Patents

Literature

43 results about "Grinder pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A grinder pump is a wastewater conveyance device. Waste from water-using household appliances (toilets, bathtubs, washing machines, etc.) flows through the home’s pipes into the grinder pump’s holding tank. Once the wastewater inside the tank reaches a specific level, the pump will turn on, grind the waste into a fine slurry, and pump it to the central sewer system or septic tank.

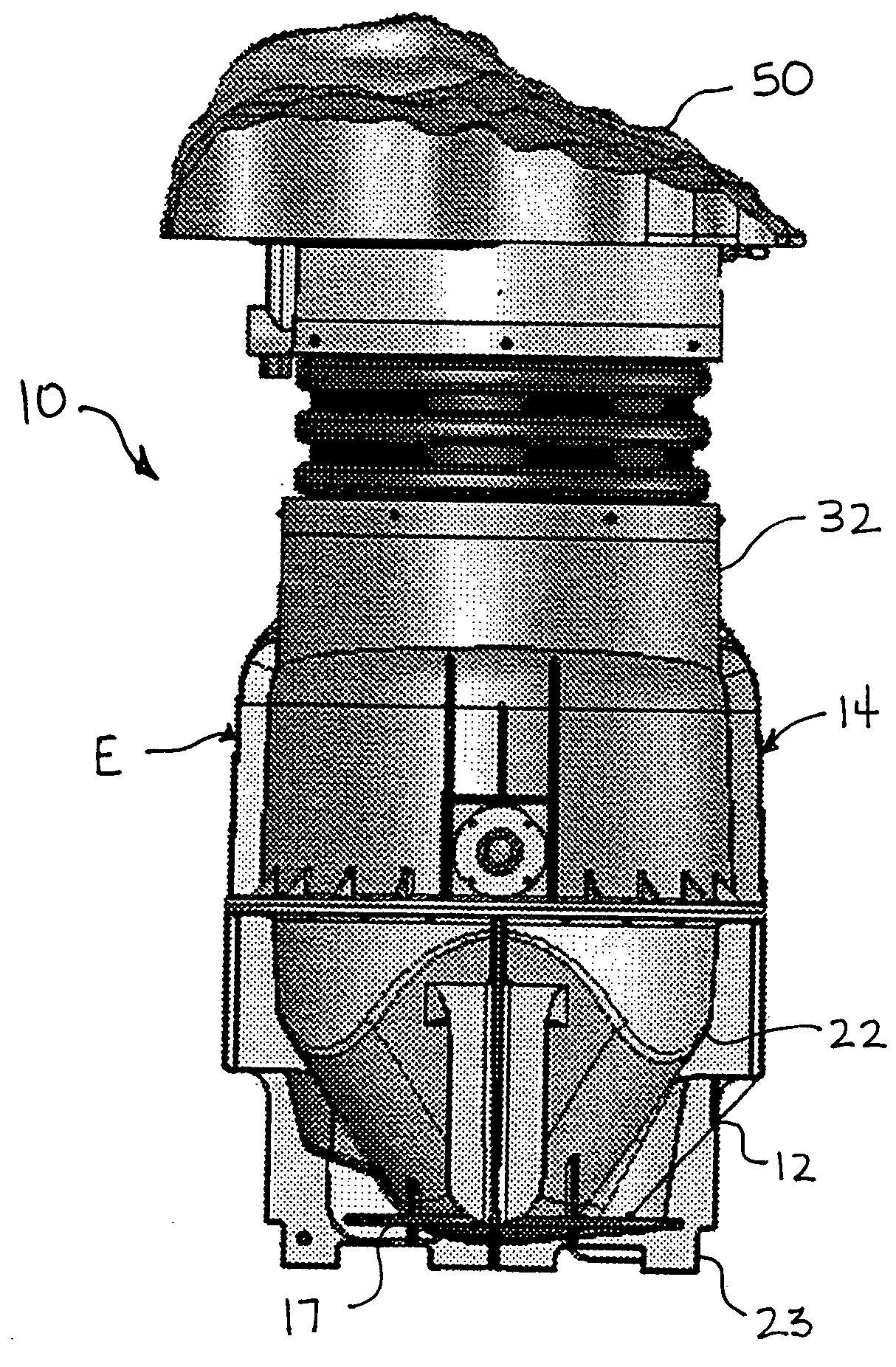

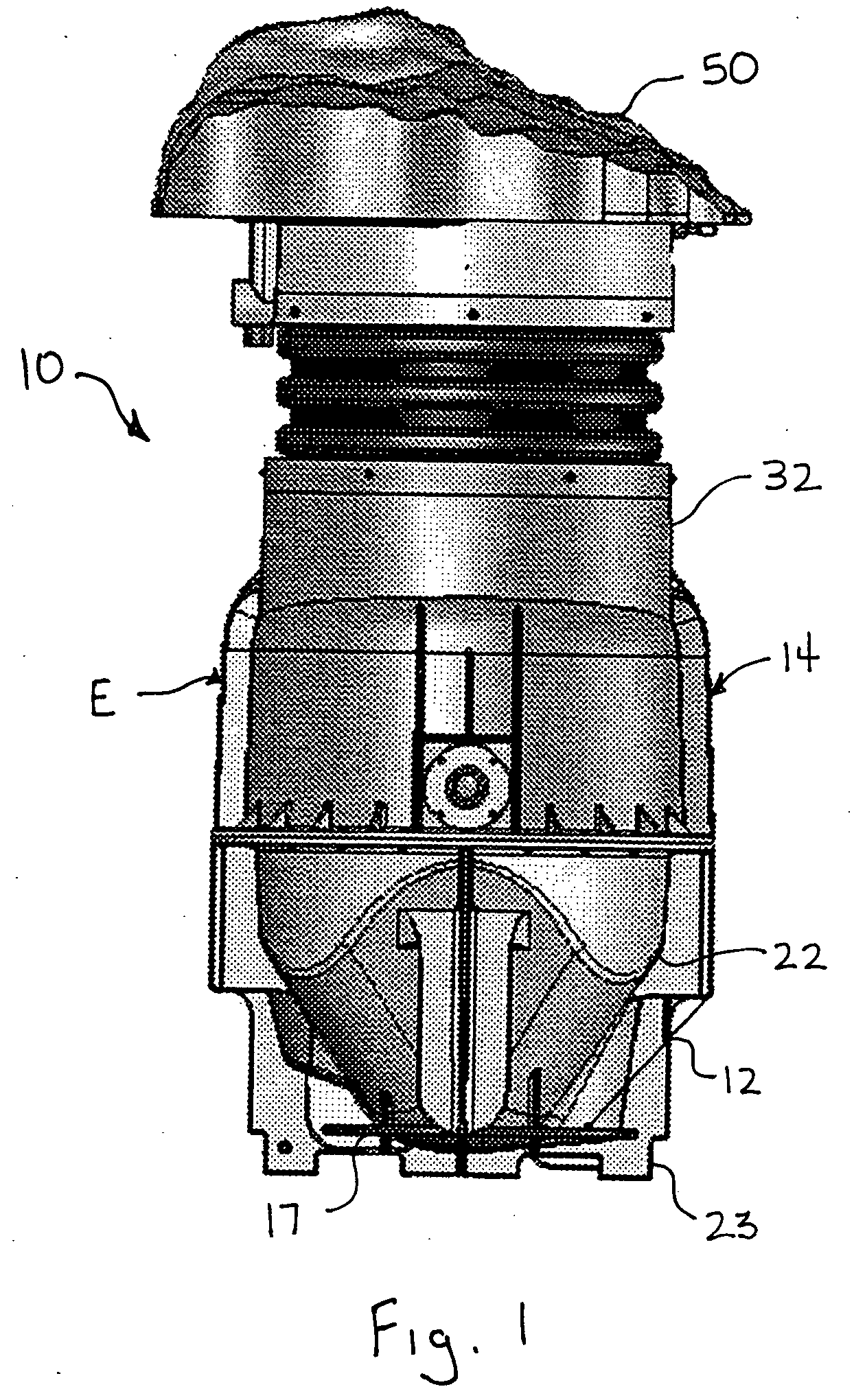

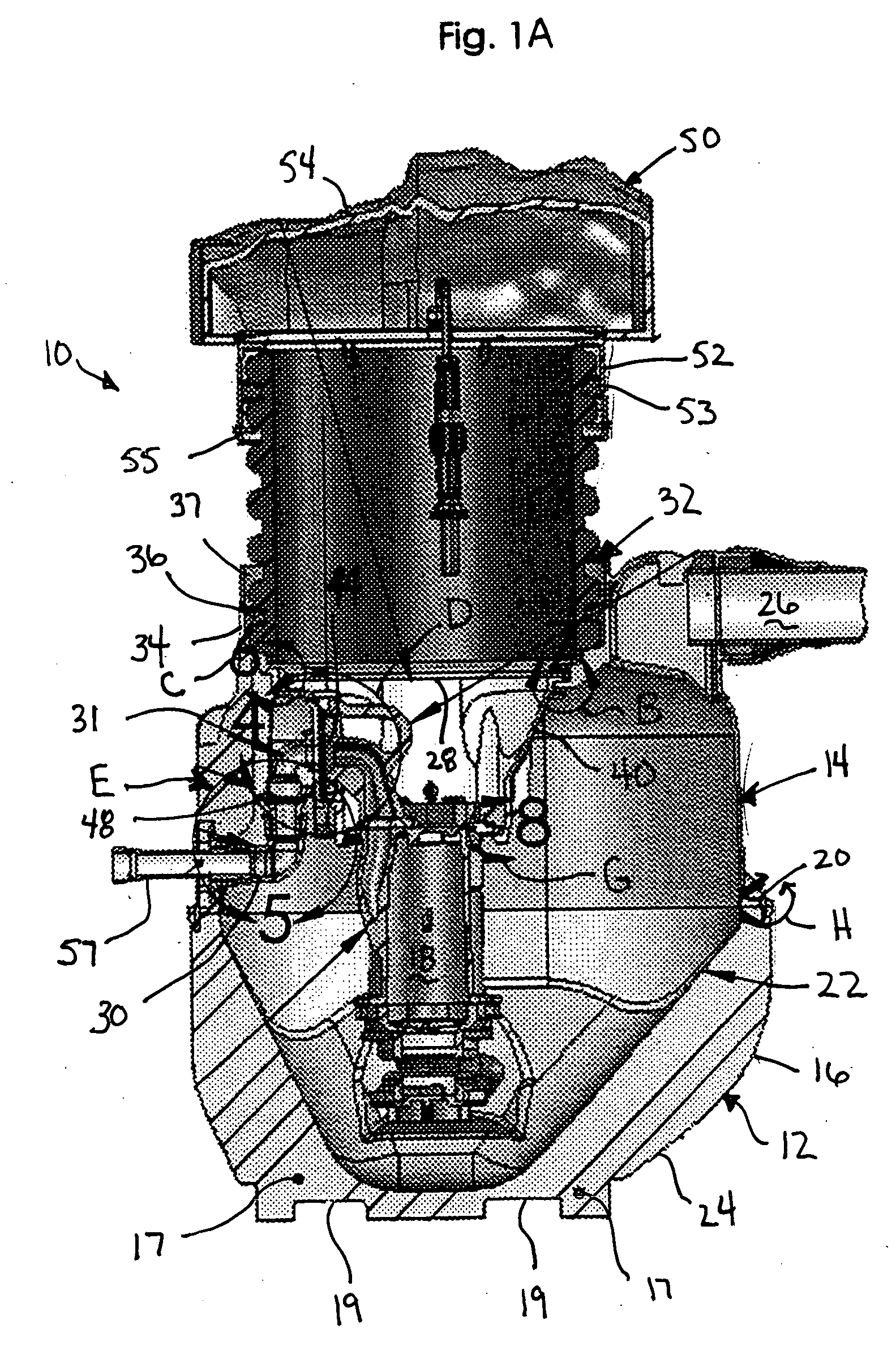

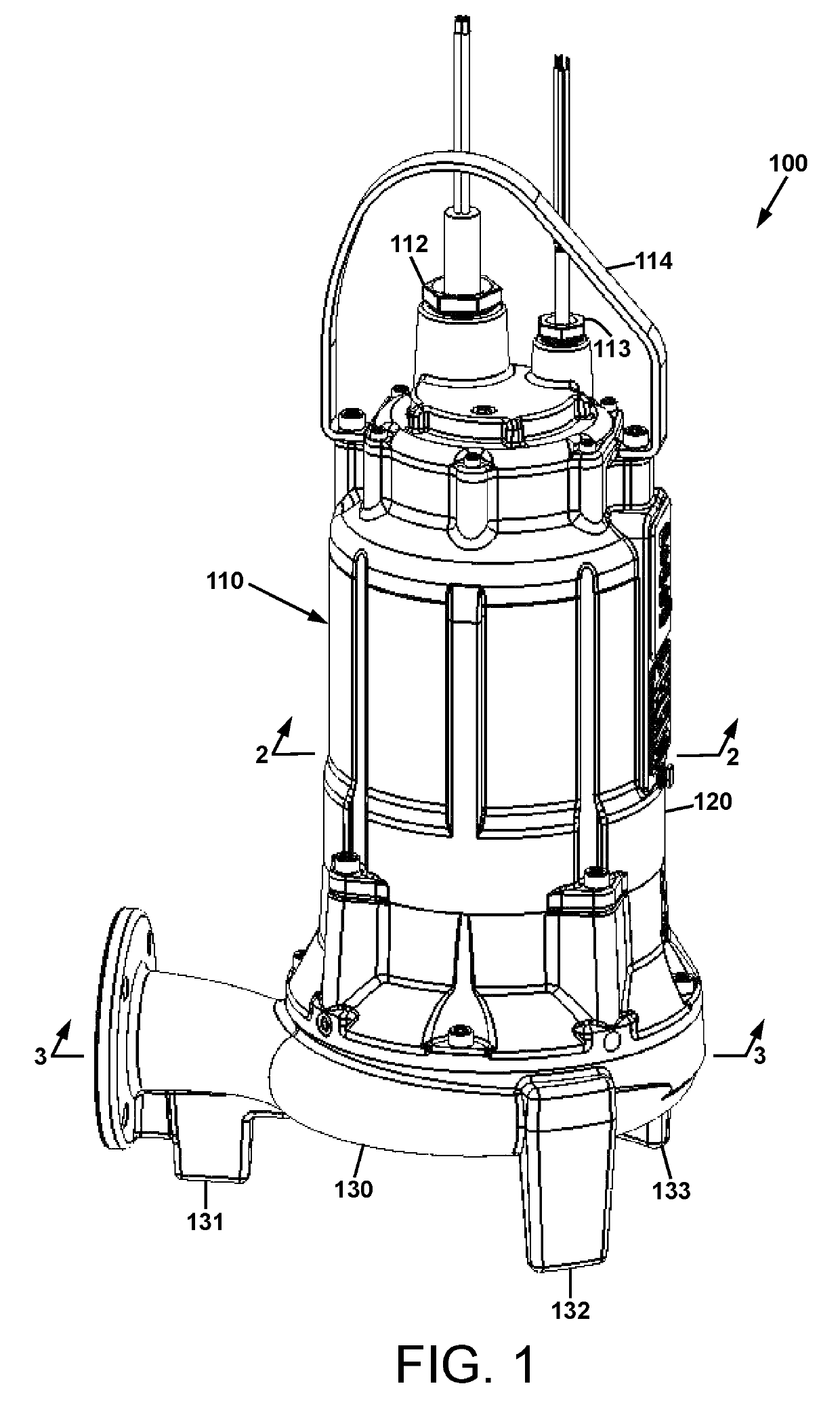

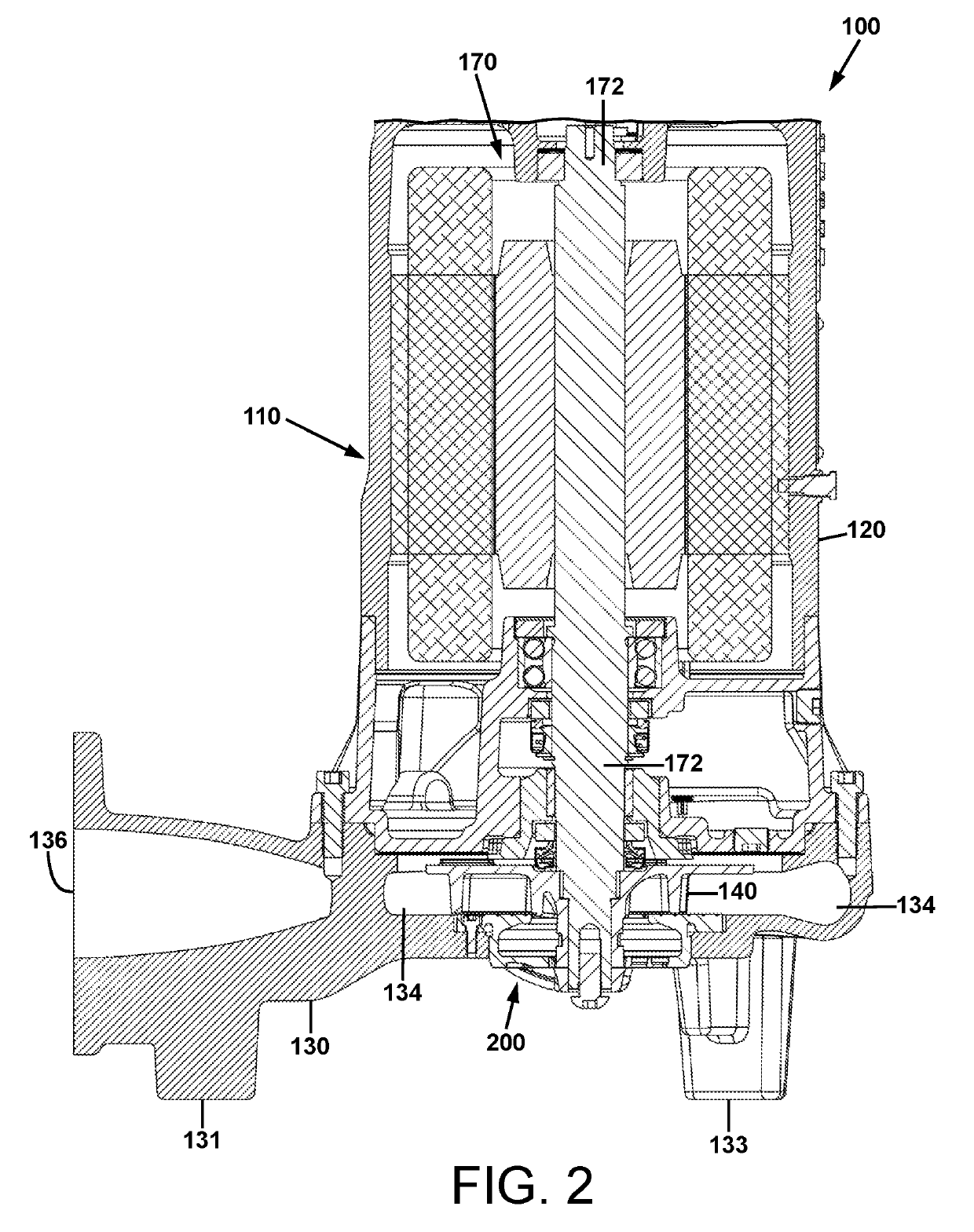

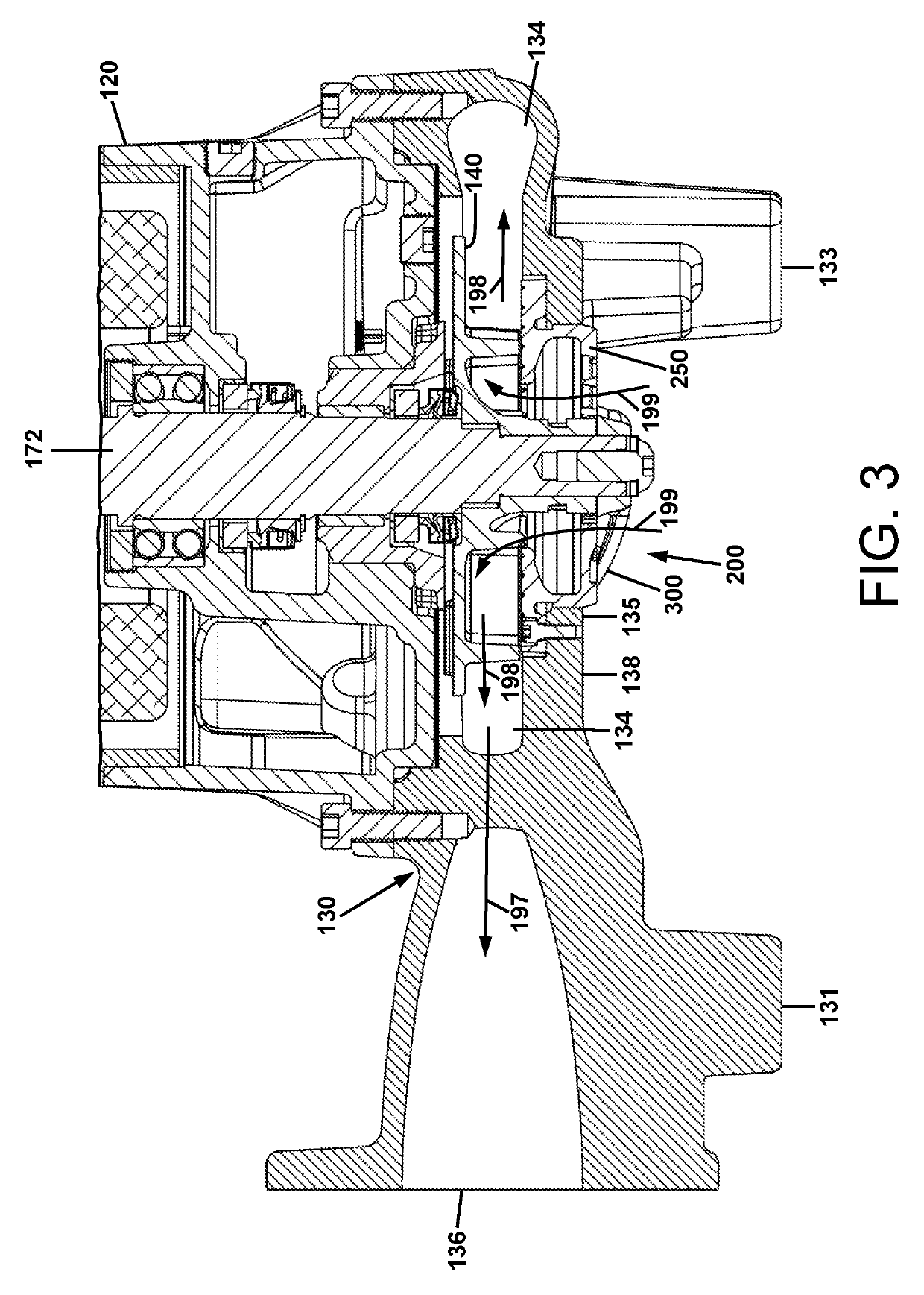

Cutter assembly for a grinder pump

A cutting assembly for a grinder pump comprised of a rotary cutter rotatable against an opposing plate cutter. The cutting edges of the plate cutter include a plurality of V-slice cutting teeth, which create bridging spaces to pinch material which is being sucked in to ports and begin cutting along the V-slice and then for cut material to pass through and onward into the volute of the pump. The rotary cutter has a ground edge with a rake angle which shears the gathered material in cooperation with the cutting edges of the plate cutter. A grinder pump including the cutter assembly is also disclosed.

