A kind of electret ultrafine fiber cigarette filter material and preparation method thereof

A superfine fiber and electret technology, applied in the direction of e-liquid filter, fiber chemical characteristics, tobacco, etc., can solve the problem of low filtration efficiency of cigarette filter materials, and achieve high electrostatic adsorption performance, fiber strength improvement, and high filtration effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method of an electret superfine fiber cigarette filter material, specifically comprising the following steps:

[0028] Step S1, uniformly mixing 94-99 parts by weight of thermoplastic material and 1-6 parts by weight of electret masterbatch to obtain a mixture;

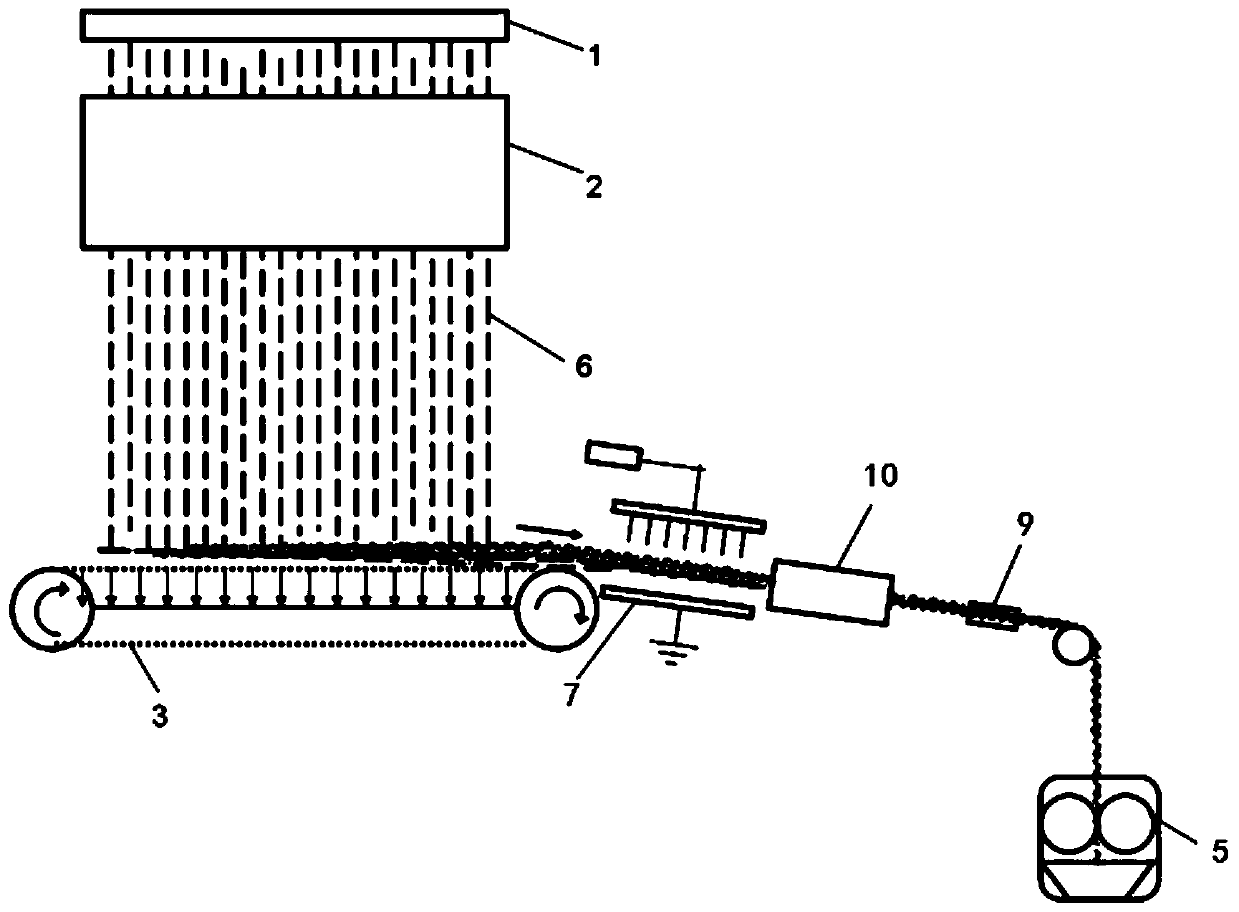

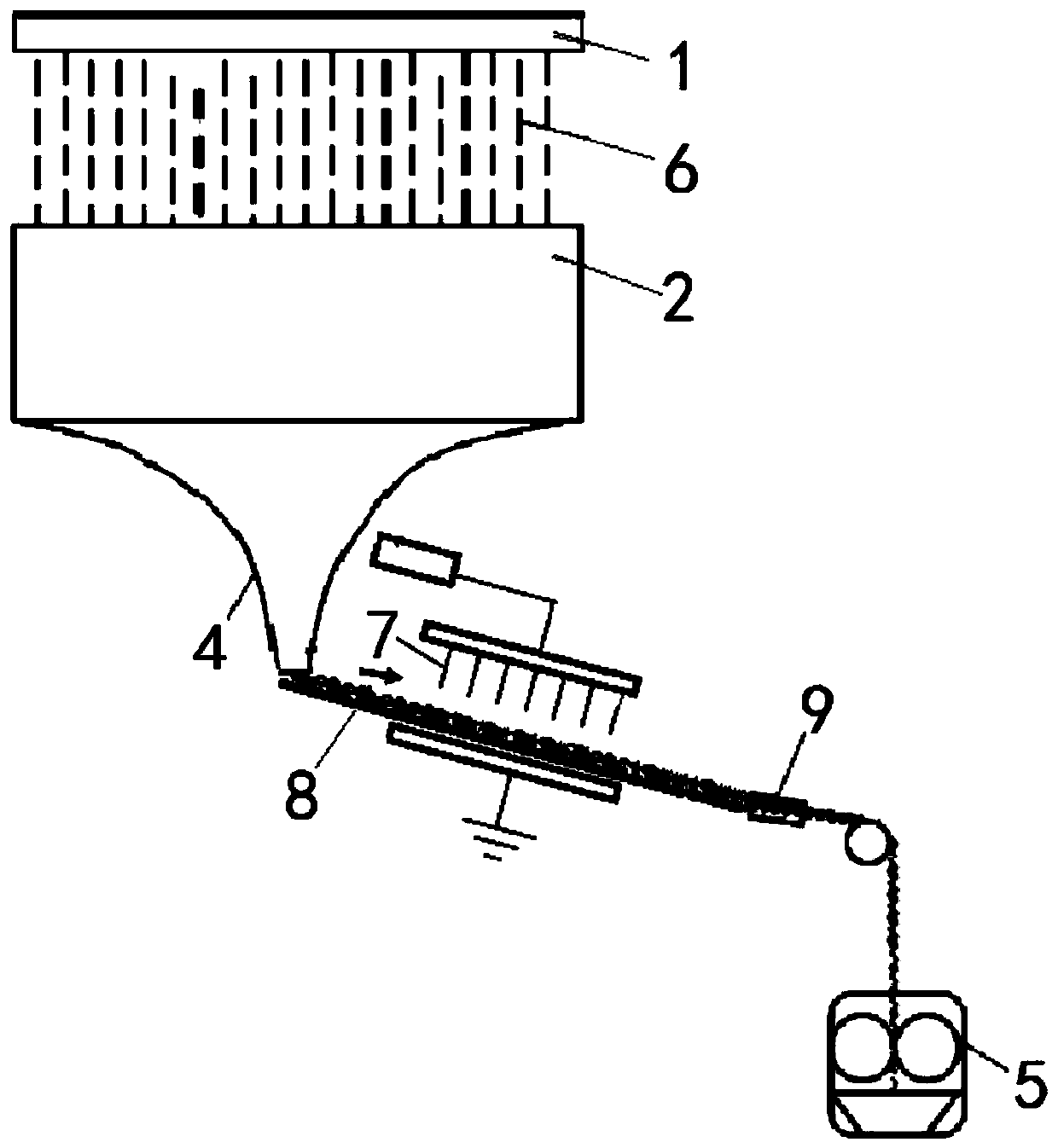

[0029] Step S2, the melt-blown device 1 prepares melt-blown ultrafine fibers 6 using the mixture;

[0030] Step S3, the cooling and bundling device cools and bundles the melt-blown ultrafine fibers 6 ejected from the melt-blown device 1;

[0031] Step S4, the collection device 5 processes and collects the melt-blown ultrafine fibers 6 to obtain electret ultrafine fiber cigarette filter materials.

[0032] In the first embodiment of the cooling and clustering device, the cooling and clustering device in the step S3 includes a cold air box 2 and a screen receiving device 3; the step S3 is specifically: the cold air box 3 cools the melt-blown ultrafine fiber 6, The cooled melt-blown ultrafine fiber...

Embodiment 1

[0051] A preparation method of an electret superfine fiber cigarette filter material, comprising the following steps:

[0052] Step S1, taking 96 parts by weight of polypropylene pellets and 4 parts by weight of electret masterbatch and mixing them uniformly to obtain a mixture;

