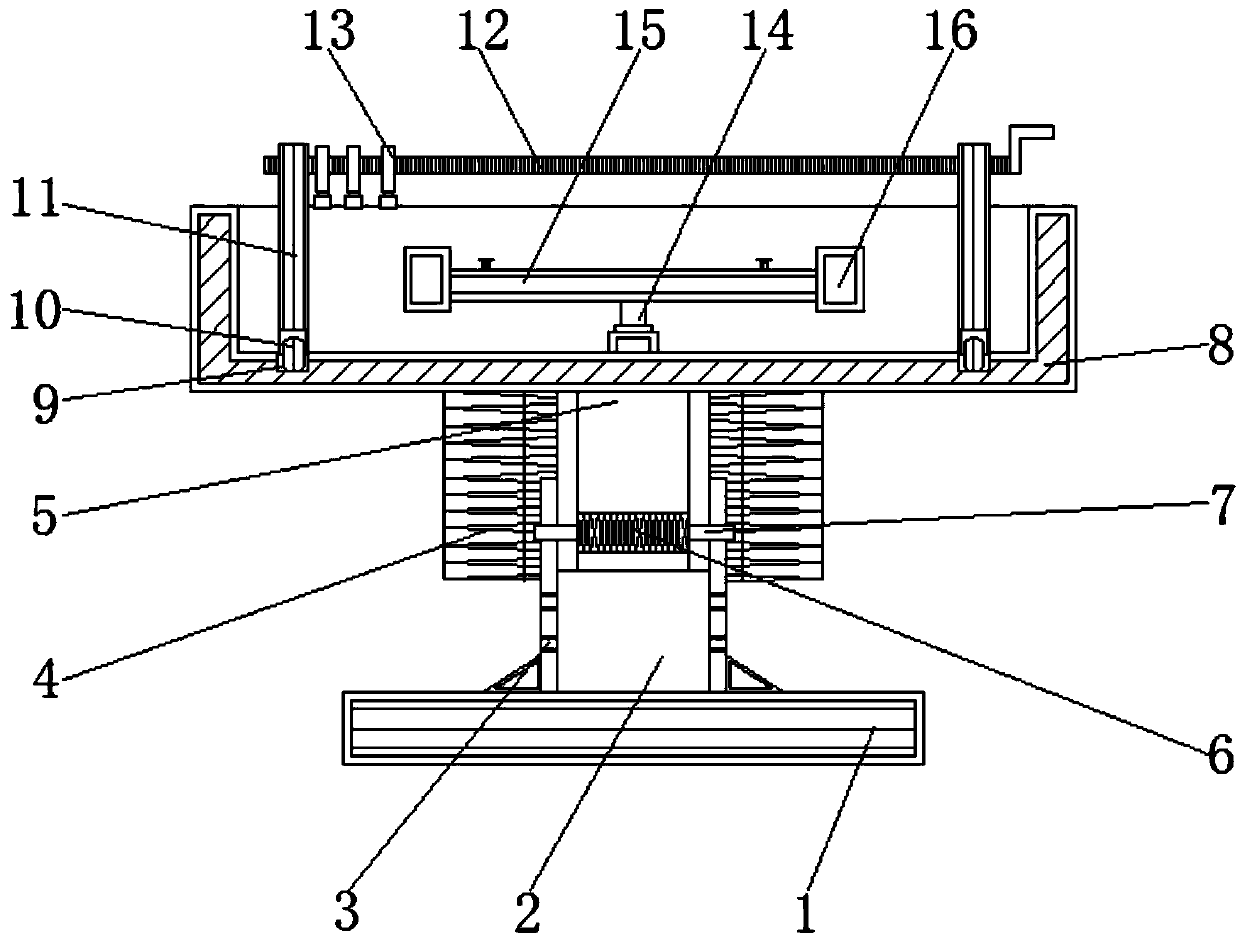

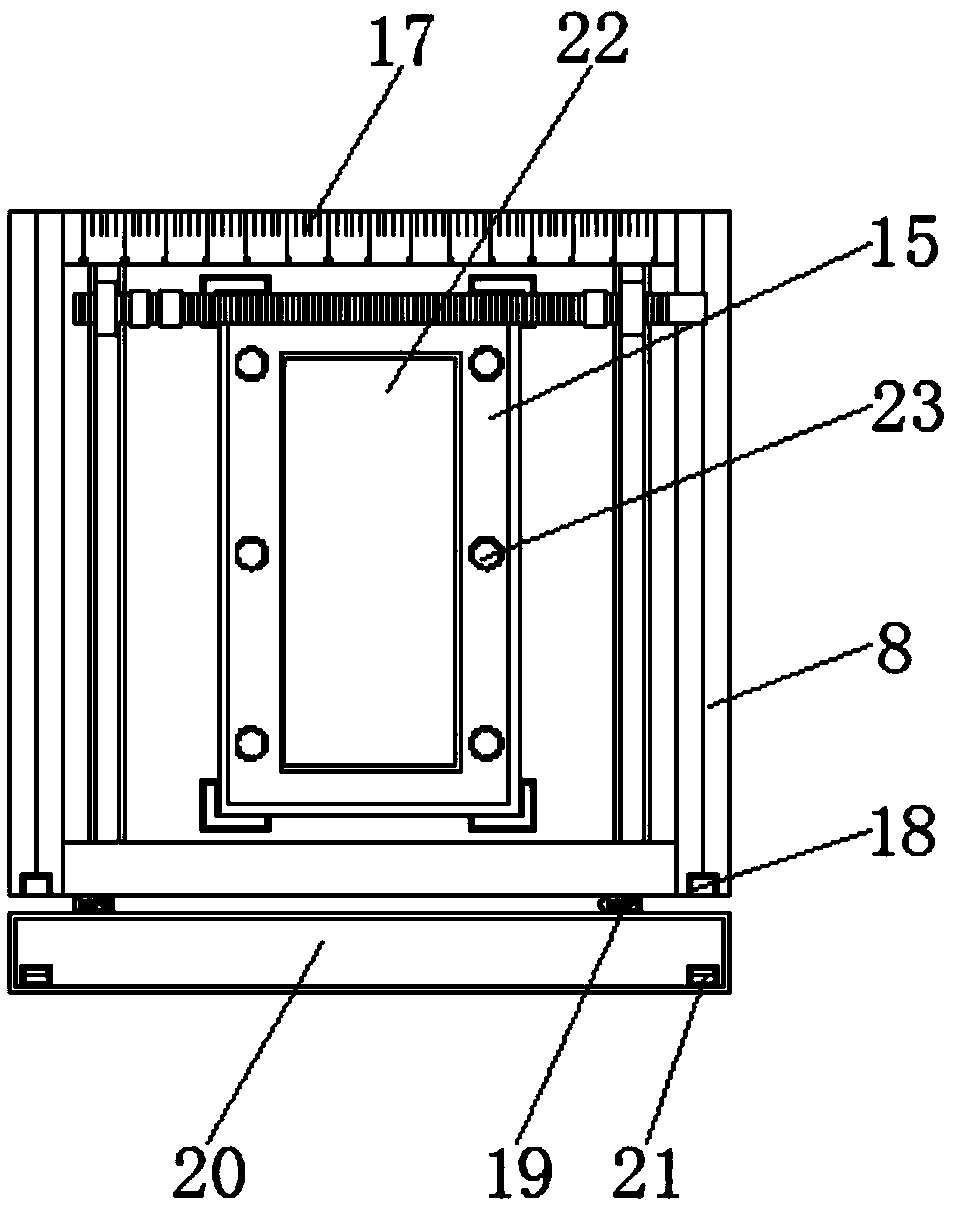

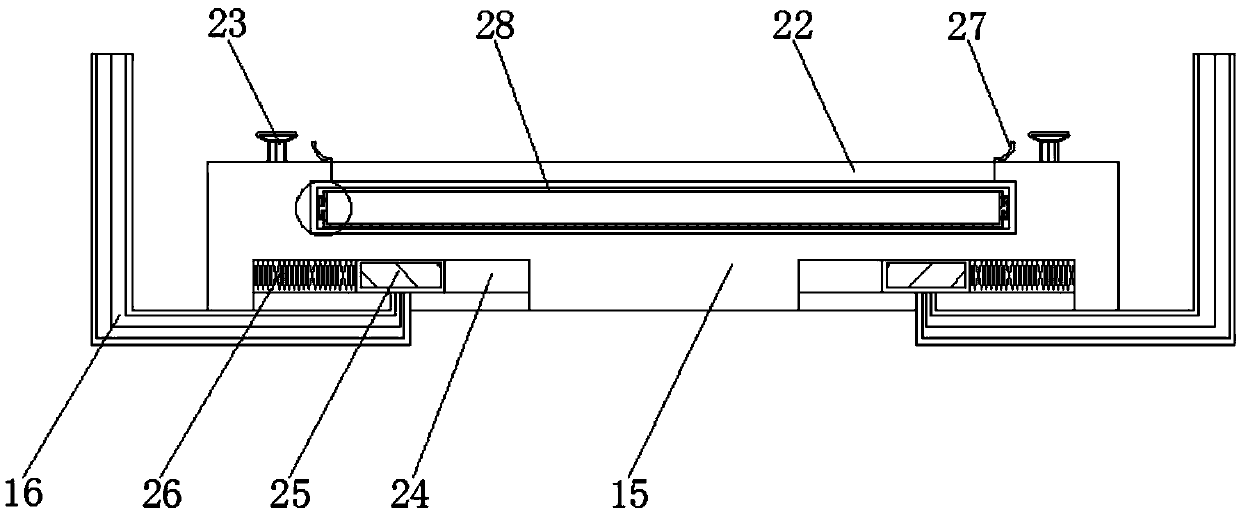

Stable cutting device with position limitation structure for tempered glass production

PendingCN108675625AImprove pass rateGuaranteed errorGlass severing apparatusCutting glassPulp and paper industry

The invention relates to a stable cutting device with a position limitation structure for tempered glass production. The stable cutting device comprises a base plate, a movable rod, a guide plate, a fixed clamp block and a cutter head, wherein a lower support rod is fixed above the base plate. Through the arrangement of a position limiting rod, the glass can be subjected to position limiting treatment; the dimension deviation during the cutting is enabled to be avoided, so that the qualification rate of the cut glass can be improved; meanwhile, the connecting block and an invisible groove forman elastic structure through a third spring; the glass with the area being greater than a cutting table can be subjected to fixing treatment; the practicability of the device is improved; meanwhile,the duplex fixing treatment is performed on the glass through a suction disc; during the cutting, the glass cannot swing or deviate, so that the dimension error of the cut glass is enabled to be in areasonable range; through the arrangement of the upper support rod and the lower support rod, the cutting disc can be subjected to stable support treatment; through the arrangement of the through hole, the second spring and the clamp rod, the height sum of the lower support rod and the upper support rod can be regulated.

Owner:郭婷

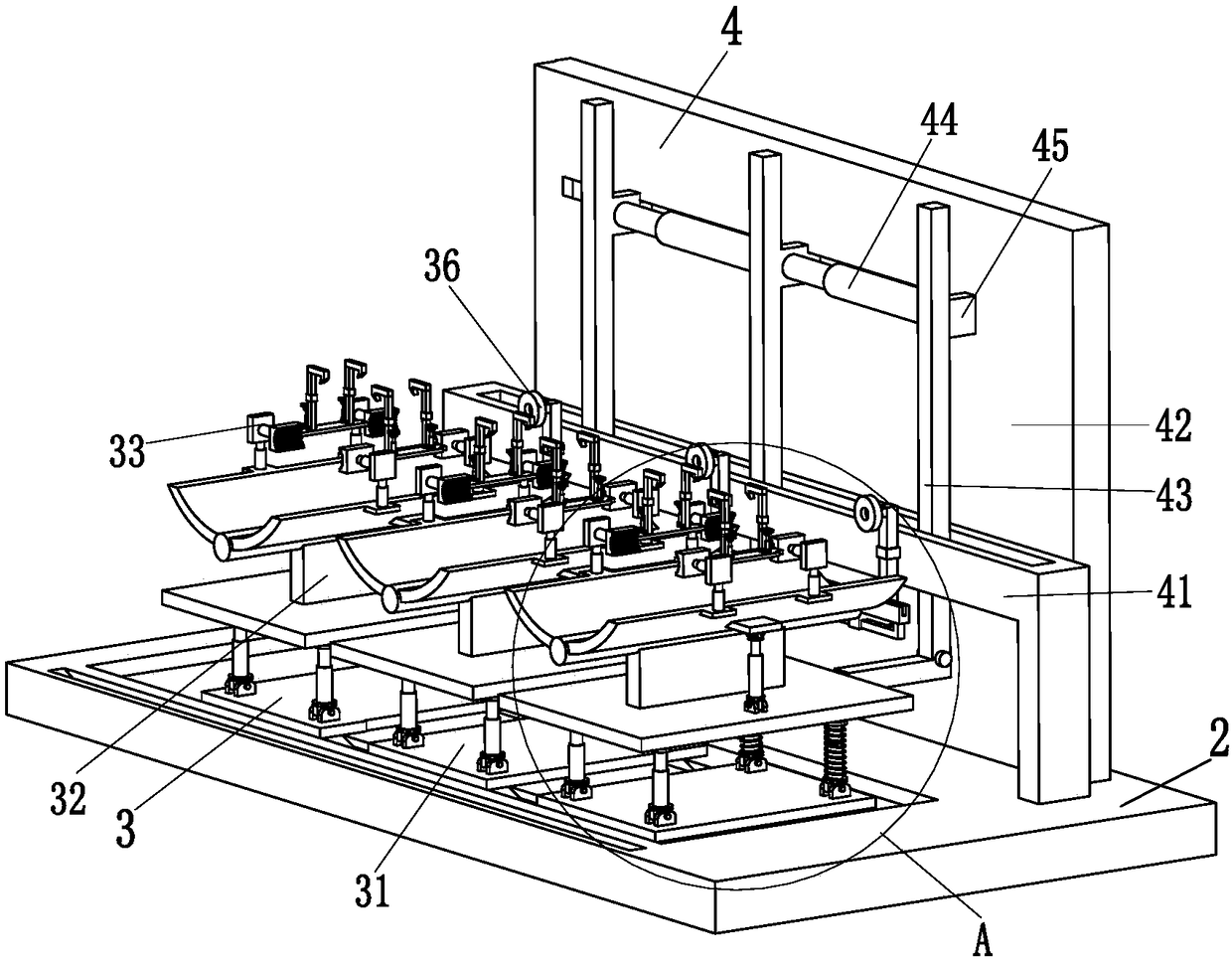

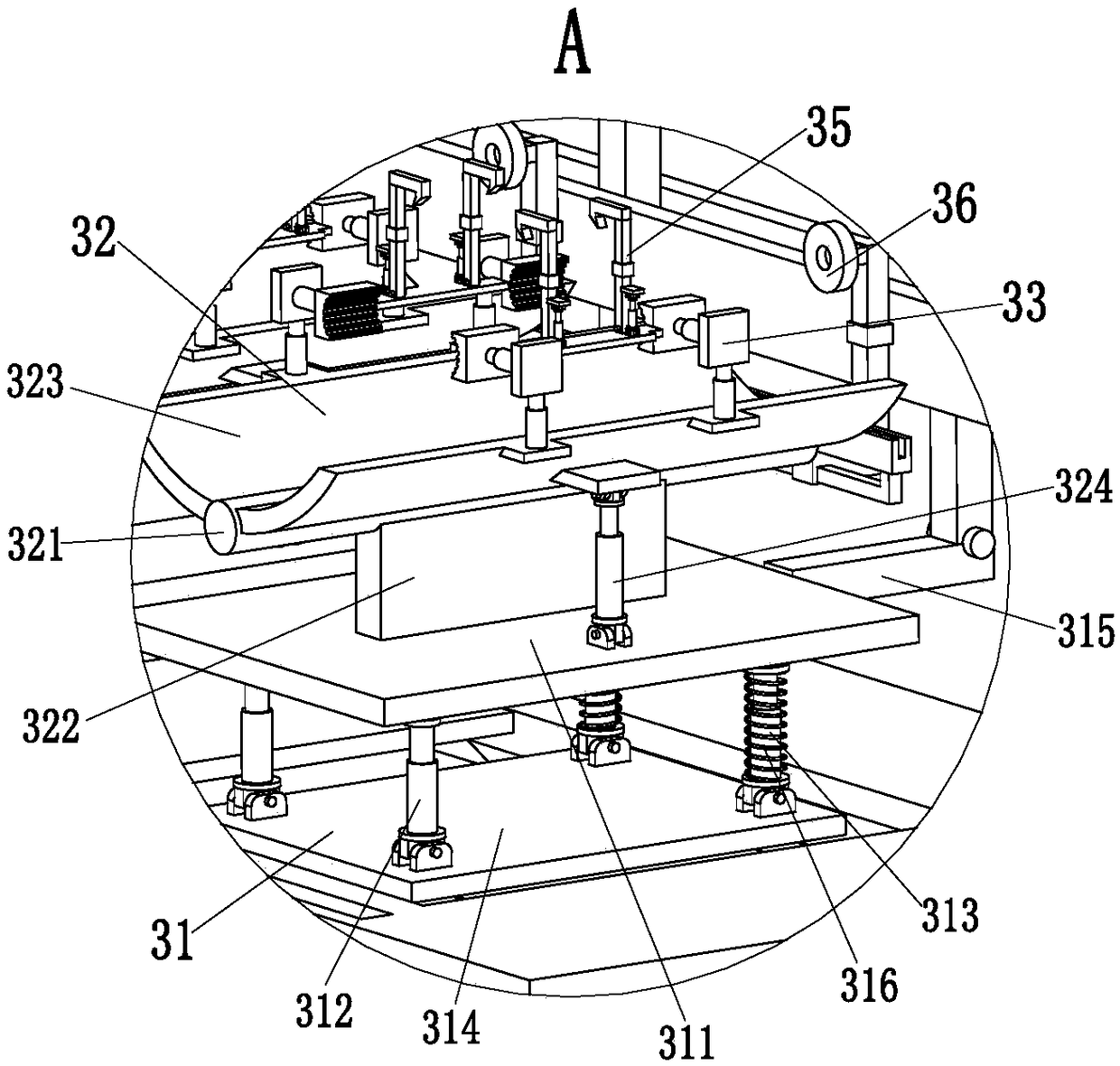

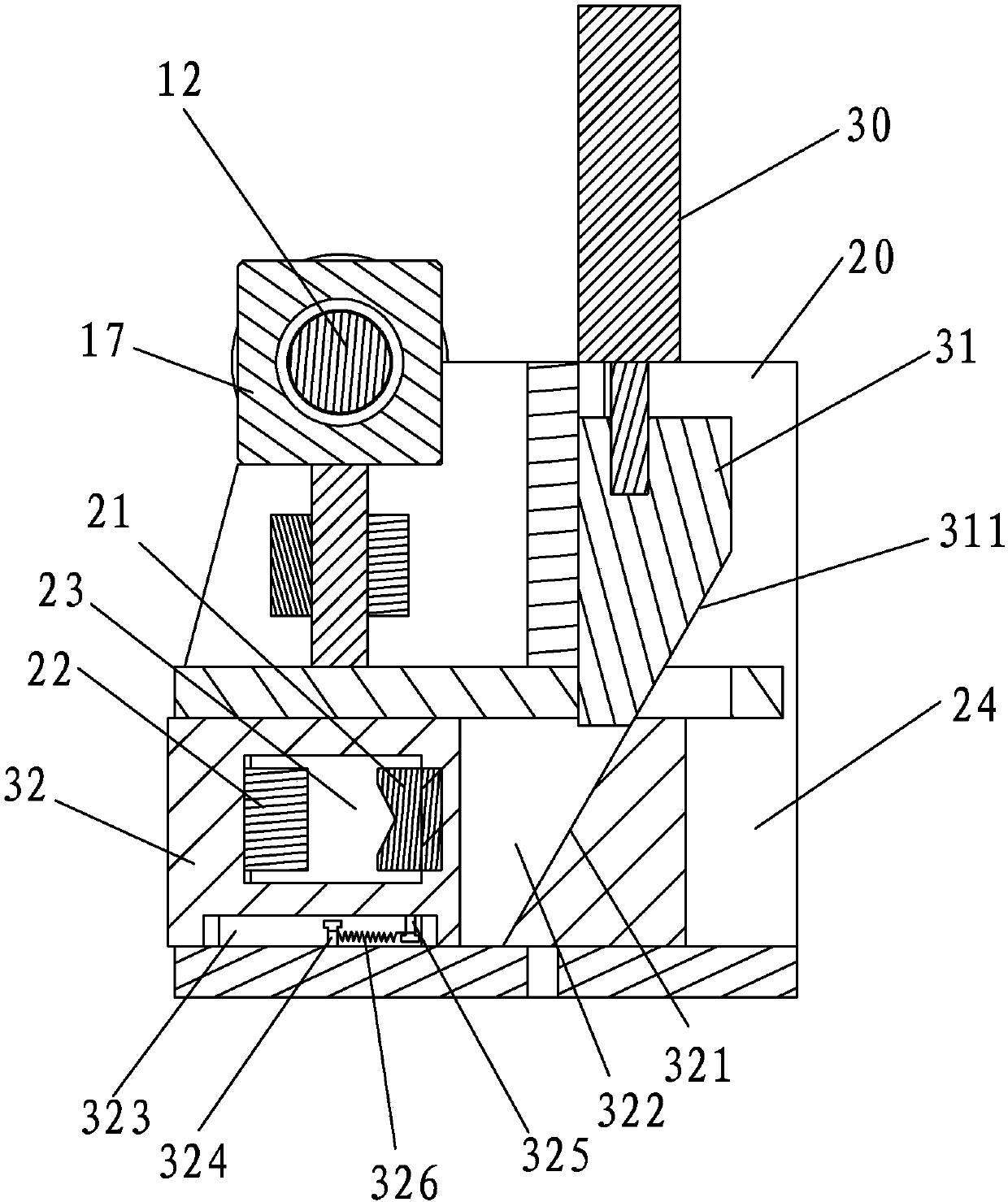

Feeding device of shearing machine

InactiveCN106346072AStable jobReduce failureShearing machine accessoriesMechanical engineeringEngineering

The invention relates to a feeding device of a shearing machine. The feeding device comprises a clamping mechanism for clamping a bar and a feeding mechanism for feeding the bar to a shearing system of the shearing machine. The feeding mechanism comprises a support and a feeding cylinder for driving the clamping mechanism to move back and forth. The feeding cylinder is connected to the support. The feeding device further comprises a guiding bearing bar. The clamping mechanism is erected on the guiding bearing bar in the mode of sliding relative to the guiding bearing bar. The clamping mechanism is improved, stable clamping is ensured, and meanwhile an adjusting device is added, so that bar conveying abrasion is avoided. The feeding device has the advantages of being simple in structure and capable of improving the product quality and prolonging the service life of a machine table.

Owner:泉州鹏宜机械有限公司

Automatic recycling machine of carbon battery

InactiveCN108321407AThe function of stable cuttingImprove work efficiencyReclaiming serviceable partsBattery recyclingPulp and paper industryBattery recycling

The invention relates to an automatic recycling machine of a carbon battery. The automatic recycling machine comprises a supporting frame, three fixing devices, a positioning adjusting device and cutting devices, wherein a square groove is formed in the upper end face of the middle part of the supporting frame; two sliding grooves are symmetrically formed in the square groove of the supporting frame; a cutting sliding groove is formed in the top of the left side of the square groove of the supporting frame; the three fixing devices are uniformly mounted at the top of the supporting frame; onecutting device is distributed at the upper end of each fixing device; the positioning adjusting device is mounted at the top of the right end of the supporting frame; the upper end of the positioningadjusting device is connected with the cutting devices. By adopting the automatic recycling machine of the carbon battery, the difficulties in an existing carbon battery recycling process that the battery cannot be fixed and limited in a battery cutting process, the cut carbon battery cannot be automatically shaken, a positive electrode end of the carbon battery cannot be independently separated,the plurality of carbon batteries cannot be cut in one step, carbon rods in the carbon batteries are easily chopped and the like can be solved.