Owner:LIBERTY PUMPS

Slag reduction pump

A grinder pump assembly includes at least one grinder pump stage that has a diffuser and an impeller. The grinder pump assembly also includes a diffuser cap that includes cap contact surfaces. The impeller includes a plurality of upper vanes and lower vanes. The diffuser includes a plurality of lower contact surfaces, a plurality of diffuser vanes and plurality of upper contact surfaces. The upper vanes of the impeller are configured to rotate in proximity with the lower contact surfaces on the diffuser. The lower vanes of the impeller are configured to rotate in proximity with the cap contact surfaces. Multiple grinder pump stages may be used within a single grinder pump assembly.

Owner:BAKER HUGHES ESP INC

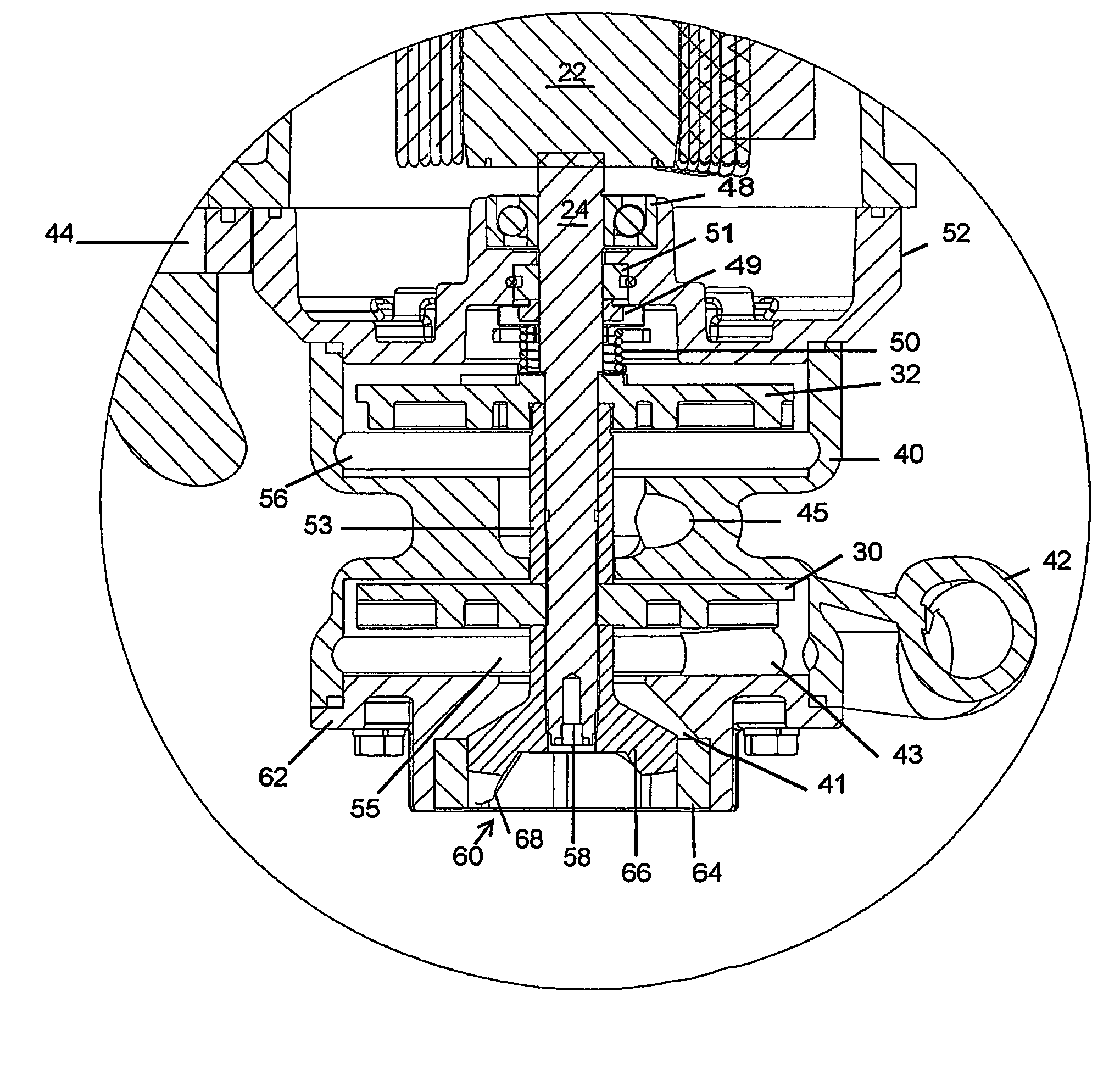

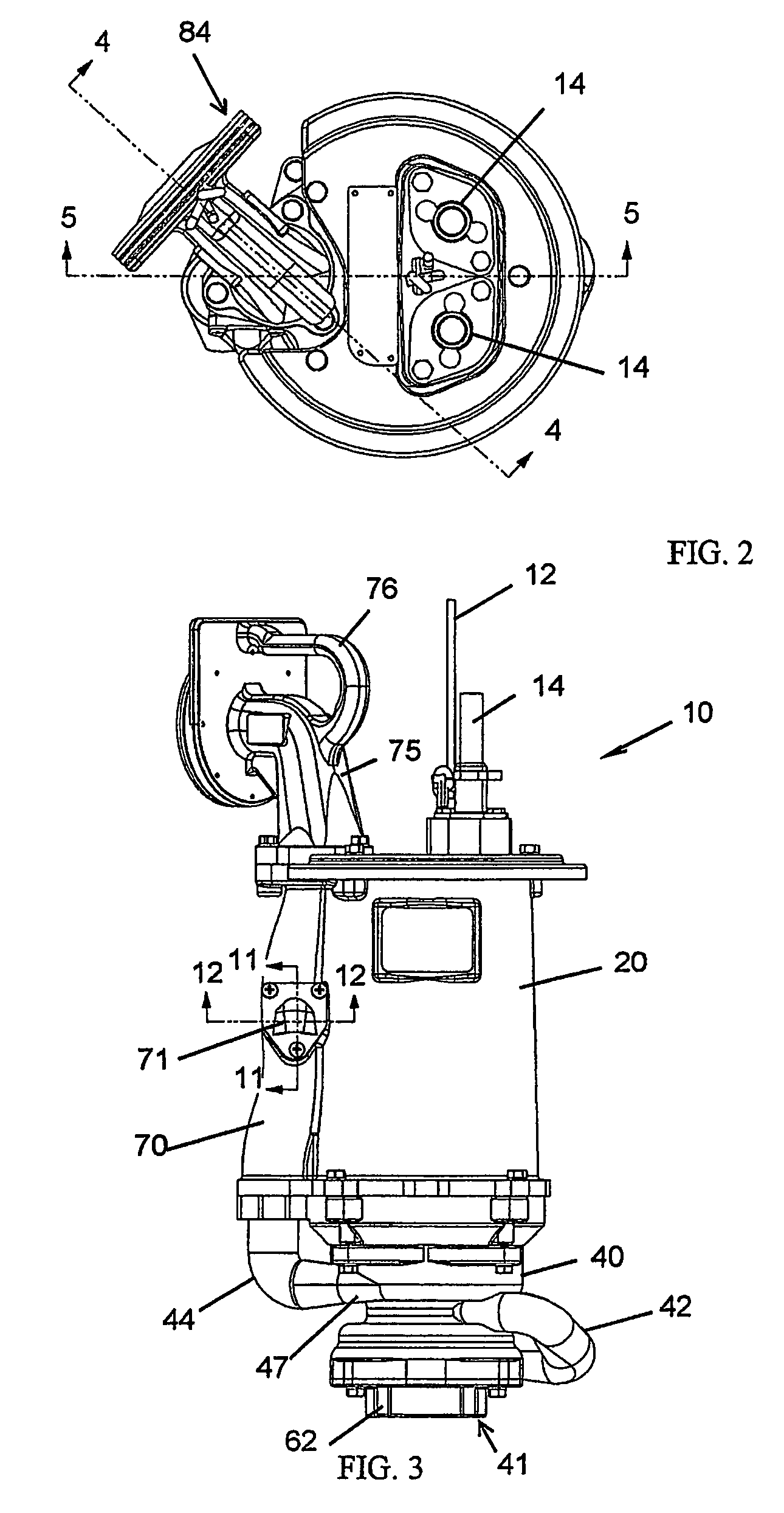

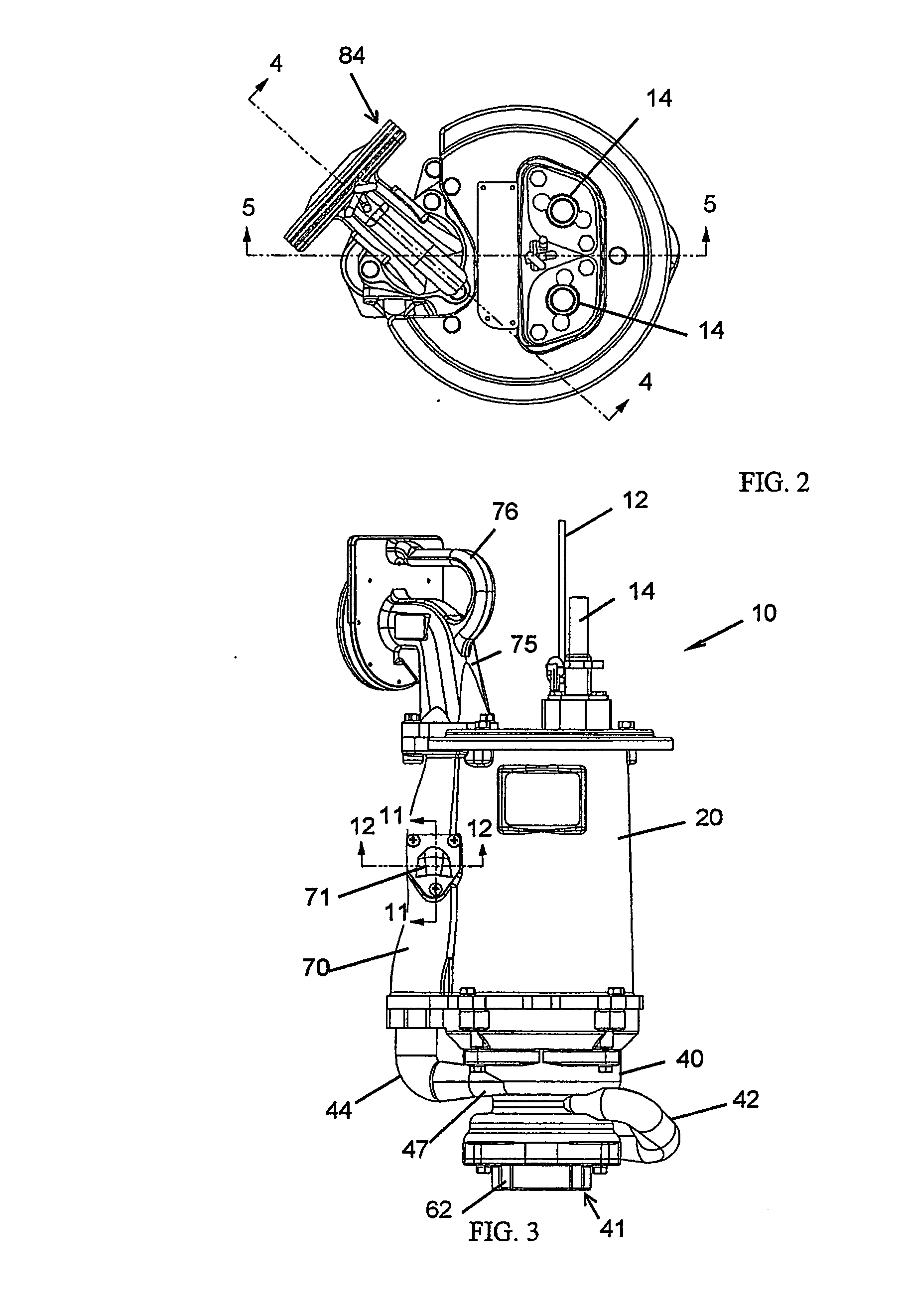

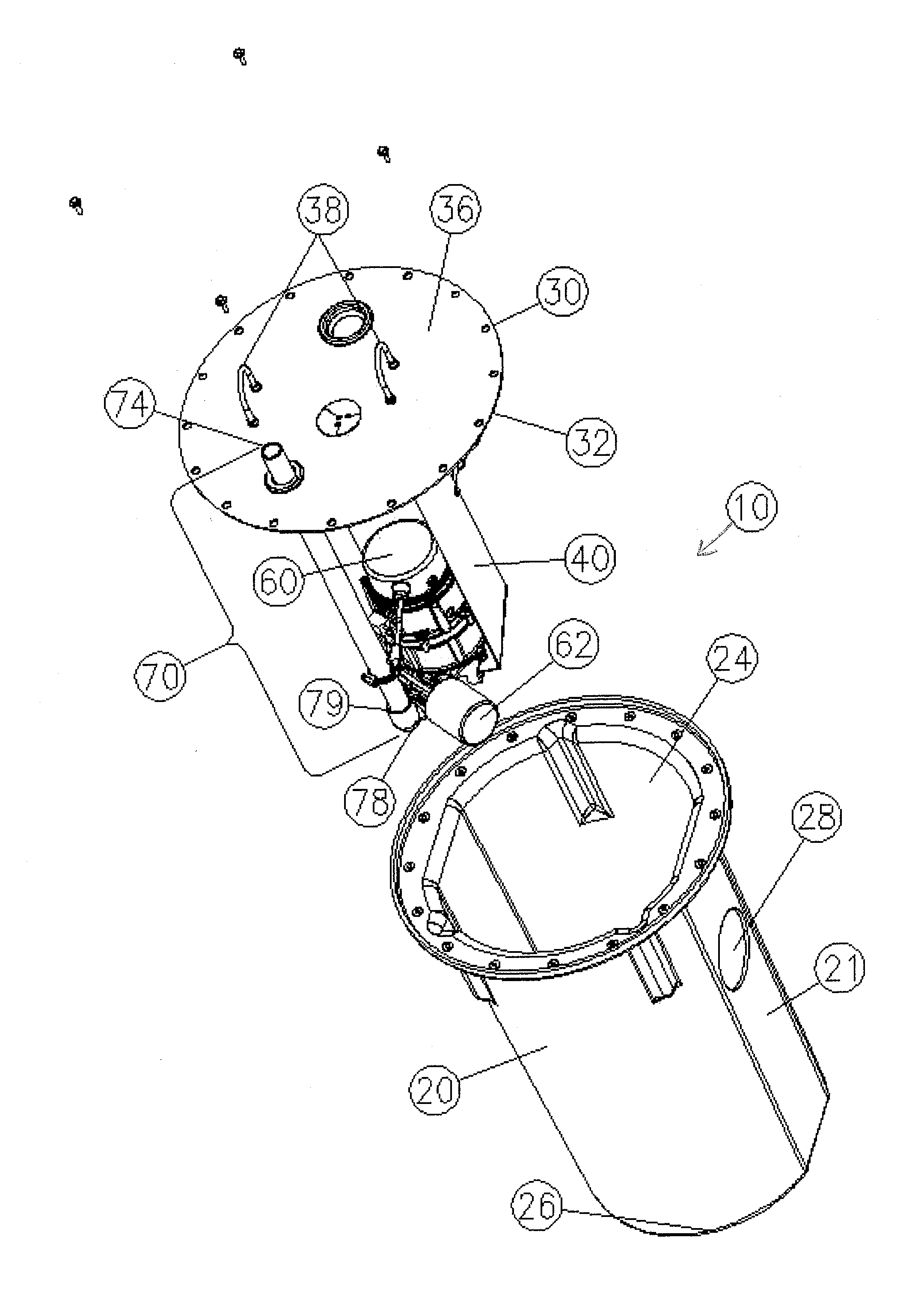

