Gun magazine speed loader and methods

a technology of speed loader and gun magazine, which is applied in the field of improved gun magazine speed loader, can solve the problems of cartridge tumbling and jamming in the magazine, time-consuming and uncomfortable one-by-one cartridge insertion into the gun magazine by hand, and not providing a practical means of placing the cartridge into the magazin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

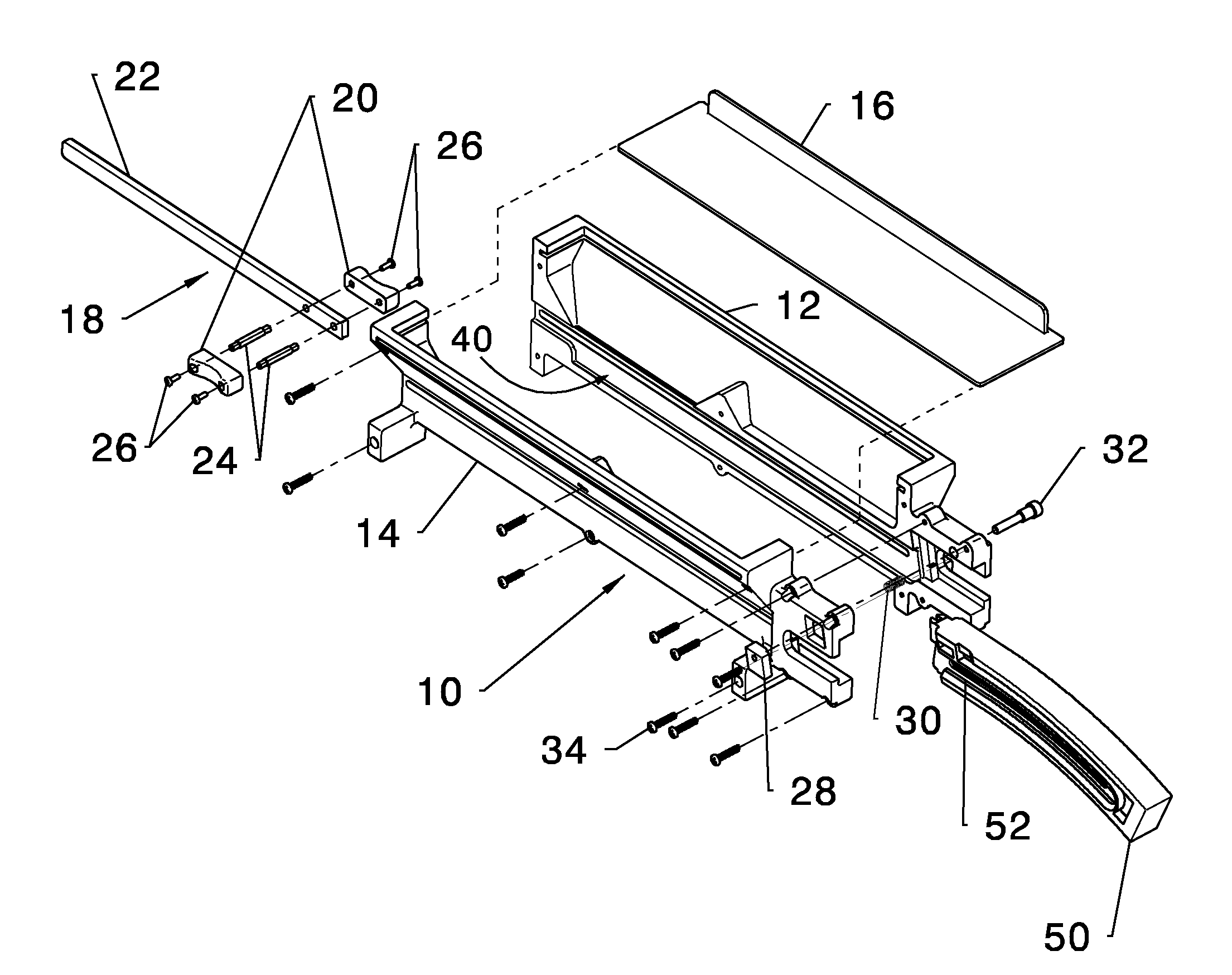

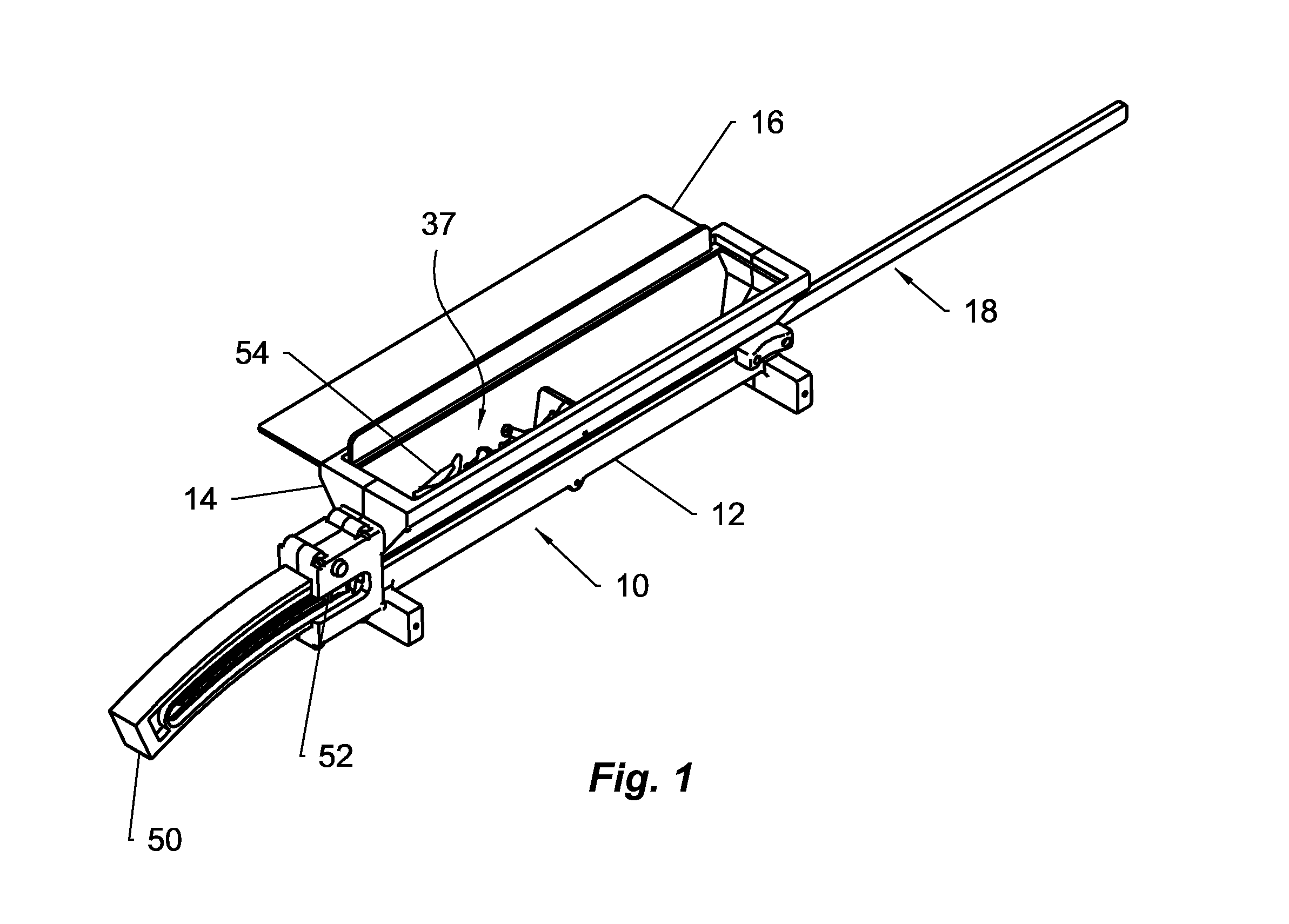