Owner:龚大娇

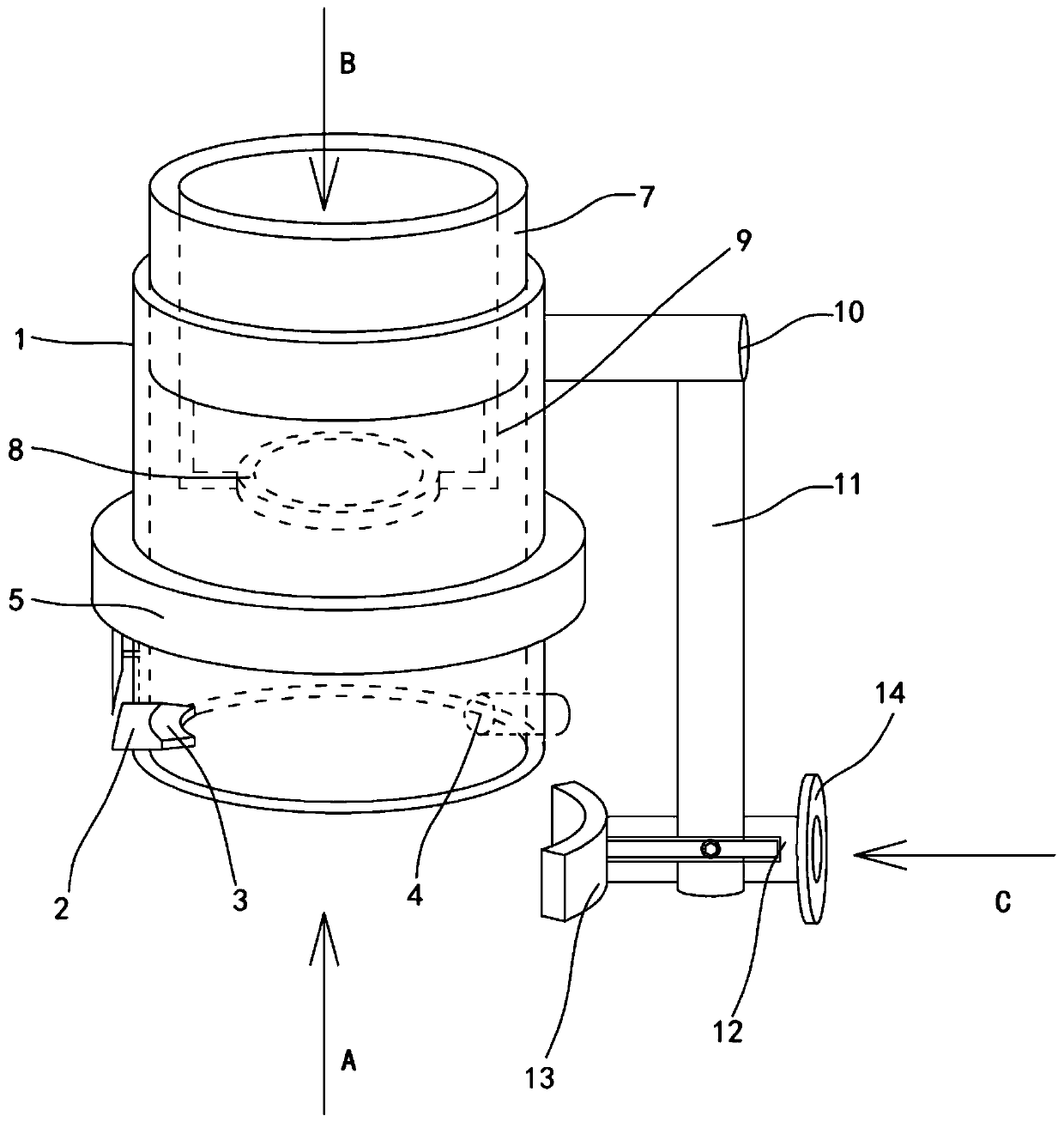

Method for disassembling a boiler

InactiveUS20090044766A1Stable cuttingDisassembling boilerSteam generation heating methodsSolid waste disposalEngineeringMechanical engineering

A method for disassembling a boiler supported on a supporting structure is disclosed. The method includes a holder installation step for providing a vertically extendable ascent-descent holder below the boiler; a holder lifting step for increasing a height of the ascent-descent holder to a position close to or in contact with a lower end of the boiler; a cutting step for cutting off a lower part of the boiler, the lower part extending from the lower end of the boiler to a predetermined height; and a removal step for removing the lower part from the holder, after the lower part being cut off and the weight of the lower part being transferred to the ascent-descent holder; the holder installation step, the holder lifting step, the cutting step, and the removal step are repeatedly carried out for successively disassembling the boiler from a bottom side thereof.

Owner:BESUTERA

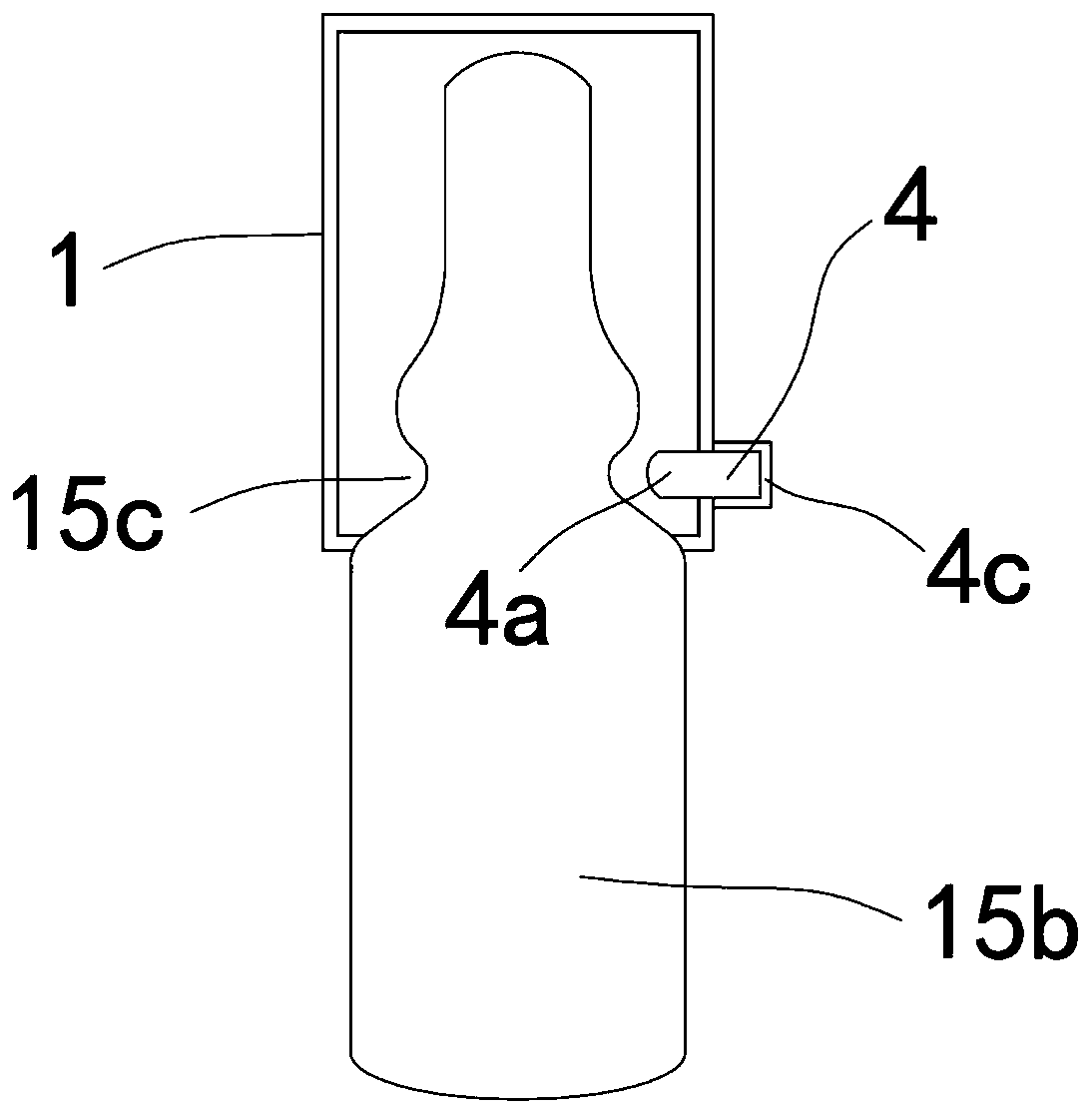

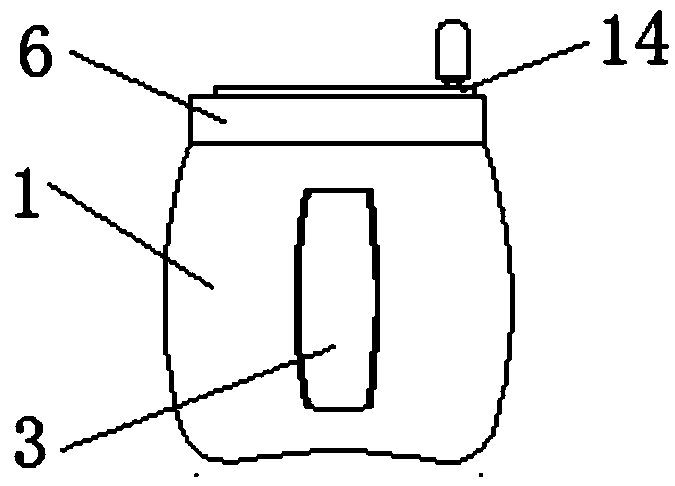

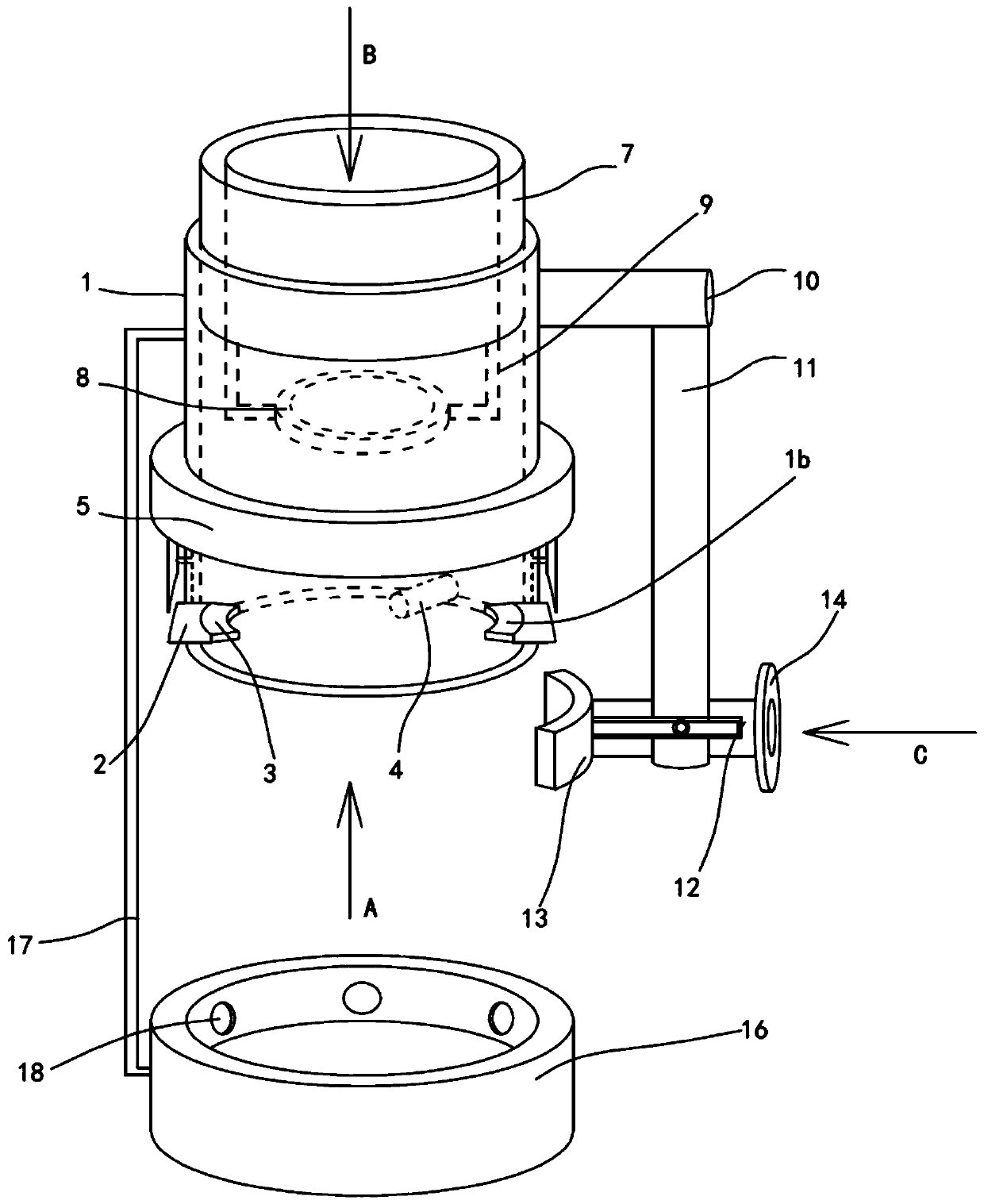

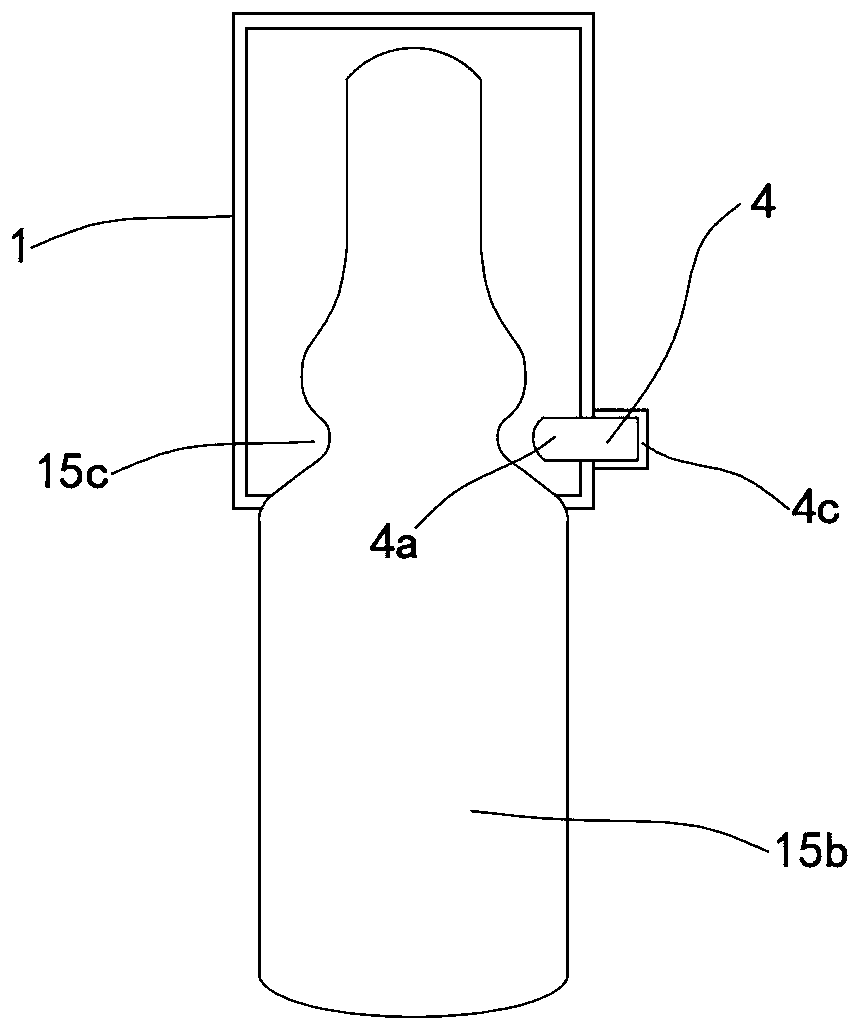

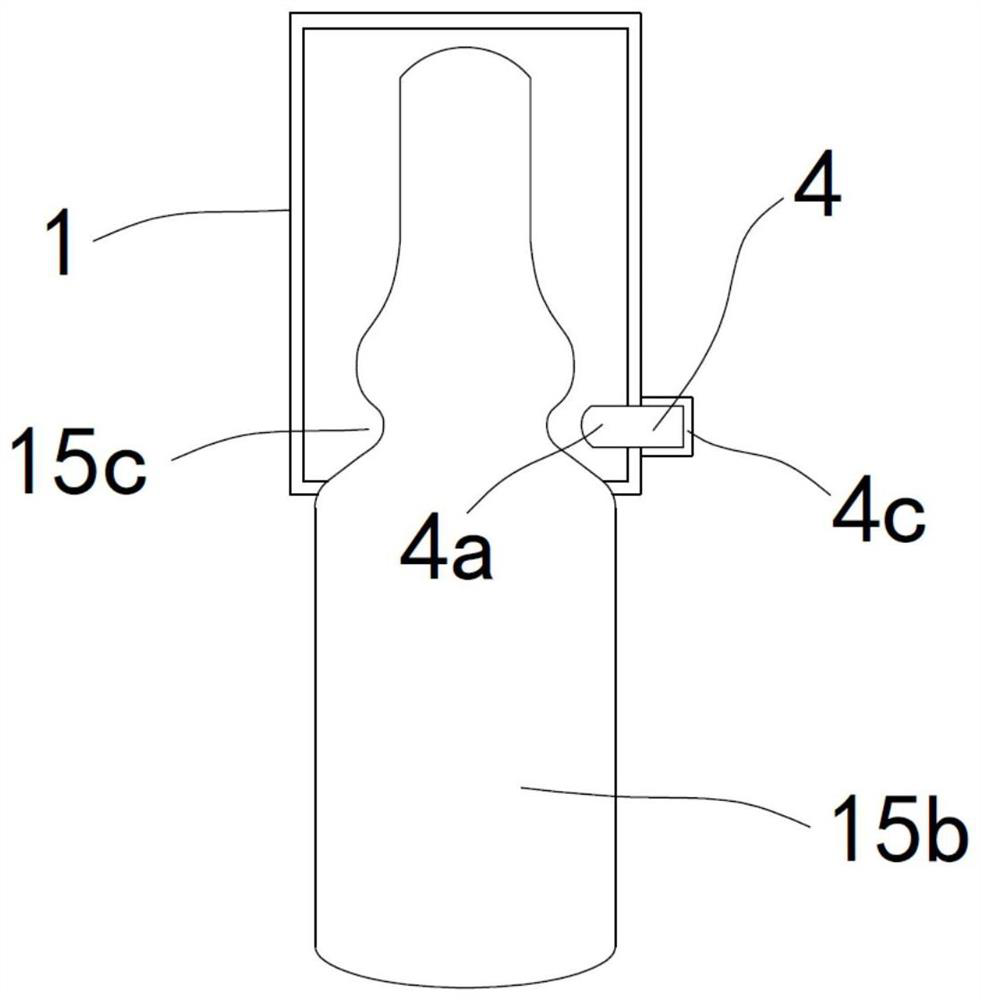

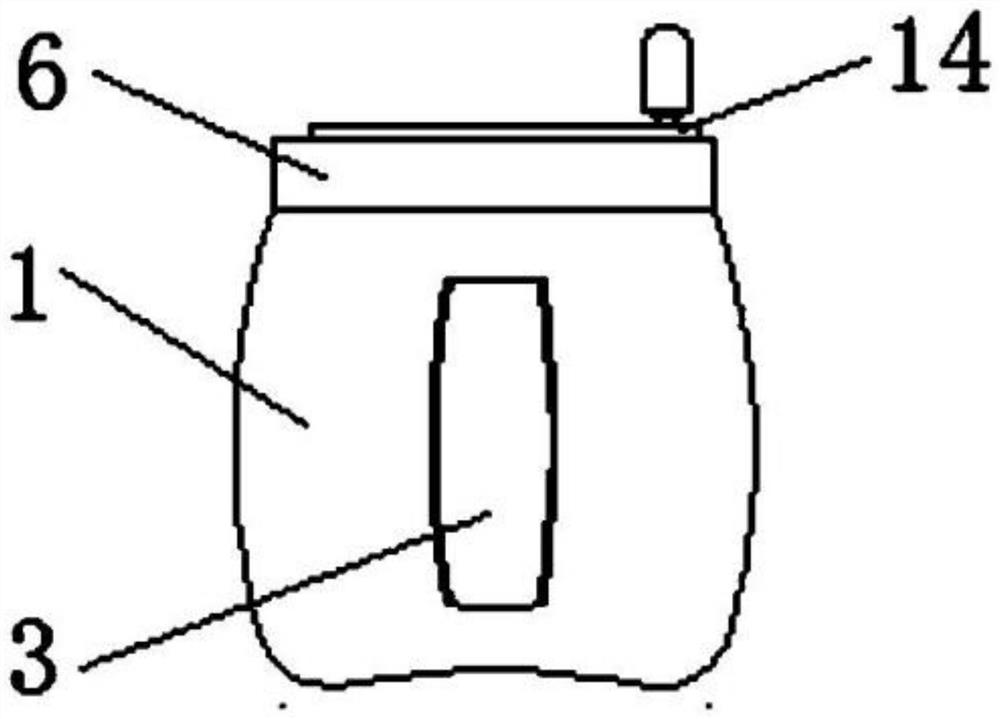

Ampoule bottle safety standard breaking-off device and an application method thereof

ActiveCN110357017AAvoid pollutionAvoid the phenomenon of grinding wheel lossOpening closed containersBottle/container closureEngineeringBottle

The invention relates to the technical field of medical instruments, in particular to an ampoule bottle safety standard breaking-off device and an application method thereof. The ampoule bottle safetystandard breaking-off device comprises a hard sleeve, a first driving sleeve ring, a second driving sleeve ring and an ejection device, wherein the upper end and the lower end of the hard sleeve areopened; the inner edge of the opening at the lower end of the hard sleeve is provided with a grinding wheel sheet and a disinfection rod which penetrate through the inner wall of the opening; the first driving sleeve ring rotatably sleeves the hard sleeve, and drives the grinding wheel sheet reciprocates along the radial direction of the penetrated hard sleeve wall; the second driving sleeve ringis sleeved with the hard sleeve and fixedly matched with a bottle head of a ampoule bottle; the ejection device is fixed at the upper end of the hard sleeve; and the ejection device is in contact withand matched with the bottle body of the ampoule bottle. The ampoule bottle safety standard breaking-off device has the advantages of standard ampoule bottle breaking-off operation, high breaking-offsafety coefficient, thorough disinfection and high operation efficiency.

Owner:HEBI CITY PEOPLES HOSPITAL

Safe and standard opener for medical ampoule bottle and using method thereof

ActiveCN110357016AAvoid non-standard operationBreak apart the safety factor and high operating efficiencyOpening closed containersBottle/container closureSafety coefficientEngineering

The invention relates to the technical field of medical instruments, in particular to a safe and standard opener for a medical ampoule bottle and a using method thereof. The opener comprises a hard sleeve, a positioning sliding piece, a first driving sleeve ring, a second driving sleeve ring, an ejecting device and a bottle body fixing sleeve ring; the upper end and the lower end of the hard sleeve are both provided with openings, the inner edge of the opening in the lower end of the hard sleeve is provided with the movable positioning sliding piece penetrating through the inner wall of the hard sleeve, a grinding wheel piece and a disinfecting bar; the first driving sleeve ring rotationally sleeves the hard sleeve; the positioning sliding piece is used for driving the grinding wheel pieceto do reciprocating motion in the radial direction of the penetrated wall of the hard sleeve; the second driving sleeve ring sleeves in the hard sleeve and is fixedly matched with a head of an ampoule bottle; and the ejecting device is fixed at the upper end of the hard sleeve and is in contact fit with the body of the ampoule bottle. When the ampoule bottle is opened by using an opener, the operation is standard, the safety coefficient is high, the disinfection is thorough, the bottle body is rotated so as to prevent the bottle body from slipping and the operation efficiency is high.

