printer

A technology of printers and fixed blades, applied in printing devices, printing, etc., can solve the problems of knife jamming and cannot prevent knife jamming, and achieve the effect of preventing collision and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

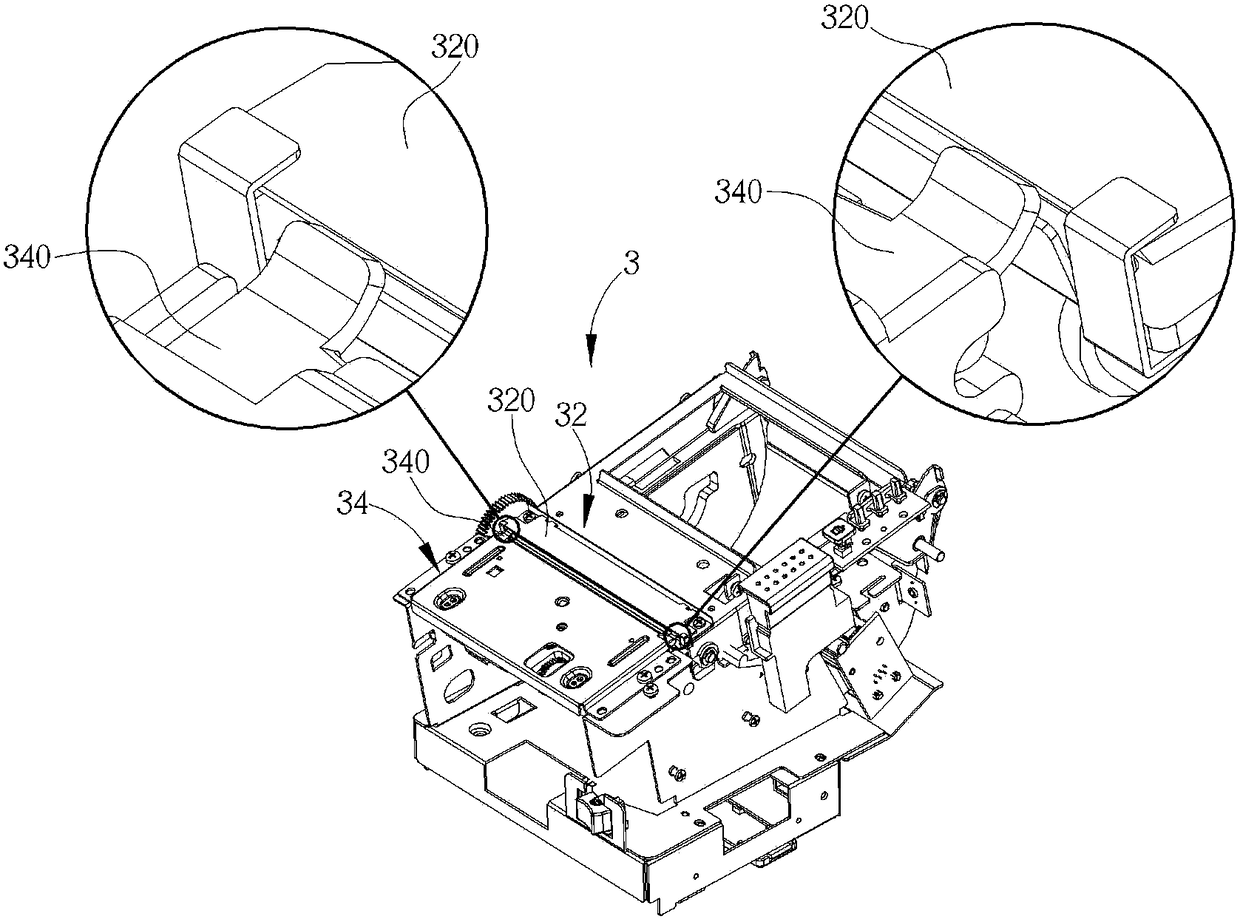

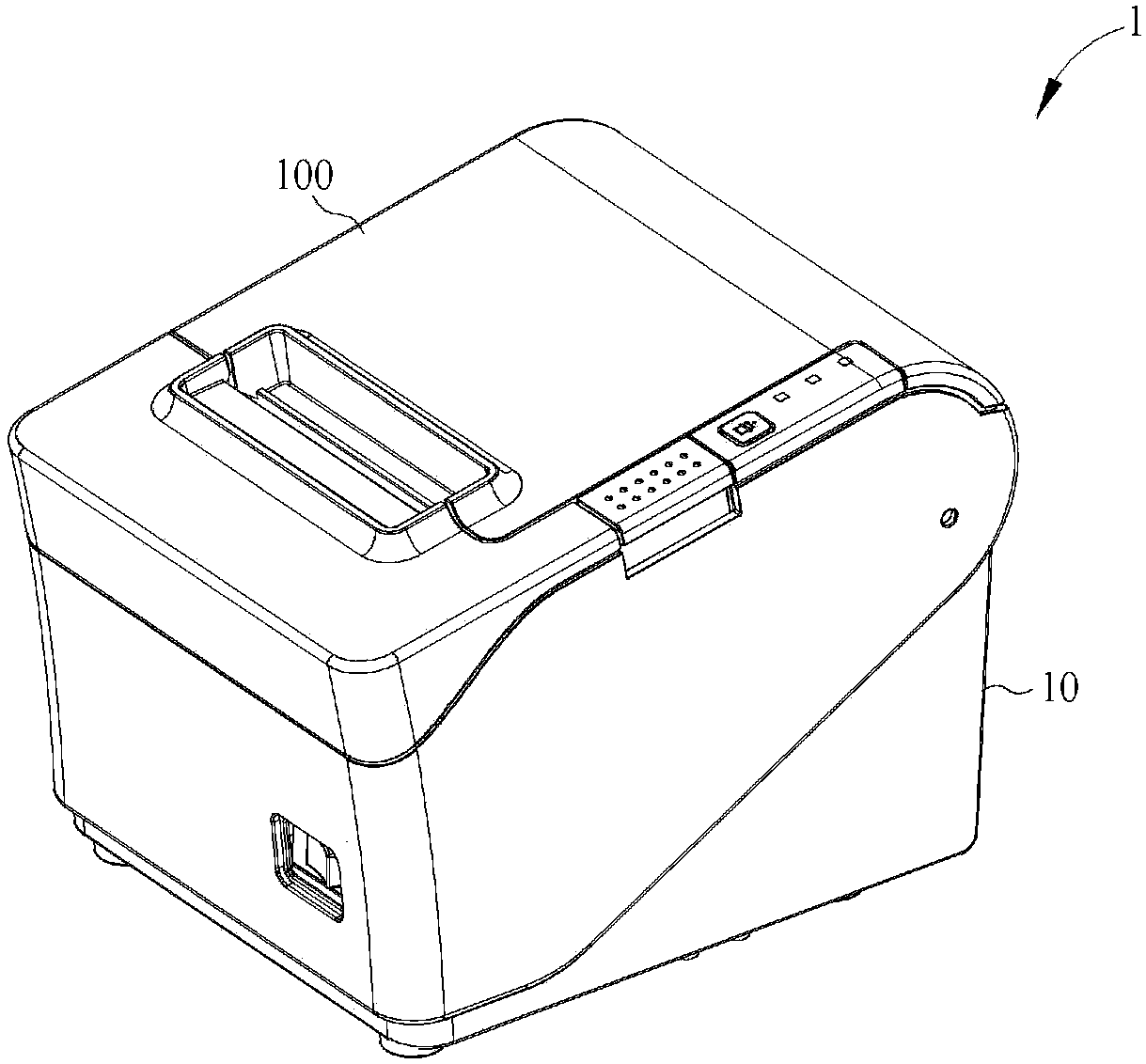

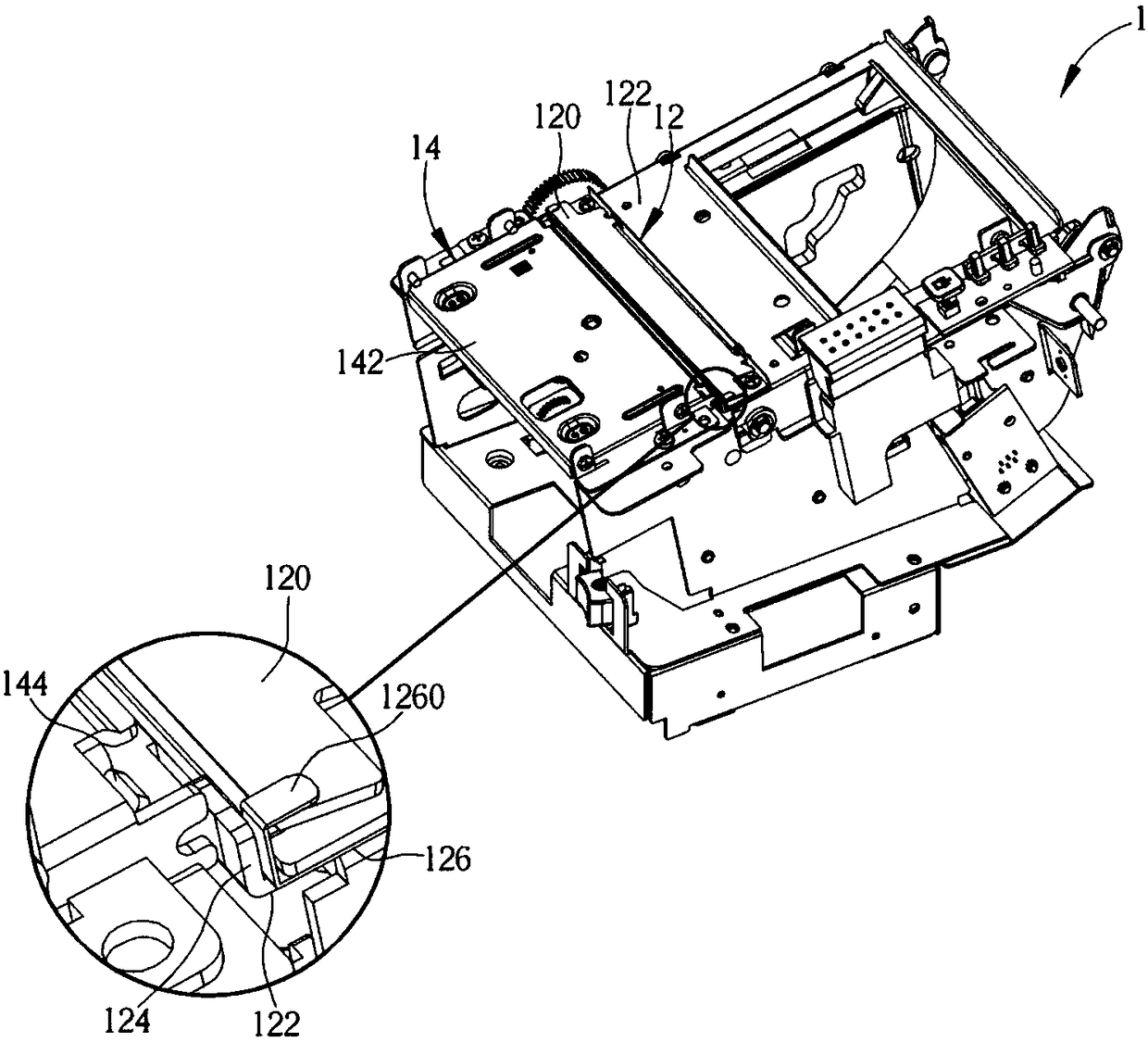

[0026] see Figure 2 to Figure 8 , figure 2 It is a schematic diagram of the appearance of the printer 1 according to an embodiment of the present invention, image 3 for figure 2 The internal schematic of the printer 1 in, Figure 4 for image 3 The exploded schematic diagram of the second bracket 142 in Figure 5 for Figure 4 Partial side view of printer 1 in, Figure 6 for Figure 5 A schematic diagram of the moving blade 140 moving towards the fixed blade 120 in Figure 7 for figure 2 The schematic diagram after the upper cover 100 is opened in Figure 8 for figure 2 Functional block diagram of printer 1 in .

[0027] Such as Figure 2 to Figure 7 As shown, the printer 1 includes a housing 10 , a fixed knife set 12 and a movable knife set 14 . I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com