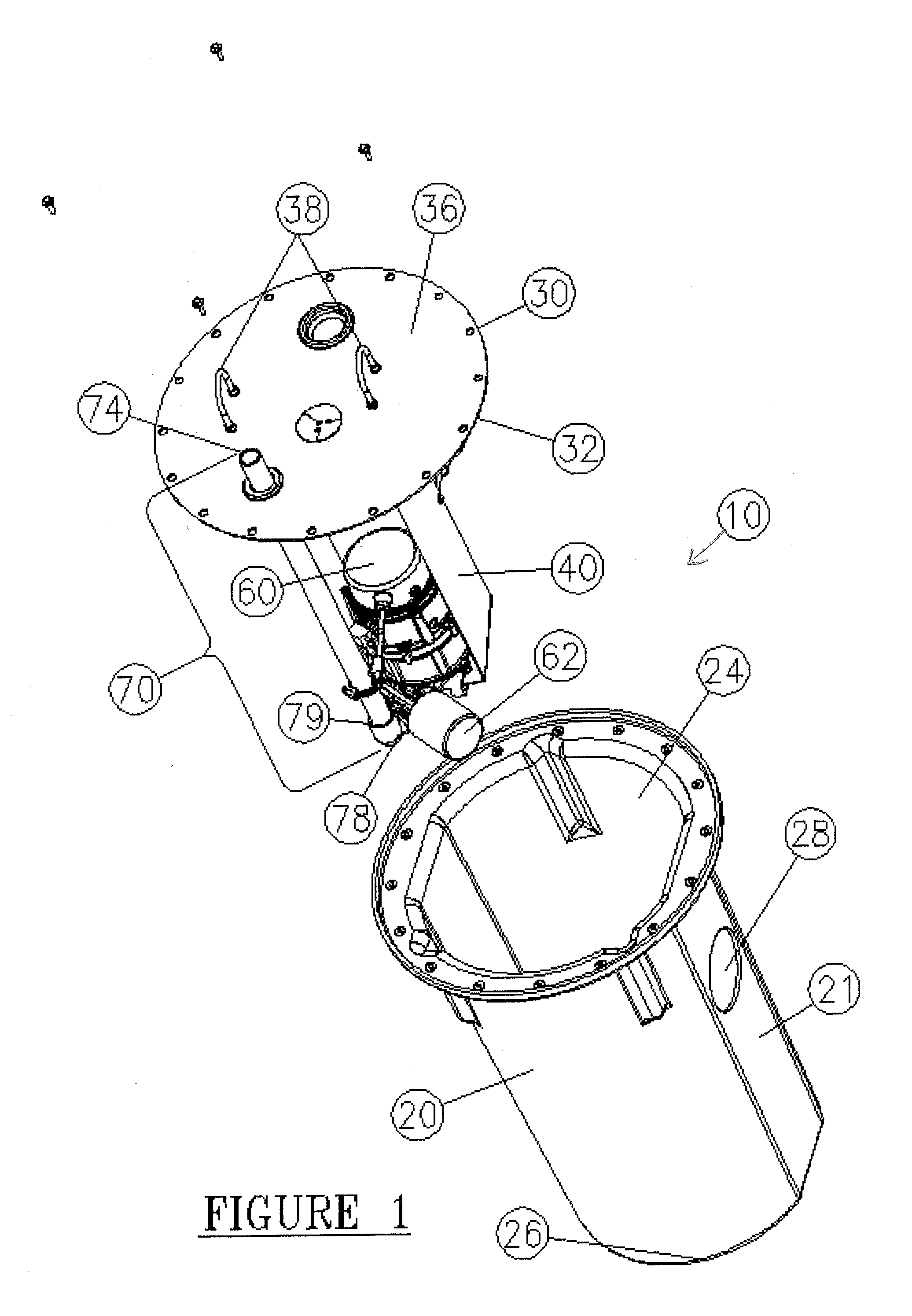

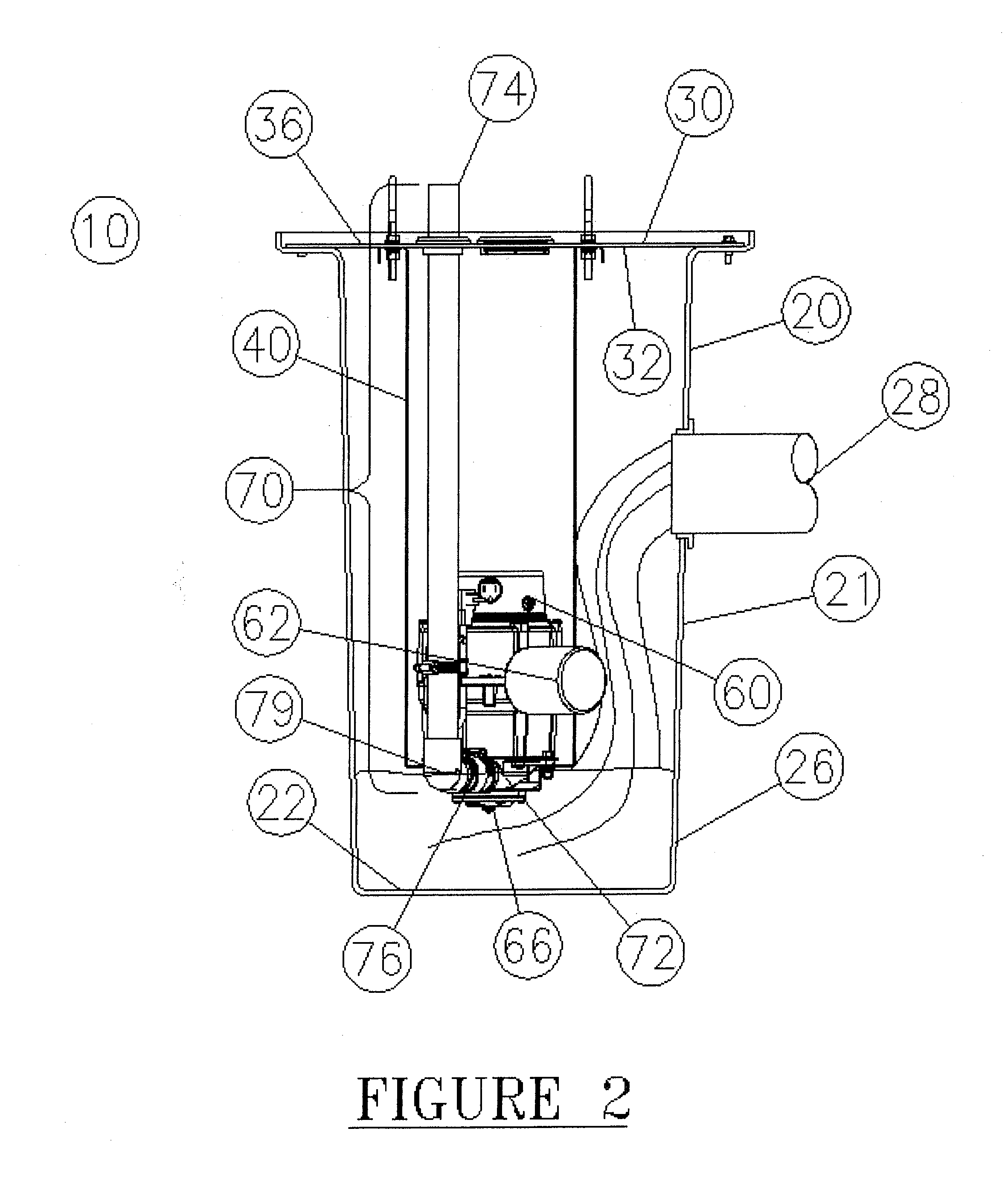

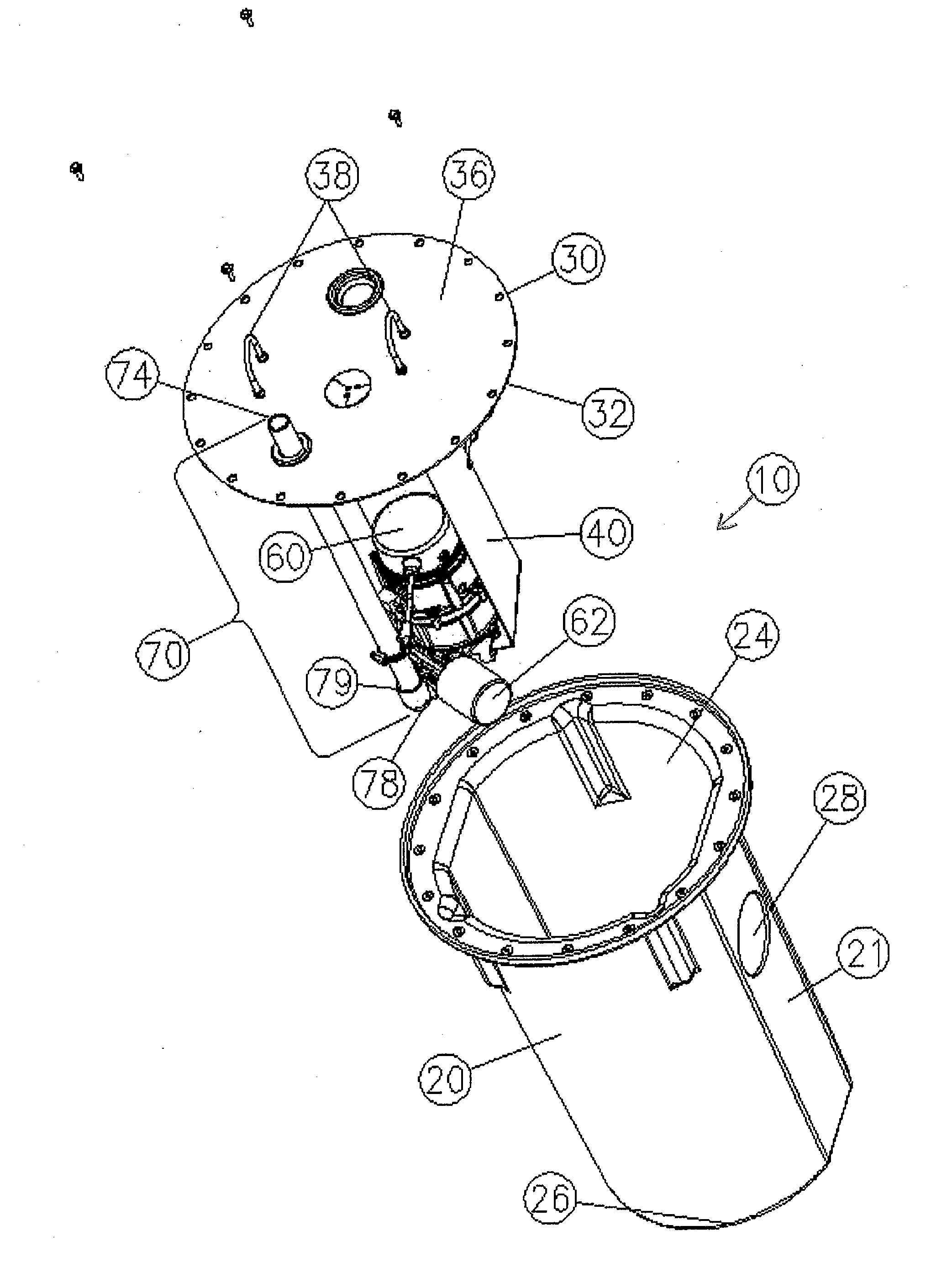

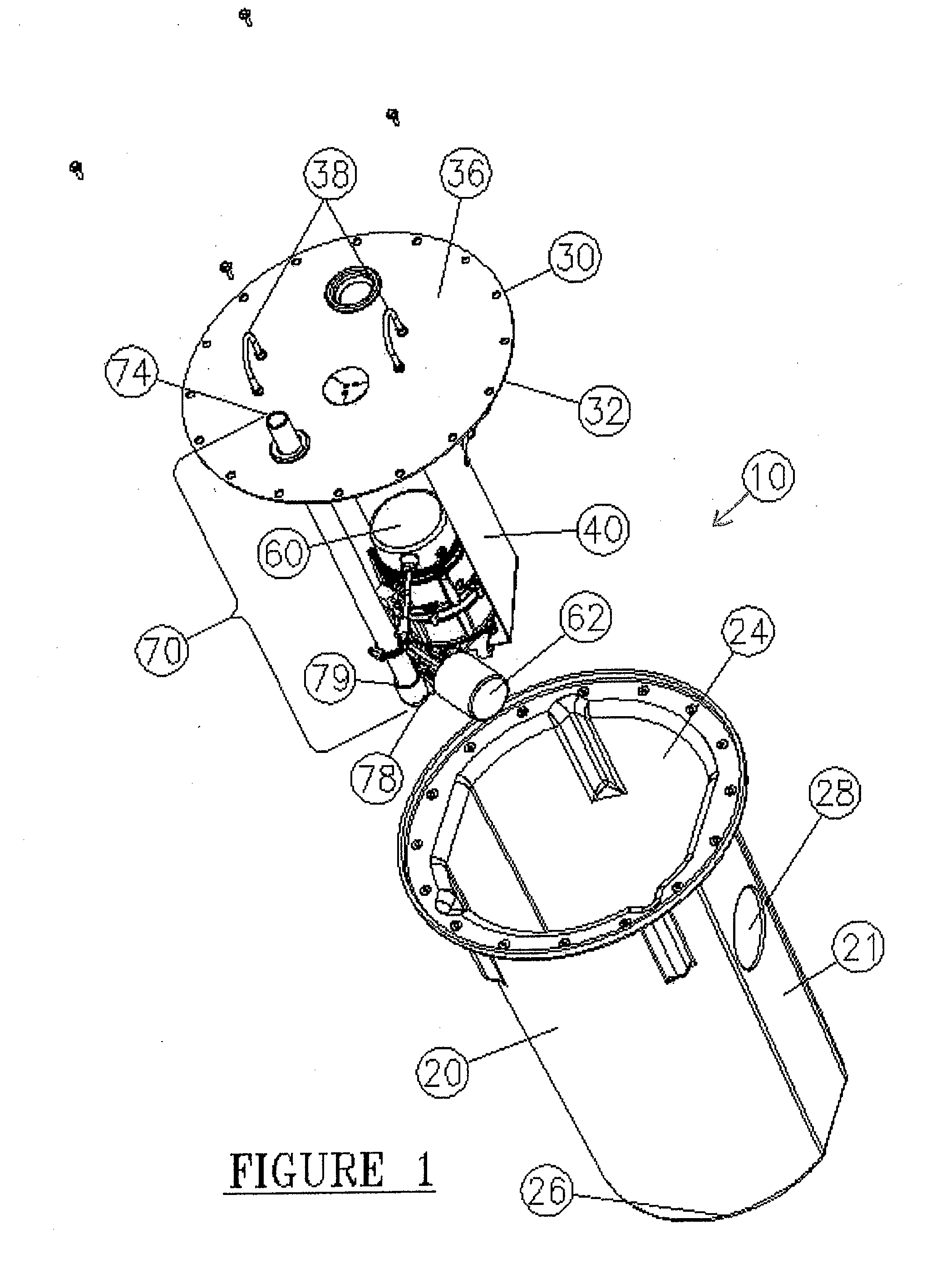

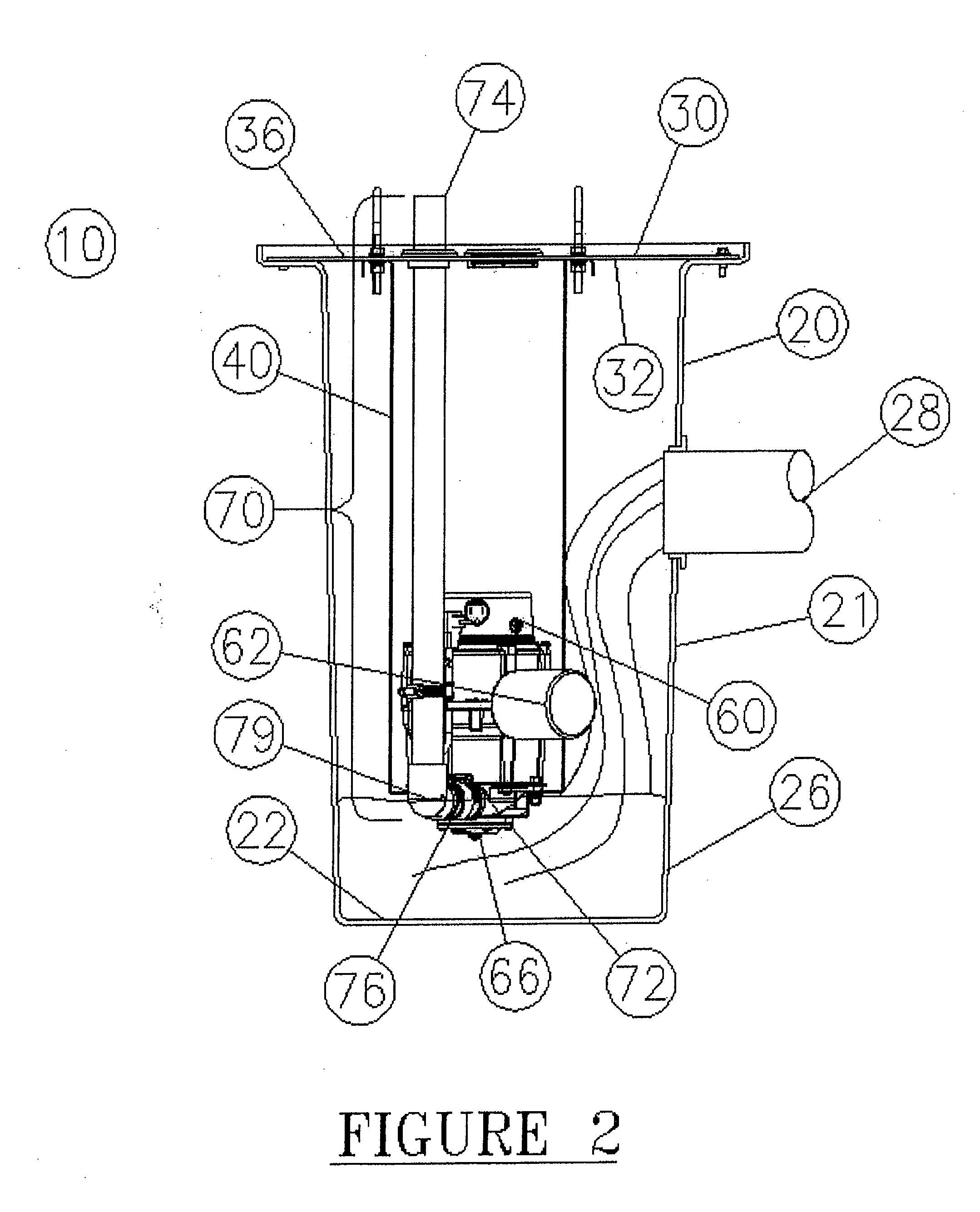

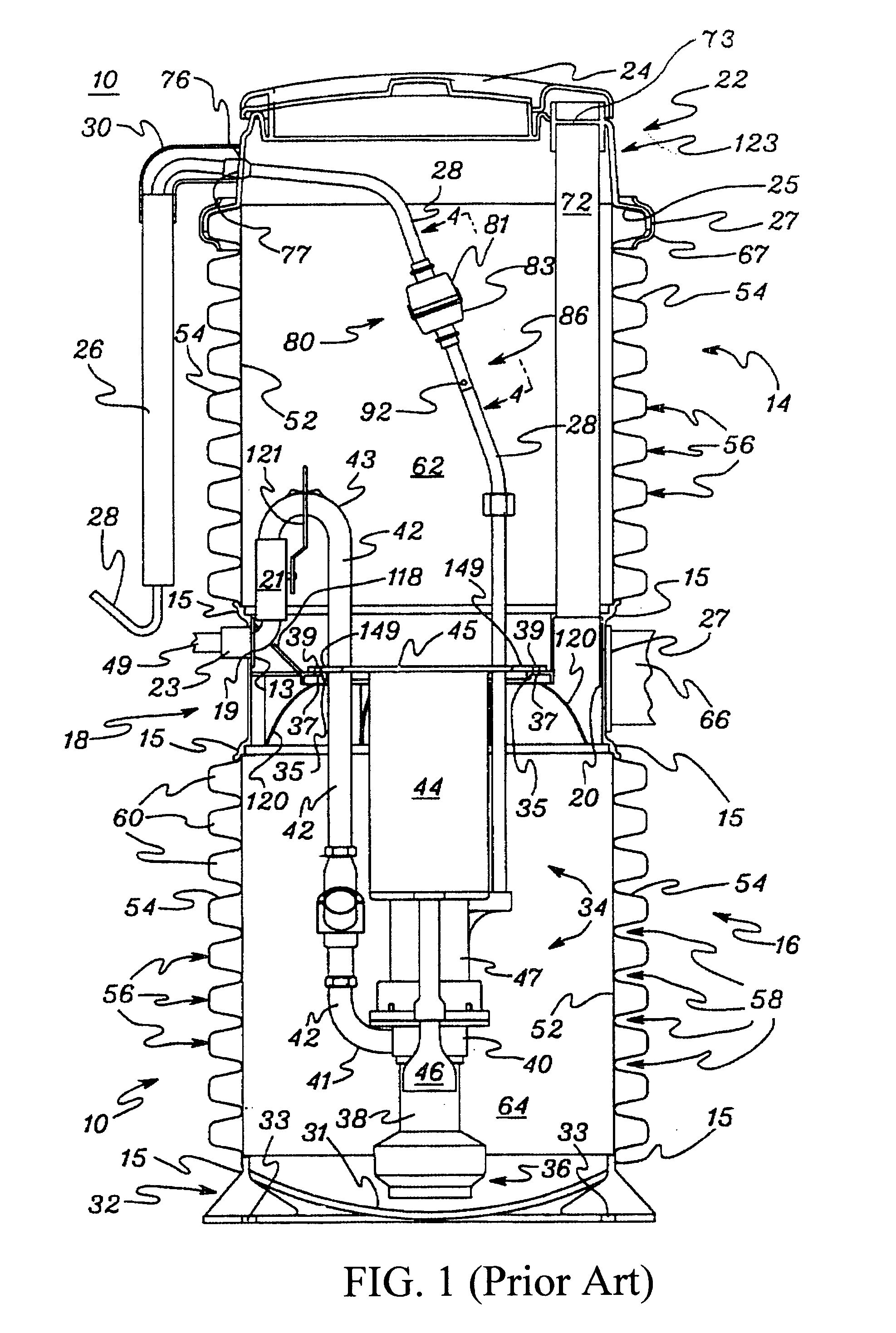

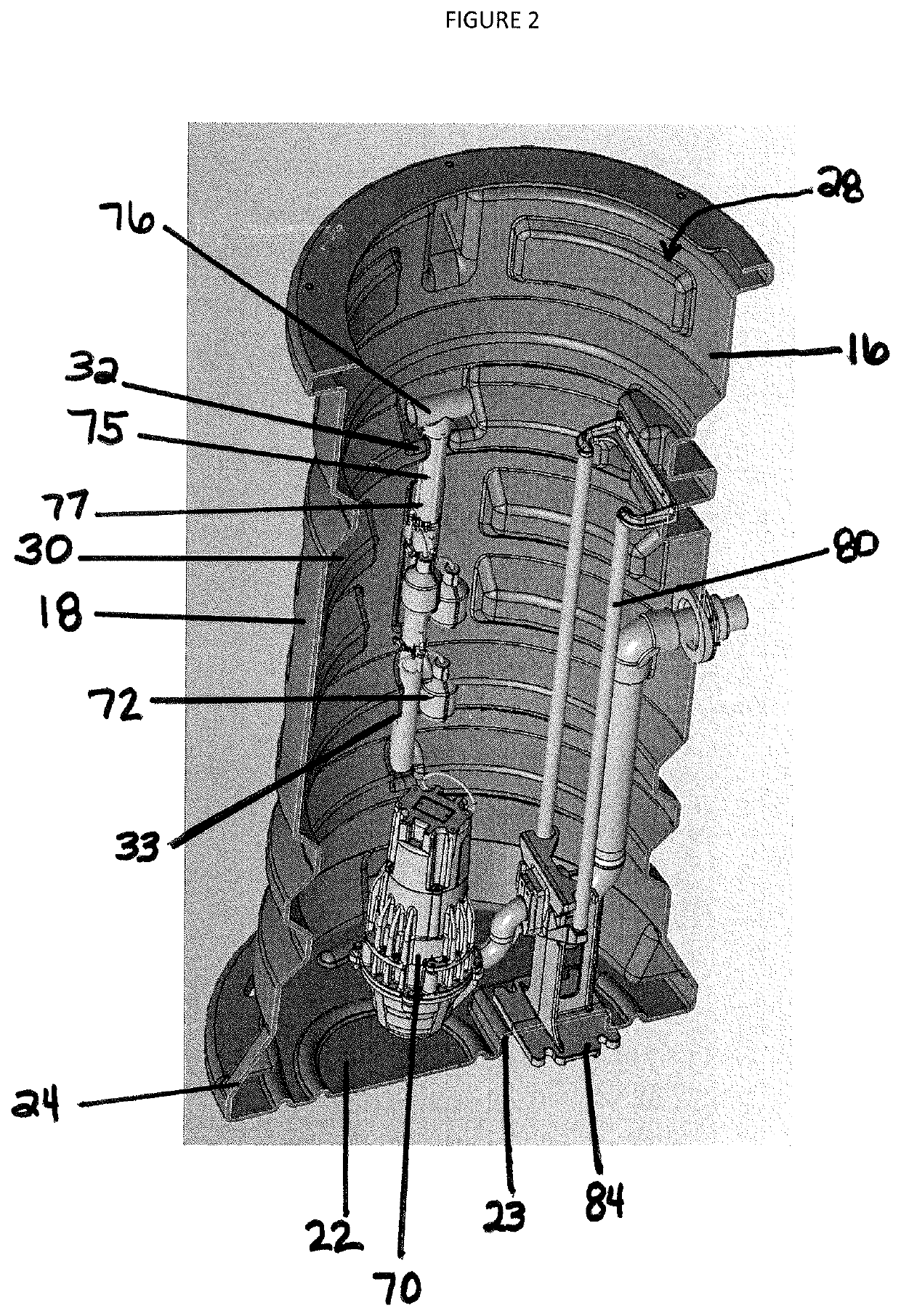

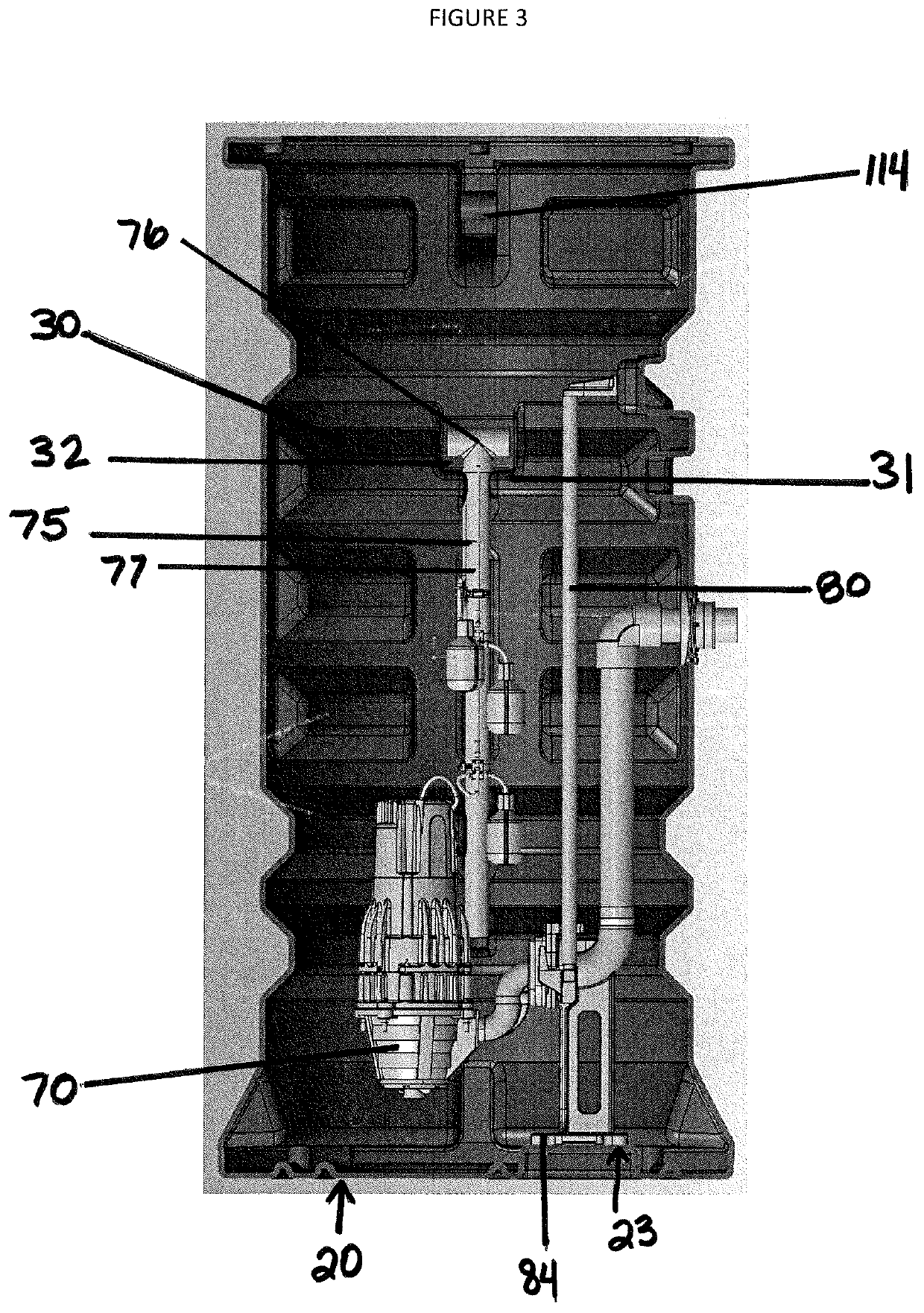

Two stage sewage grinder pump

A two-stage sewage grinder pump (10) having two impellers (30, 32) and a grinder (60) attached to the motor shaft (24). Preferably, both impellers are vortex impellers and are positioned between the grinder and the motor. The motor housing includes a discharge conduit (70) that is monolithic with the motor housing (20). An anti-siphon valve (71) is integral with the discharge conduit. An integral discharge flange (75) and check valve (78) are attached to the discharge conduit to connect the sewage grinder pump to a sewage outlet.