Owner:HEBI CITY PEOPLES HOSPITAL

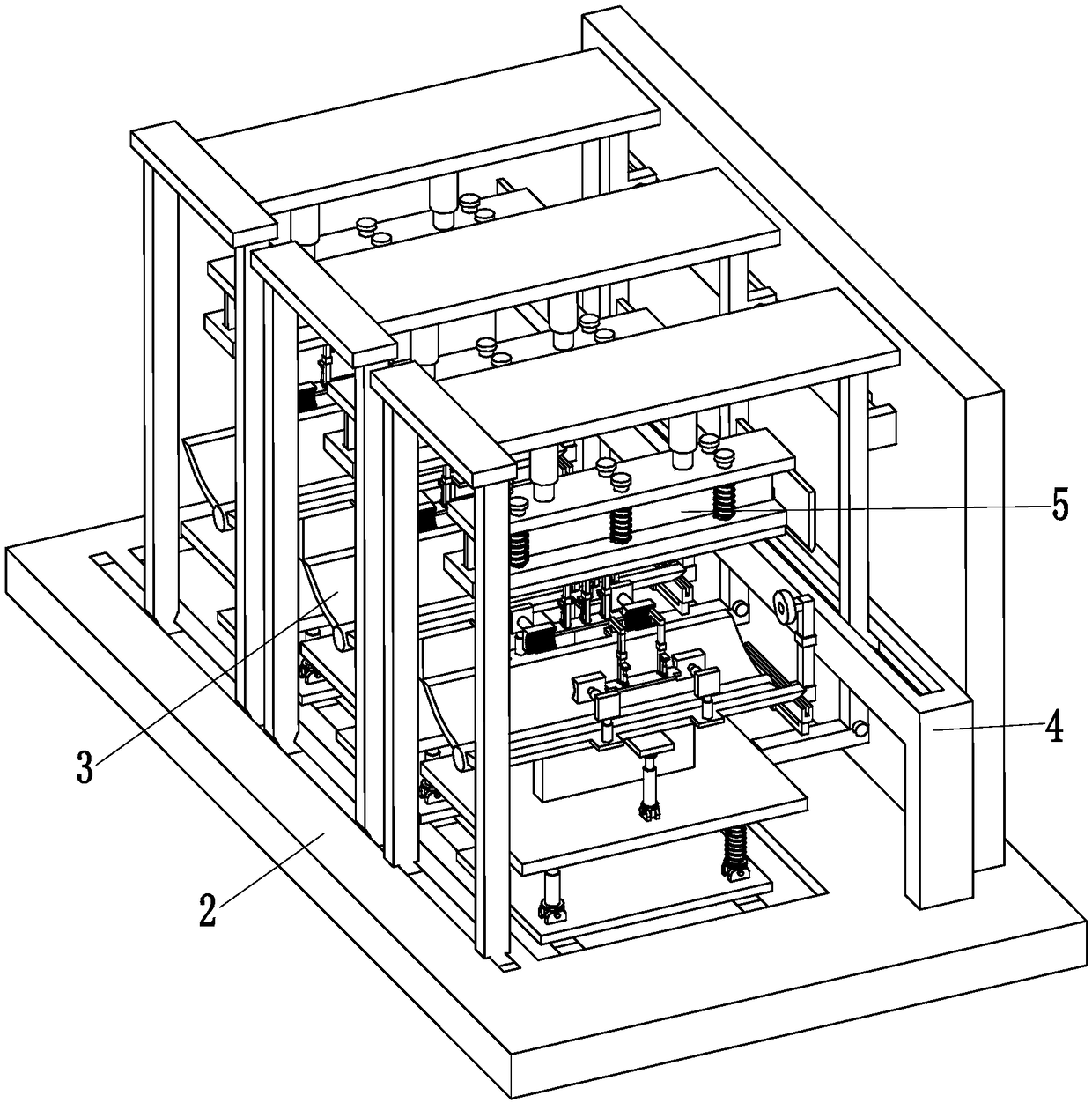

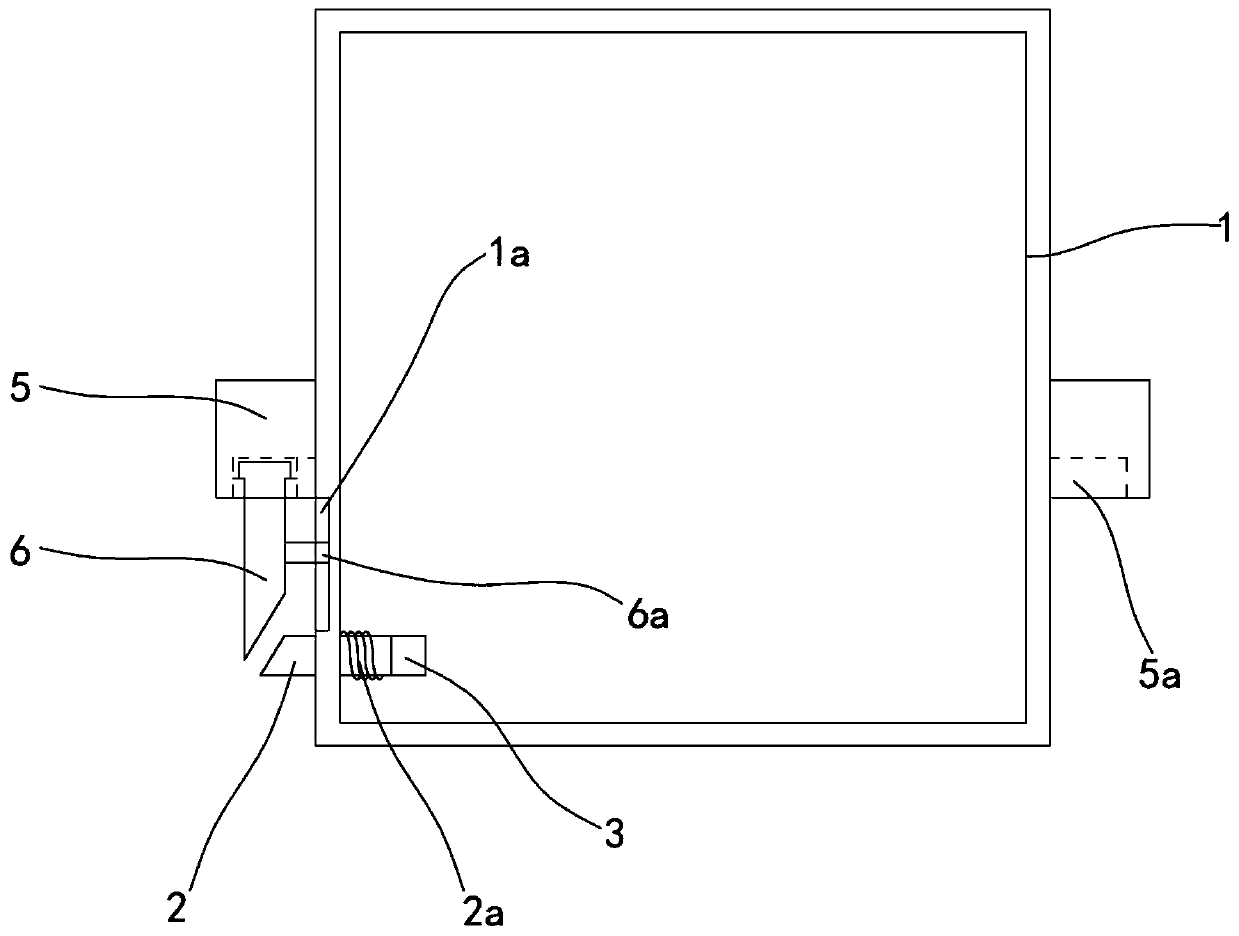

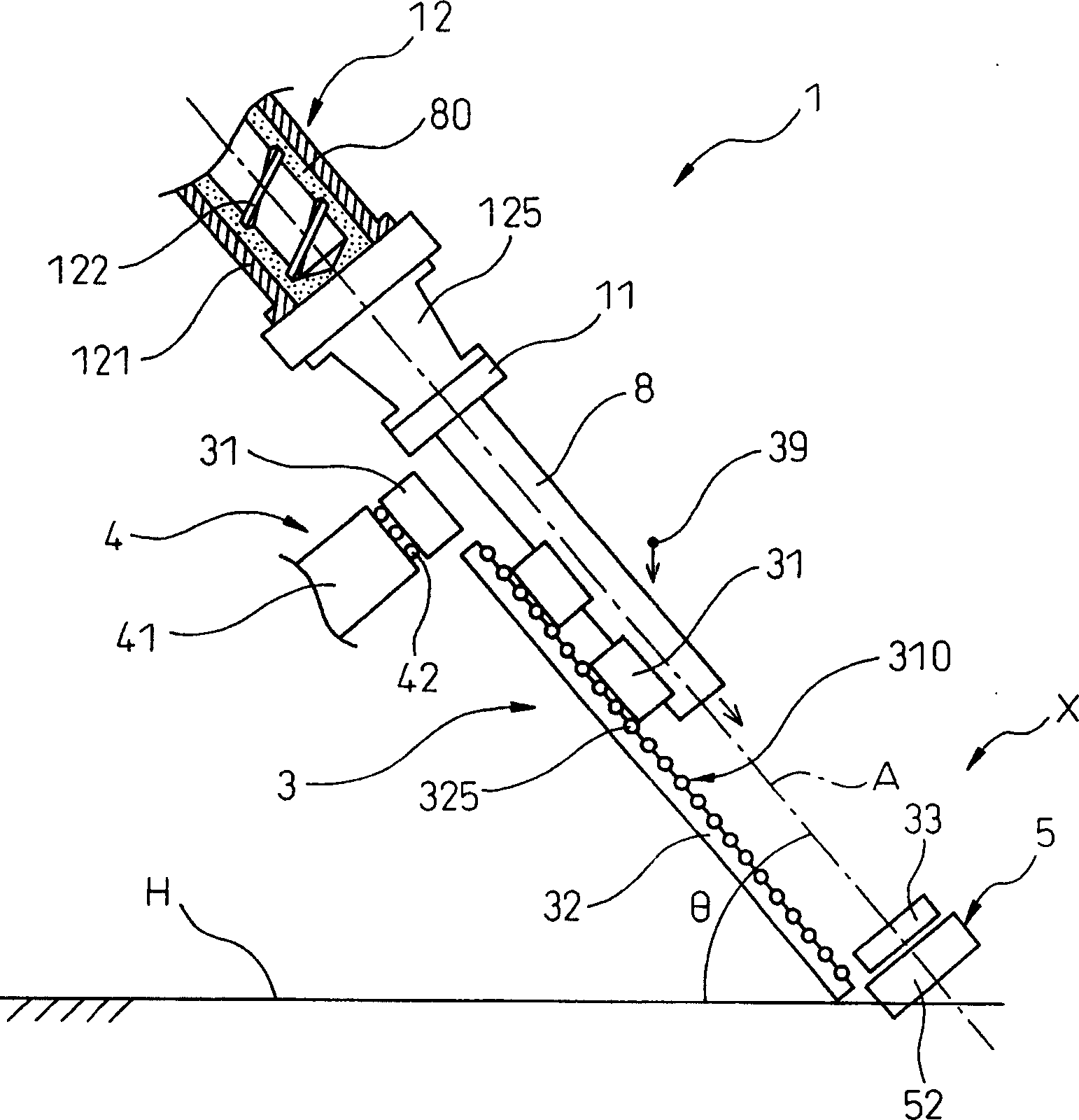

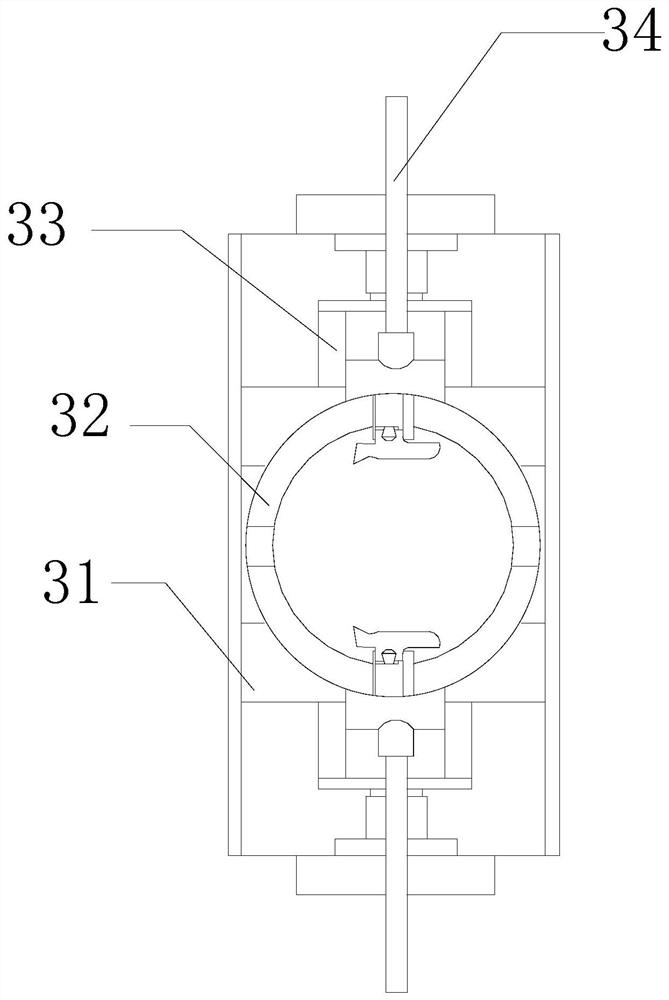

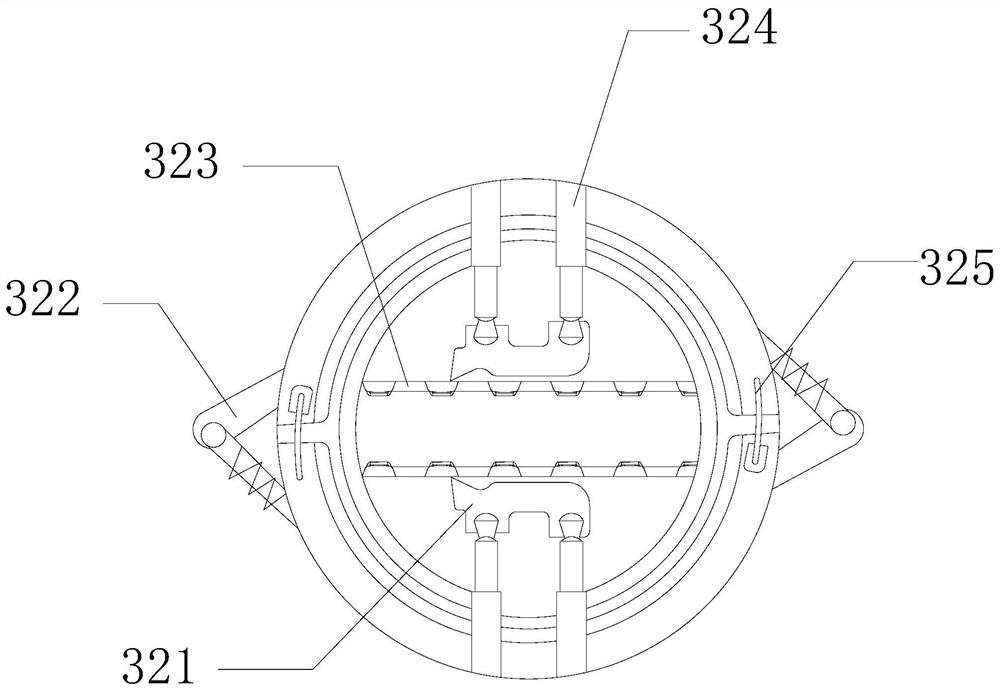

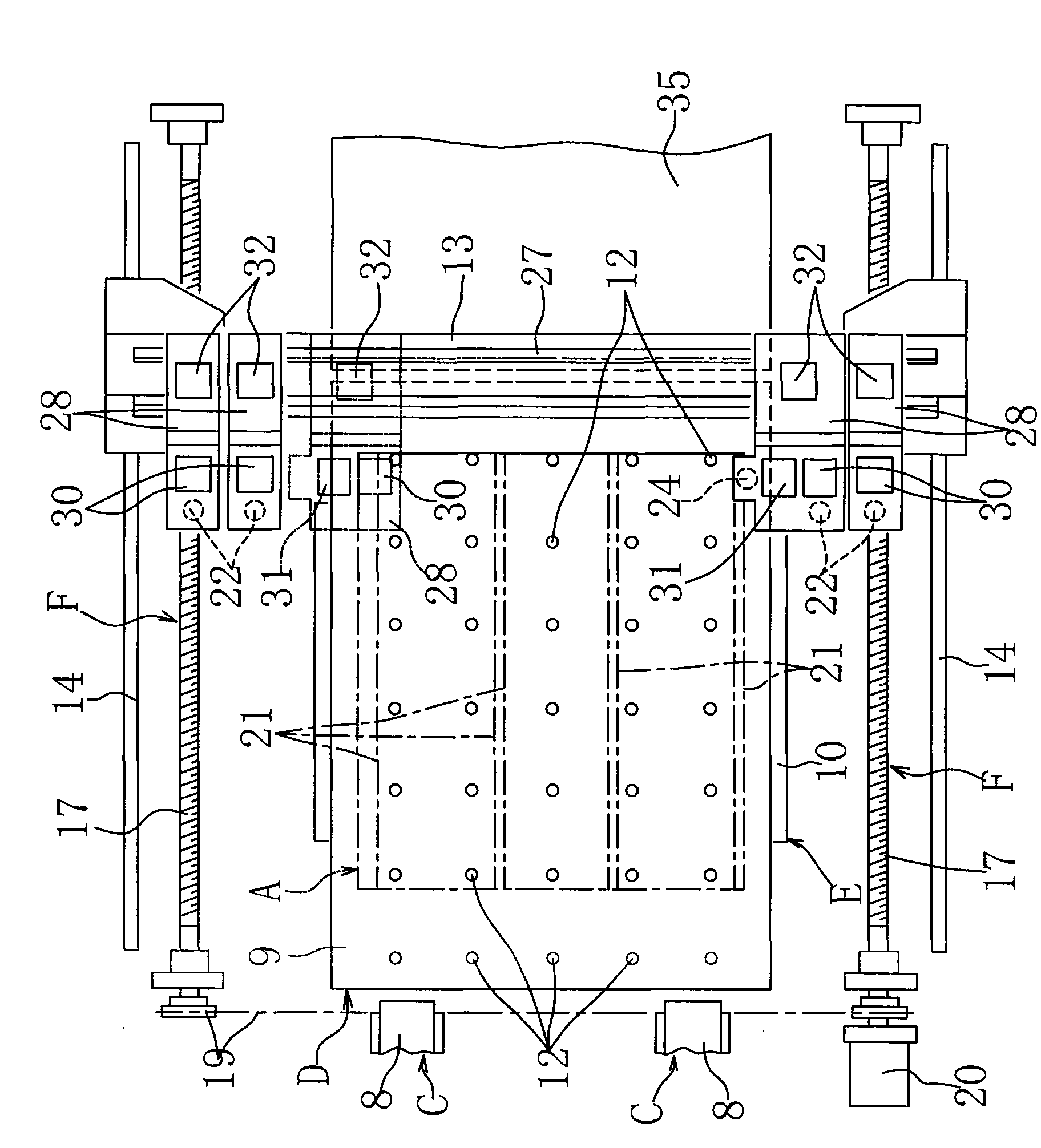

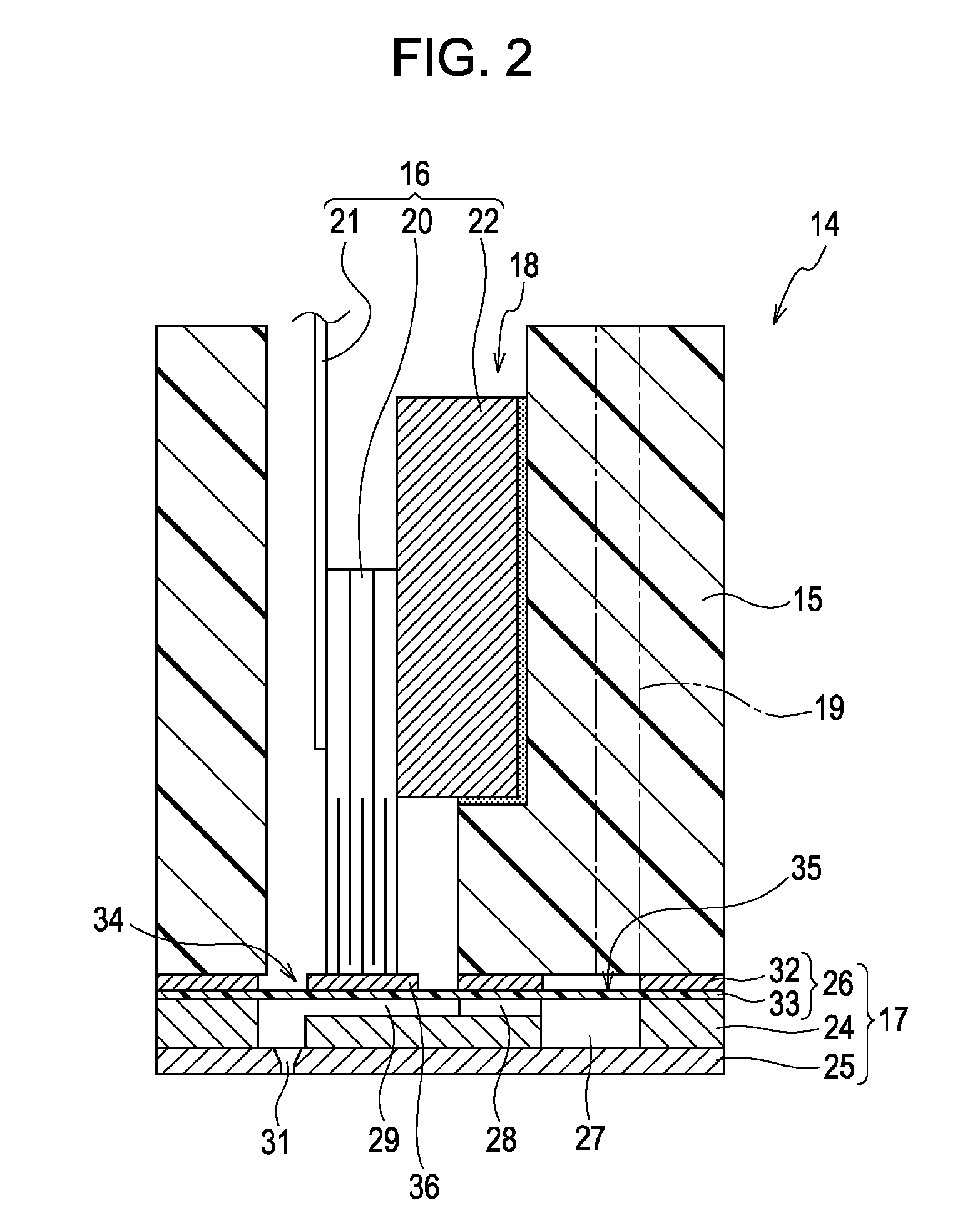

Extrusion molding apparatus and extrusion molding method

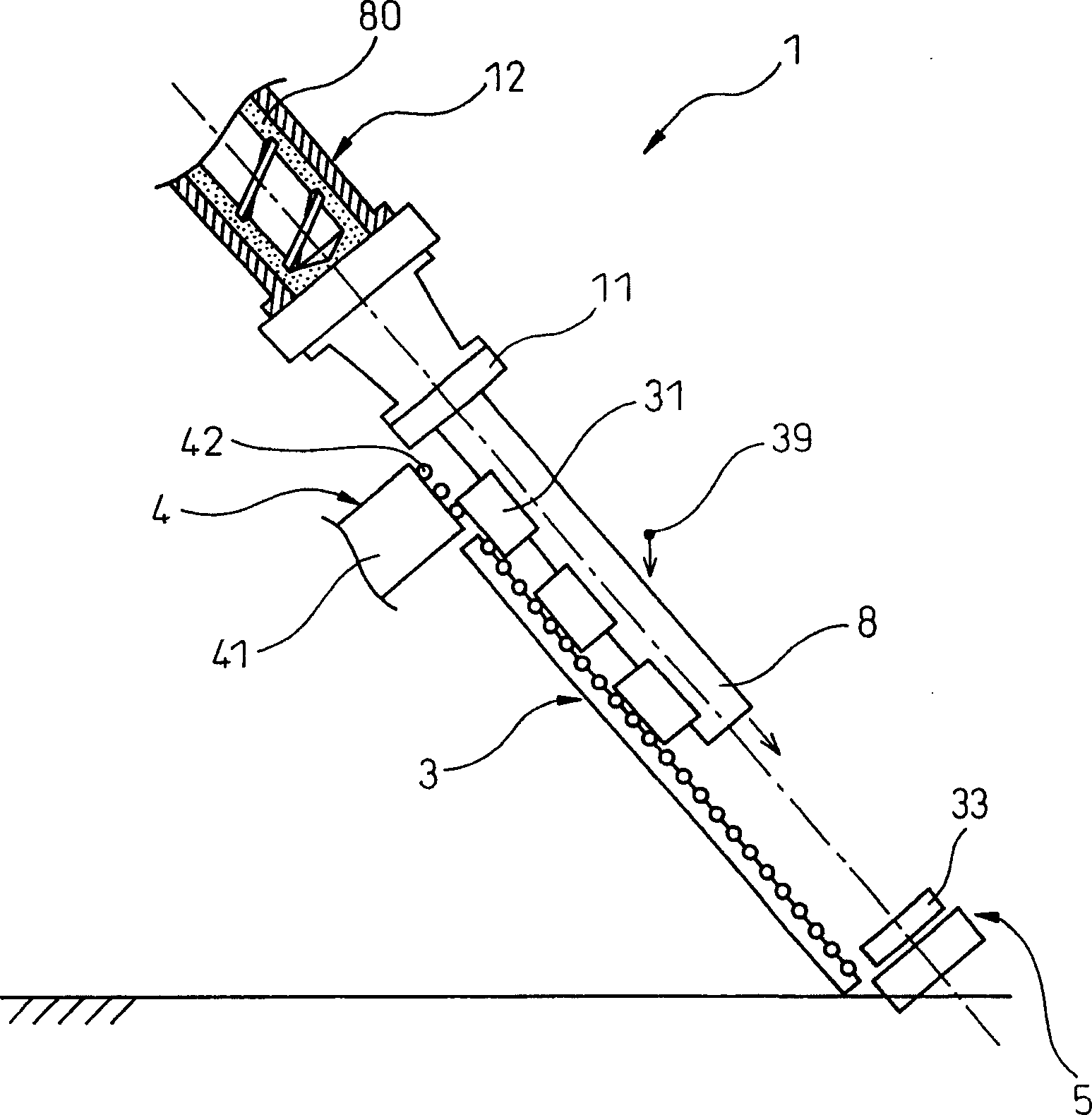

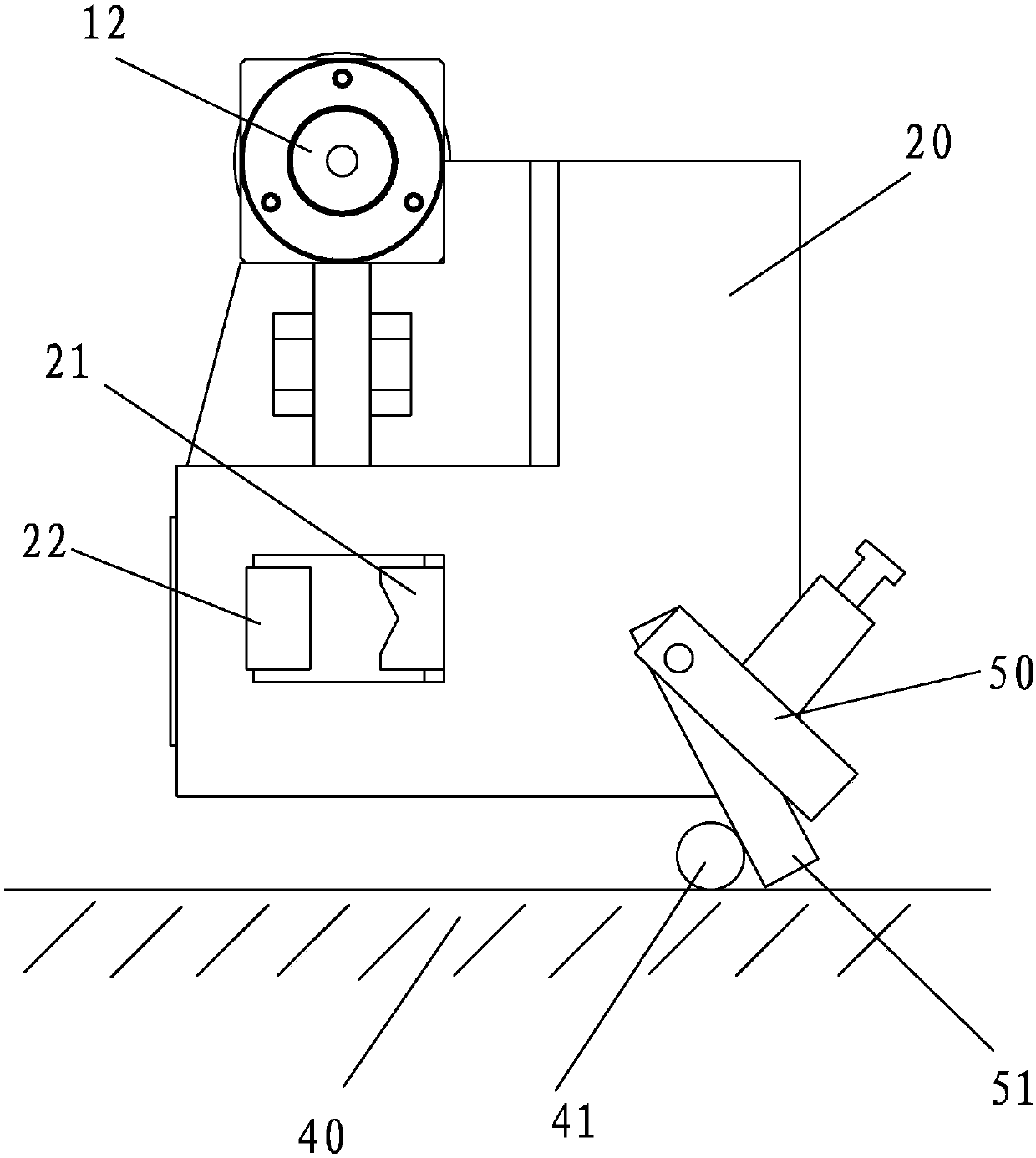

InactiveCN1721154AReduce reaction forceStable cuttingCeramic shaping apparatusShaping pressHorizontal axisMaterials science

An extrusion molding apparatus and an extrusion molding method is provided that permits deformation of molded body to be prevented and a sound extrusion molded body to be obtained even in the case where a soft extrusion molded body having low rigidity in a direction perpendicular to extrusion direction is molded. An extrusion molding apparatus 1 comprises a screw extruder 12 that kneads a molding raw material 80 and extrudes an extrusion molded body 8 from a molding die 11, and a conveying apparatus 3 that supports said extrusion molded body 8 extruded continuously from the screw extruder 12 and conveys same in the extrusion direction. The screw extruder 12 has an inclination angle theta between the extrusion axis A and horizontal axis H in the range of 15 degree to 85 degree. The conveying apparatus 3 is constructed so as to move a reception stage 32 that supports said extrusion molded body 8 extruded along said extrusion axis A on the outer circumferential surface thereof, generally in parallel to said extrusion axis A. The inclination angle theta is preferably in the range of 30 degree to 75 degree.

