Extrusion molding apparatus and extrusion molding method

A technology of extrusion molding and extrusion direction, which is used in ceramic molding machines, material molding presses, presses, etc., can solve problems such as complexity and reduce efficiency, and achieve the effect of reducing deformation force and preventing deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

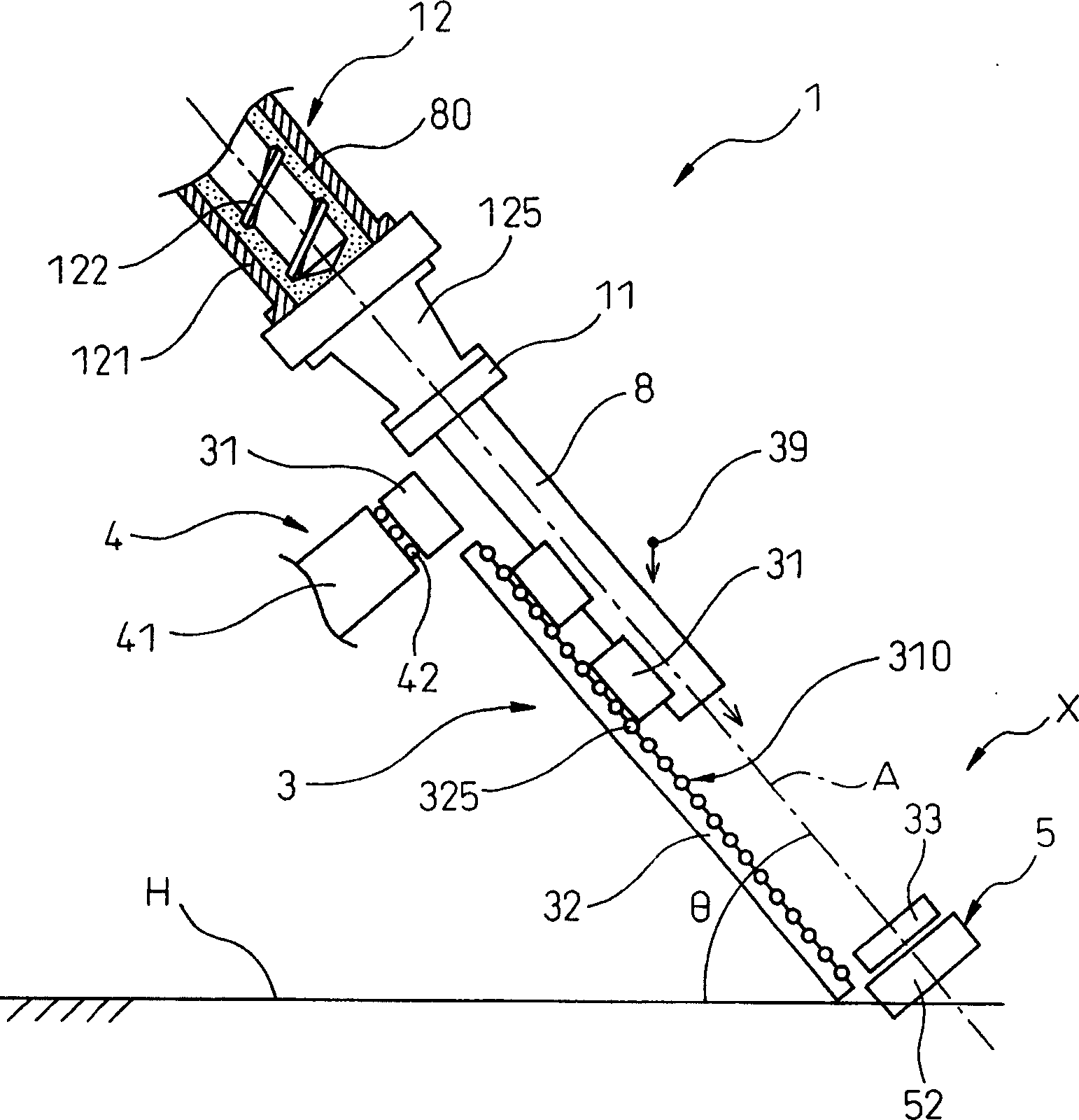

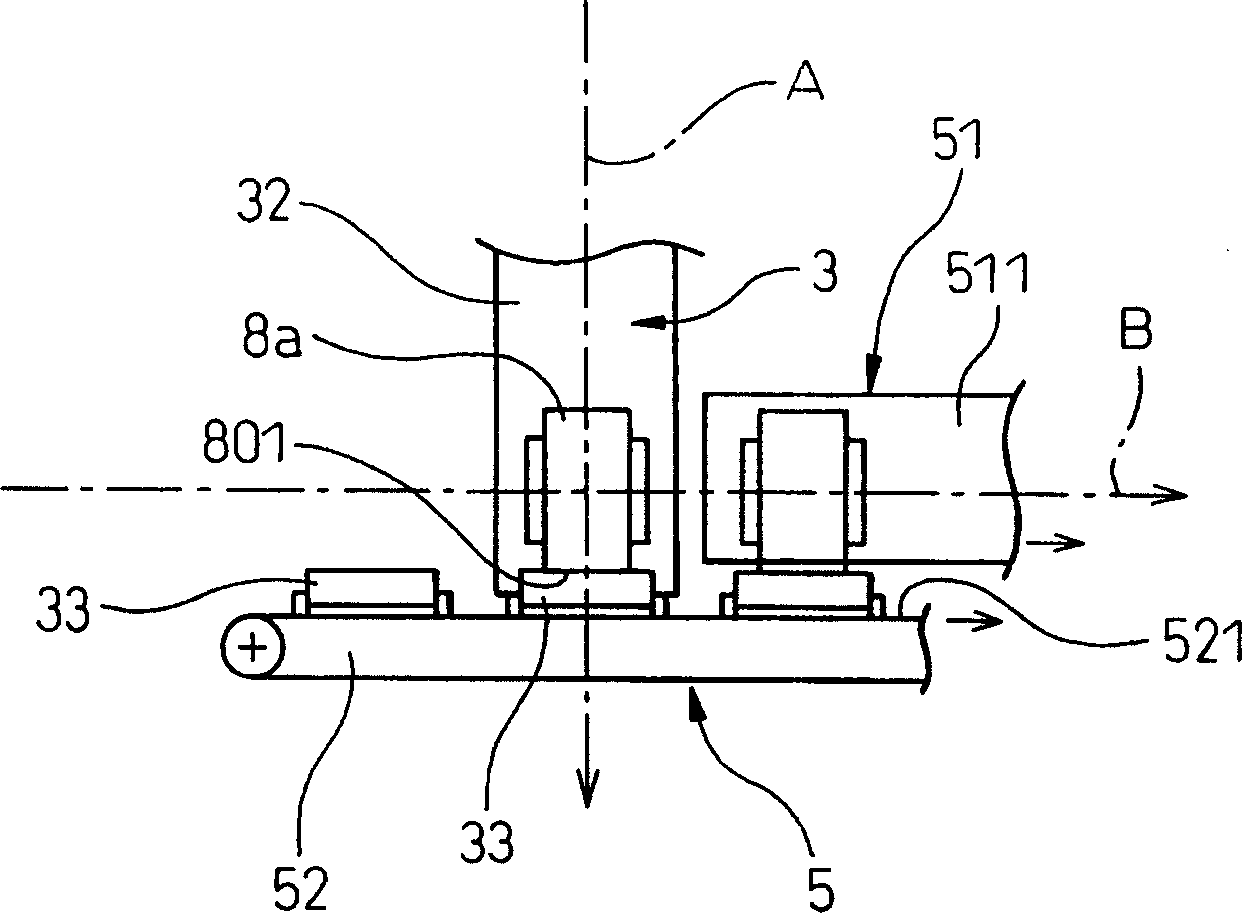

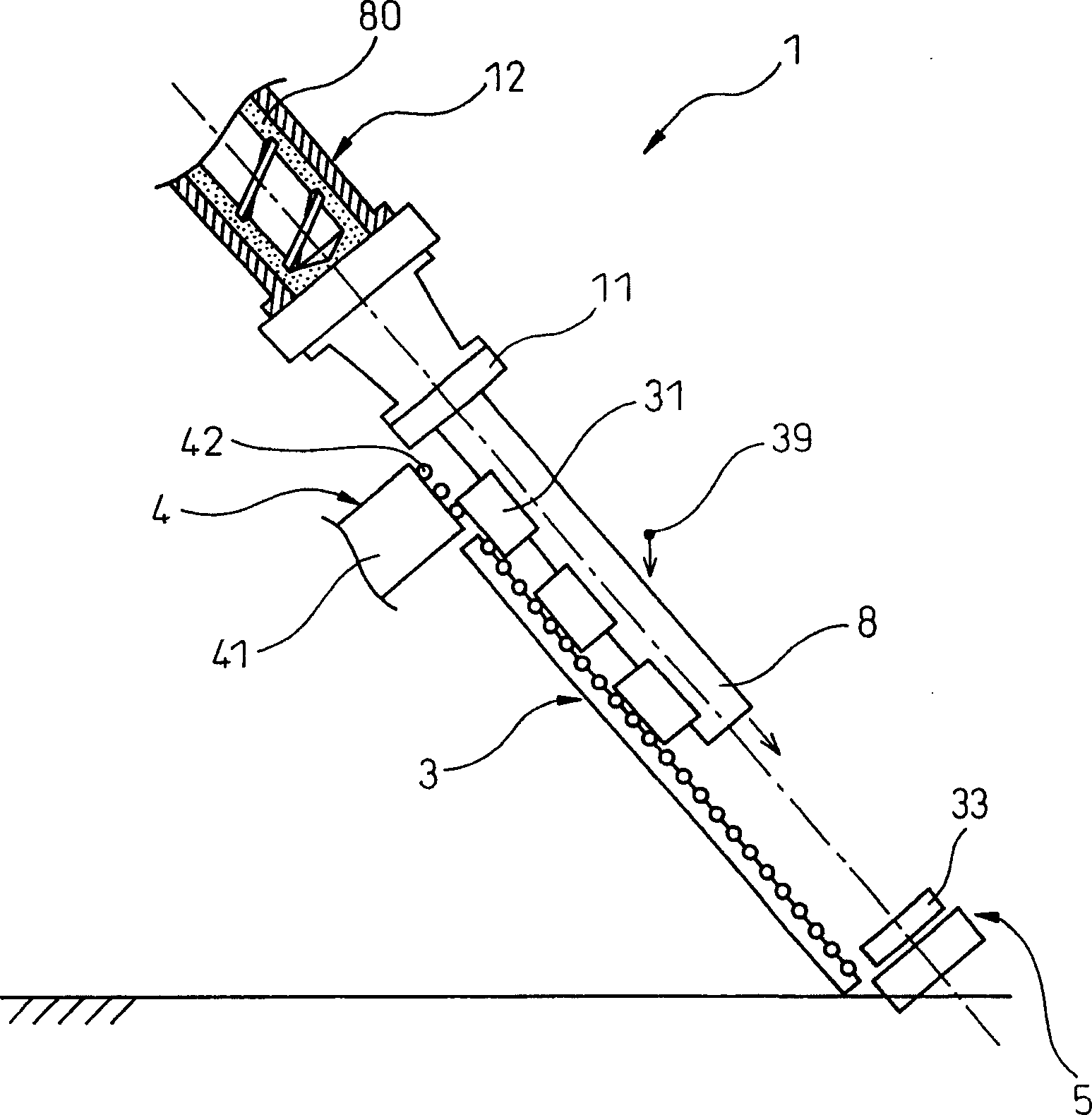

[0048] see Figures 1 to 5 , the extrusion molding device and extrusion molding method according to the embodiments of the present invention will be described in detail below.

[0049] Such as figure 1 As shown, the extrusion molding device 1 of the present embodiment includes a screw extruder 12 and a conveying device 3; The conveying device 3 supports the extruded molded body 8 continuously extruded from the screw extruder 12, and conveys the extruded molded body 8 along the extrusion direction.