Owner:CRANE PUMPS & SYST INC

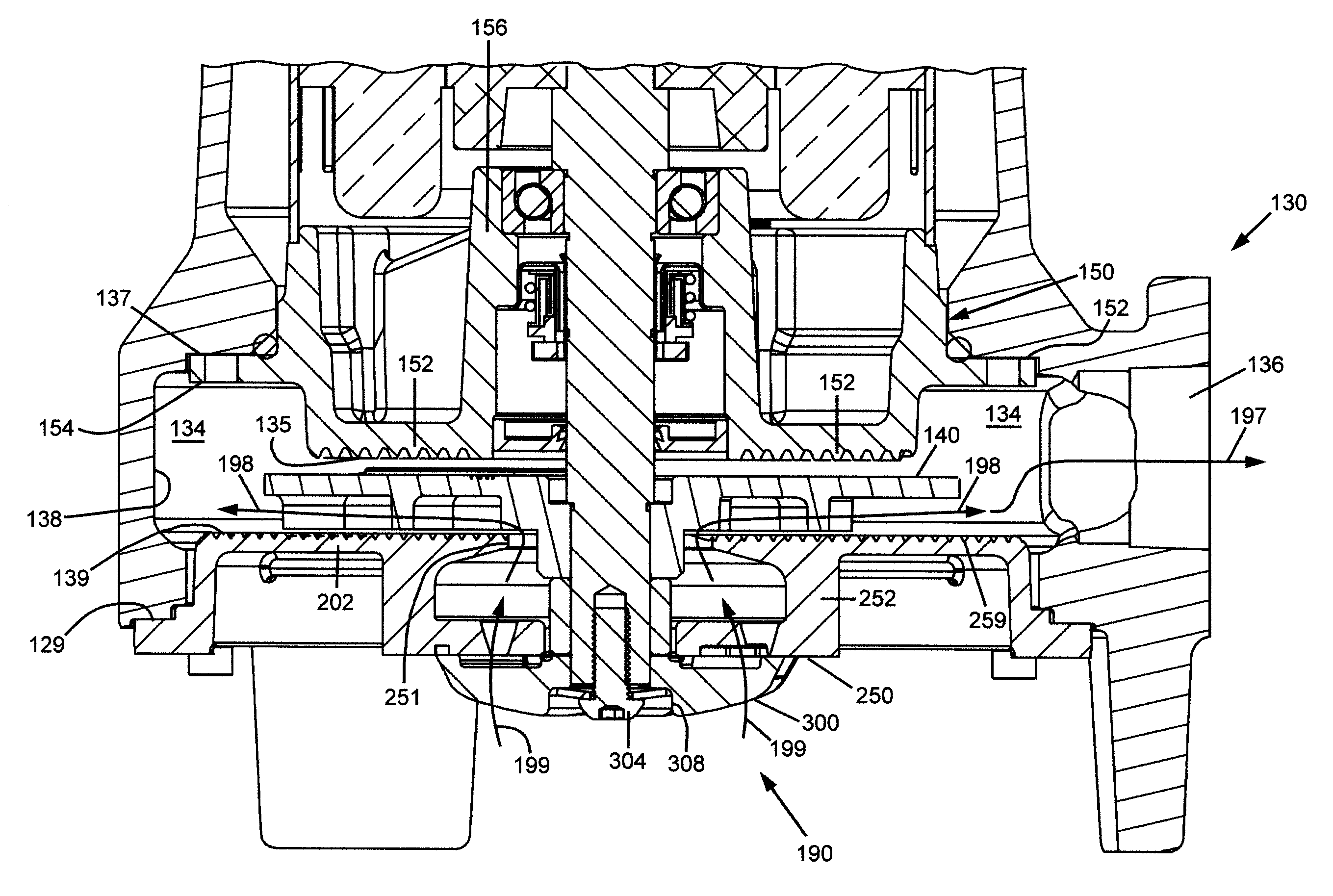

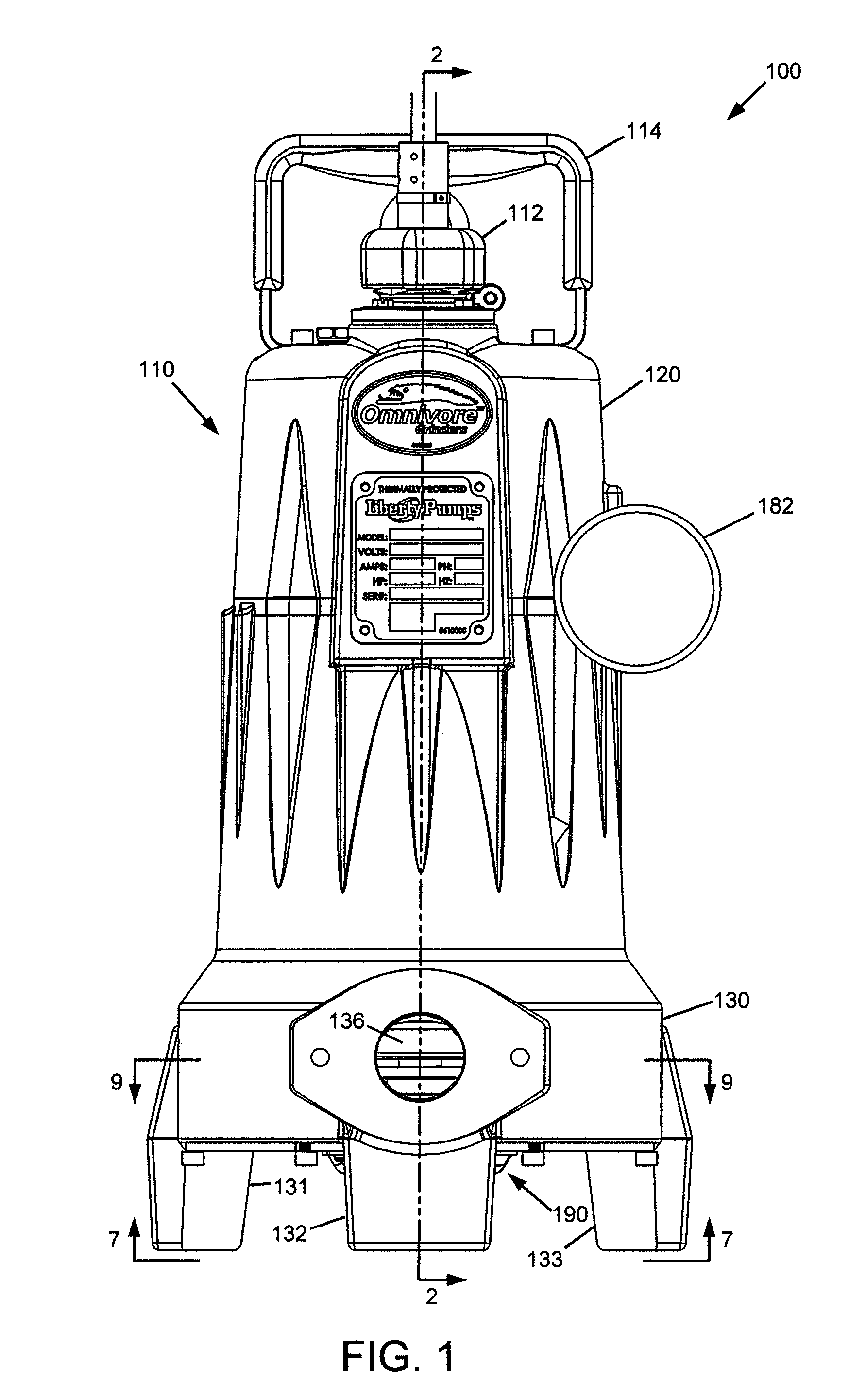

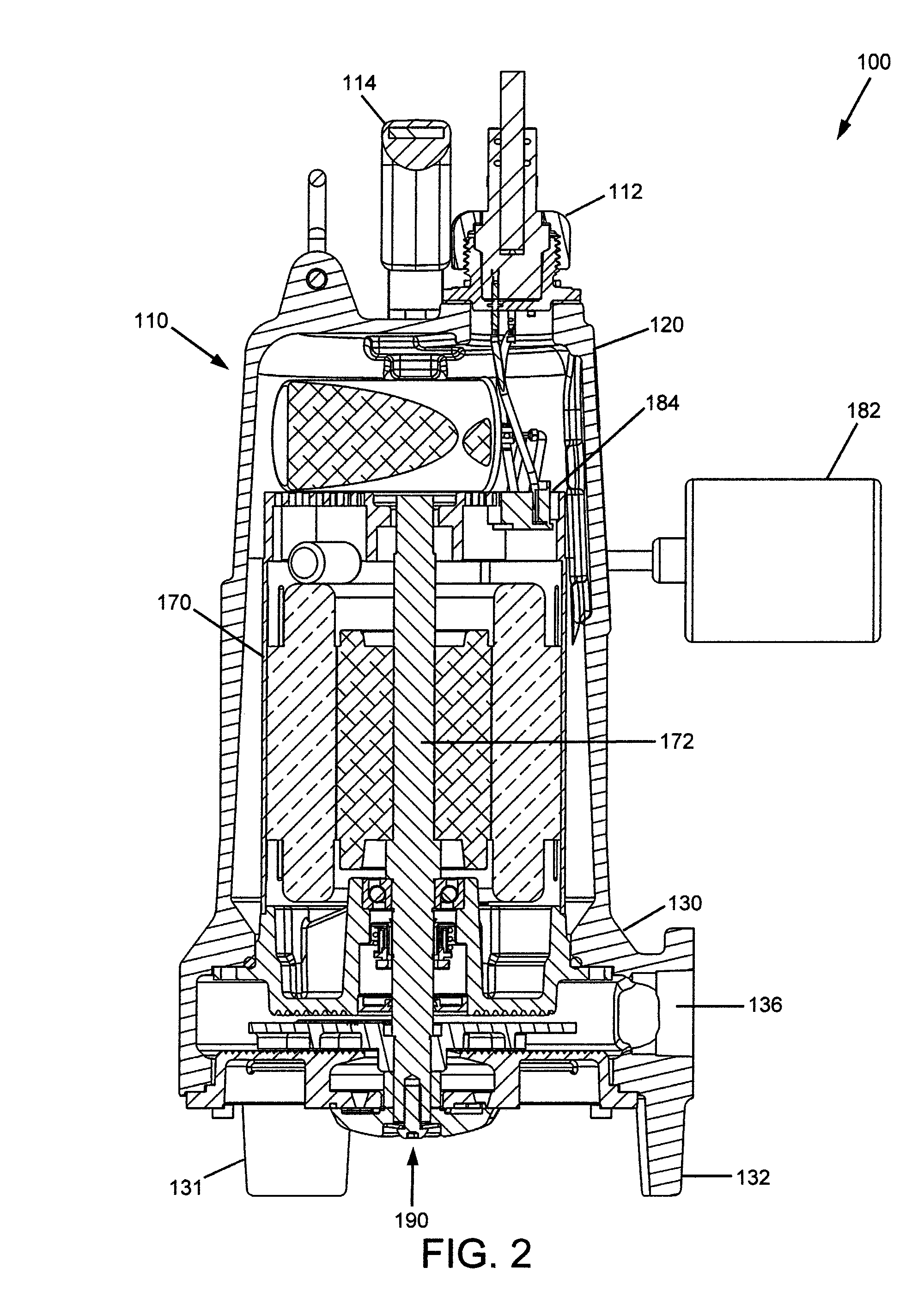

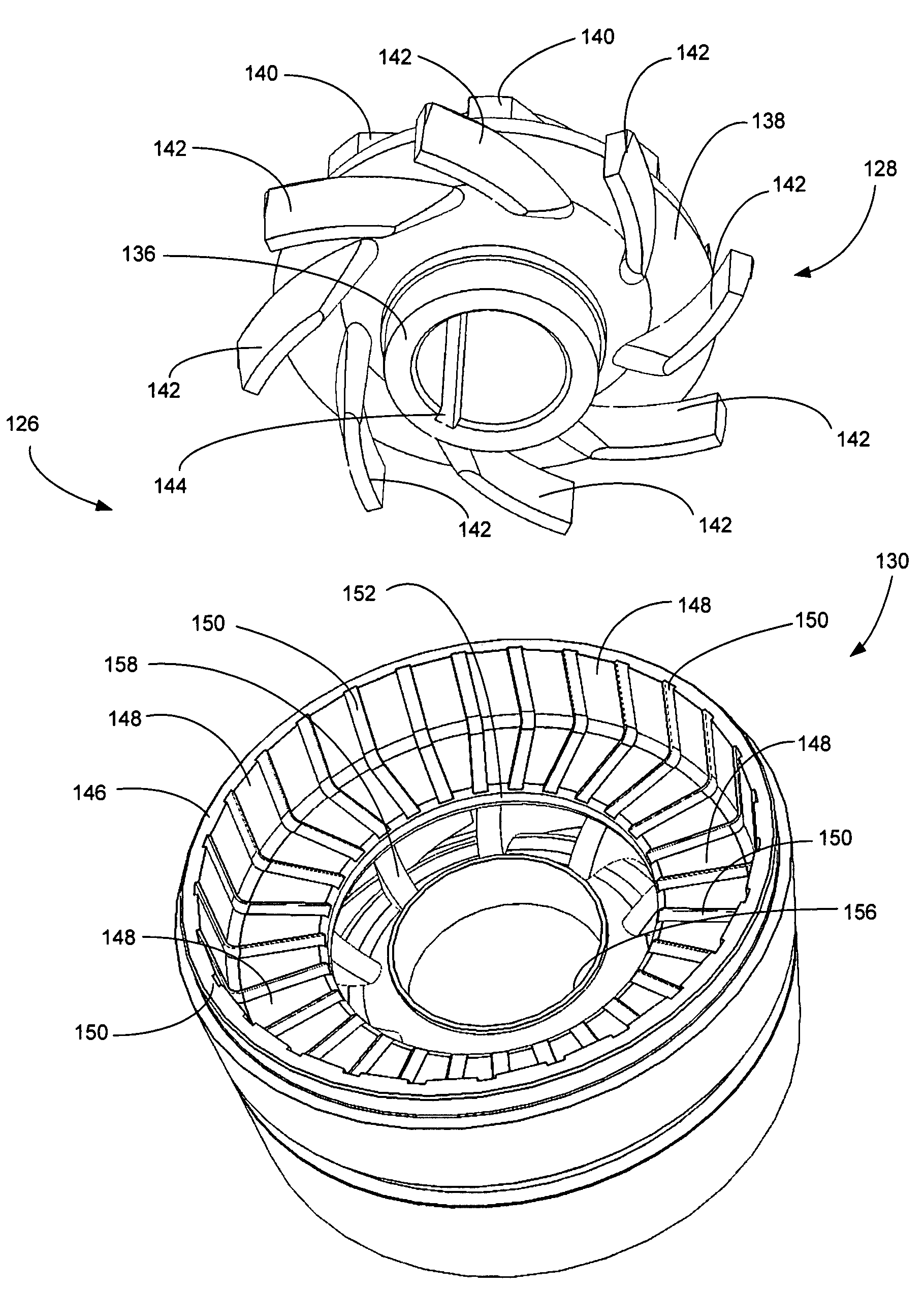

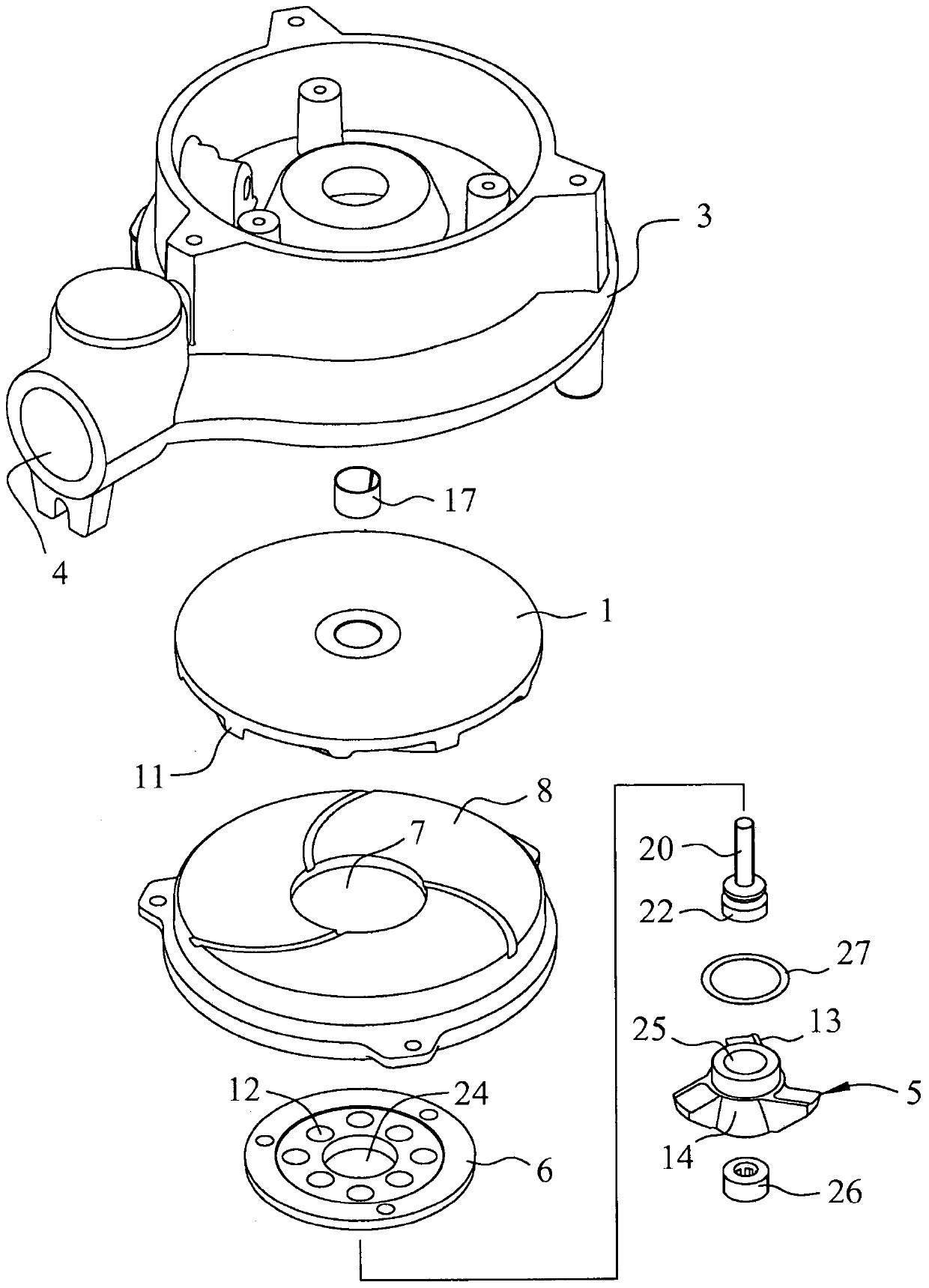

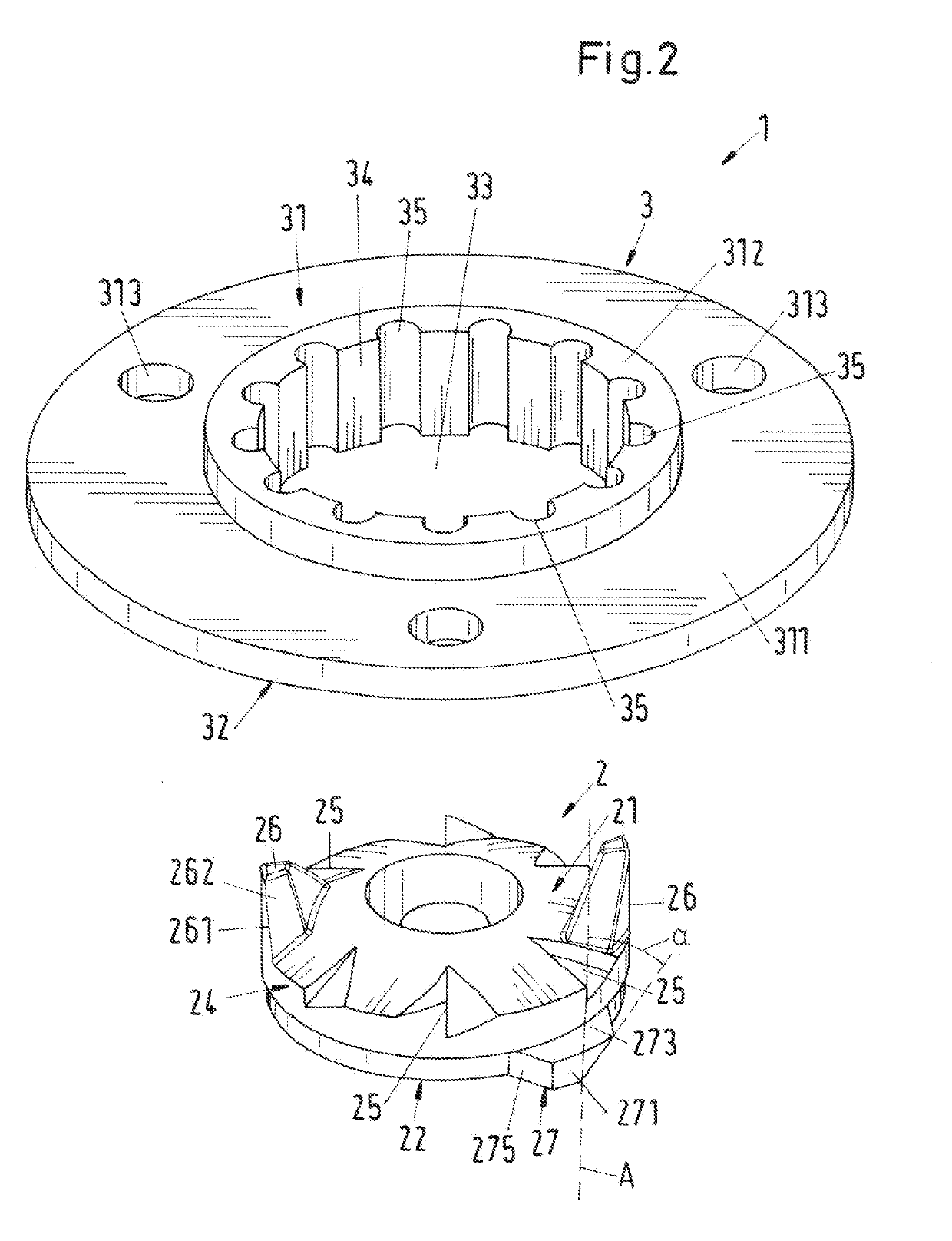

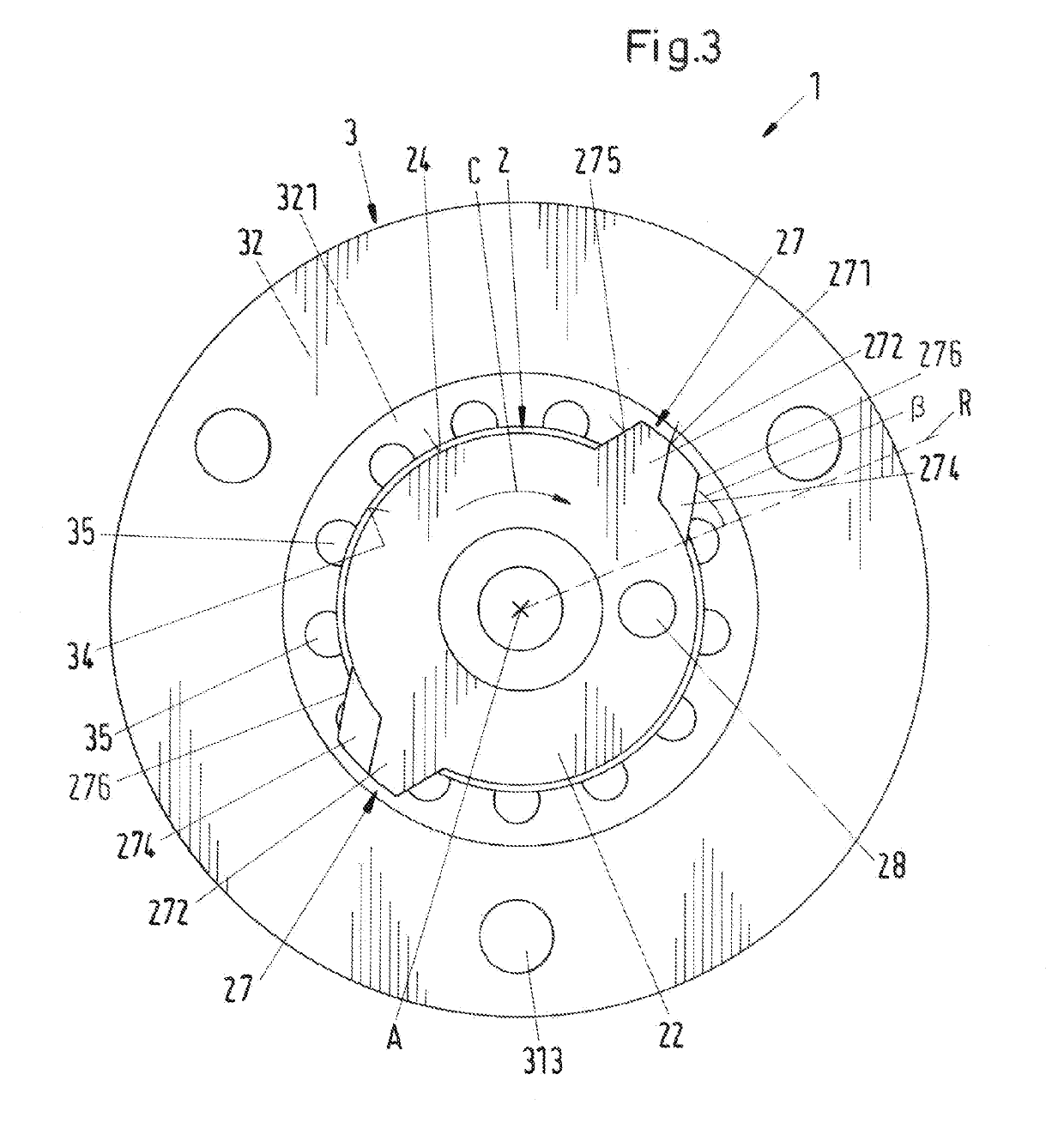

Grinder pump and cutting assembly thereof

ActiveUS20180202453A1High rate of wearReduced life of cuttingSpecific fluid pumpsPump componentsEngineeringMechanical engineering

A cutting assembly and a grinder pump including the cutting assembly are disclosed. The cutting assembly includes a cutting plate that has a plurality of cutting ports with cutting edges that are distributed over a range of radial locations of the plate. The cutting edges of the cutting ports define a series of cutting regions of the cutting blades of a rotary cutter that operate in a shearing action with the cutter plate. The cutting action by the blades of the rotary cutter is distributed over nearly the entire lengths of the cutting edges of the cutting blades, thereby distributing the wear on the cutting blades evenly, and extending cutting assembly life.

Owner:LIBERTY PUMPS

Two stage sewage grinder pump

ActiveUS20070069050A1Increase pressureSpecific fluid pumpsWater/sludge/sewage treatmentImpellerSiphon