Owner:DENSO CORP

Loop-breaking eight-treasure porridge ring-pull can opening device based on lever principle

ActiveCN109336030AImprove adhesionOpen quicklyBottle/container closurePower operated devicesEngineeringAdditive ingredient

The invention provides a loop-breaking eight-treasure porridge ring-pull can opening device based on the lever principle, and relates to the field of articles of daily use. The loop-breaking eight-ingredient porridge ring-pull can opening device based on the lever principle comprises an outer cover fixing cylinder, the side part of the outer cover fixing cylinder is provided with a protruding pressing block, a mounting bearing is adhered to the top of the outer cover fixing cylinder, and an autorotation fixing rod is adhered to the inner wall of the mounting bearing; and scribing and prying handles are arranged in the inner part of the mounting bearing and located on the side part of the autorotation fixing rod. According to the loop-breaking eight-ingredient porridge ring-pull can openingdevice based on the lever principle, when a top cover is scribed and cut, the scribing and prying handles are pressed downwards to be parallel to the top of the can, and namely a scribing-and-cuttingarc sheet can be controlled to open the top of the can; and when the similar ring-pull can of a carbonated beverage is opened, the scribing-and-cutting arc sheet is positioned at a drinking opening,one ends away from the scribing and prying handles are lifted away, the ring-pull can can be easily opened by utilizing the lever principle, simpleness and convenience are achieved, and accidental events of scratching due to slip off when a user holds the ring-pull can using sharp objects to pry up the ring-pull can are avoided.

Owner:山东沂南园区开发建设有限公司

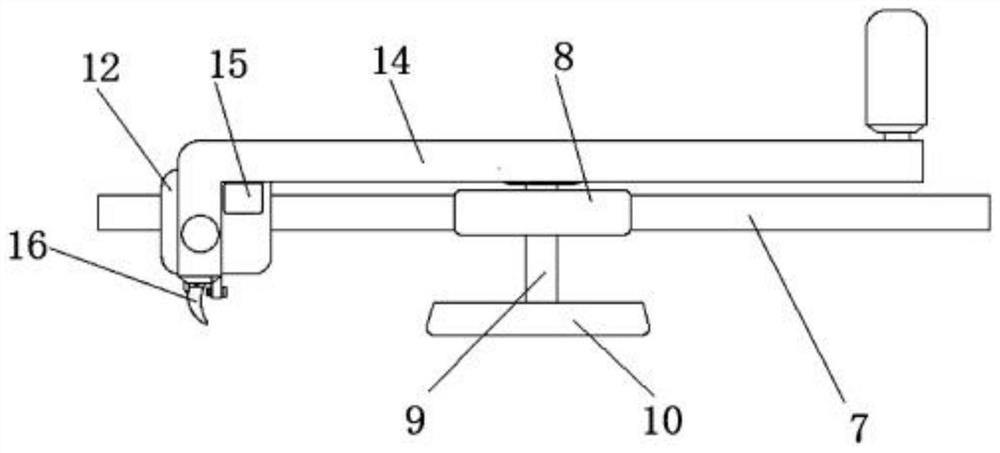

Equipment for quickly stripping insulating layer of power cable

ActiveCN111864645AAvoid displacementStable cuttingApparatus for removing/armouring cablesBar pressingStructural engineering

The invention discloses equipment for quickly stripping an insulating layer of a power cable. The equipment structurally comprises a main body, a pulling-out table, a pulling device, a clamping piece,a processing groove, a cutting device, a supporting block and an operating rod. During use after improvement, the cable is arranged on a connecting cavity in a penetrating manner, a guide wheel and aconnecting elastic piece are matched to fix the cutting edge on a rotating wheel for stable cutting, then a limiting supporting plate is used for fixing the position of the rotating wheel, the rotating wheel is prevented from moving in the rotating process, the cutting edge can stably cut a cable insulation layer, and the use efficiency of a power cable is improved. A to-be-stripped cable is placed on the blocking assembly. A pressing rod and an extruding piece are matched to push the blocking assembly inwards, so that the cable and the friction plate are tightly overlapped together, the resistance between the cable and the friction plate is large, when a cable insulation sleeve is pulled away, a slipping phenomenon caused by the smooth sheath of the insulation sleeve is avoided, and thestripping efficiency of the cable insulation layer is improved.

Owner:邢台国泰发电有限责任公司

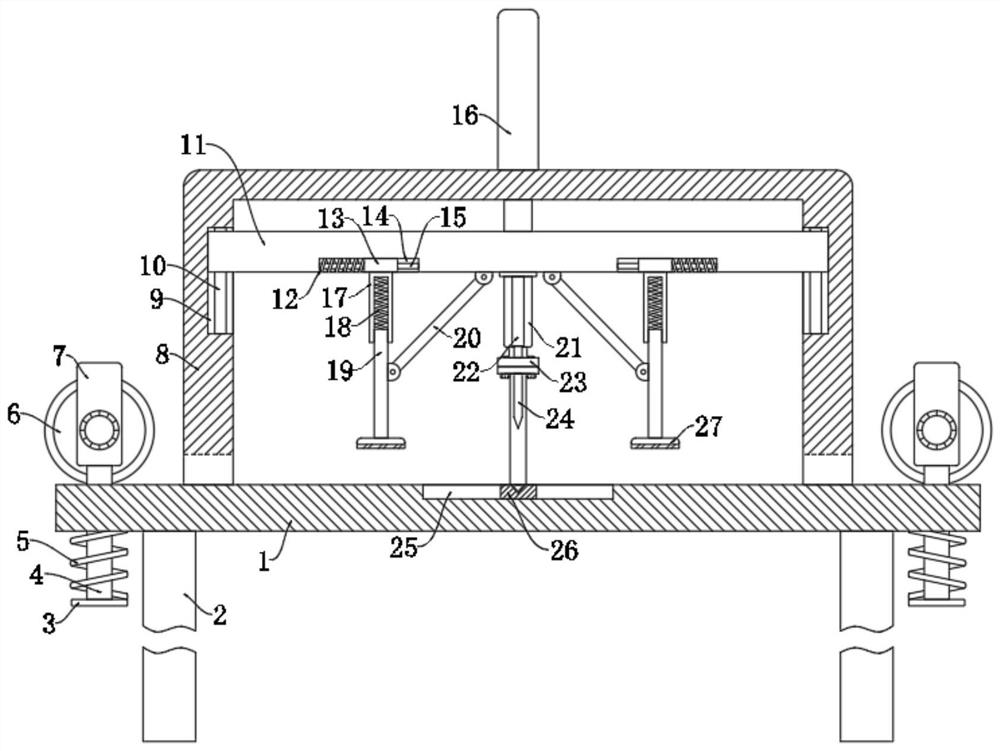

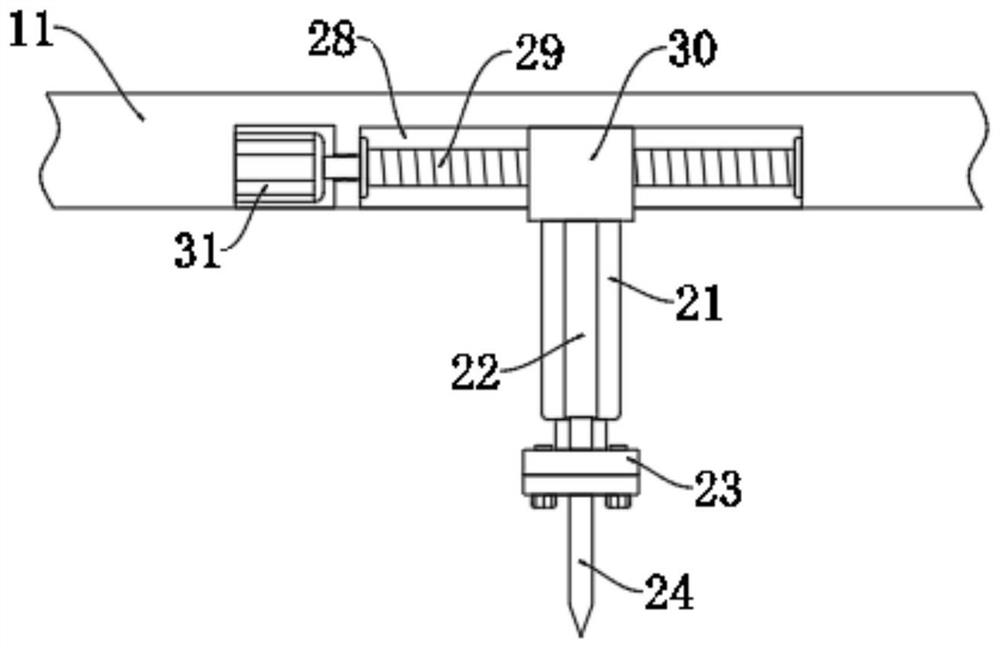

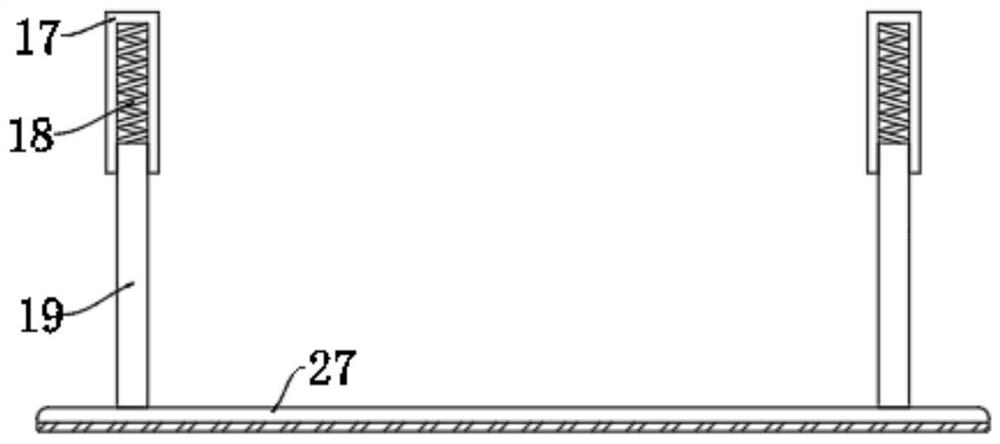

High-precision textile novel material cutting equipment

InactiveCN112609437AEasy to fixStable cuttingSevering textilesMetal working apparatusStructural engineeringMachining

The invention discloses high-precision textile novel material cutting equipment which comprises a machining table; a mounting frame is fixedly connected with the upper end of the machining table; feeding mechanisms are arranged at the two sides of the upper end of the machining table; a lifting air cylinder is mounted at the top of the mounting frame; a piston end of the lifting air cylinder downwards penetrates through the mounting frame and is fixedly connected with a moving plate; limiting grooves are formed in the two opposite inner side walls of the mounting frame correspondingly; the two sides of the moving plate extend into the two limiting grooves correspondingly; limiting rods which penetrate through the moving plate and are slidably connected with the moving plate are arranged in the limiting grooves; the upper ends and the lower ends of the limiting rods are fixedly connected with the inner walls of the limiting grooves correspondingly; and a mounting groove is formed in the middle of the lower end surface of the moving plate. According to the high-precision textile novel material cutting equipment, textile materials can be fully tensioned and stably pressed and fixed, so that the stability of subsequent textile material cutting is guaranteed; and the position of the cutter can be accurately adjusted, so that high-precision cutting of the textile materials is achieved, adjustment is convenient, and use is convenient and fast.

Owner:夏秋兰

Medical safety standard breaking device for ampoule bottle and using method of device

InactiveCN110407145AAvoid pollutionAvoid the phenomenon of grinding wheel lossOpening closed containersBottle/container closureReciprocating motionEngineering

The invention relates to the technical field of medical instruments, in particular to a medical safety standard breaking device for an ampoule bottle and a using method of the device. The device comprises a hard sleeve, a positioning sliding piece, a first driving lantern ring, a second driving lantern ring, an ejection device and a bottle body fixing sleeve ring. The upper end and the lower end of the hard sleeve are each provided with an opening, and the positioning sliding piece, a grinding wheel piece and a disinfection rod which penetrate through the inner wall of the hard sleeve and canmove are installed on the inner edge of the opening in the lower end of the hard sleeve. The first driving lantern ring rotationally sleeves the hard sleeve. The positioning sliding piece drives the grinding wheel piece to do reciprocating motion in the radial direction of the wall of the hard sleeve, and the second driving lantern ring is sleeved with the hard sleeve and is fixedly matched with the bottle head of the ampoule bottle. The ejection device is fixed at the upper end of the hard sleeve, and the ejection device is in contact fit with a bottle body of the ampoule bottle for work. Thedevice has the advantages that the operation of breaking the ampoule bottle is standard, the breaking safety coefficient is high, disinfection is thorough, the bottle body is rotated to prevent the bottle body from slipping, and the operation efficiency is high.

Owner:朱世新

Broad bean processing device

InactiveCN106962738AAct as a downward pressureEasy to limitMetal working apparatusFood scienceSoft layerEngineering

The invention discloses a broad bean processing device which comprises a rack. An extruding mechanism, a processing box and a deep-frying mechanism are arranged on the rack. The extruding mechanism comprises a rotating motor, an extruding plate, an auxiliary table and an extruding column, wherein the rotating motor and the auxiliary table are fixedly connected with the rack, the rotating motor is higher than the auxiliary table, and a cam is arranged on the rotating motor. The extruding plate is located between the cam and the auxiliary table, and a compression spring is arranged between the extruding plate and the auxiliary table. One end of the extruding column penetrates through the auxiliary table to be fixedly connected with the extruding plate, and the other end of the extruding column is detachably connected with a cutter. The width of the processing box is gradually decreased from top to bottom, a plurality of soft layers are arranged at the bottom of the processing box in a penetrating mode, through holes are formed in the middles of the soft layers, and the middles of the through holes are gradually enlarged towards two ends. The deep-frying mechanism comprises a deep-frying box and a heater. By adopting the scheme, the problem that a traditional broad bean cutting process is low in efficiency and makes hands likely cut is mainly solved.

Owner:CHONGQING ZHOUYI FOOD CO LTD

Cutting method for mass broad beans

InactiveCN107097267AAvoid harmImprove processing efficiencyMetal working apparatusFood treatmentBiotechnologyDeep frying

The invention discloses a broad bean processing method. The method comprises the following steps that (1) preparation is conducted, specifically, a broad bean cutting device is used; (2) selecting is conducted, specifically, broad beans uniform in particle size are selected out; (3) bean soaking is conducted, specifically, the broad beans are soaked into clear water; (4) airing is conducted, specifically, the soaked broad beans are aired; (5) edible oil is added, specifically, the edible oil is added into a deep-frying tank; (6) a processing tank is loaded, specifically, the aired broad beans are placed into the processing tank, and move into through holes of a flexible layer under guidance of the side wall of the processing tank; (7) cutting is conducted, specifically, a rotary motor is started to drive a cam to rotate, the cam intermittently squeezes a squeezing plate to drive a squeezing column to reciprocate vertically under the effect of a compressed spring, and a tool cuts the broad beans and squeezes the broad beans to fall into the deep-frying tank from the through holes; and (8) deep frying is conducted, specifically, a heater is started, and the edible oil in the deep-frying tank is heated by the heater so as to deep fry the broad beans. By adoption of the scheme, the problems that a traditional broad bean cutting process is low in efficiency, and the hands are prone to being cut are mainly solved.

Owner:CHONGQING ZHOUYI FOOD CO LTD

A kind of ampoule bottle safety standard opening device and using method thereof

ActiveCN110357018BStable cuttingBottleneck scratches are goodOpening closed containersBottle/container closureReciprocating motionEngineering

The invention relates to the technical field of medical devices, in particular to an ampoule bottle safety standard opening device and a method of use thereof, comprising a hard sleeve, a positioning slide, a first driving collar, a second driving collar and an ejecting device. The upper and lower ends of the hard sleeve are both open, and the inner edge of the lower end opening of the hard sleeve is equipped with a movable positioning slide, a grinding wheel piece and a disinfection rod that penetrate the inner wall of the hard sleeve. on the hard sleeve, and the positioning sliding piece and the driving grinding wheel reciprocate along the radial direction of the penetrating hard sleeve wall, the second driving collar is sleeved in the hard sleeve, and is connected with the ampoule The bottle head of the bottle is fixedly matched, the ejector device is fixed on the upper end of the hard sleeve, and the ejector device contacts and cooperates with the bottle body of the ampoule bottle. The present invention has the advantages of operation standards for opening ampoule bottles, safety factor for opening, thorough disinfection and high operating efficiency.

Owner:HEBI CITY PEOPLES HOSPITAL

A safety standard opener for medical ampoules and its application method

ActiveCN110357016BStable cuttingBottleneck scratches are goodOpening closed containersBottle/container closureReciprocating motionApparatus instruments

The invention relates to the technical field of medical devices, in particular to a medical ampoule bottle safety standard opener and a method for using the same, including a hard sleeve, a positioning slide, a first driving collar, a second driving collar, an ejection device and The bottle body is fixed with a collar, the upper and lower ends of the hard sleeve are open, and the inner edge of the lower end opening of the hard sleeve is equipped with a movable positioning slide, a grinding wheel piece and a disinfection rod that penetrate the inner wall. A driving collar is rotatably fitted on the hard sleeve, and the positioning slide and the driving grinding wheel reciprocate along the radial direction of the penetrating hard sleeve wall, and the second driving collar is sleeved on the hard sleeve. The sleeve is fixedly matched with the bottle head of the ampoule bottle, and the ejector device is fixed on the upper end of the hard sleeve, and the ejector device works in contact with the bottle body of the ampoule bottle. In the present invention, the ampoule bottle of the present invention has the operating standard for opening, safety factor for opening, thorough disinfection, rotation of the bottle body to prevent it from slipping, and high operating efficiency.

Owner:HEBI CITY PEOPLES HOSPITAL

Base assembly of voice coil motor and voice coil motor

The present disclosure provides a base assembly of voice coil motor and a voice coil motor. The base assembly includes a base body having a first elastic piece connecting area, a lower elastic piece disposed on the first elastic piece connecting area, and a first terminal disposed in the base body. The first terminal has: a first conductive part disposed in the base body; a first terminal connecting part disposed on one side of the first conductive part and extending toward a direction away from the first conductive part, wherein a part of the first terminal connecting part protrudes from the first elastic piece connecting area and is connected with the lower elastic piece; and an engaging part disposed on one side of the first terminal connecting part and extending toward a direction away from the first terminal connecting part.

Owner:KUNSHAN LIANTAO ELECTRONICS CO LTD

Panel cutting jig

PendingUS20220234175A1Made evenlyStably fixGuide fencesGripping devicesClassical mechanicsStructural engineering

Owner:RICO BLINDS CO LTD

Colored glass manufacturing process

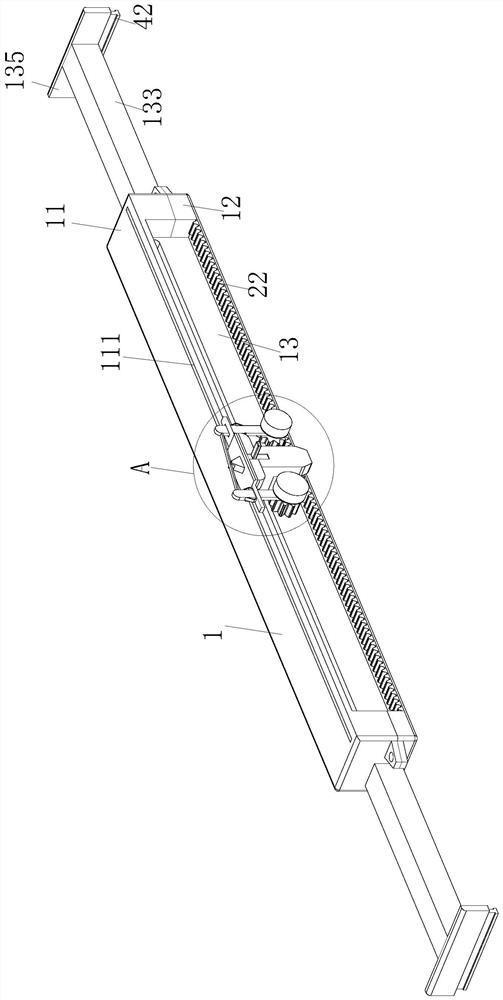

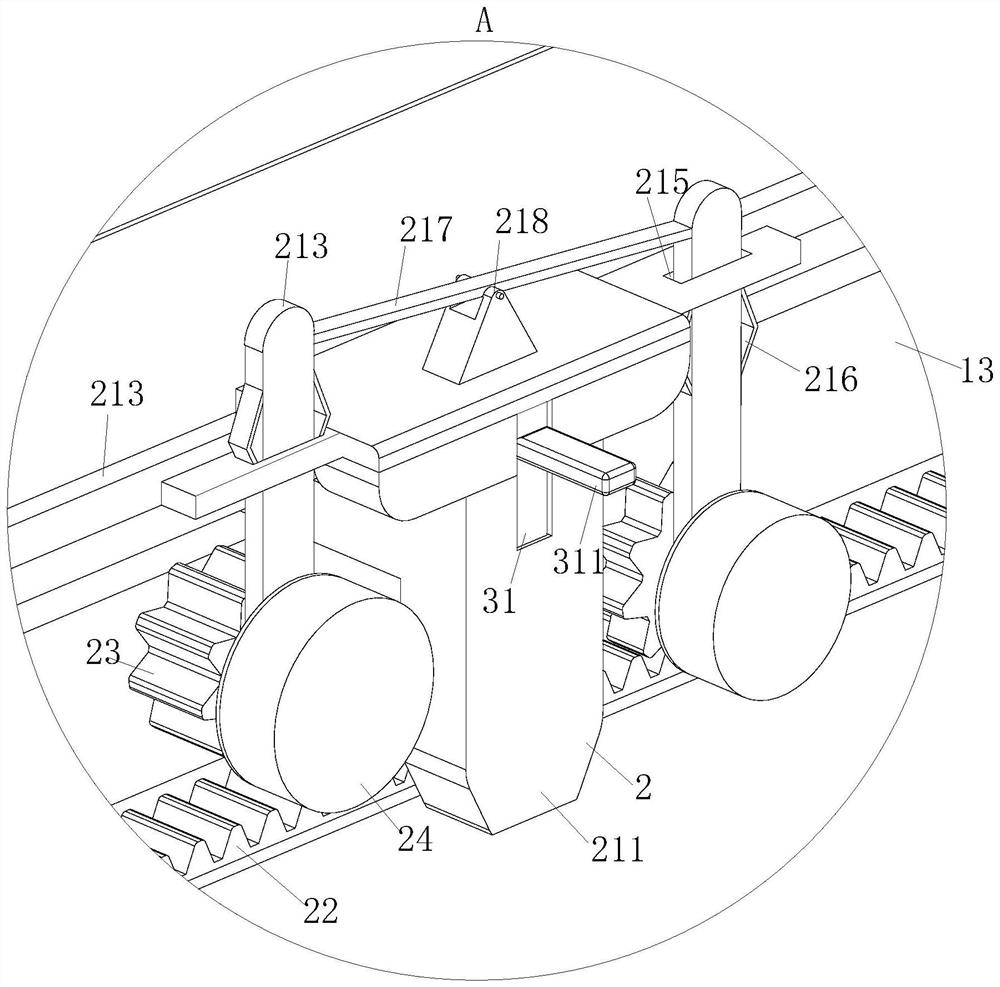

InactiveCN111775349AAvoid sweeping into scratchesAvoid fragmentationDecorative surface effectsWorking accessoriesColor glassMechanical engineering

The invention belongs to the technical field of glass, and particularly relates to a colored glass manufacturing process. A cutting device used in the process comprises a glide plate; the glide platecomprises an upper shell and a lower shell; two ends of the upper shell and the lower shell are connected through a bolt; a No.1 slot is formed between the upper shell and the lower shell; a cutting unit is arranged in the No.1 slot, and comprises a cutting base, a rack, gears and hairbrushes; a T-shaped rod is arranged at the rear end of the cutting base and is embedded into a T-shaped groove formed in the No.1 slot; a cutter is arranged at the lower end of the cutting base; connecting plates are arranged on two sides of the cutting base; a No.1 rod is hinged to the lower end of each connecting plate; one hairbrush is fixedly connected to the front end of each No.1 rod; one gear is fixedly connected to the rear end of each No.1 rod and meshes with the rack placed on the lower bottom faceof the No.1 slot; and through the cutting unit, glass can be cut, and glass slags in a glass cutting seam can be cleaned.