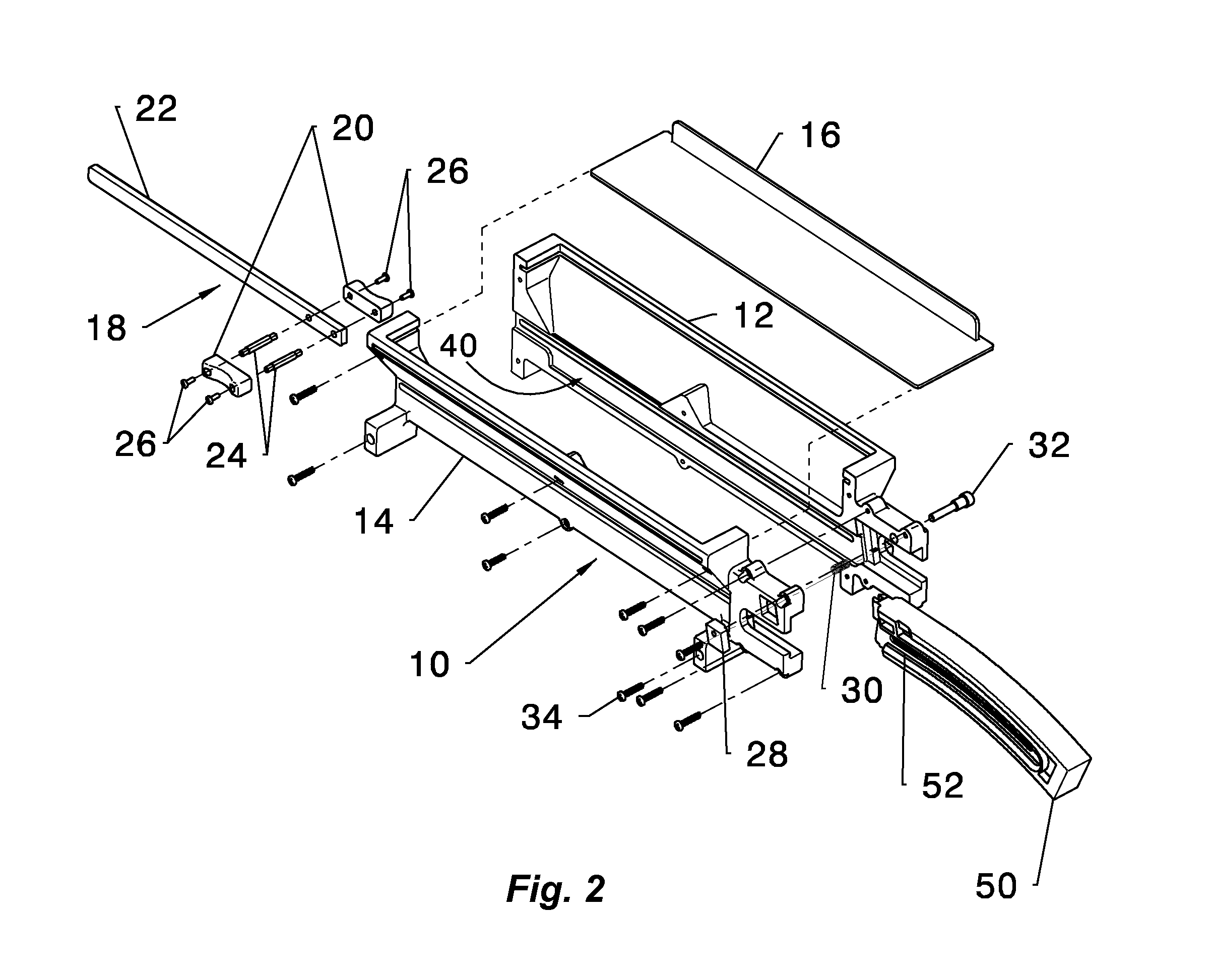

[0060]Speed loaders were designed and made for pistol and rifle magazines. Models tested include the Walther P22 pistol and the GSG MP5 caliber 22LR, GSG AK-47 caliber 22LR, Umarex HK416 caliber 22LR, Umarex MP5 caliber 22LR, Umarex Colt M4 caliber 22LR, Umarex Uzi caliber 22LR, Smith & Wesson MP15-22 caliber 22LR rifles. Operating characteristics are as described for the preferred embodiment below. These magazines have in common an external follower and are built for rimmed cartridges.

[0061]Other pistols for which a speed loader of the invention may be developed include the Ruger SR22, Smith & Wesson MRP-22, Sig Mosquito, ISSC MK22 pistols and the Remington 522 caliber 22LR and ISSC MK22 caliber 22LR rifles.

[0062]Regarding cartridge types, caliber is not a limiting factor in operation of a magazine and speed loader. For magazines have an external follower, a partial list of ammunition calibers includes the following types—1. Rifle cartridges: .22 LR, .22 Short, .17 Hornady Mach 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com