A two-stage sewage grinder pump (10) having two impellers (30, 32) and a grinder (60) attached to the motor shaft (24). Preferably, both impellers are vortex impellers and are positioned between the grinder and the motor. The motor housing includes a discharge conduit (70) that is monolithic with the motor housing (20). An anti-siphon valve (71) is integral with the discharge conduit. An integral discharge flange (75) and check valve (78) are attached to the discharge conduit to connect the sewage grinder pump to a sewage outlet.

Owner:CRANE PUMPS & SYST INC

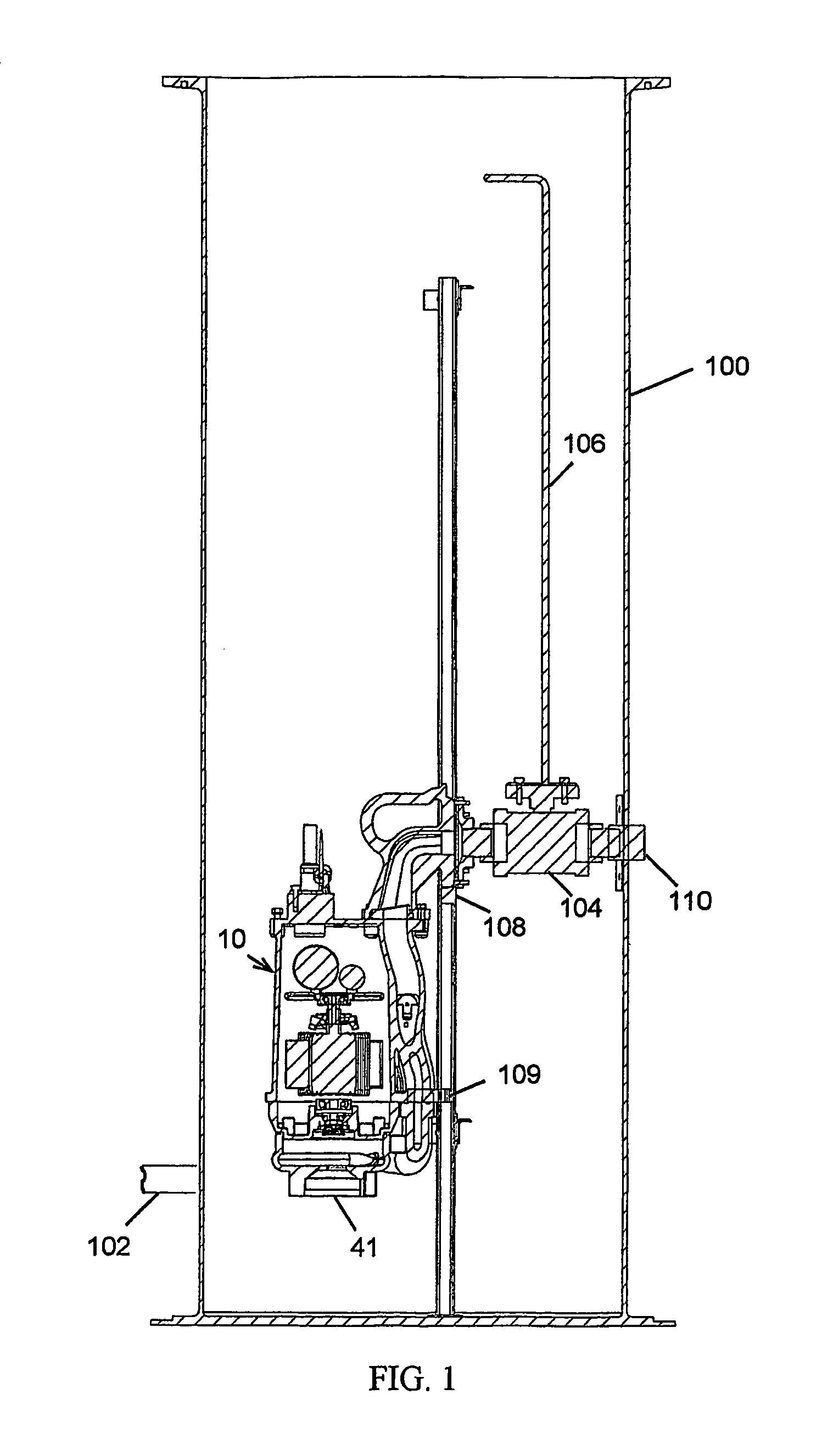

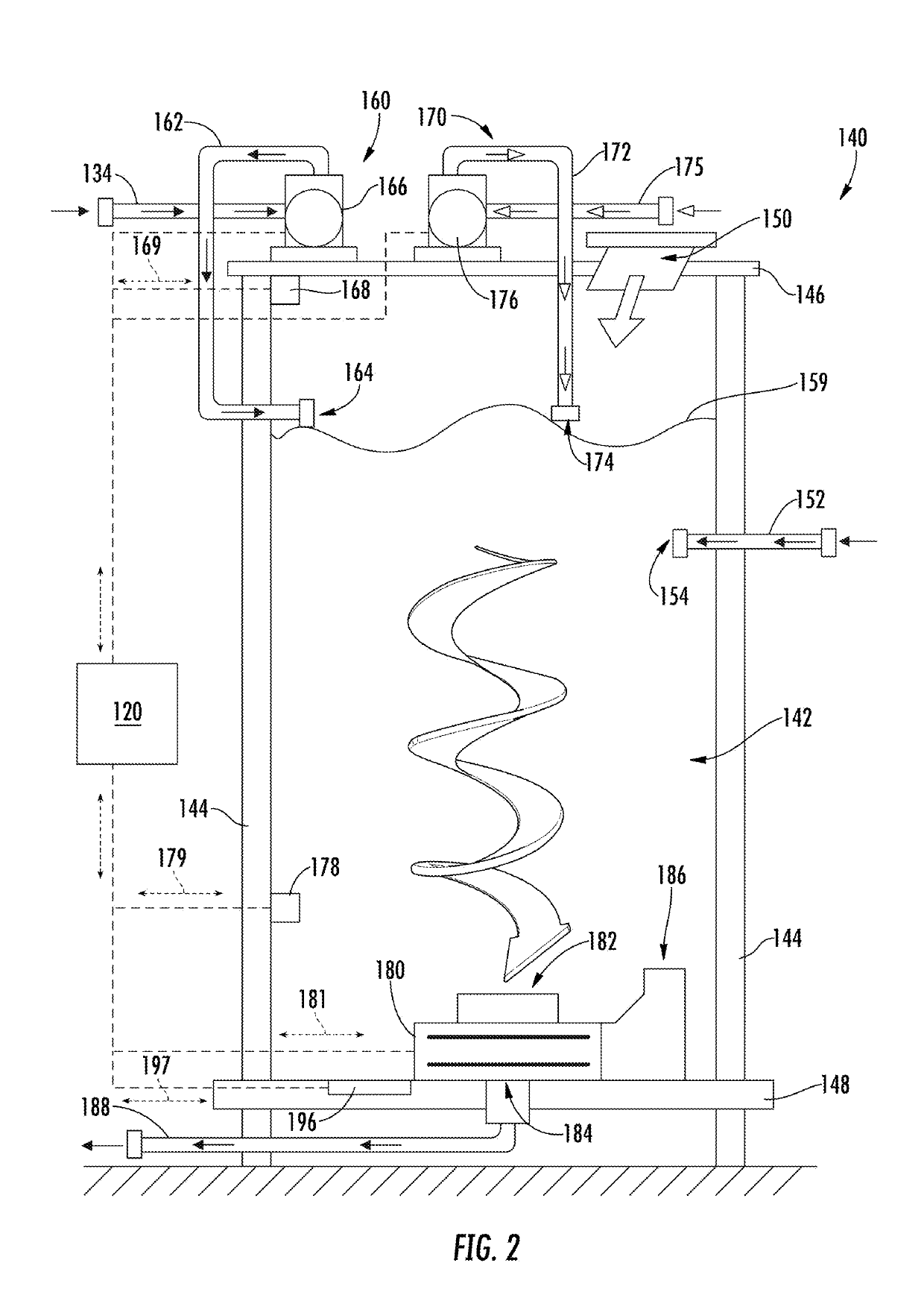

Grinder pump basin system

ActiveUS20120085688A1Effectively and efficiently cutSpecific fluid pumpsPump componentsGrinder pumpEffluent

A grinder pump basin system is provided which includes a basin; a cover plate; a bracket secured to the cover plate; and a grinder pump with cutter plate with openings and a cutter blade secured to the bracket above a bottom surface of the basin. The bracket includes a front portion, which prevents waste water from interacting adversely with the grinder pump when it enters the basin. A discharge system for the grinder pump is secured to an outlet of the grinder pump and includes a discharge pipe and a flexible discharge coupling. Flow directional jets are also provided in an elbow of the pump discharge system to direct waste water and solids away from the grinder pump.