Owner:李晓洁

Roller car of thread hooking mechanism

PendingCN110983665AMeet severMeet the pullNeedle severing devicesStructural engineeringMechanical engineering

The invention belongs to the field of sewing equipment, and particularly discloses a roller car of a thread hooking mechanism. The roller car comprises an elastic sheet, a suction nozzle, a thread hooking hook, a driving lever, a thread hooking cylinder assembly and a cylinder fixing frame. According to the difference of sewing conditions, the thread pressing pressure can be adjusted by a pressureregulating nut, so that an upper thread can be stably cut off, and the attractiveness of a sewing stitch is not influenced by the tension of the upper thread also can be met; after automatic thread trimming is completed after sewing is completed, a thread end of the upper thread is withdrawn through the thread hooking hook, so that the thread of the upper thread is not repeatedly sewn during seamreinforcing, and a lump of threads are prevented from being accumulated on the back face of a sewn product; the thread hooking position can be flexibly adjusted, and when the thickness of a sewing material changes, the thread hooking position can be flexibly adjusted, so that the thread hooking time is more reasonable; the thread hooking mechanism adopts a plurality of mutually matched structures, is small in occupied space and more suitable for shoemaking occasions with compact operation space, and the whole mechanism is simple to install and convenient to debug.

Owner:ANHUI JIEYU SHOEMAKING MACHINERY TECH CO LTD

Cutting device of LCD panel

ActiveCN101628784BStable cuttingStable marking depthGlass severing apparatusManufacturing lineLiquid crystal

The invention provides a cutting device of LCD panel marking the cutting lines on the A surface in the X and Y axe, marking the cutting lines for rough cutting and precious cutting on the B surface, and cutting each cutting line of a large LCD panel on a marking table of one production line. First and second cutters for marking in the X and Y axes are arranged on the marking table, in front of which a cutter of the cutting line for rough cutting, a cutting roller for cutting the cutting line, a cutter of the cutting line for precious cutting, and a cutting roller for cutting the cutting line are provided, and a first supplement table and a second supplement table for forward delivery are arranged above the cutters and cutting rollers, moreover, a cutting device is arranged in front of each supplement table.