[0050] The screw extruder 12 has an inclination angle θ between the extrusion axis A and the horizontal axis H, which ranges from 15° to 85°. The conveying device 3 is configured such that in a direction substantially parallel to the extrusion axis A, the receiving table 31 which supports the extruded material extruded along the extrusion axis A on the outer peripheral surface (of the extrusion molded body 8 ) is moved. Molded body 8.

[0051] This will be explained in more de...

Embodiment 2

[0074] In this example, if Figure 6 As shown, the structure of the conveying device 3 is modified from the extrusion molding device 1 in Example 1.

[0075] Therefore, the conveying device 6 of this embodiment adopts belt conveyors 61 and 62 instead of the above-mentioned conveyor 32 composed of roller conveyors. Each belt conveyor 61 , 62 has a conveying surface 611 , 621 respectively, each intended to accommodate a receiving table 31 arranged substantially horizontally to the axis A of extrusion. A plurality of stoppers 612, 622 are provided on the conveying surfaces 611, 612 by which the receiving table 31 is supported on its front end face in the direction of movement; and the stoppers are constructed such that the continuous supply to the conveyor The receiving table 31 can be continuously supported by the stoppers 612, 622 and can move forward.

[0076] The belt conveyor 61 on the upstream side and the belt conveyor 62 on the downstream side are configured to change t...

Embodiment 3

[0079] In this example, if Figure 7 and 8 As shown, the structure of the delivery device 3 in Embodiment 1 is changed.

[0080] Therefore, the conveying device 7 of the present embodiment employs the conveyer 71 having the turner 75 attached at the lowest stage instead of the conveyer 32 including the simple roller conveyer as described above.

[0081] The turner 75 has an L-shaped cross-section and the first surface 751 and the second surface 752 are arranged approximately perpendicular to each other, and the turner 75 is configured to be rotatable between the following two positions, that is, the first position refers to The delivery working surface of the first surface 751 is parallel to the extrusion axis A (such as Figure 7 shown), the second position refers to that the second surface 752 is horizontal (as Figure 8 shown).

[0082] In the present embodiment, a secondary conveying device 76 having a conveying direction C in the horizontal direction is connected down...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com