Owner:ZOELLER PUMP

Grinder pump system

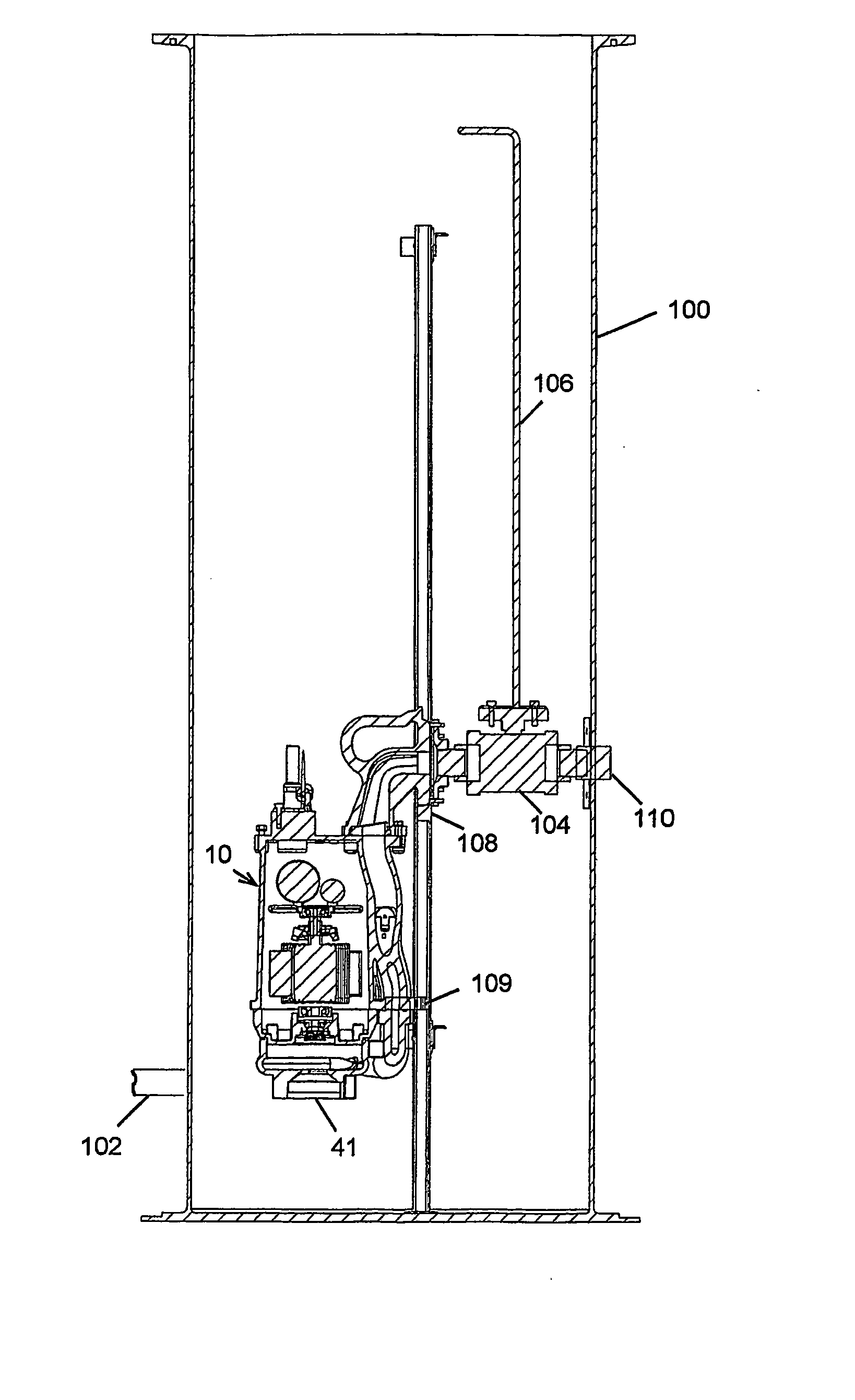

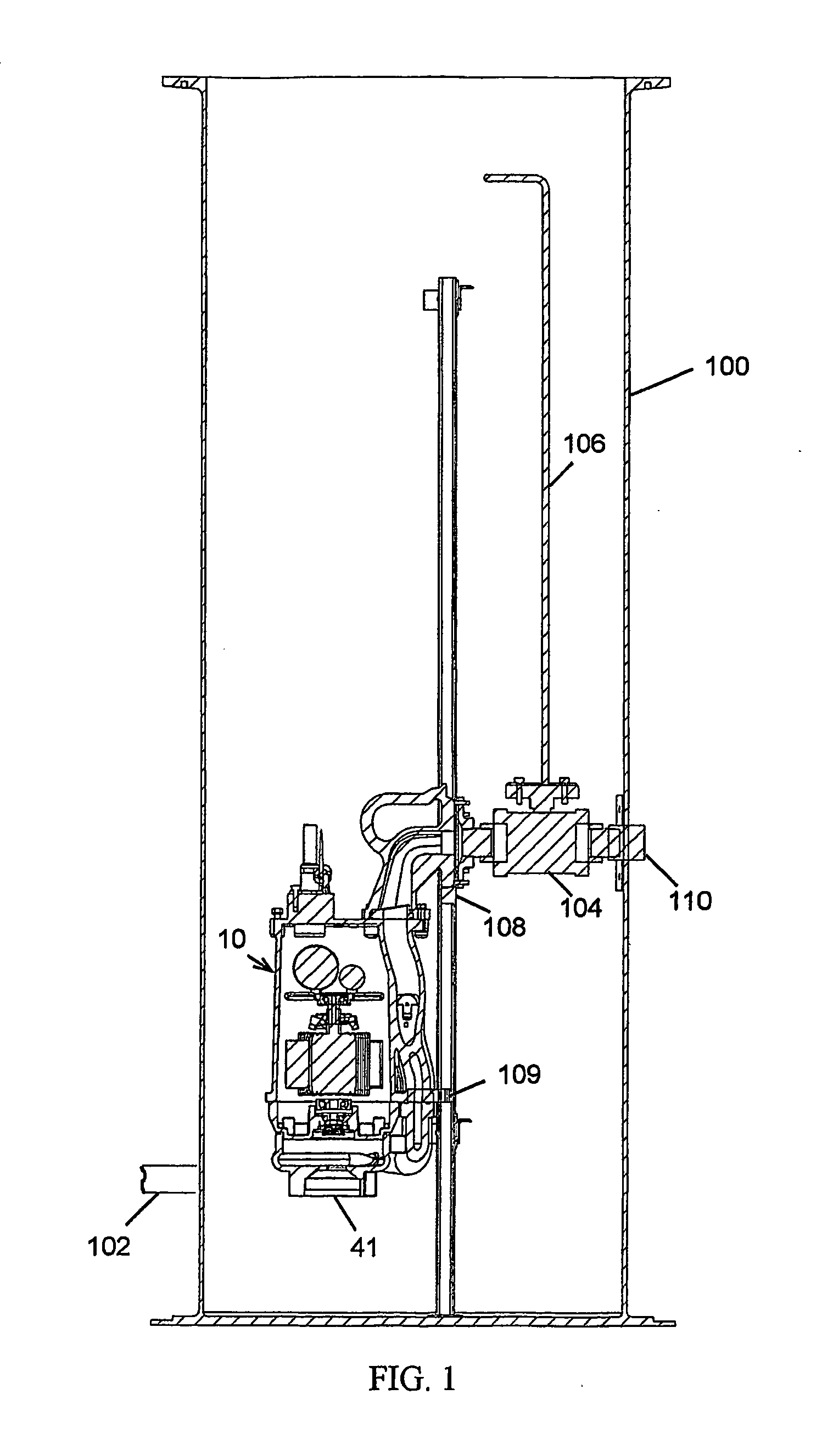

InactiveUS20060060685A1Easy to installEasy accessSpecific fluid pumpsGas current separationVertical tubeEngineering

A grinder pump system that is simpler to install, and permits ready access to the pump system components, has a grinder pump station for receiving a grinder pump. The pump station has a basin with an interior volume to provide a well for receiving sewage. A sewage inlet port and a sewage discharge port allow, sewage to flow into and out of the basin interior volume. The basin is positioned below grade, and sewage is directed thereto through a sewage source. An access riser is selectively coupled to the basin, and extends to the ground surface. Pump system components mounted within the basin are accessible via the access riser and an opening on the basin top surface. A lid assembly is selectively removably coupled to the access riser to close the system from the environment.