Owner:SHIRAI IRON WORKS

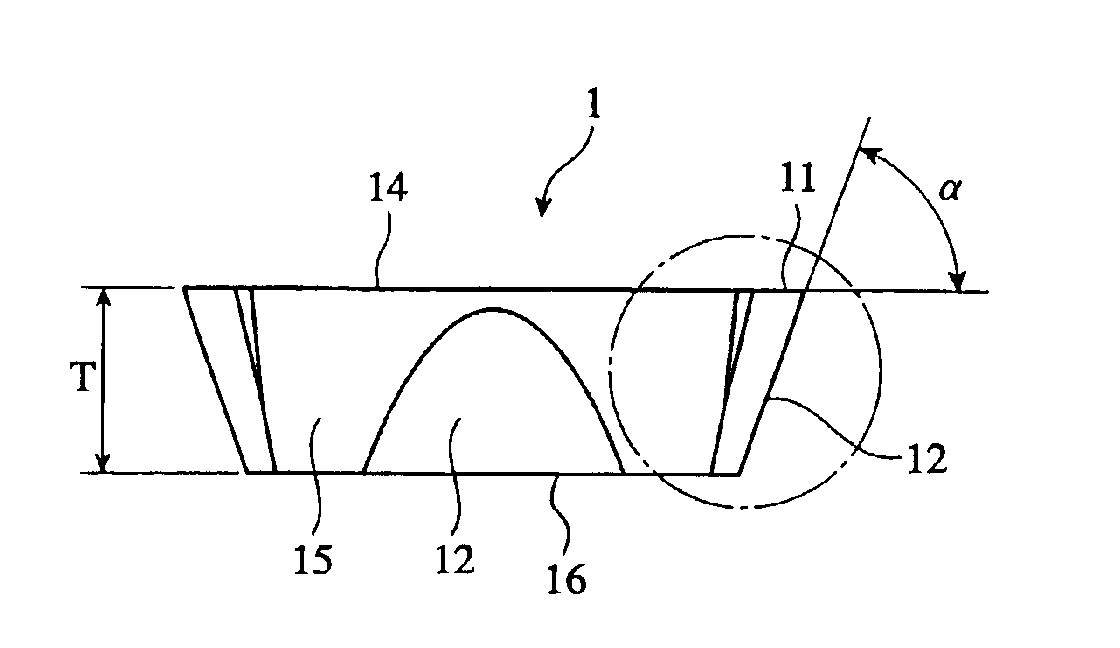

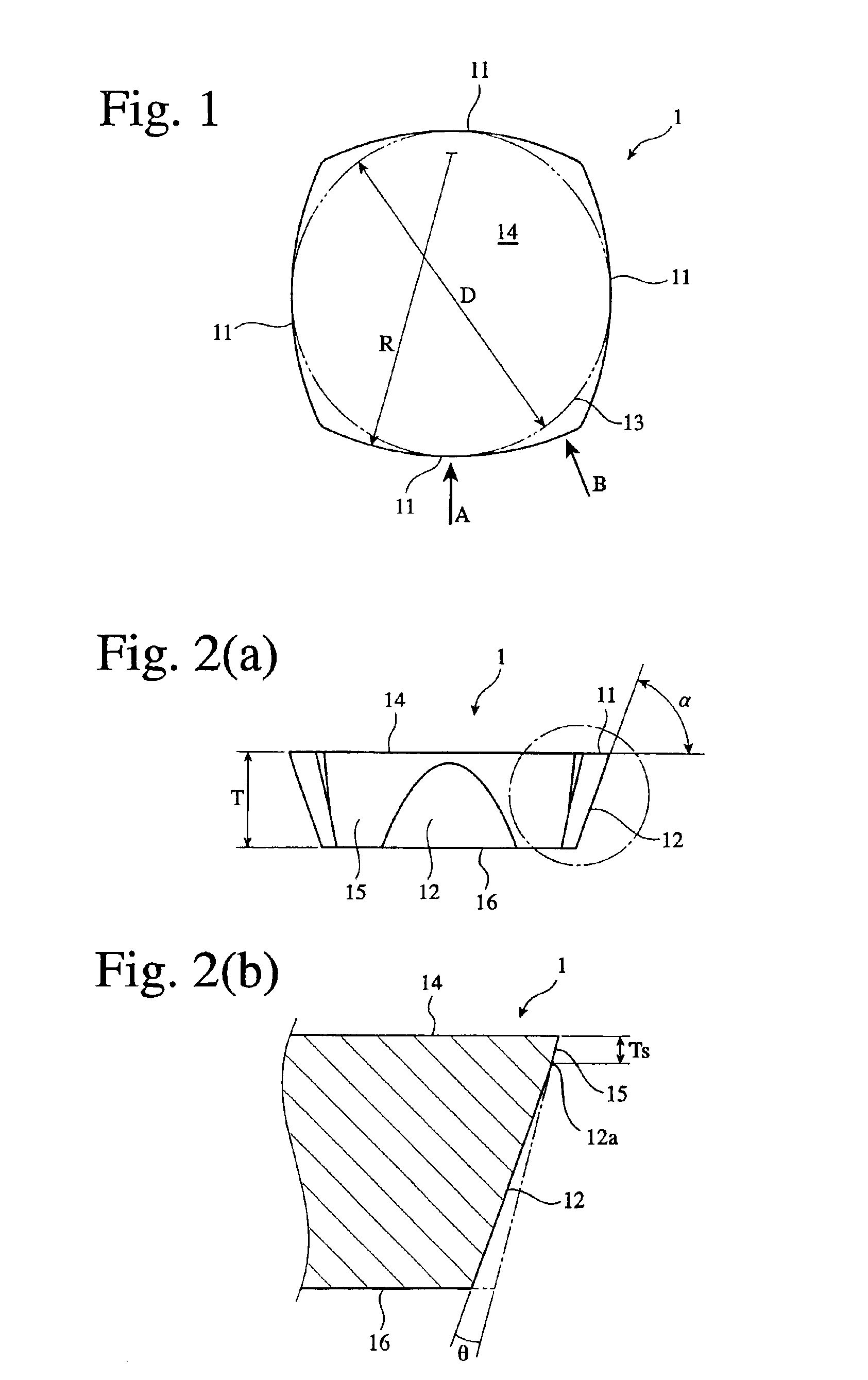

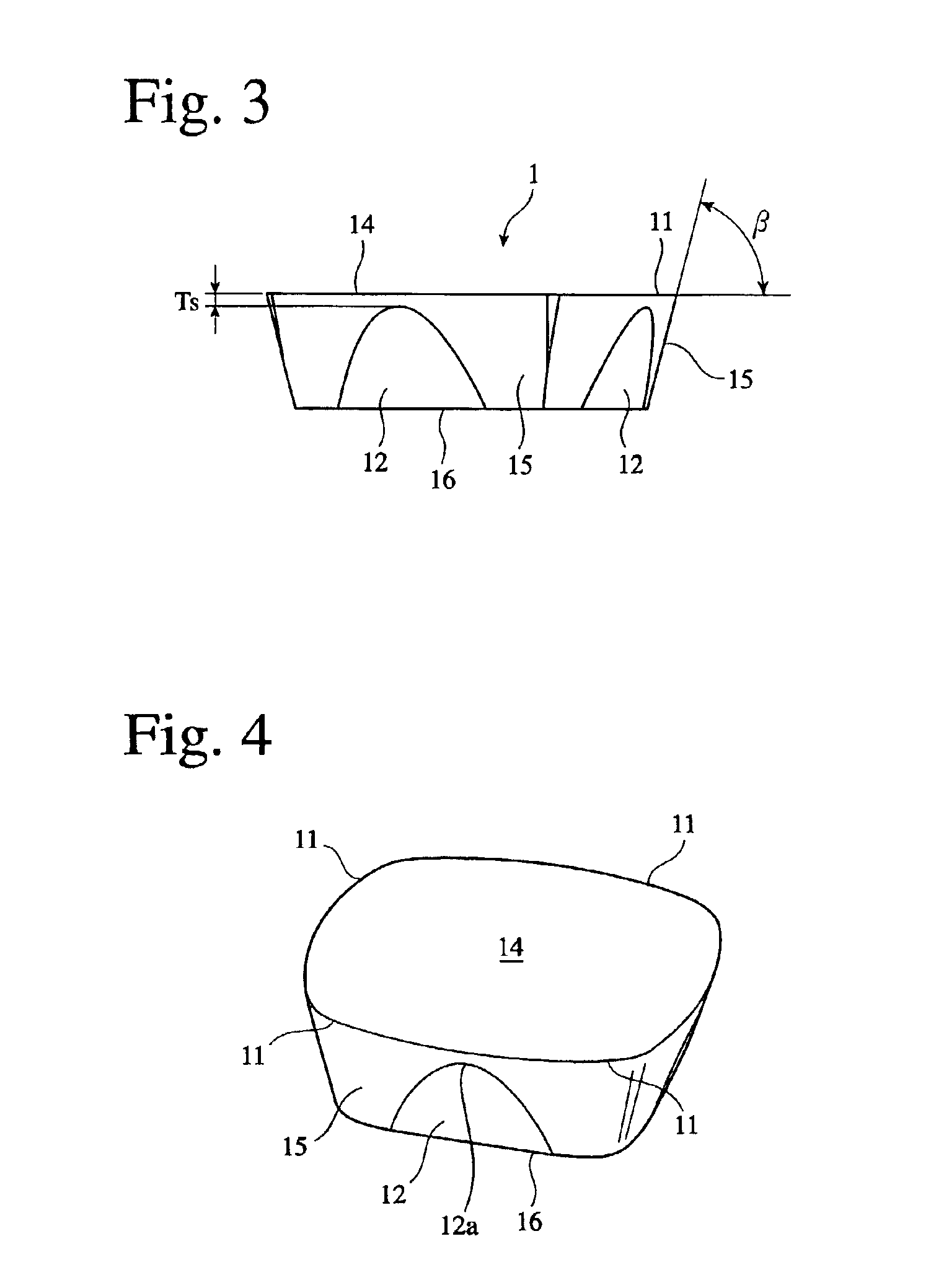

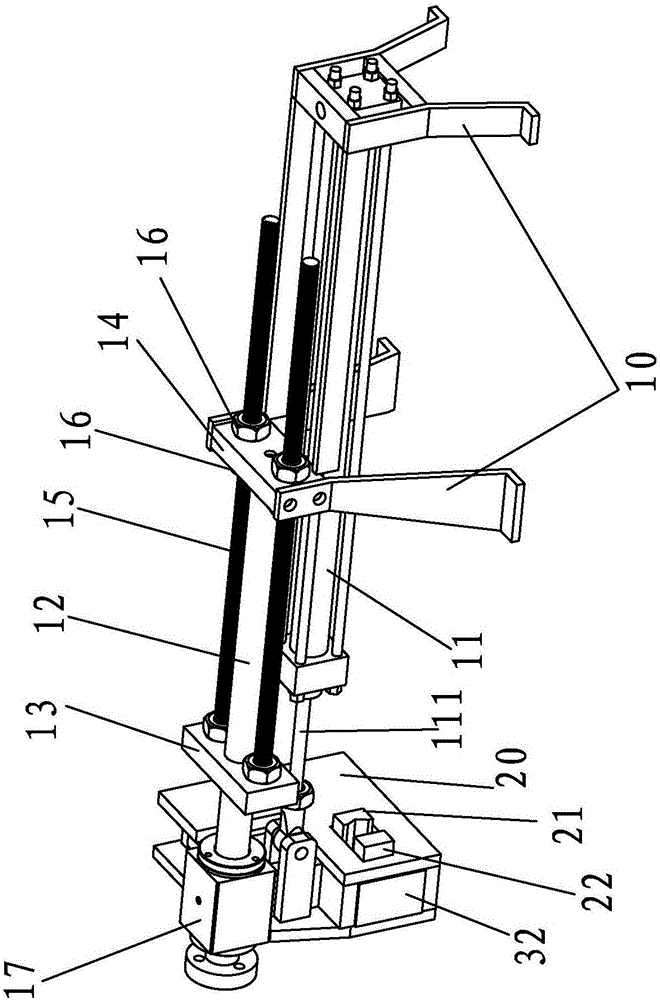

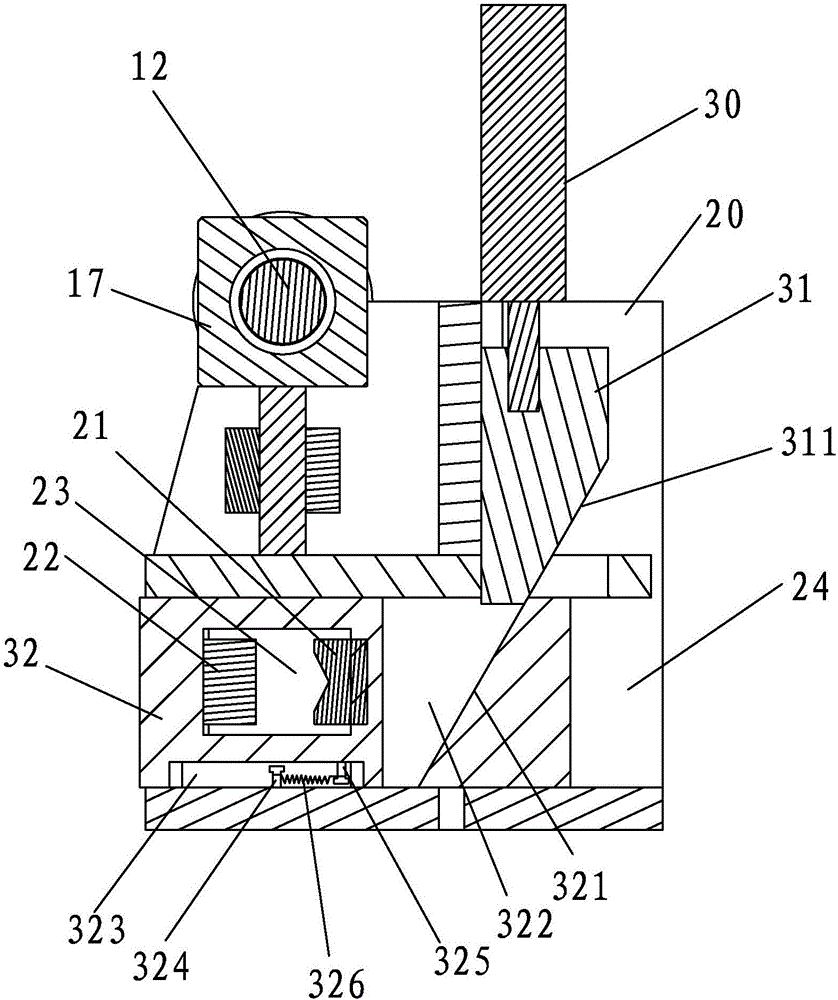

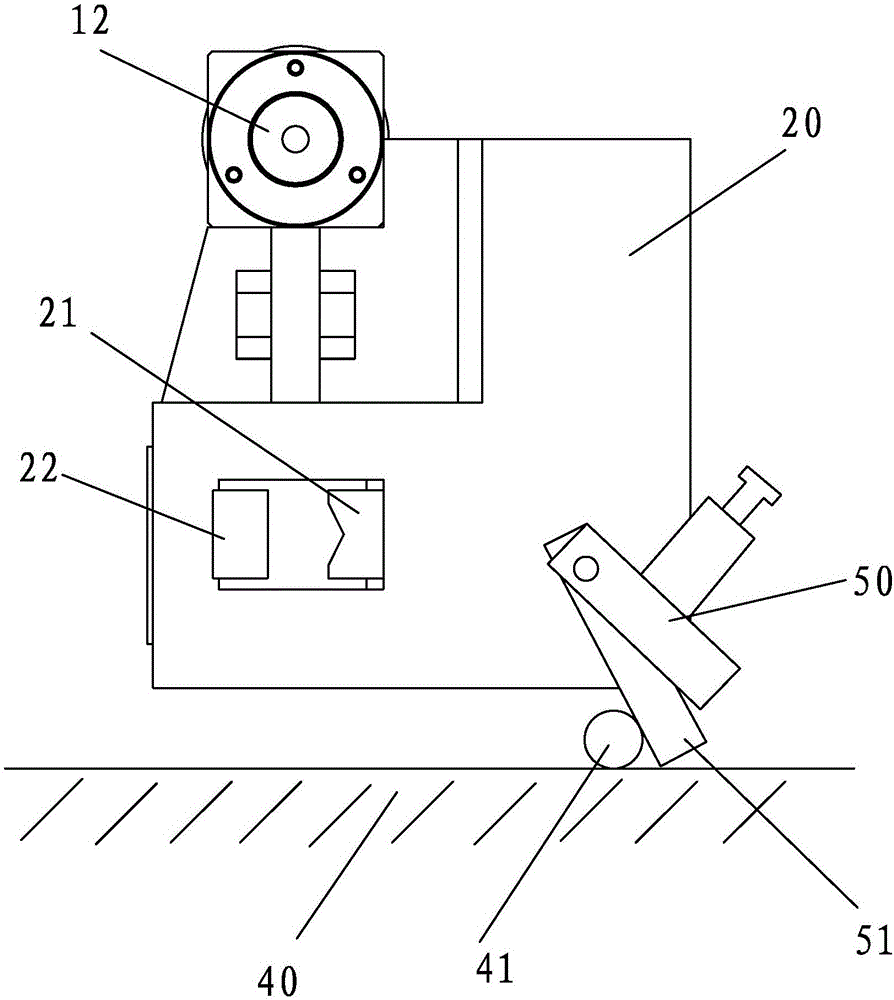

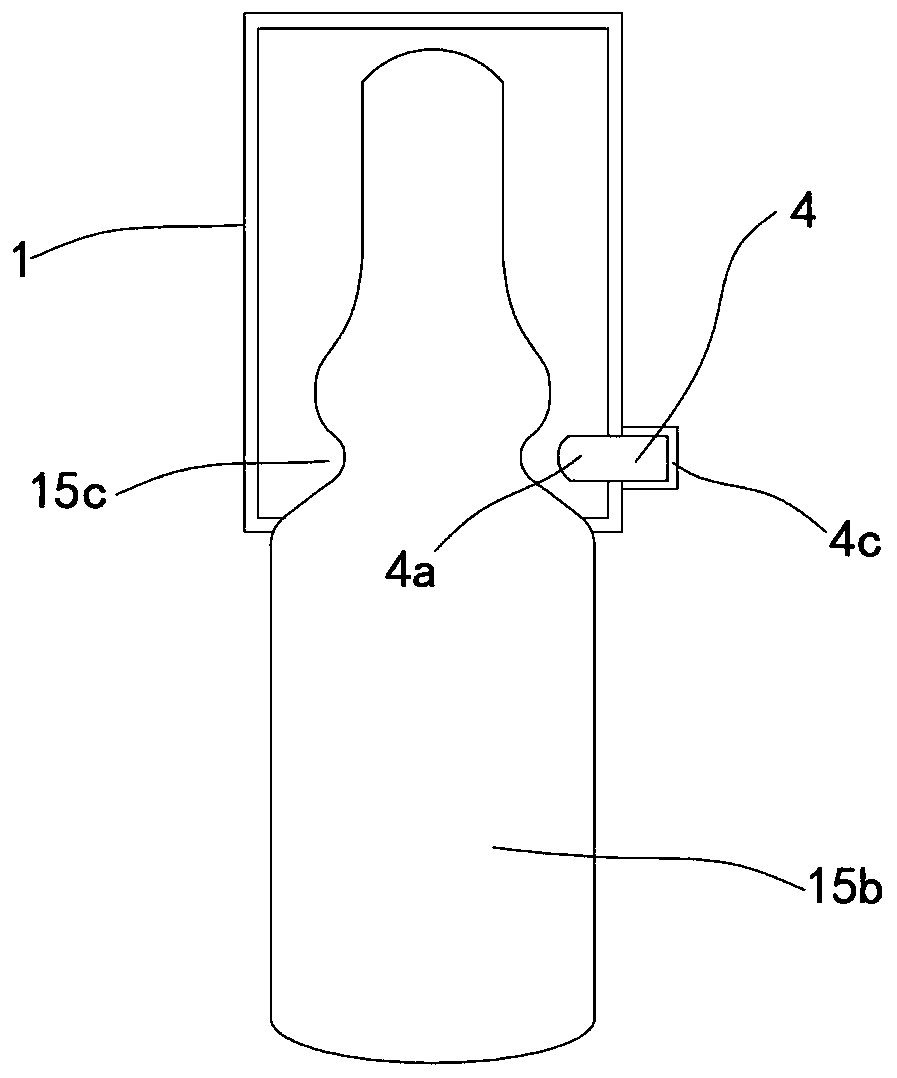

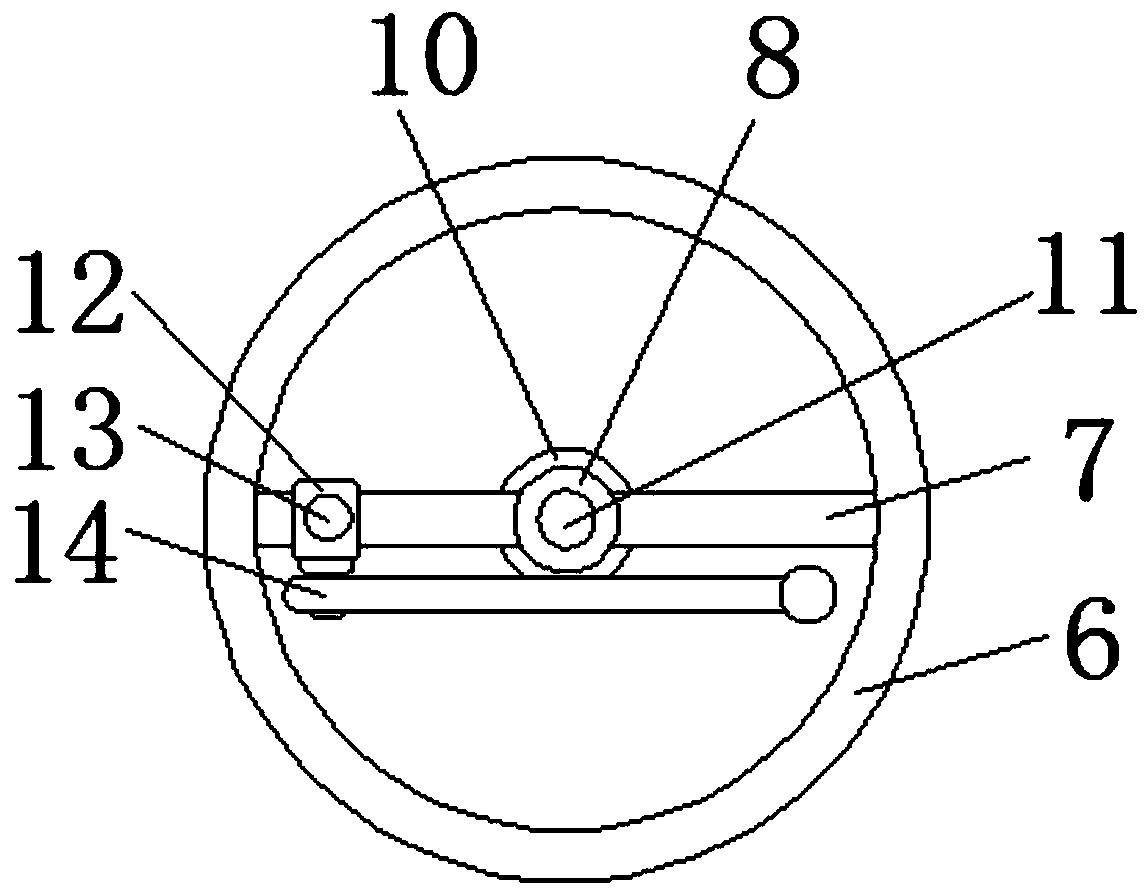

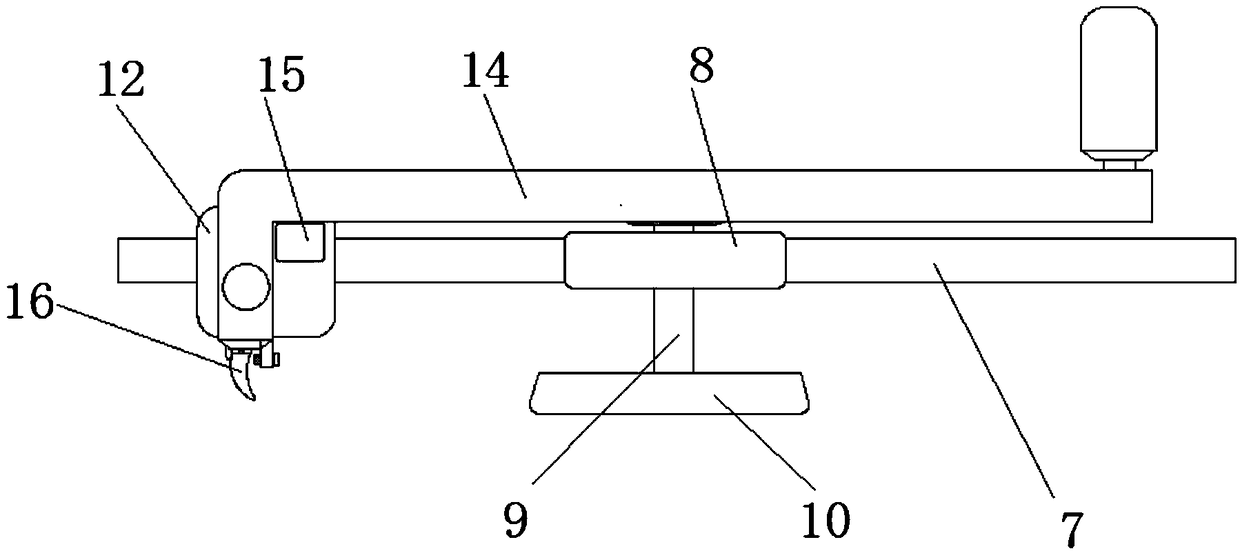

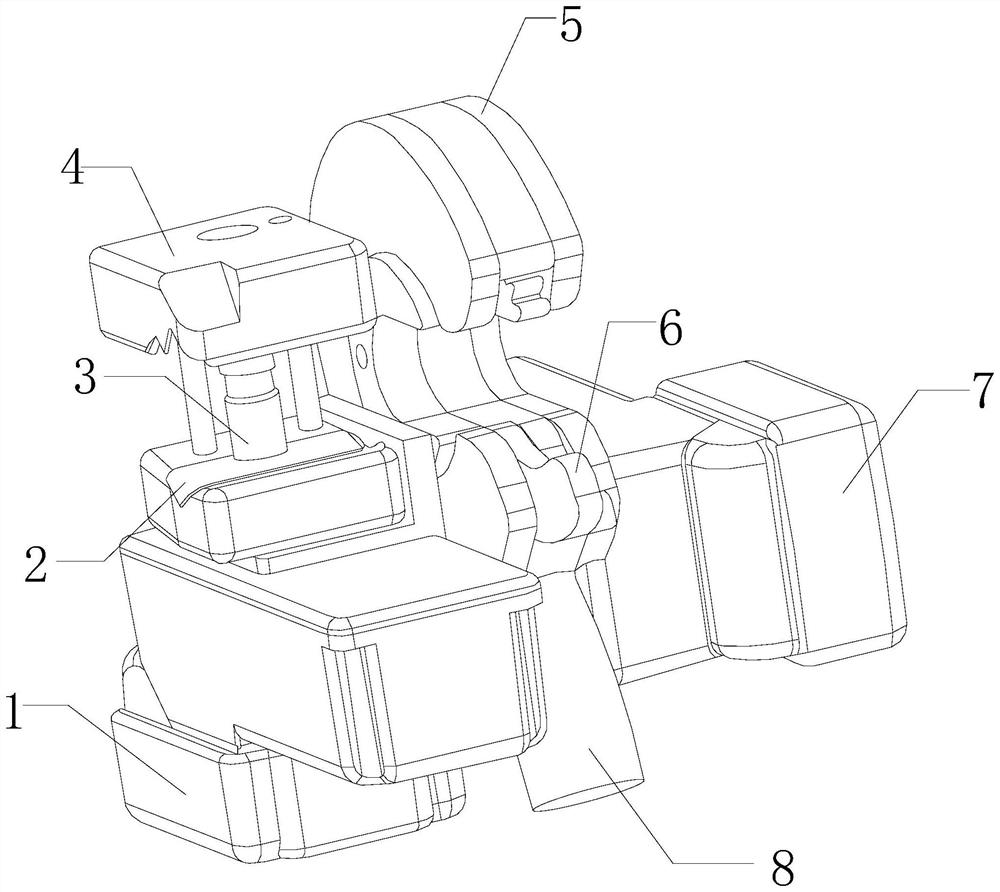

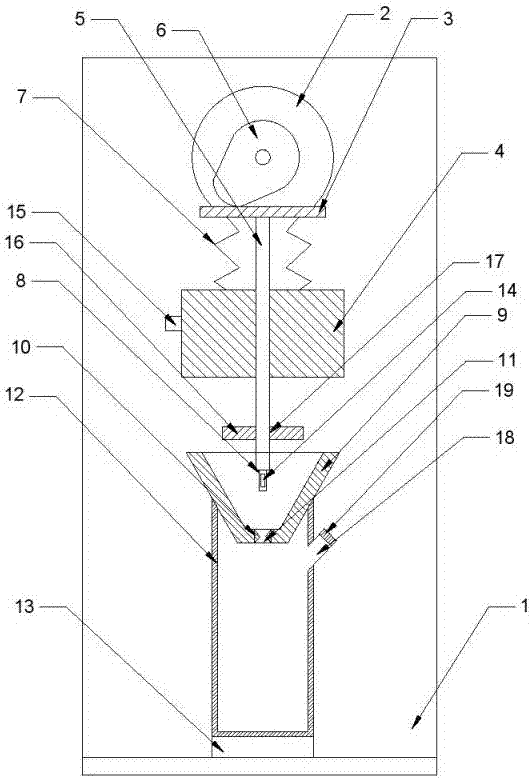

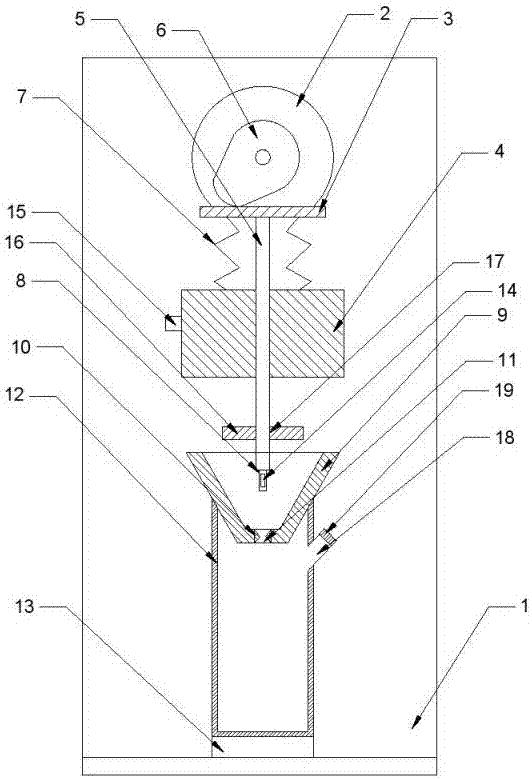

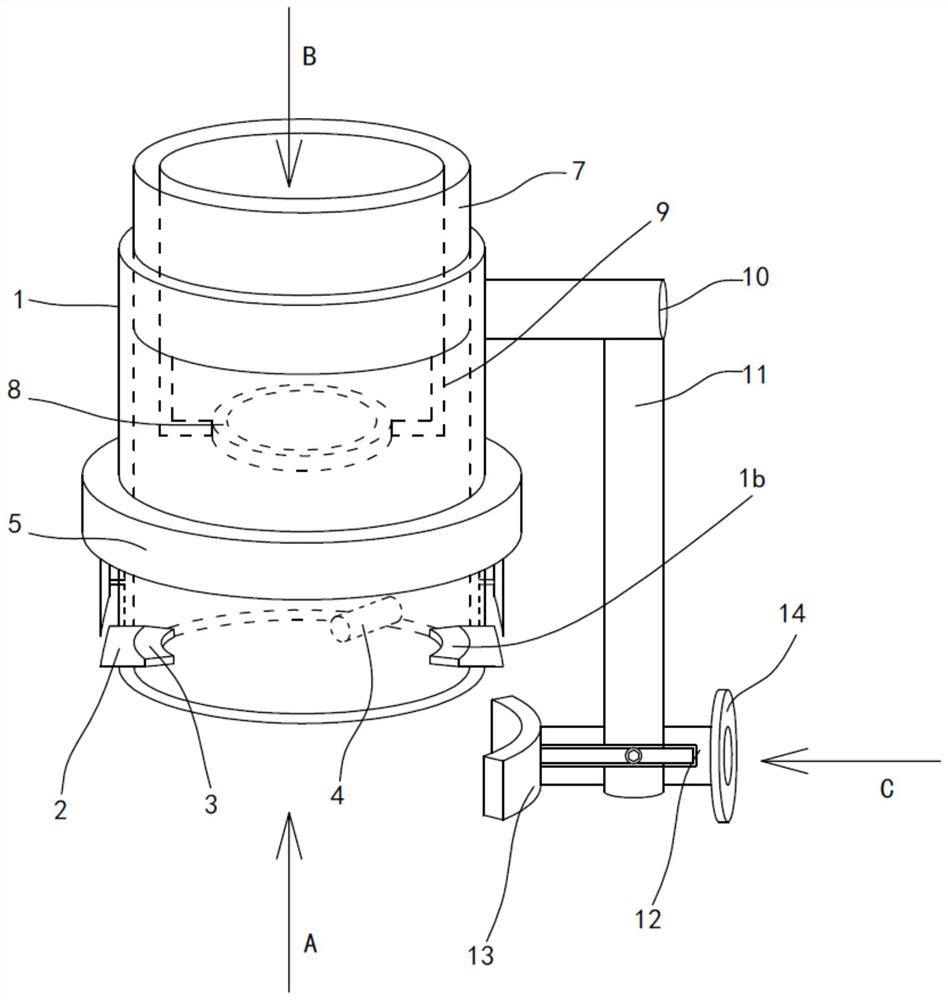

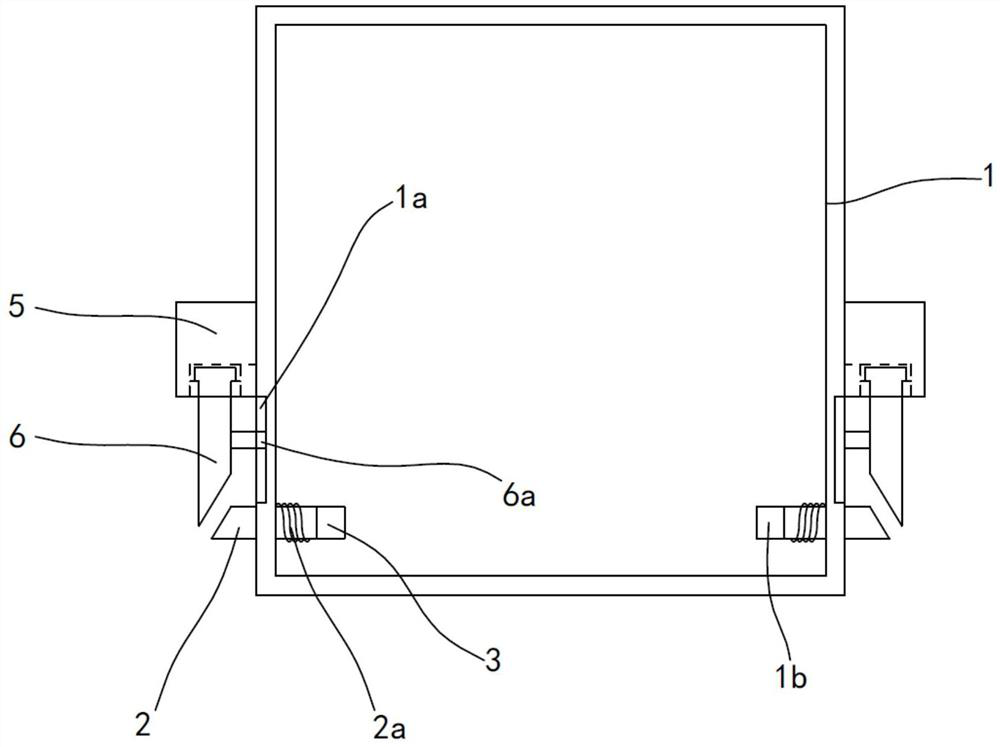

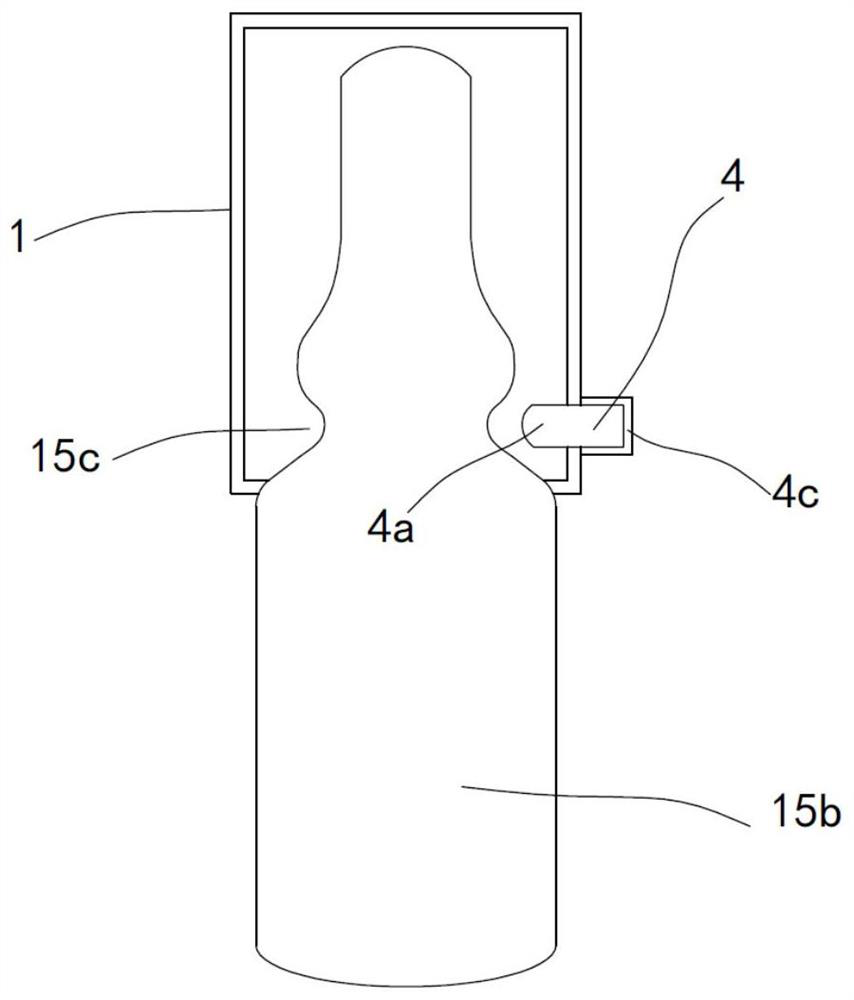

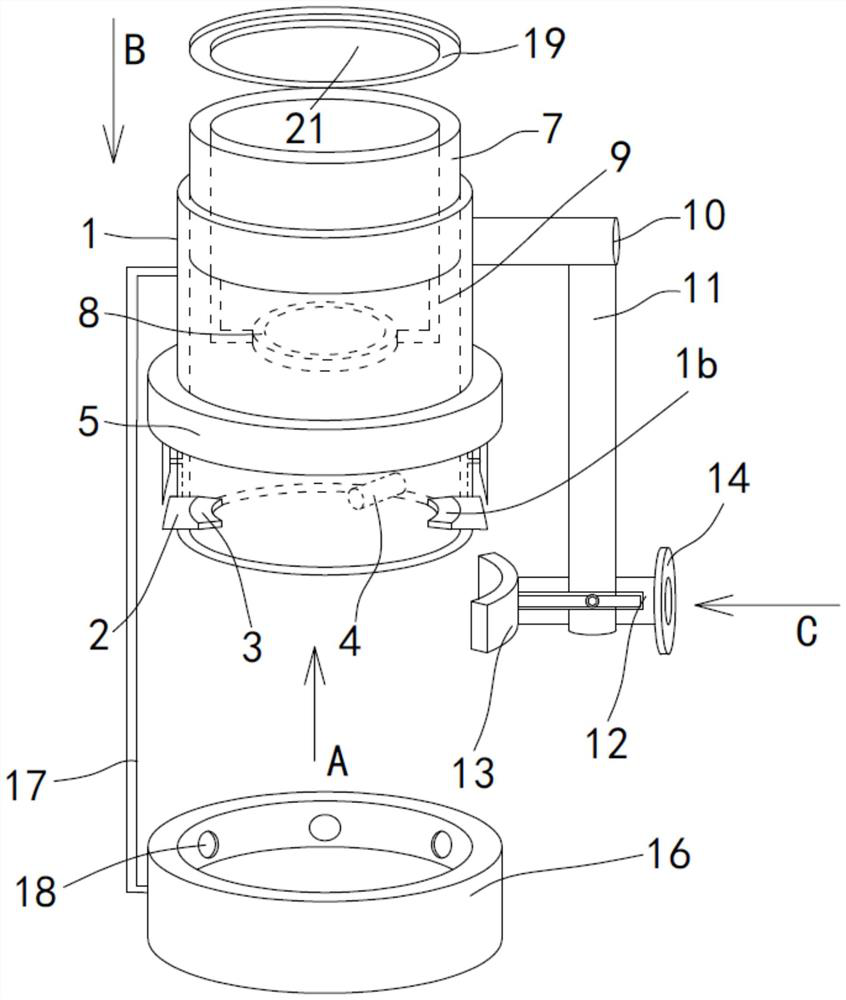

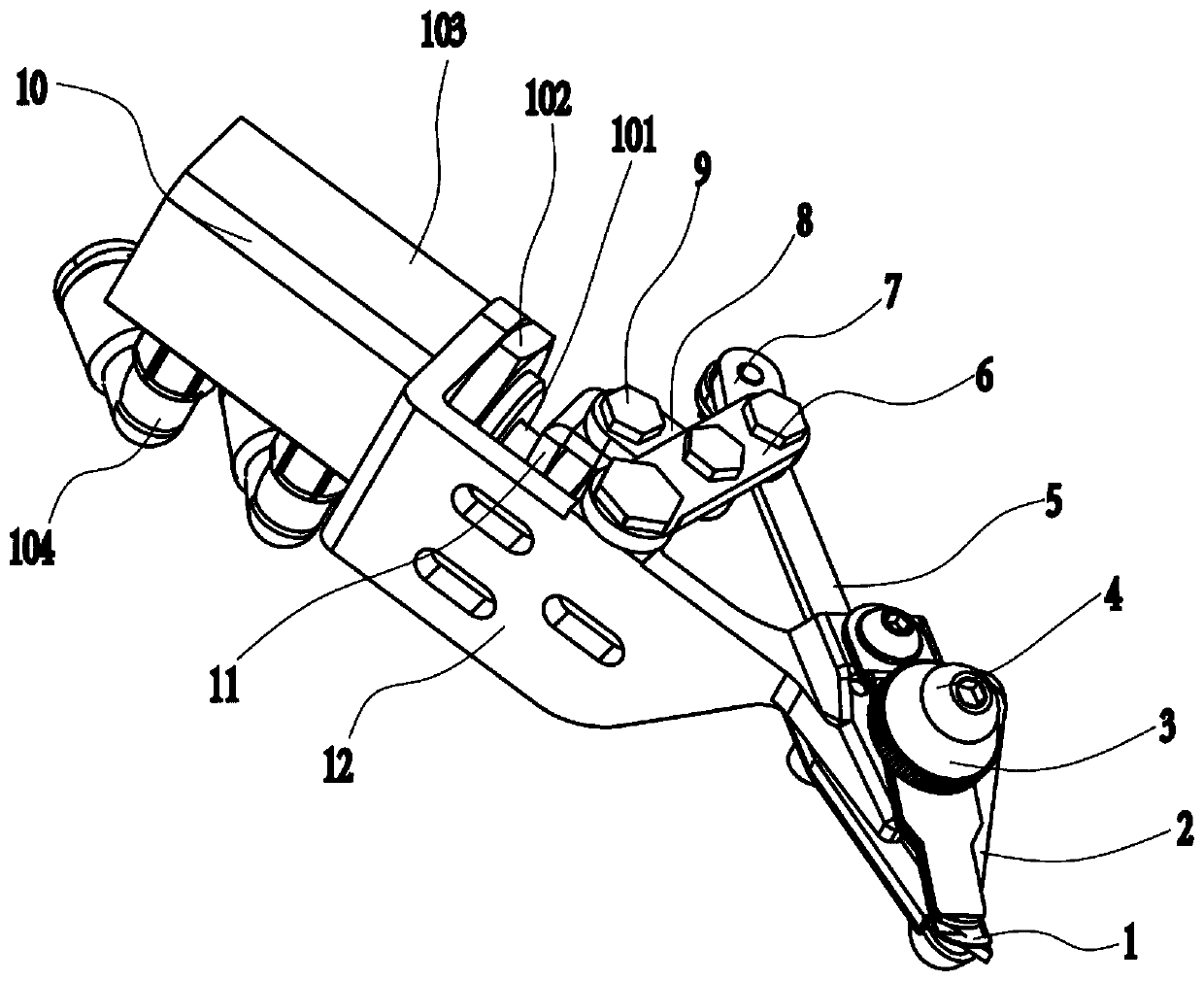

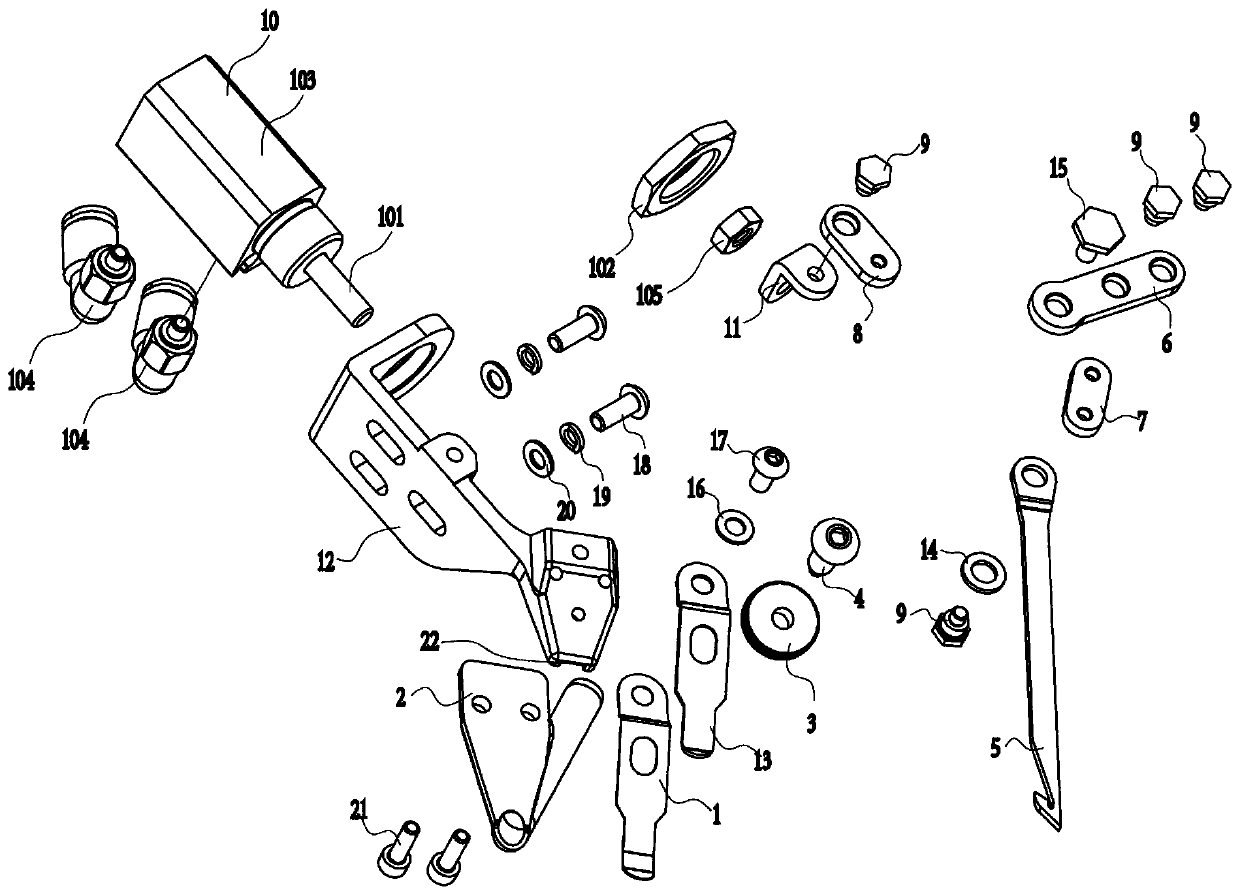

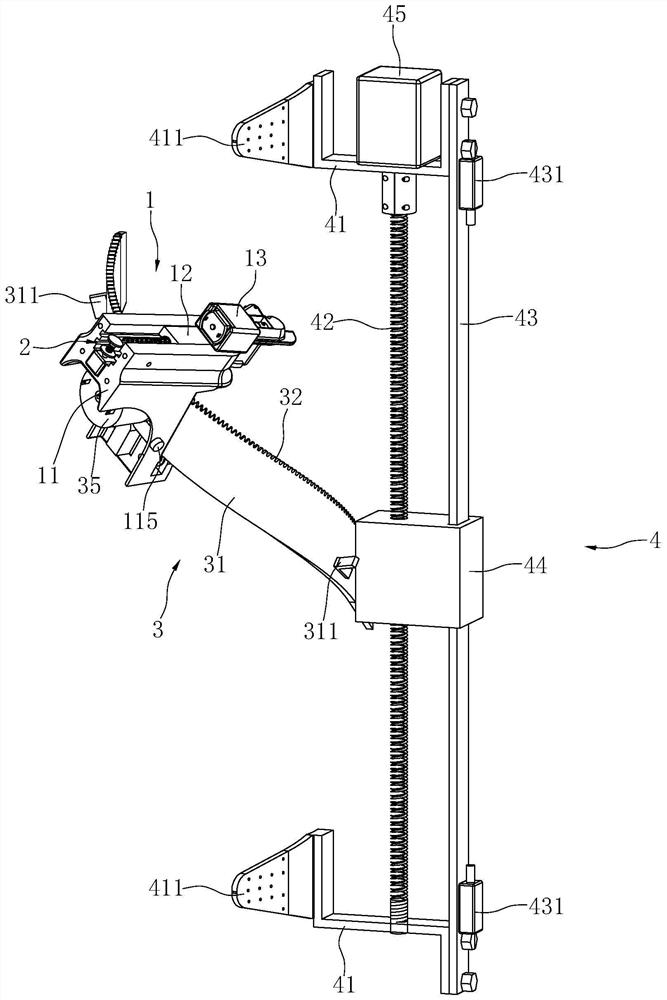

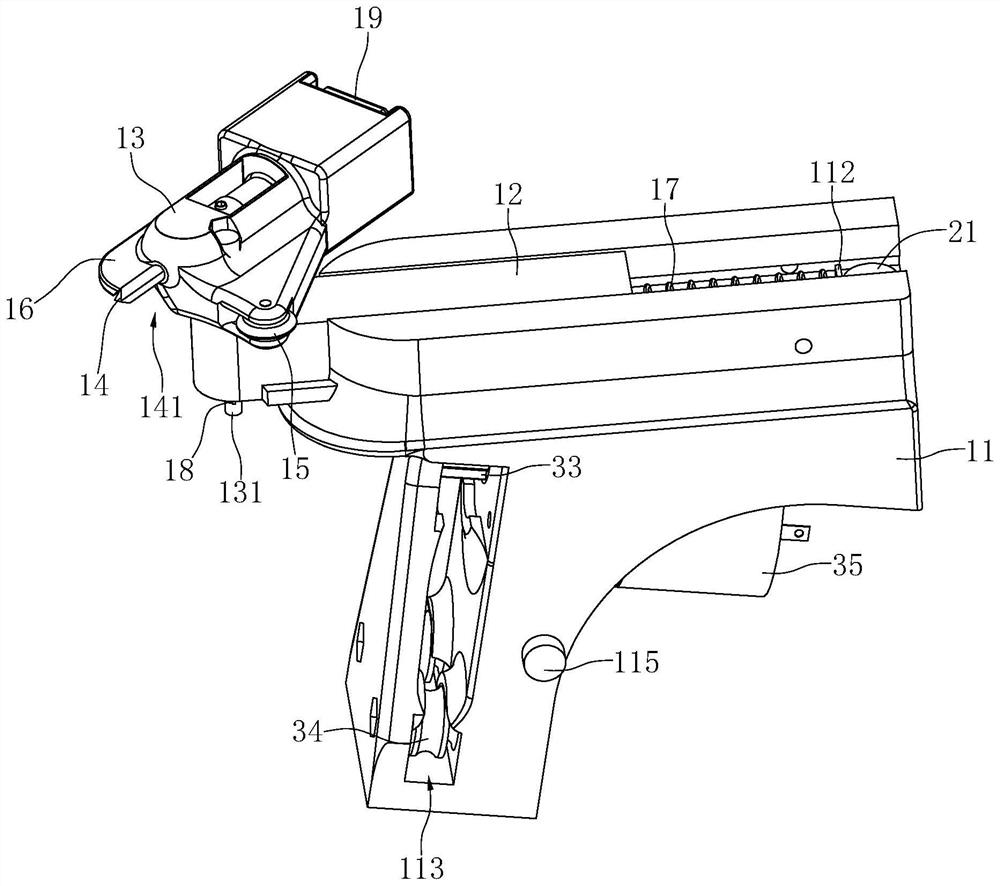

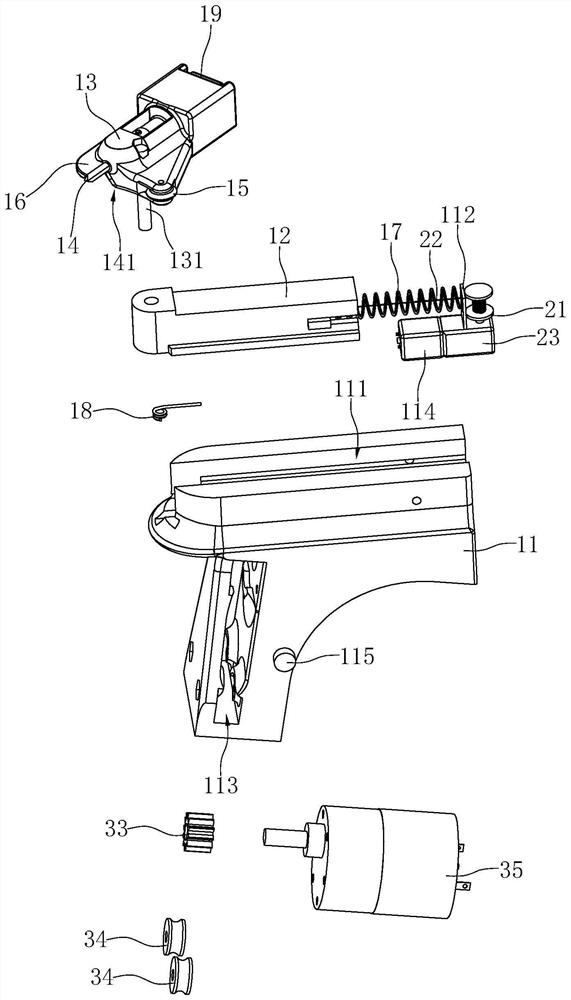

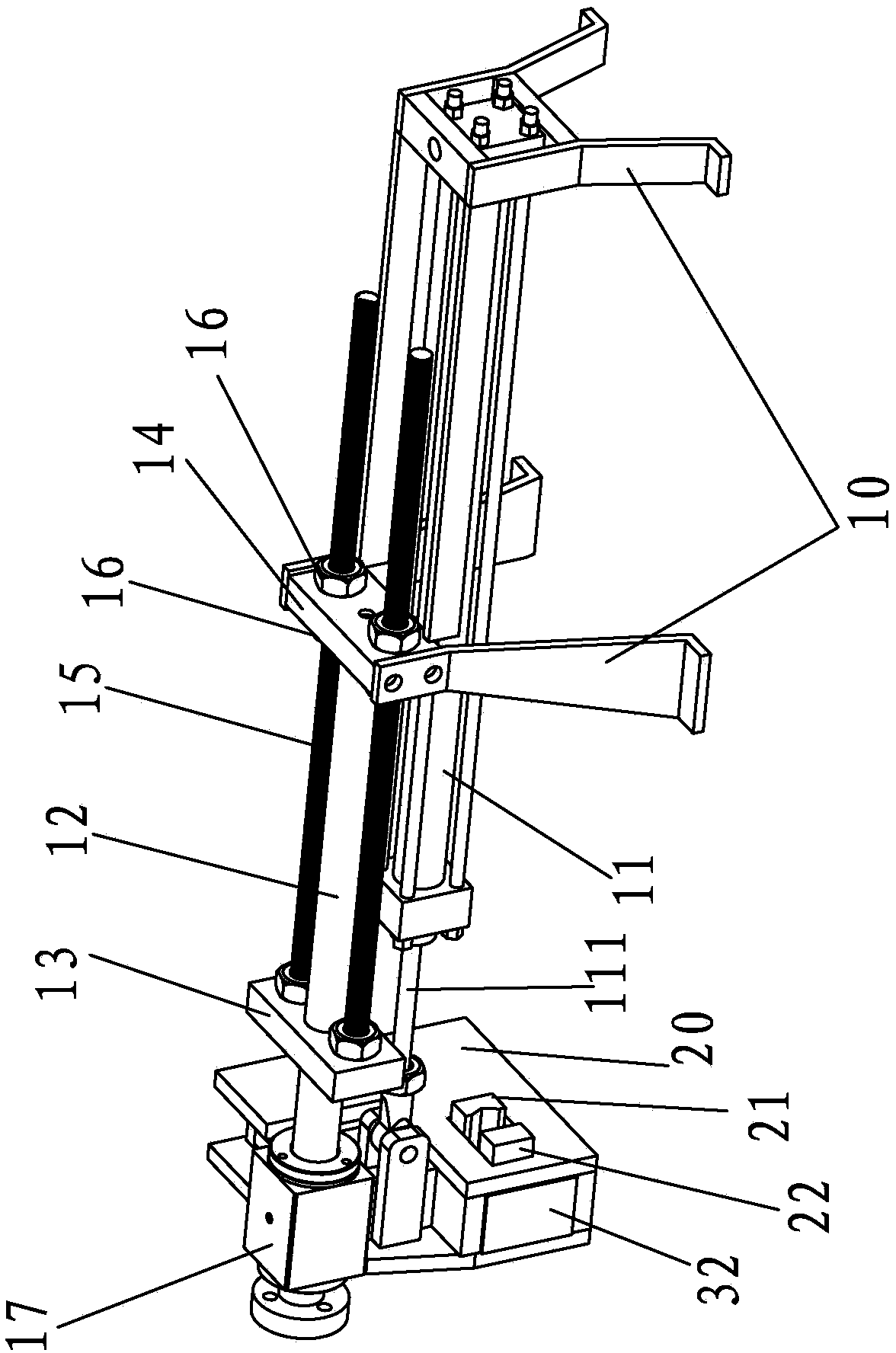

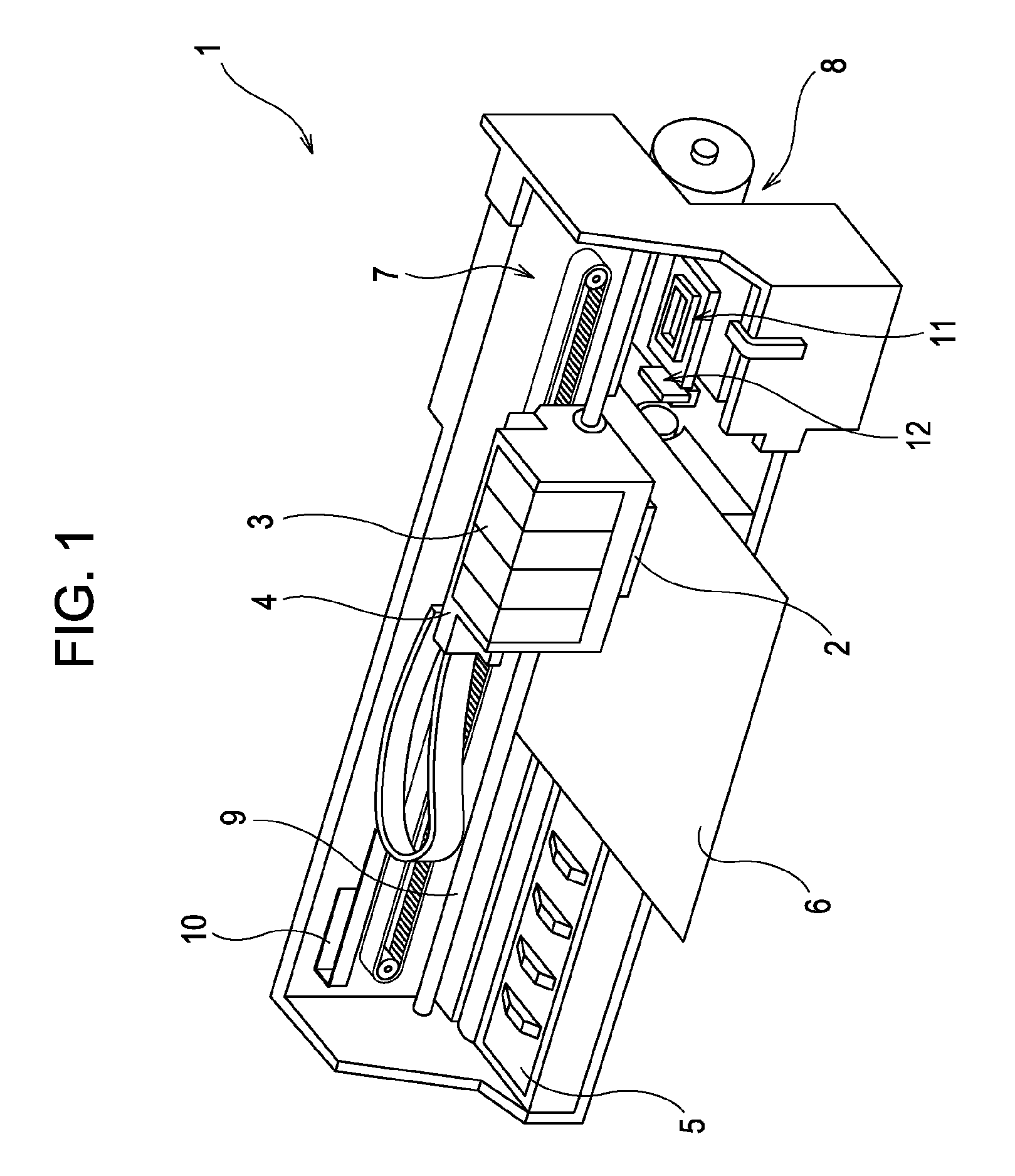

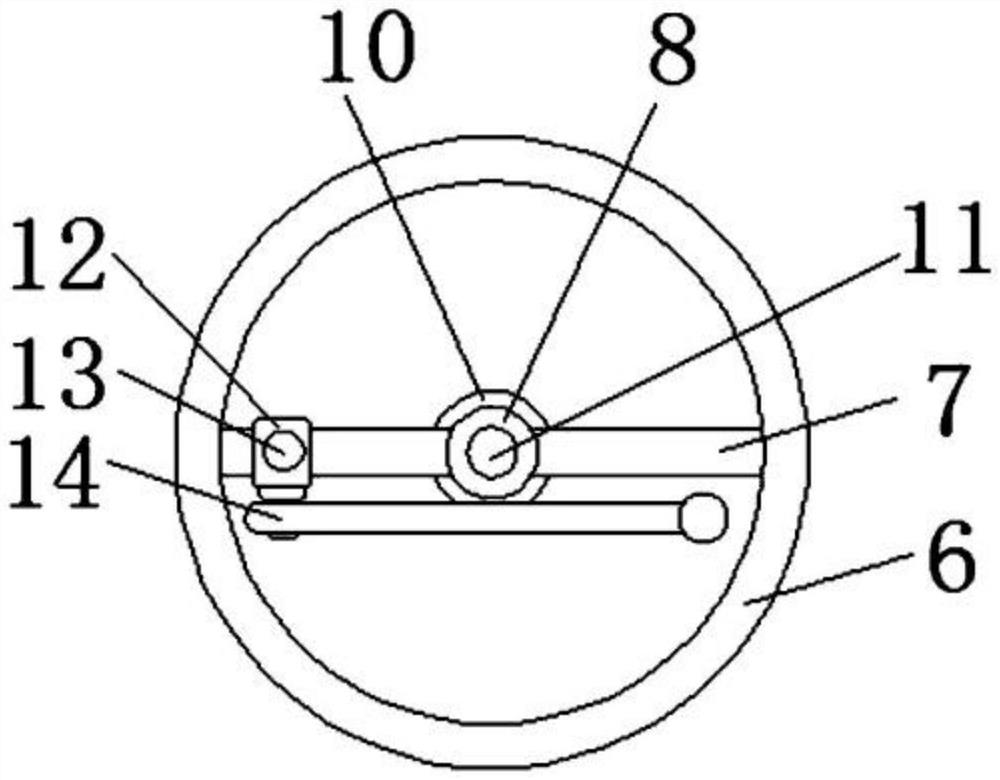

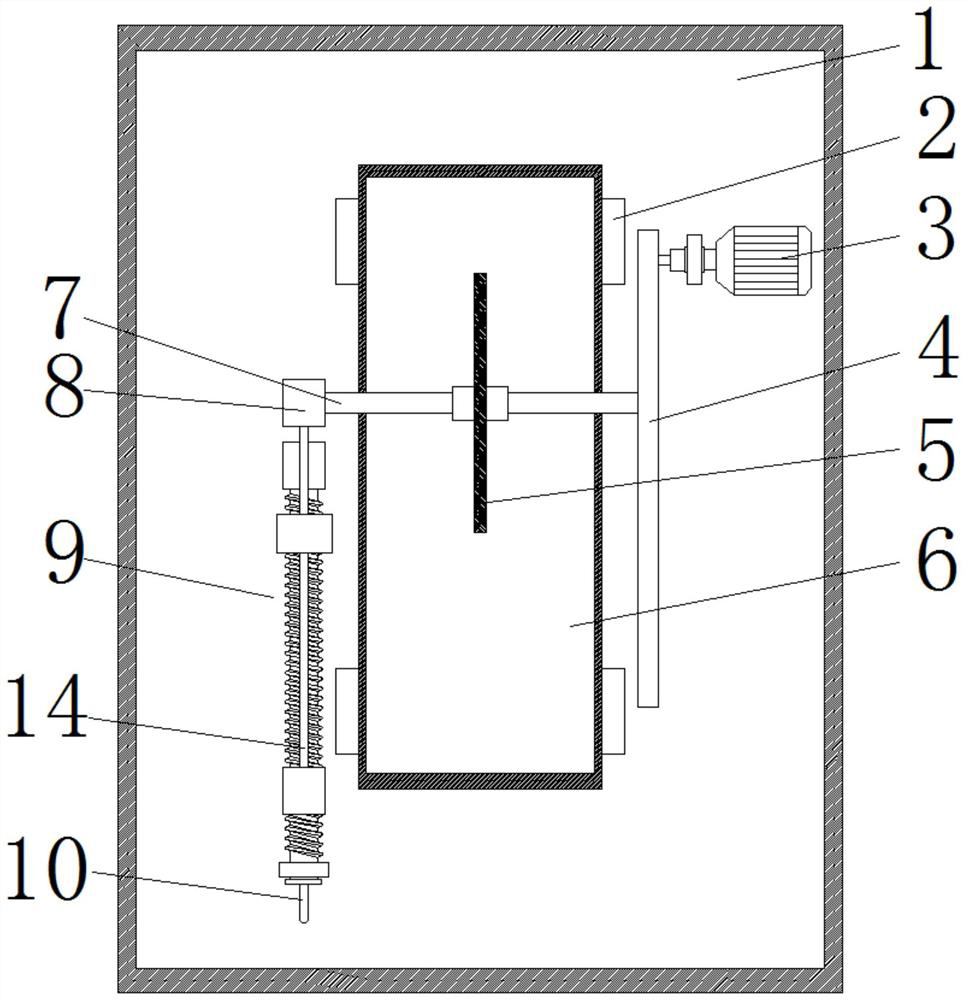

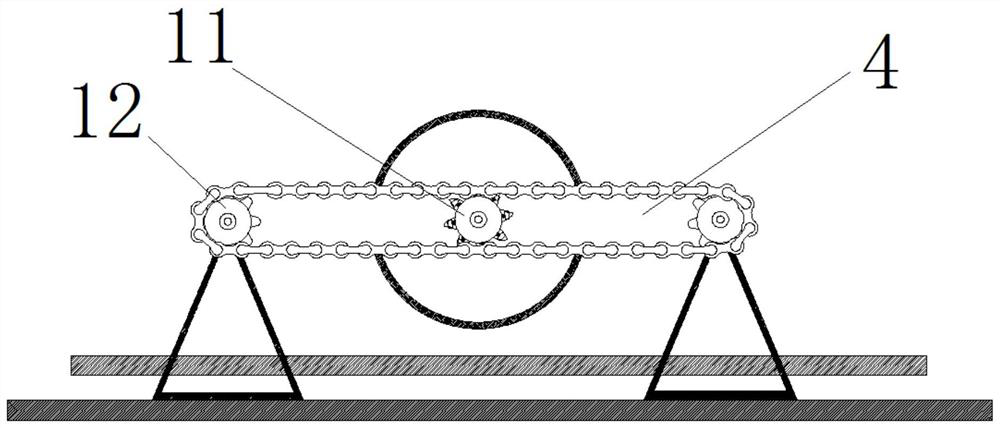

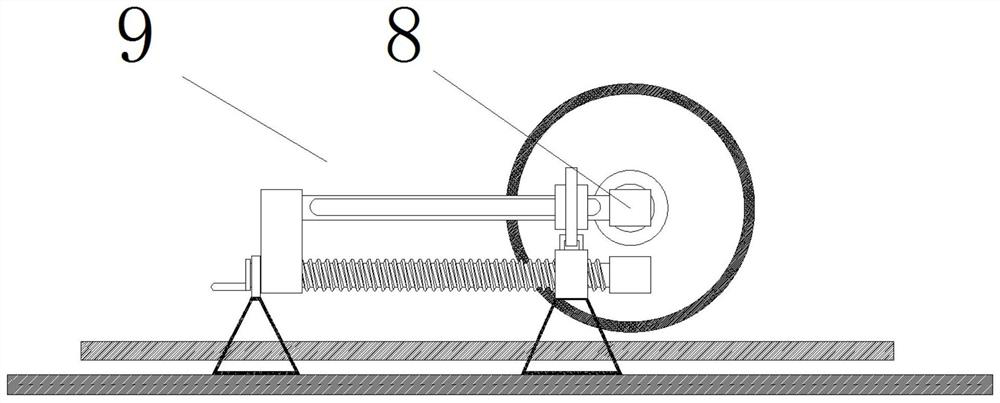

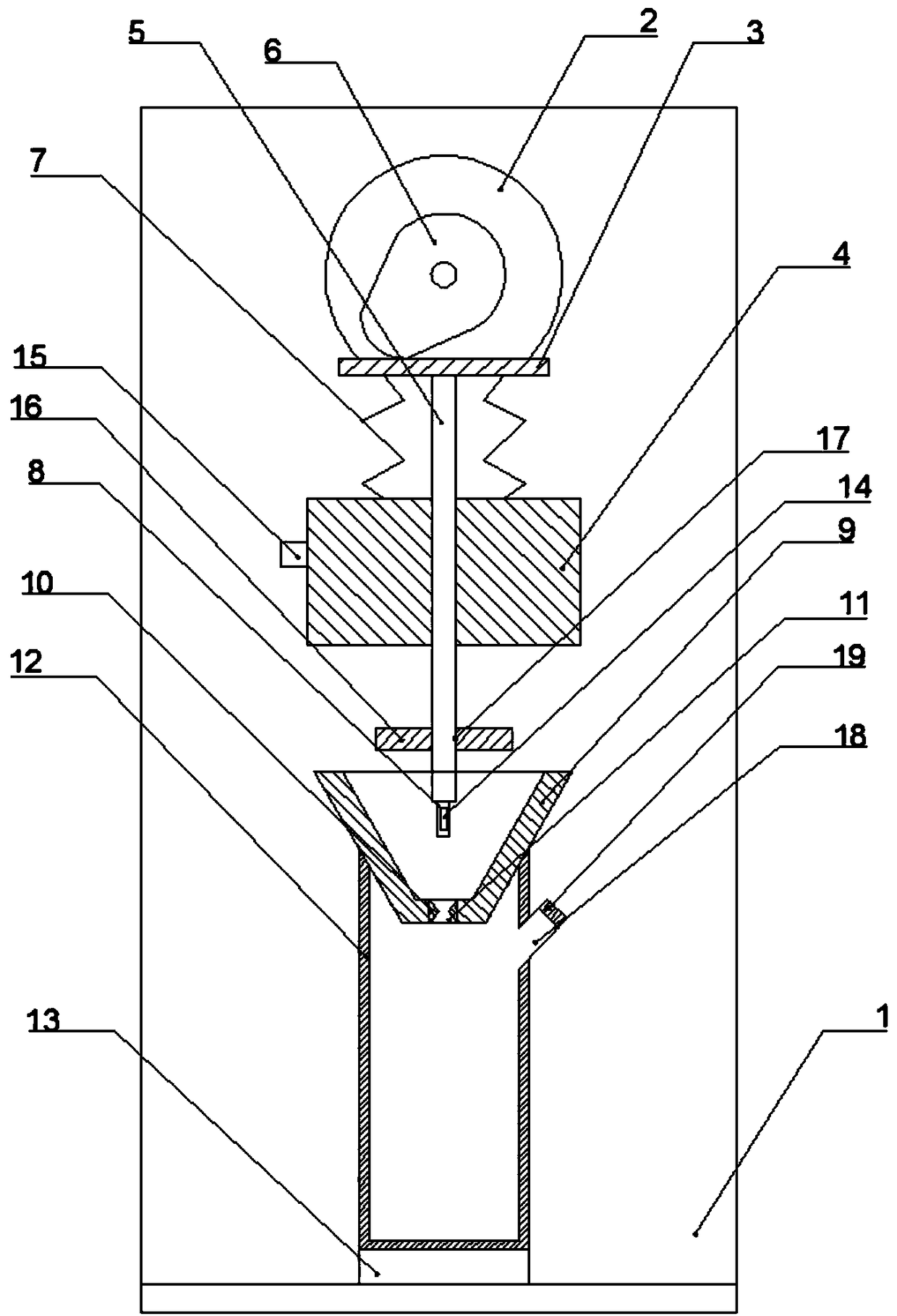

Automatic rubber tapping machine and control method thereof

The invention discloses an automatic rubber tapping machine which comprises a cutter assembly (1) and a first driving mechanism (3), and is characterized in that the cutter assembly (1) comprises a cutter rest (11) provided with a sliding groove (111); at least part of the sliding arm (12) is inserted into the sliding groove (111); the rotating seat (13) is rotatably mounted on the sliding arm (12); the tool bit (14), the guide piece (15) and the tool depth limiting guide plate (16) are all located on the rotating seat (13); the first elastic piece (17) can enable the sliding arm (12) to always have a trend of moving close to the rubber tree; and the second elastic piece (18) can enable the guide piece (15) positioned on the rotating seat (13) to always have a trend of abutting against the rubber tree. The invention further discloses a control method of the automatic rubber tapping machine. Compared with the prior art, the automatic rubber tapping machine is stable in channel cutting and capable of avoiding tool clamping.

Owner:黄伟

Feeding device of a shearing machine

InactiveCN106346072BStable jobReduce failureShearing machine accessoriesEngineeringMechanical engineering