[0053] Step S2, set the temperature of the four areas of the electret ultrafine fiber cigarette filter material preparation device at 260°C, 260°C, 270°C, and 270°C respectively, and feed the mixture obtained in step S1 into the silo of the screw extruder , forming a melt through a screw melt extruder;

[0054] Step S3, the melt is sprayed out through the spinneret after the metering pump, and drawn under 220°C and 0.4MPa hot air to obtain melt-blown ultra-fine fibers. After the melt-blown ultra-fine fibers are cooled, they are bundled with a curtain collection device or a clustering device ;

[0055] Step S4, performing electret treatment on the melt-blown ultrafine fibers obtained in step S3 by m...

Embodiment 2

[0059] Step S1, taking 95 parts by weight of polypropylene pellets and 5 parts by weight of electret masterbatch and mixing evenly to obtain a mixture;

[0060] Step S2, set the temperature of the four areas of the electret ultrafine fiber cigarette filter material preparation device at 260°C, 260°C, 270°C, and 270°C respectively, and feed the mixture obtained in step S1 into the silo of the screw extruder , forming a melt through a screw melt extruder;

[0061] Step S3, the melt is sprayed out through the spinneret after the metering pump, and drawn under 220°C and 0.4MPa hot air to obtain melt-blown ultra-fine fibers. After the melt-blown ultra-fine fibers are cooled, they are bundled with a curtain collection device or a clustering device ;

[0062] Step S4, performing electret treatment on the ultrafine fibers obtained in step S3 by means of high-voltage corona discharge, the electret voltage is 20kV, the electret interval is 20mm, and the electret time is 10s;

[0063] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com