Owner:CRANE PUMPS & SYST INC

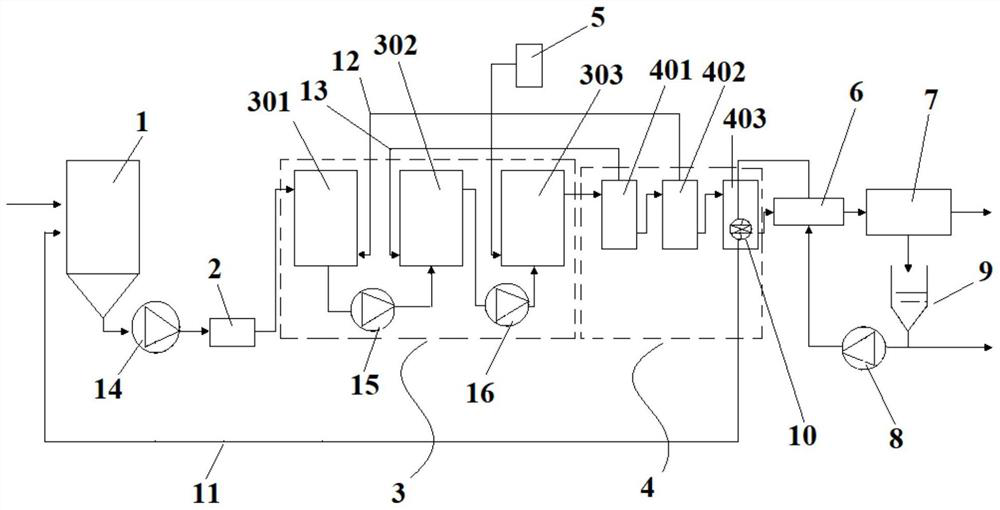

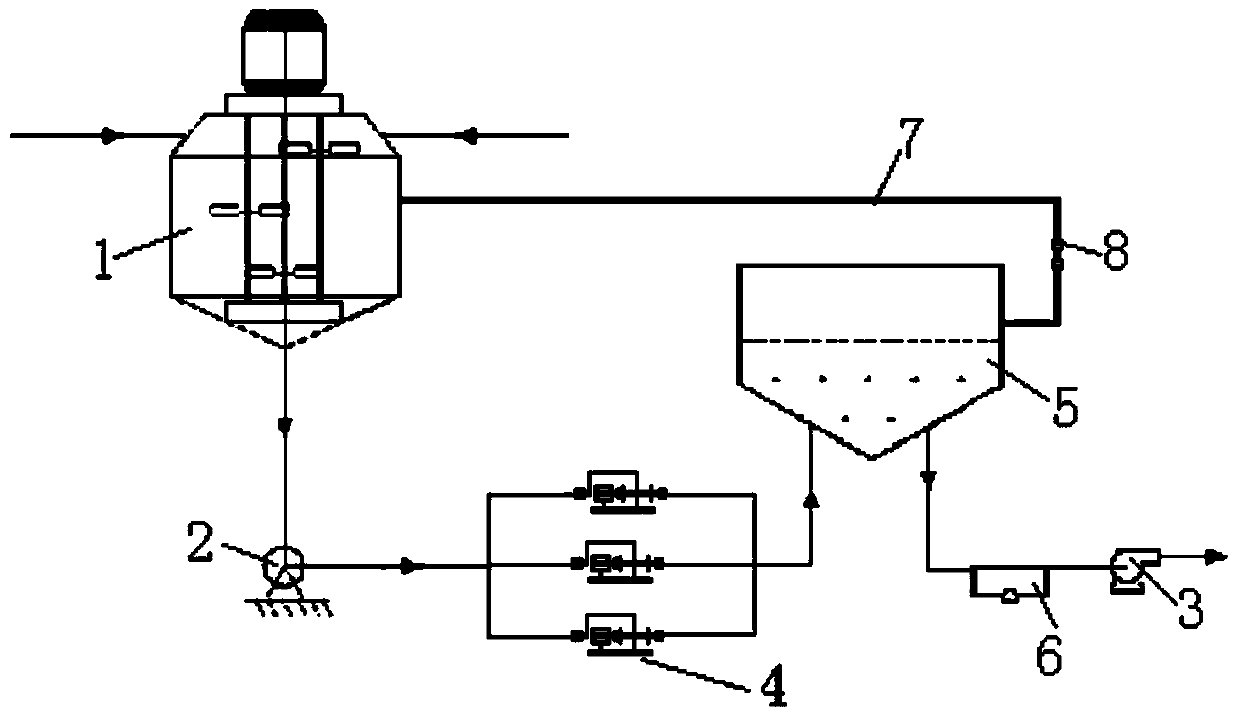

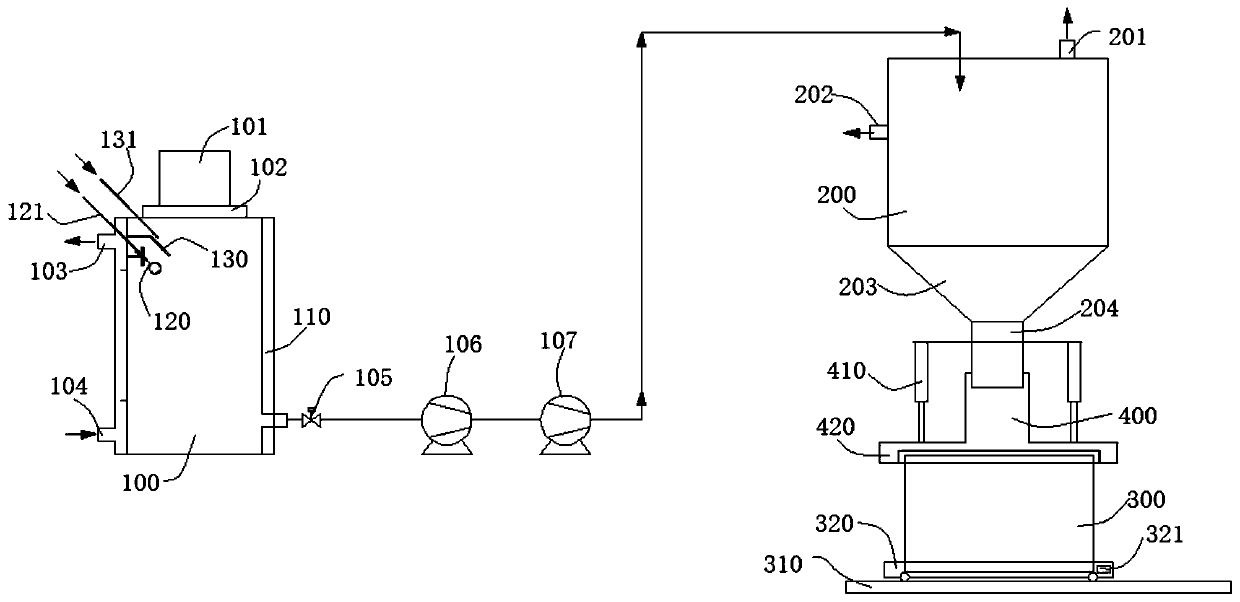

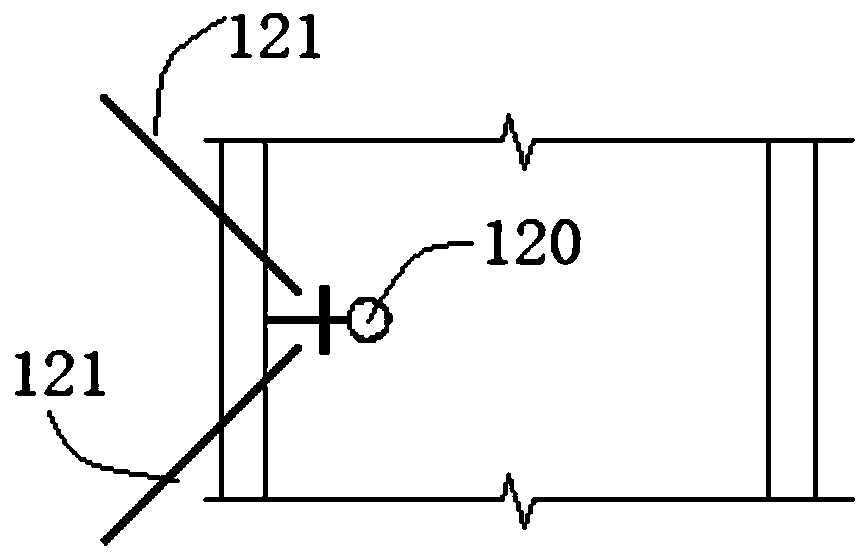

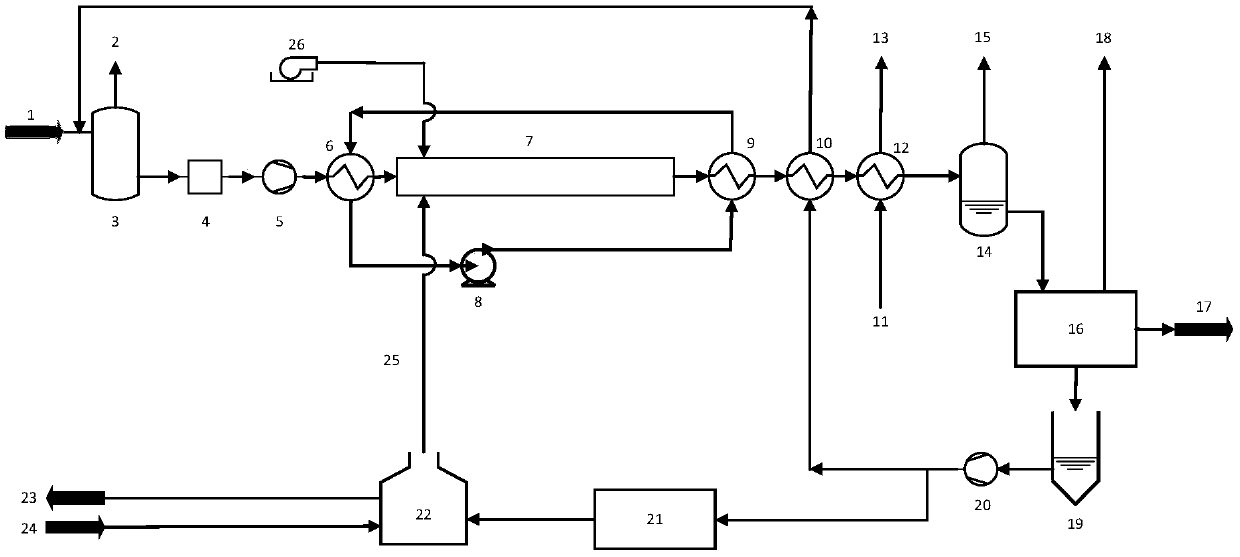

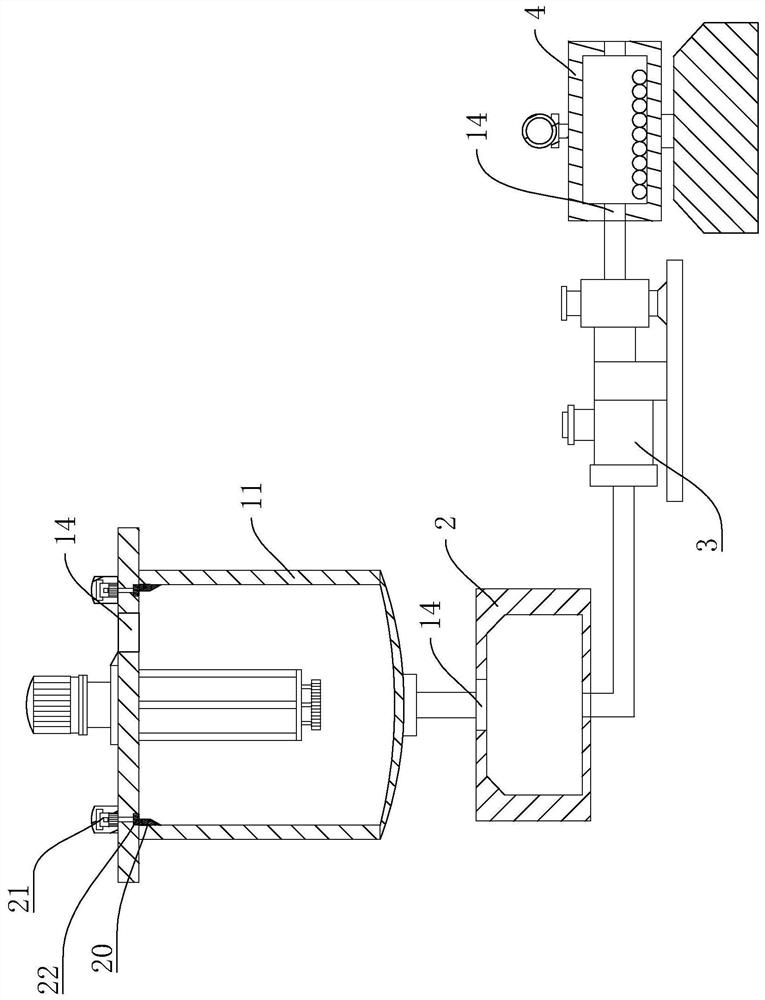

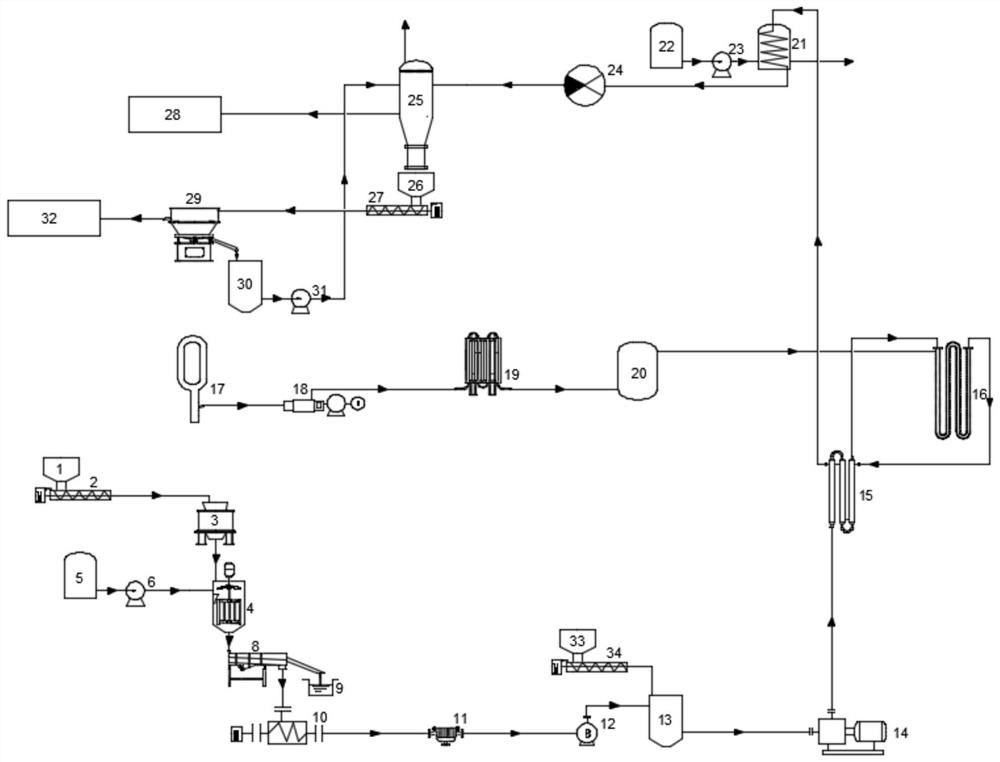

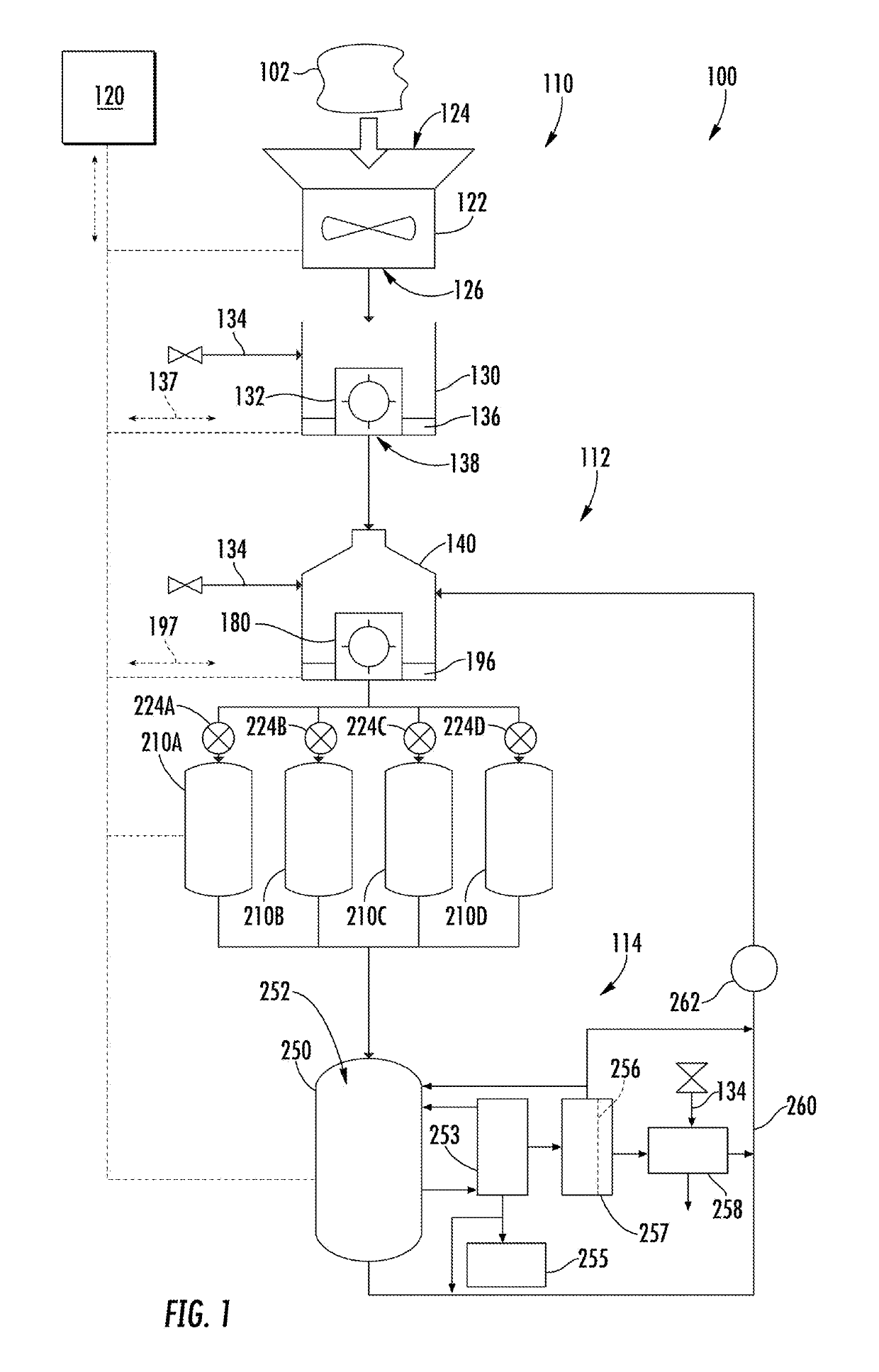

Continuous sludge pyrohydrolysis system and process capable of realizing efficient and sufficient pyrohydrolysis

PendingCN112094015AFully hydrolyzedThorough degree of thermal hydrolysisSludge treatment by pyrolysisWater treatment multistage treatmentsSludgeMulti-stage flash distillation

The invention provides a continuous sludge pyrohydrolysis system and process capable of realizing efficient and sufficient pyrohydrolysis, the system comprises a sludge bin, a discharge port of the sludge bin is connected with a grinding pump, the grinding pump is connected with a feed port of a slurrying tank in a step-by-step heating and boosting unit, and a discharge port of a hydrolysis tank in the step-by-step heating and boosting unit is connected with a feed port of a multi-stage flash evaporation unit; the step-by-step heating and boosting unit comprises the slurrying tank, a preheating tank and the hydrolysis tank which are connected in sequence; the multi-stage flash evaporation unit comprises a plurality of flash evaporation tanks which are connected in sequence; the hydrolysistank is also connected with a steam boiler; wherein a discharge port of the multi-stage flash evaporation unit is connected with a feed port of a heat exchanger, a discharge port of the heat exchangeris connected with a feed port of an automatic filter pressing system, and a discharge port of the automatic filter pressing system outputs dewatered mud cakes. According to the technology, the watercontent of the subsequent dehydrated mud cake can reach 50%, and compared with the water content of the subsequent dehydrated mud cake in the prior art of 60%, the water content of the subsequent dehydrated mud cake is reduced by 10%.

Owner:西安联创分布式可再生能源研究院有限公司

Grinder pump basin system

ActiveUS20130270375A1Effectively and efficiently cutSpecific fluid pumpsGas current separationEngineeringMechanical engineering

A grinder pump basin system is provided which includes a basin; a cover plate; a bracket secured to the cover plate; and a grinder pump with cutter plate with openings and a cutter blade secured to the bracket above a bottom surface of the basin. The openings in the cutter plate have an unique shape which assists in the cutting of material which flows through an inlet of a grinder pump. The shape of the cutter blade cooperates with the openings in the cutter plate such that solids are forced between these respective components and thereby are efficiently cut into small pieces for passing through the openings and for discharge from the grinder pump basin system.

Owner:ZOELLER PUMP

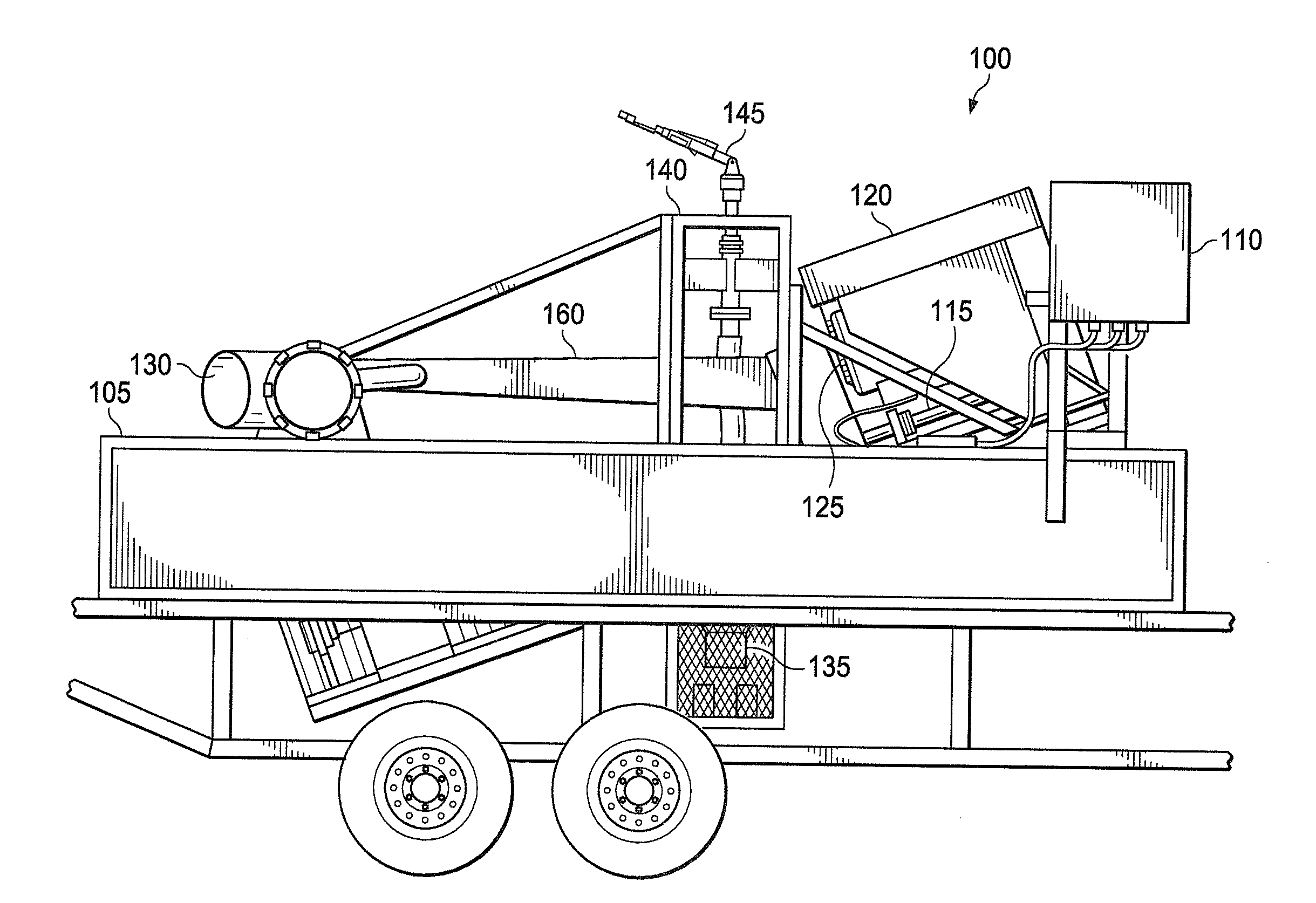

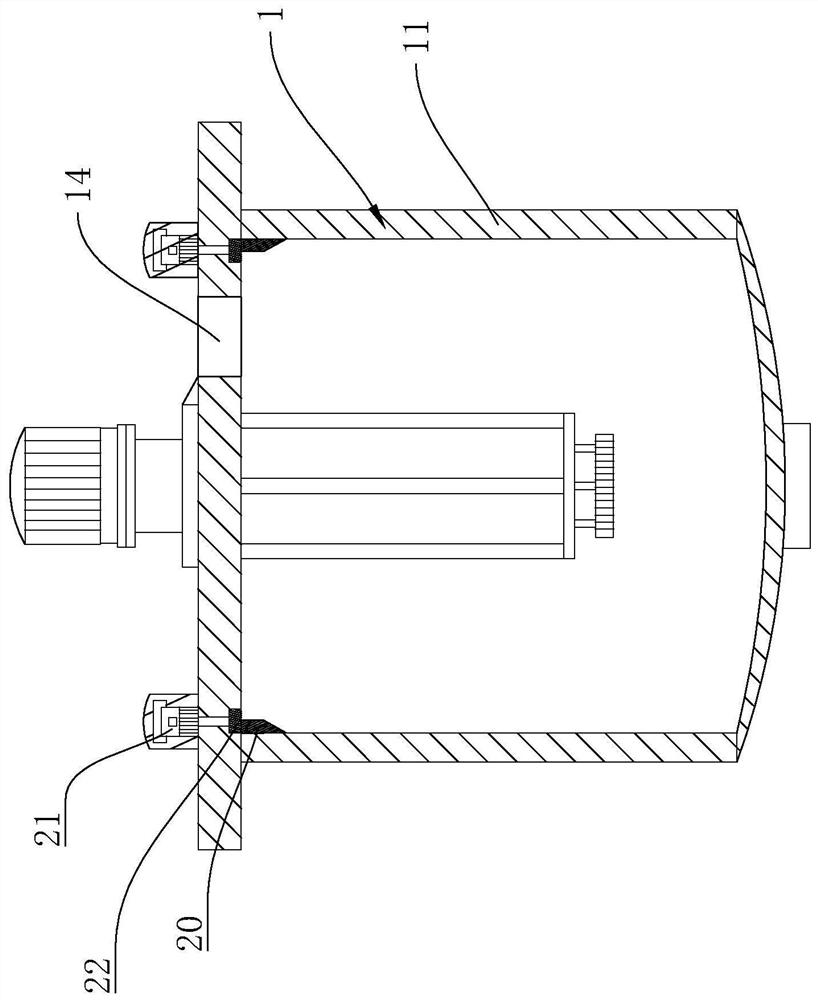

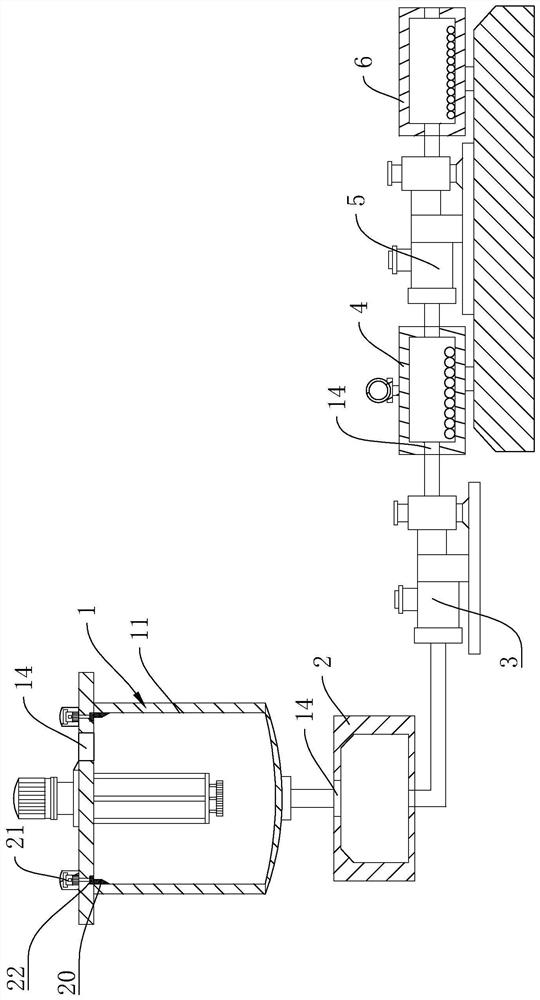

Seaborne continuous blending device for fracturing fluid

The invention relates to a seaborne continuous blending device for fracturing fluid. The seaborne continuous blending device is characterized by comprising a coaxial bidirectional agitating device, a first filling pump, a second filling pump, a multi-grade spiral grinding pump, an air pressure multi-head spraying and mixing device, a measuring device, a refilling pipeline and a solenoid valve, wherein the coaxial bidirectional agitating device is used for shearing and cutting a thickening agent and the fracturing fluid to obtain a mixed solution of the thickening agent and the fracturing fluid; the mixed solution is pumped into the spiral grinding pump by the first filling pump and then enters the air pressure multi-head spraying and mixing device after being grinded by the spiral grinding pump; the mixed solution of the thickening agent and the fracturing fluid, and seawater are sprayed and mixed in the air pressure multi-head spraying and mixing device; according to displacement data of measuring the configured fracturing fluid and the demanded quantity of the fracturing fluid in the seaborne work, one part of the configured fracturing fluid passes through the measuring device to enter the second filling pump and then is pumped into a shaft; the other part of the configured fracturing fluid is returned back into the coaxial bidirectional agitating device by the refilling pipeline through controlling the solenoid valve on the refilling pipeline.