The invention relates to a feeding device of a shearing machine. The feeding device comprises a clamping mechanism for clamping a bar and a feeding mechanism for feeding the bar to a shearing system of the shearing machine. The feeding mechanism comprises a support and a feeding cylinder for driving the clamping mechanism to move back and forth. The feeding cylinder is connected to the support. The feeding device further comprises a guiding bearing bar. The clamping mechanism is erected on the guiding bearing bar in the mode of sliding relative to the guiding bearing bar. The clamping mechanism is improved, stable clamping is ensured, and meanwhile an adjusting device is added, so that bar conveying abrasion is avoided. The feeding device has the advantages of being simple in structure and capable of improving the product quality and prolonging the service life of a machine table.

Owner:泉州鹏宜机械有限公司

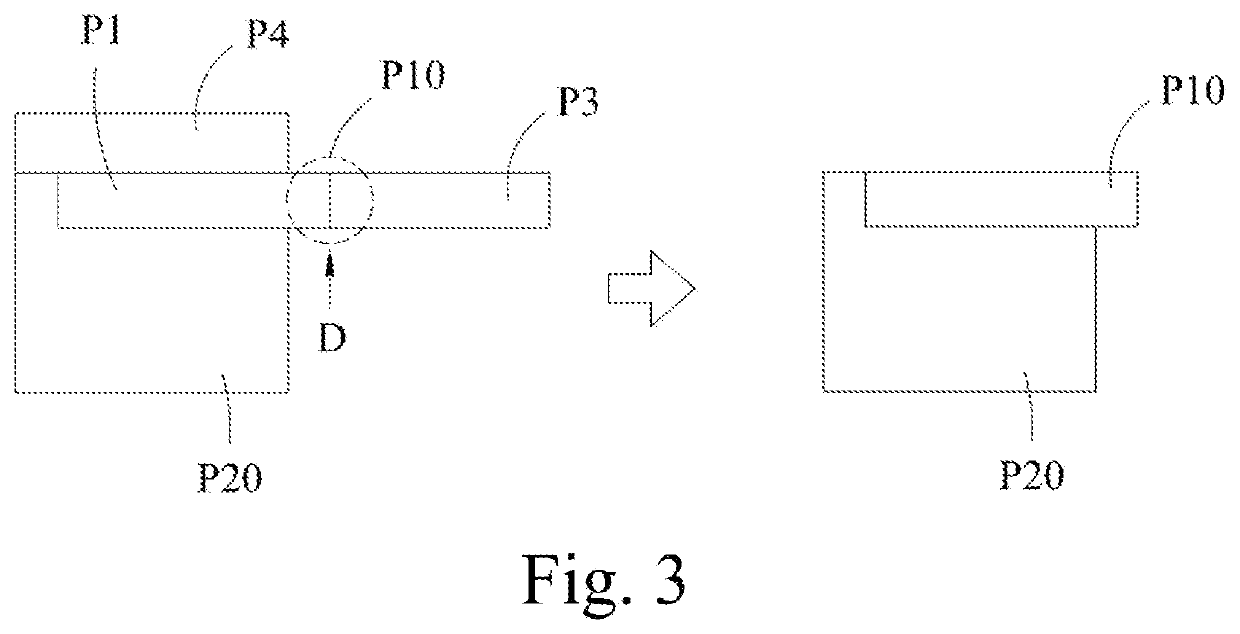

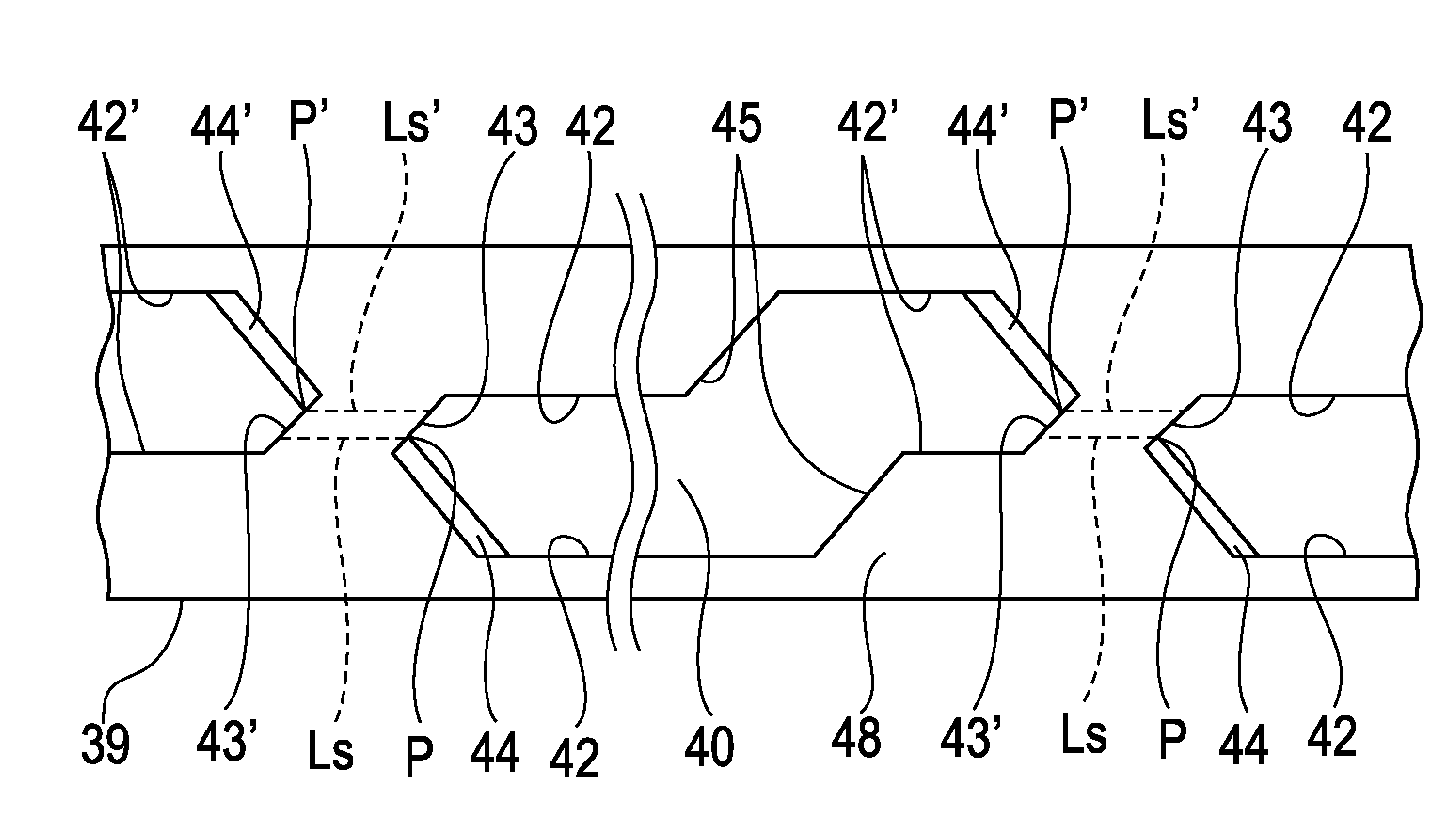

Break pattern of silicon wafer, silicon wafer, and silicon substrate

ActiveUS8502354B2Stable cuttingCut more accuratelySemiconductor/solid-state device detailsSolid-state devicesMechanical engineeringSilicon

A break pattern of a silicon wafer includes a line to be cut which is set in the silicon wafer assuming a surface as a (110) face in a surface direction of a first (111) face perpendicular to the (110) face; and through holes which are provided in a plurality of rows on the line to be cut, wherein each of the through holes has a first (111) face, a second (111) face which intersects the first (111) face, and a third (111) face which intersects the second (111) face and the first (111) face, an intersecting point with end edges of the second (111) face and the third (111) face is assumed as a point closest to the adjacent through holes.

Owner:SEIKO EPSON CORP

Broken-ring eight-treasure porridge zip-top can opening device opened according to lever principle and using method

InactiveCN113184780AIncrease distanceEasy to fixBottle/container closurePower operated devicesCarbonated drinkMechanical engineering

Owner:郭振刚

An aluminum material cutting machine that protects the motor and cuts material stably

ActiveCN111687491BStable cuttingReduce vibrationFeeding apparatusMaintainance and safety accessoriesGear driveCrank

The invention relates to the technical field of metal processing, and discloses an aluminum material cutting machine that protects the motor from cutting material stably. , the top of the foot column is fixedly connected with a chain group, and two transmission gears are meshed at both ends of the chain group, and a telescopic gear is meshed between the two transmission gears inside the chain group, and the telescopic gear wheel Teeth are slidably connected to the tops of the teeth, and the front of the bottom plate is fixedly connected with a range-adjusting rod group, and the end of the distance-adjusting rod group is fixedly connected with a rocker. The aluminum material cutting machine that protects the motor and cuts materials stably, drives the transmission gear to rotate through the motor, and the transmission gear drives the telescopic gear to rotate through the chain, and then drives the cutting knife to rotate and cut aluminum materials, so that through the transmission of the chain, the cutting knife generated when working The vibration is buffered to the minimum, which reduces the vibration of the motor and prolongs the service life of the motor.

