Automatic rubber tapping machine and control method thereof

A glue machine and automatic technology, applied in agriculture, forestry, application, etc., can solve the problems of less hang-up, less installed machines, and impact on production, and achieve the effect of fast rubber tapping, durable cutter heads, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

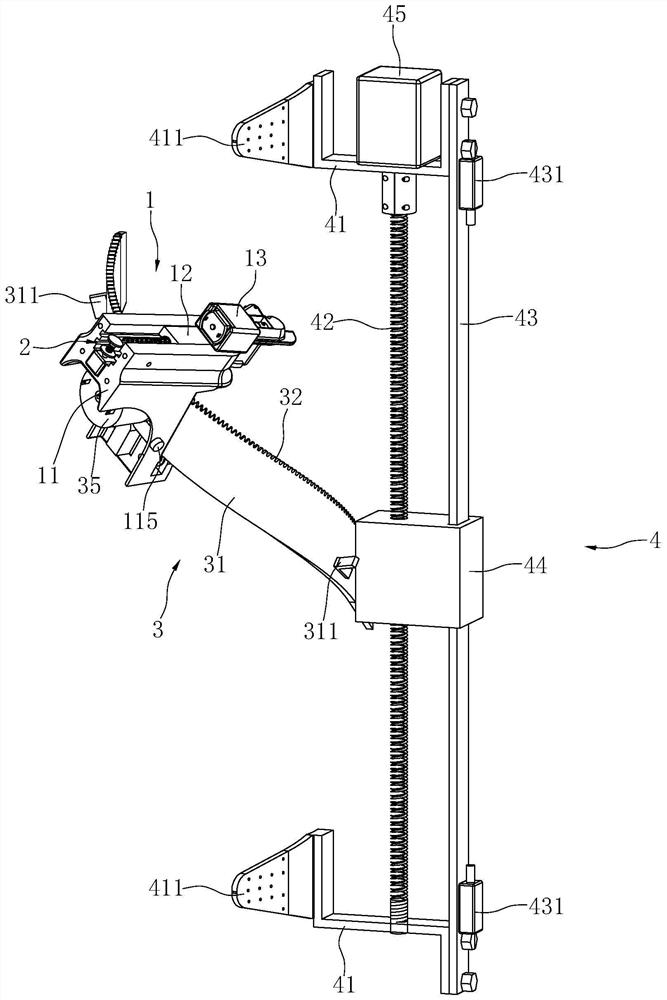

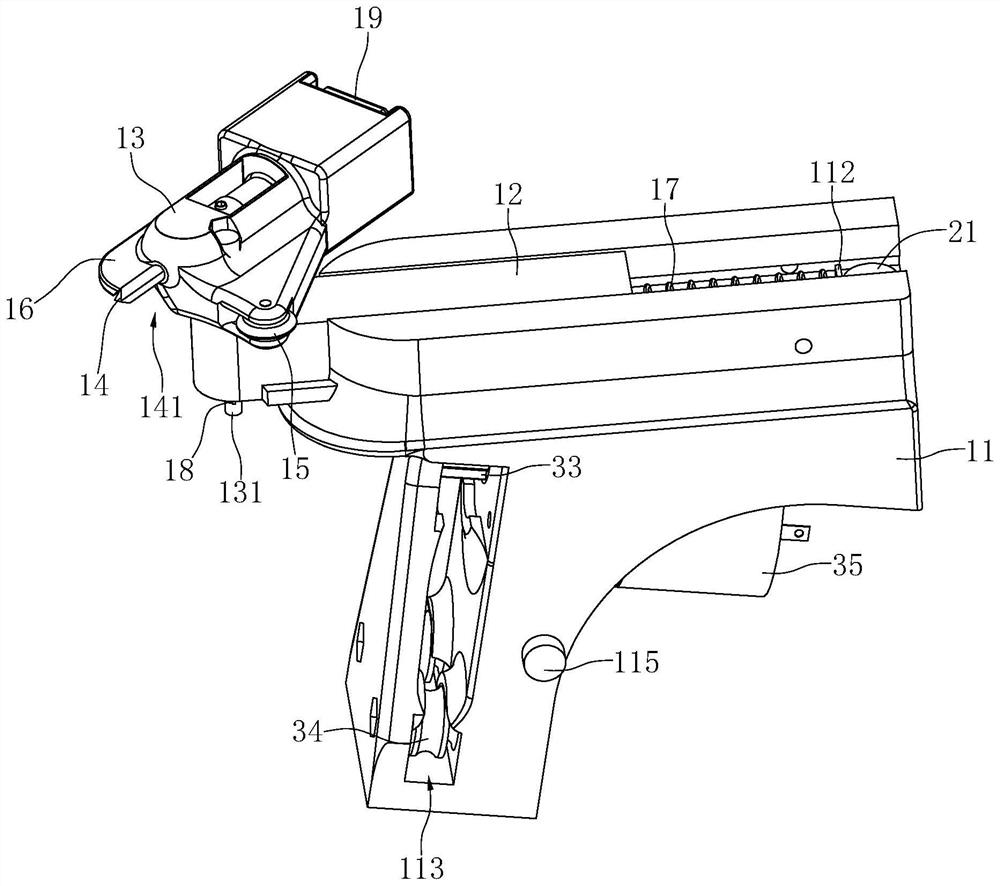

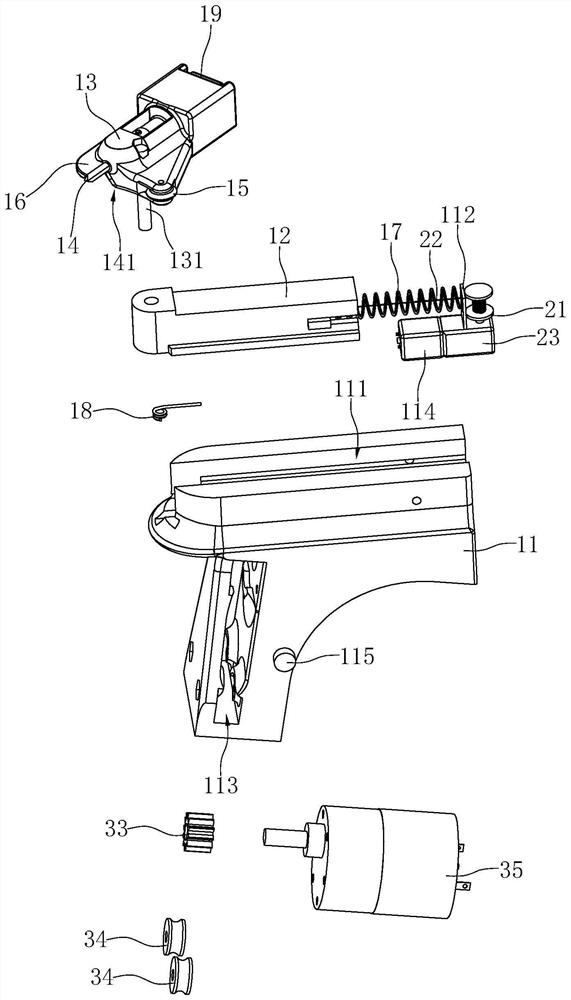

[0060] like Figure 1 to Figure 4 Shown is a preferred embodiment of the automatic rubber tapping machine of the present invention. The automatic rubber tapping machine includes a cutter assembly 1, a limit assembly 2, a first drive mechanism 3 and a second drive mechanism 4, the cutter assembly 1 is used to cut the rubber tree, and the first drive mechanism 3 is used to drive the cutter assembly 1 to spiral around the rubber tree shape rotation, the second drive mechanism 4 is used to drive the cutter assembly 1 up and down. The whole machine adopts a modular combination method so that all parts can be quickly disassembled, and the problematic parts can be quickly replaced to reduce the time for disassembly and maintenance.

[0061] Wherein, the cutter assembly 1 includes a cutter holder 11, a sliding arm 12, a rotating seat 13, a cutter he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com