Owner:浙江先川工贸有限公司

Cutting method of batch broad beans

InactiveCN107097267BAvoid harmImprove processing efficiencyMetal working apparatusFood treatmentReciprocating motionProcess engineering

This patent discloses a processing method of broad beans, the steps are as follows: (1) preparation: use a cutting device for broad beans; (2) selection: pick out broad beans with uniform particles; (3) soak beans: soak broad beans in clear water (4) drying: drying the soaked broad beans; (5) adding edible oil: adding edible oil into the frying box; (6) putting into the processing box: putting the dried broad beans into the processing box, and the broad beans are Guided by the side wall of the processing box, it moves to the through hole of the soft layer; (7) Cutting: start the rotating motor to drive the cam to rotate, the cam squeezes the extrusion plate intermittently and drives the extrusion column to move vertically under the action of the pressure spring. Do reciprocating motion in the direction, the cutter not only completes the cutting of the broad beans, but also squeezes the broad beans from the through hole and falls into the frying box; (8) Frying: start the heater, use the heater to heat the food in the frying box Oil fried broad beans. This solution mainly solves the problems of low efficiency and easy cutting of hands in the traditional broad bean cutting process.

Owner:CHONGQING ZHOUYI FOOD CO LTD

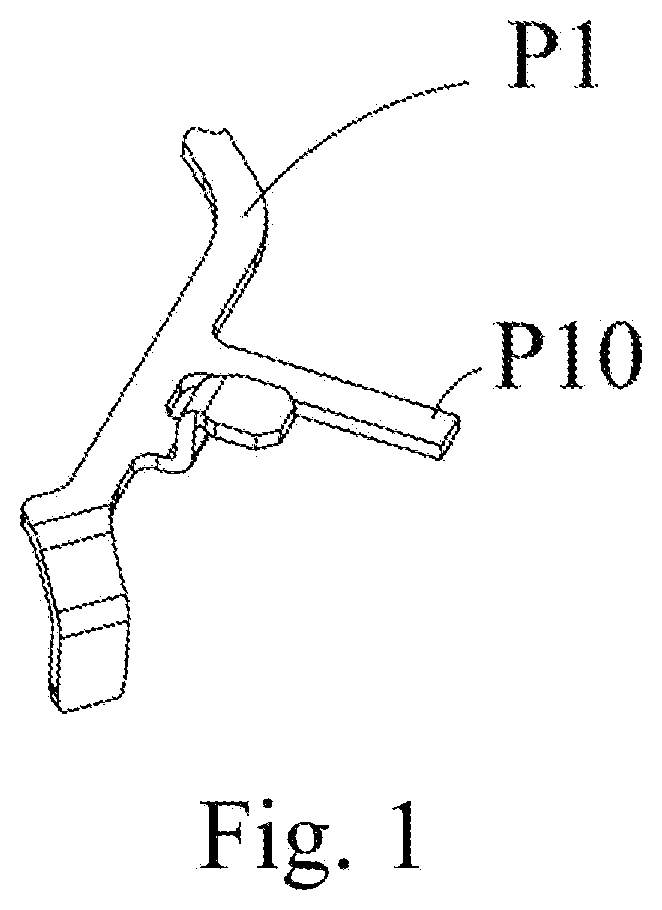

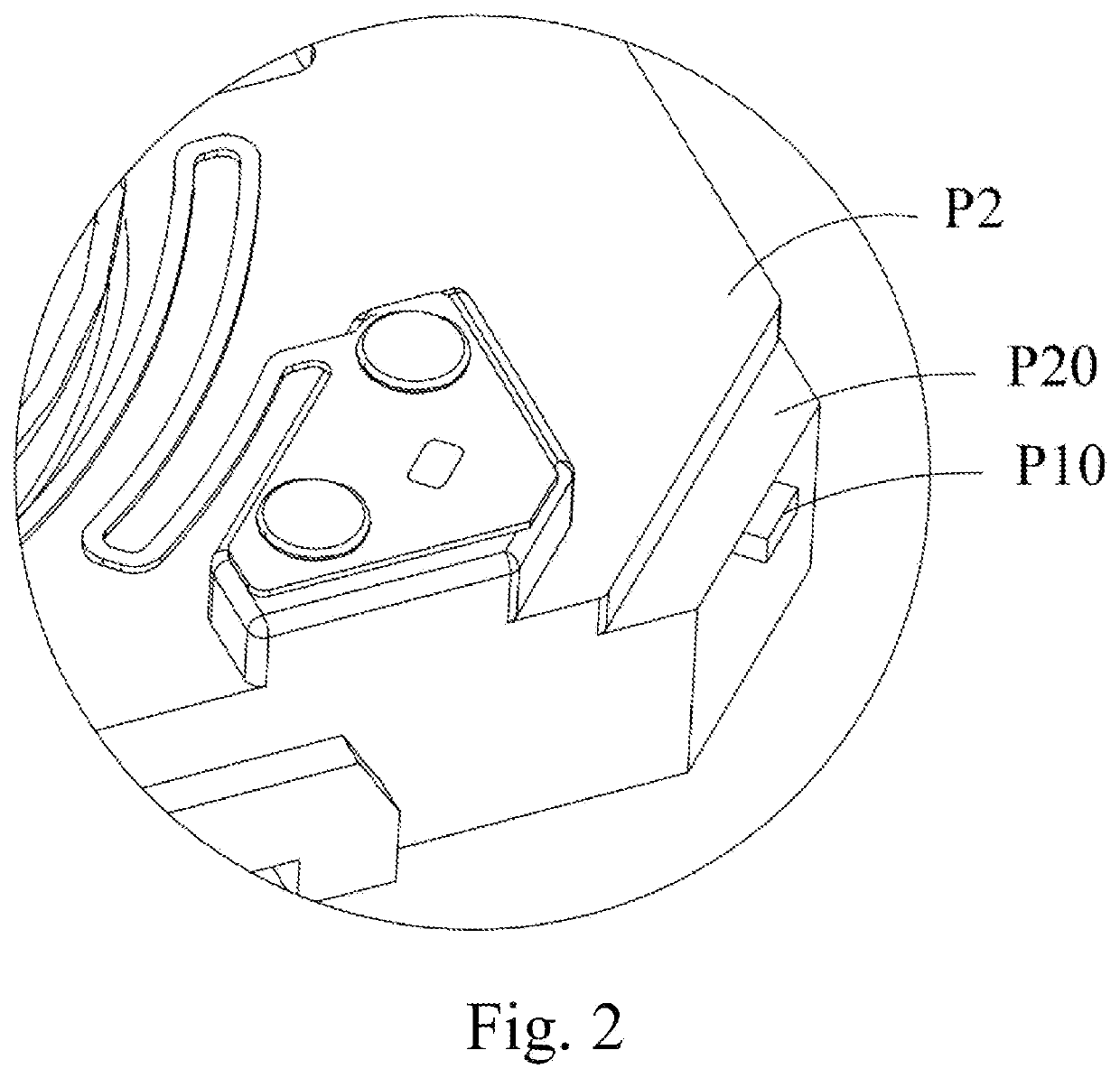

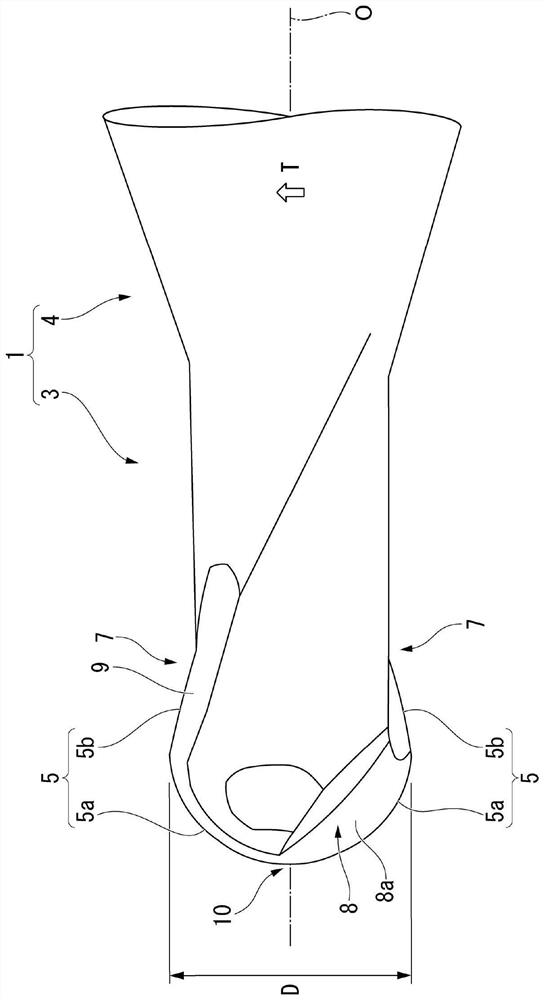

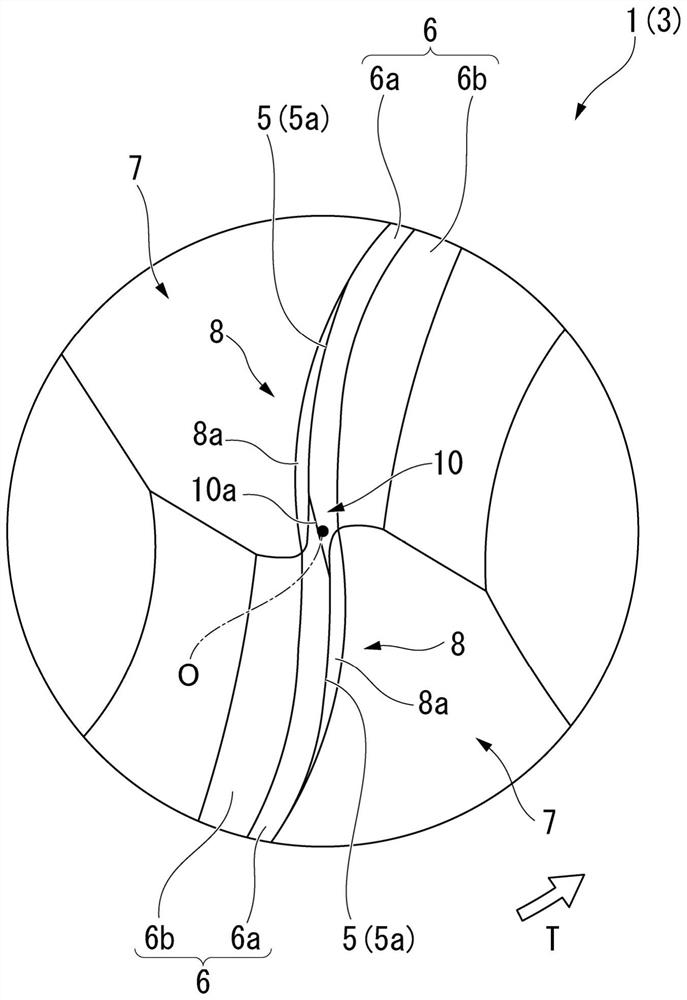

Ball end mill

ActiveCN114728352APrevent chipping and chippingStable cuttingMilling cuttersWorkpiecesStructural engineeringManufacturing engineering

An end mill is provided with: an end mill main body having a convex hemispherical end cutting edge (5a); and a hard coating film covering at least the surface of the tip of the end mill main body (1). The end cutting edge (5a) has a diameter D (mm) of 2 mm or less. The ratio W / D of the width W (mm) to the diameter D (mm) of the chisel edge part (10) is within the range of 0.020-0.060. The ratio L / D of the offset amount L (mm) to the diameter D (mm) between the chip grooves (7) is within the range of 0.014-0.090. The rake angle of the end cutting edge (5a) within the range in which the chisel edge (10a) is formed in the chisel edge part (10) is within the range of-15 DEG to-30 DEG.

Owner:MOLDINO TOOL ENG LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com