Owner:CHINA NAT OFFSHORE OIL CORP +1

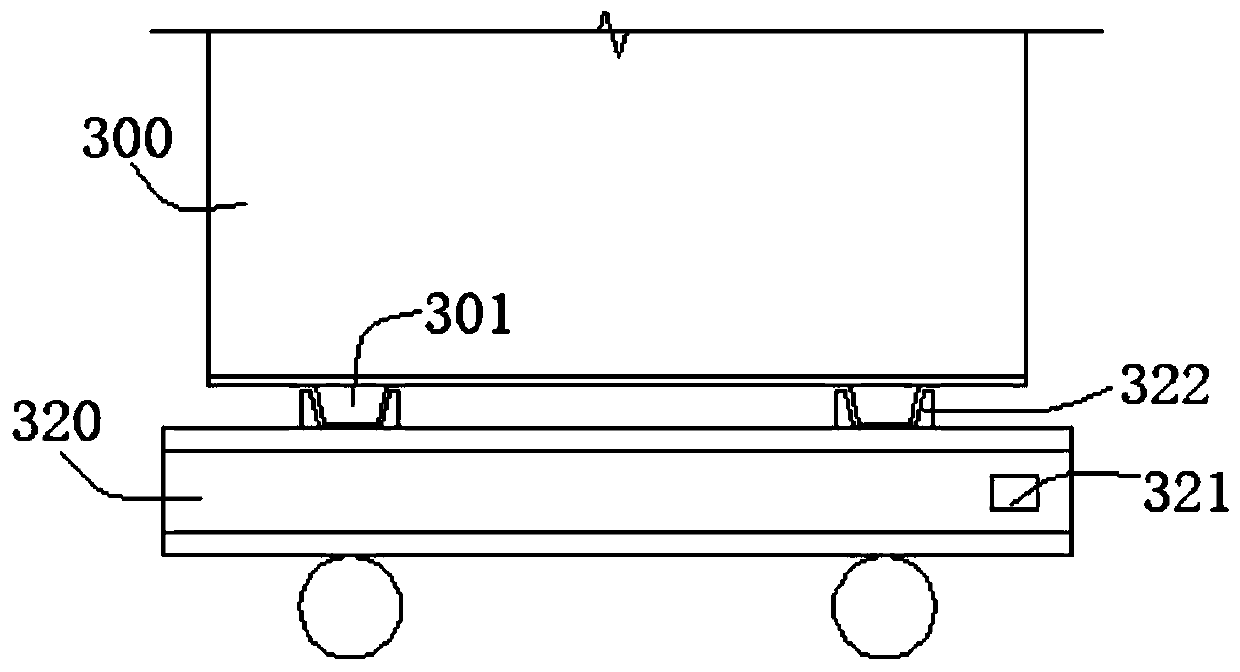

Fully-sealed environmentally-friendly recovery control system for tar residues in coal tar chemical industry

PendingCN110669540AEmission reductionPrevent extractionCoke ovensLiquid hydrocarbon mixture productionChemical industryLaser ranging

The invention discloses a fully-sealed environmentally-friendly recovery control system for tar residues in the coal tar chemical industry, and belongs to the field of pollution treatment. The systemcomprises an emulsifier, a two-phase separator and a tar residue tank, wherein a passive liquid level switch is arranged in the emulsifier, the outlet of the emulsifier is connected with the two-phaseseparator through a pipeline, and an eccentric ball valve, a grinding pump and a conveying pump are arranged on the outlet pipeline; and a sealing cover sleeves the outer side of a slag outlet pipe at the bottom of the two-phase separator in a fit manner, is connected with a driving arm, is driven by the driving arm to lift up and down, and is used for sealing the top opening of the tar residue tank, the tar residue tank is arranged on a trolley, and the trolley is provided with a laser range finder. The system can overcome the defect that tar residue treatment is difficult to automatically operate in the prior art, effectively improves the operation environment of tar residue recovery treatment, and also has the advantages of convenience in automatic control operation, high adaptabilityand wide application prospect.

Owner:马鞍山市新能环智能科技有限公司

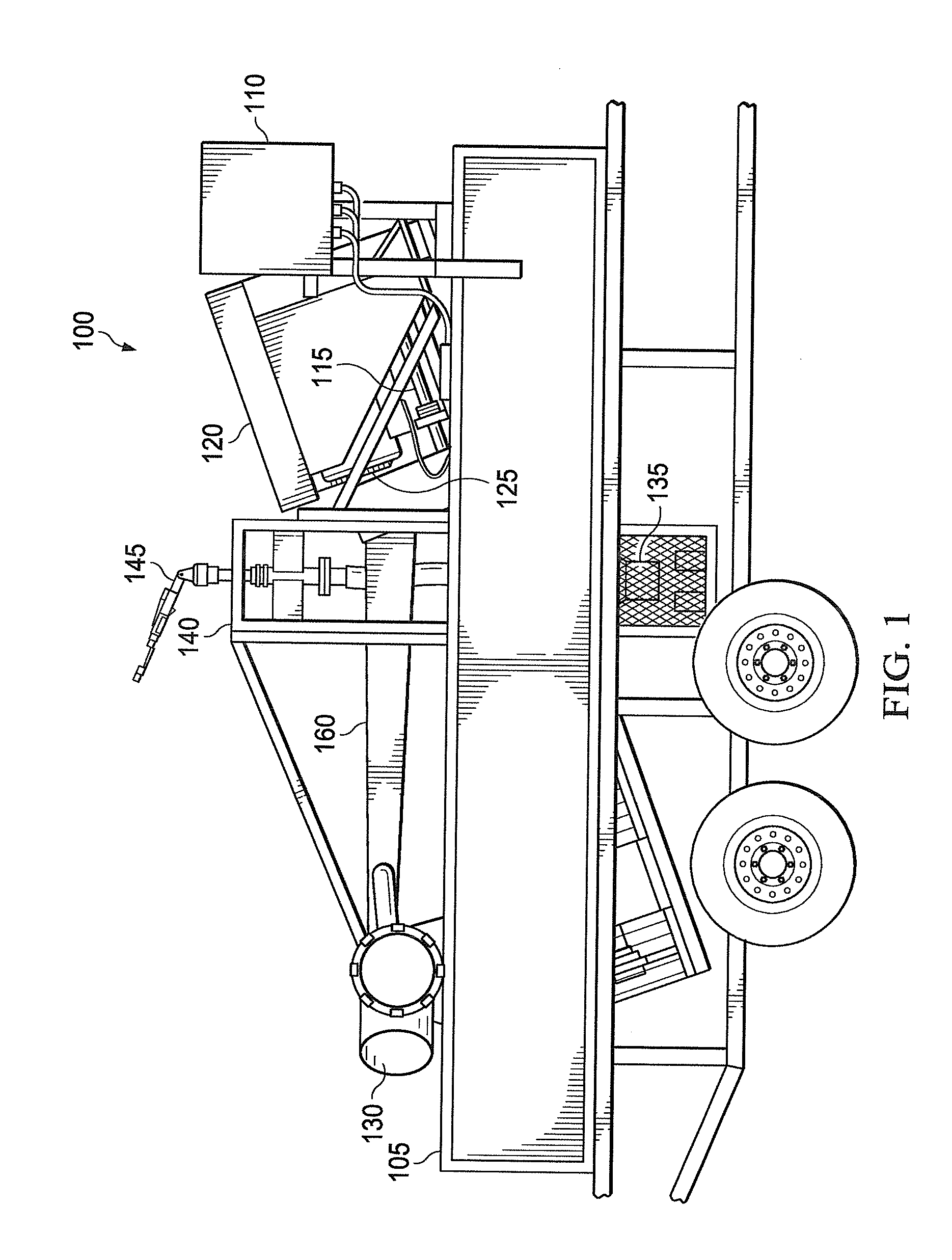

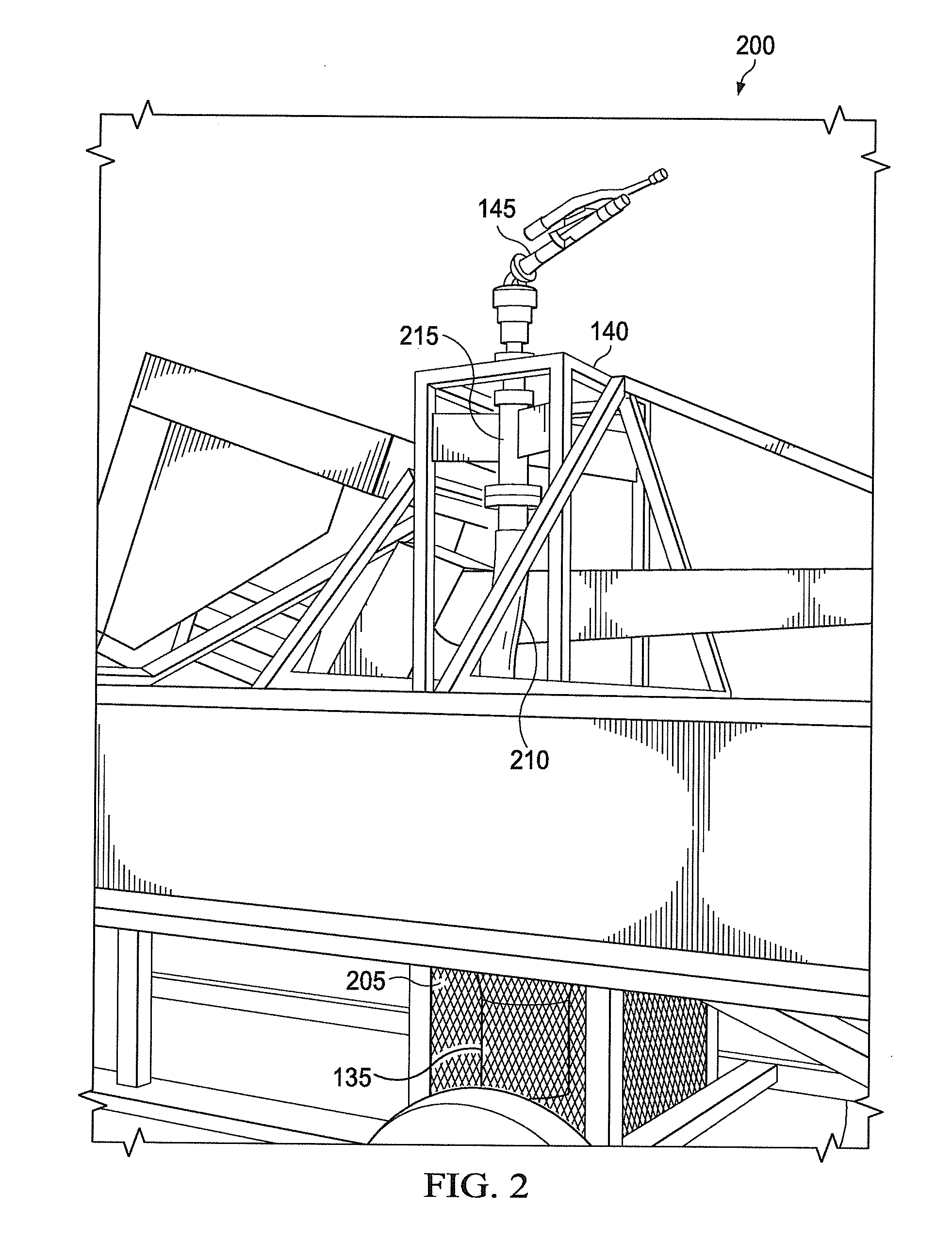

System and method for aeration

ActiveUS20140076820A1Increase dissolved oxygen levelsHigh capacity water movementWater cleaningTreatment using aerobic processesAeration systemBuoyancy

An aeration device includes a foam suppression system. The aeration device raises the level of oxygen and air in a body of substantially liquid fluid, such as an aerating-oxidizing pond, lagoon, basin, or reservoir. The aeration system is buoyant and floats on top of the body of fluid. The foam suppression system includes a submersible grinder pump coupled to a sprinkler head by a fluid conduction system. The submersible grinder pump draws in a fluid from beneath a surface of a body of fluid and pumps it through the fluid conduction system and out of the sprinkler head. The sprinkler head sprays the fluid drawn from beneath the fluid surface far outward onto an area surrounding the aeration device with surface foam. The falling water or fluid sprayed from the sprinkler head quashes the surface foam. The sprinkler head is disposed in a location on the aeration device suitable to suppress the surface foam.

Owner:AIRMASTER AERATOR L L C

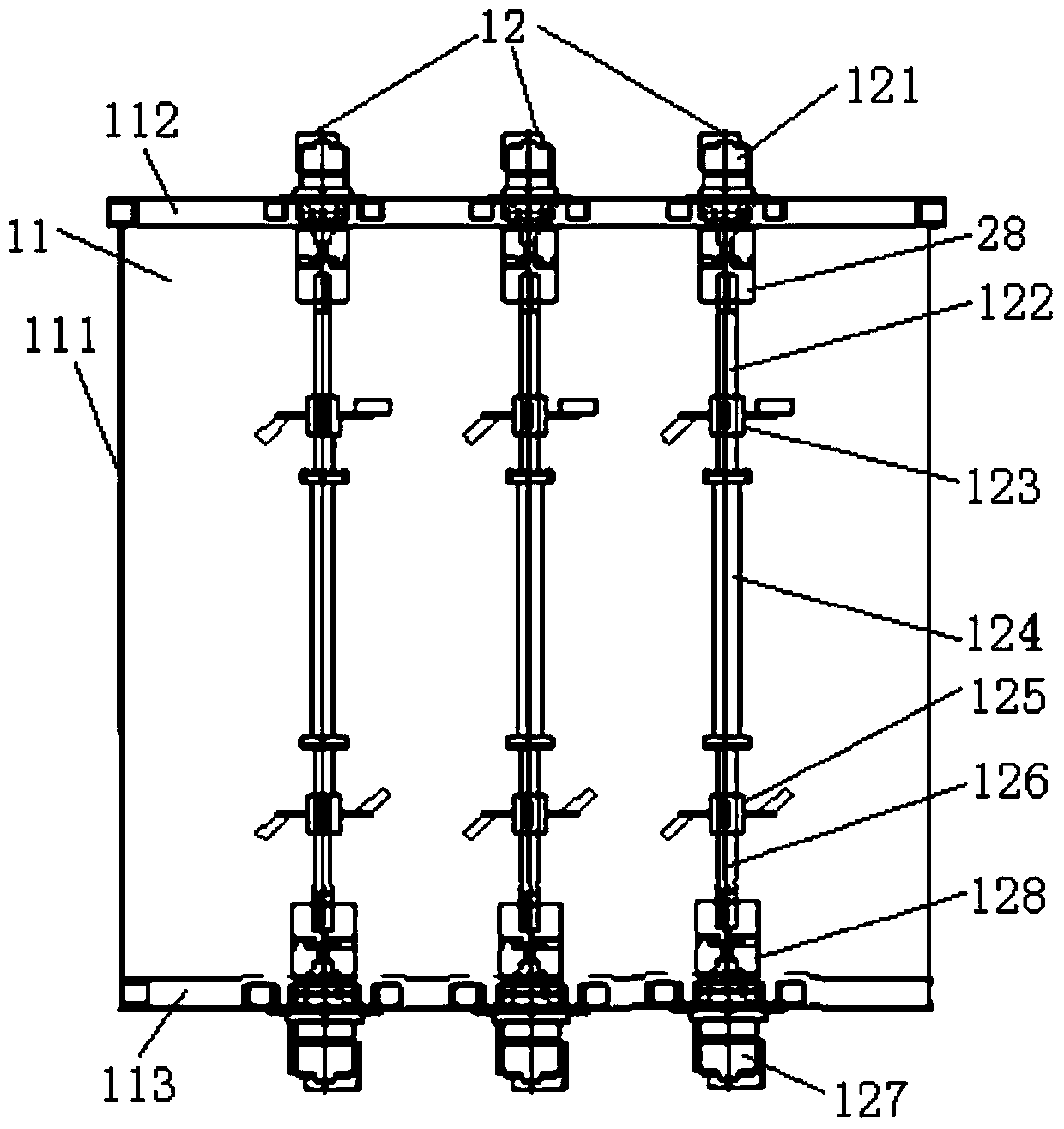

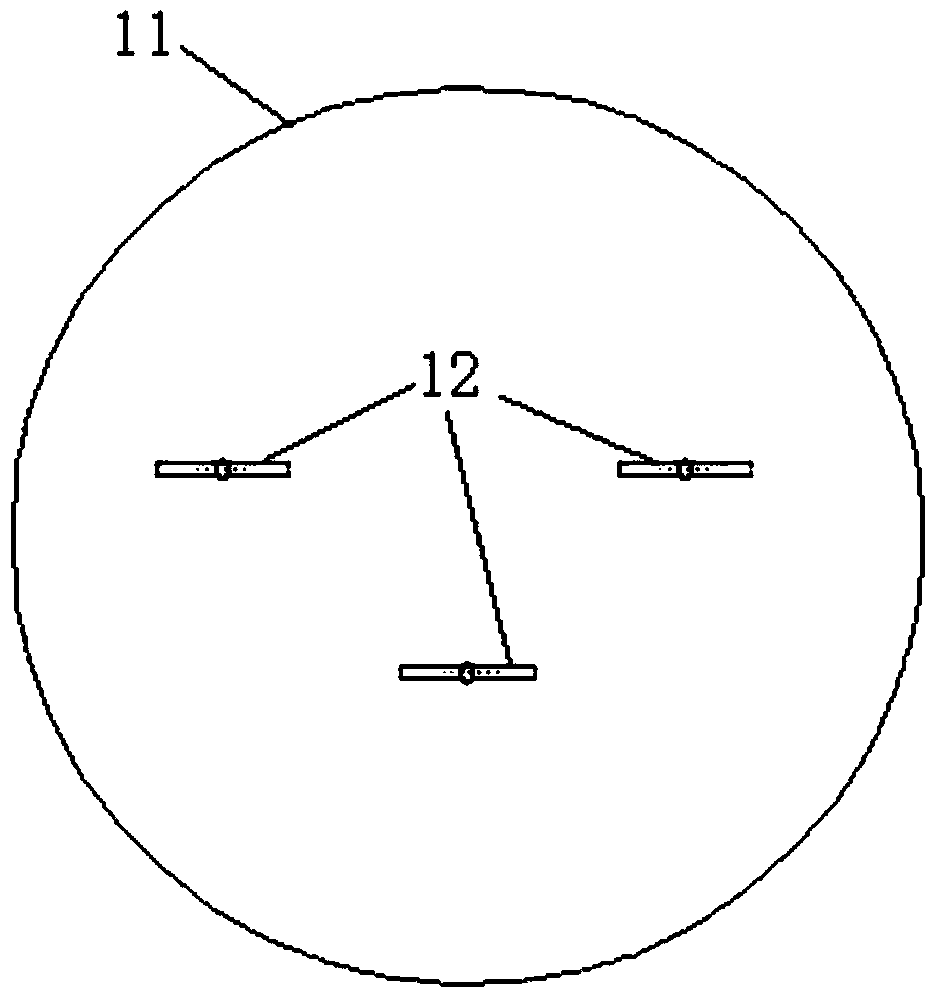

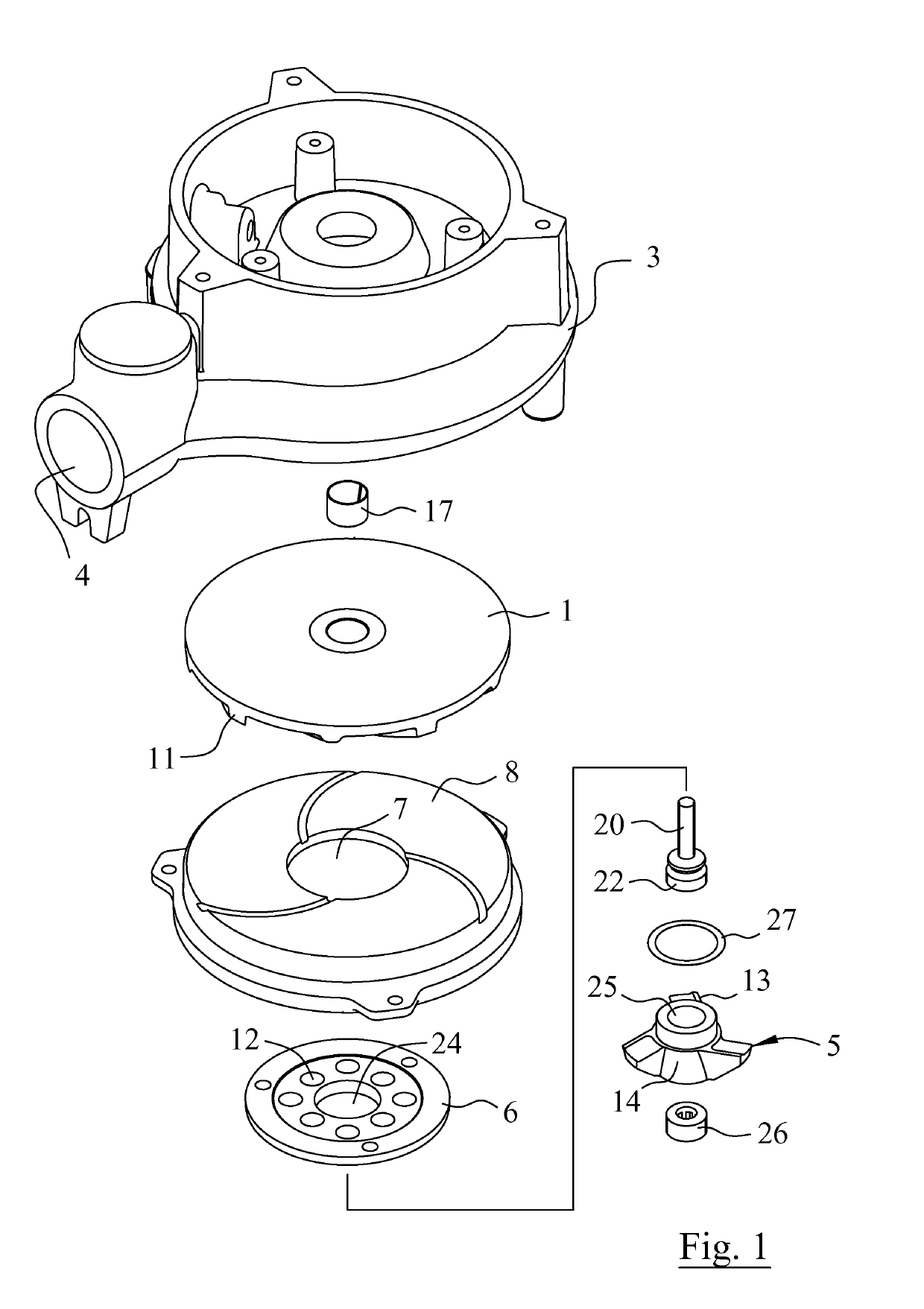

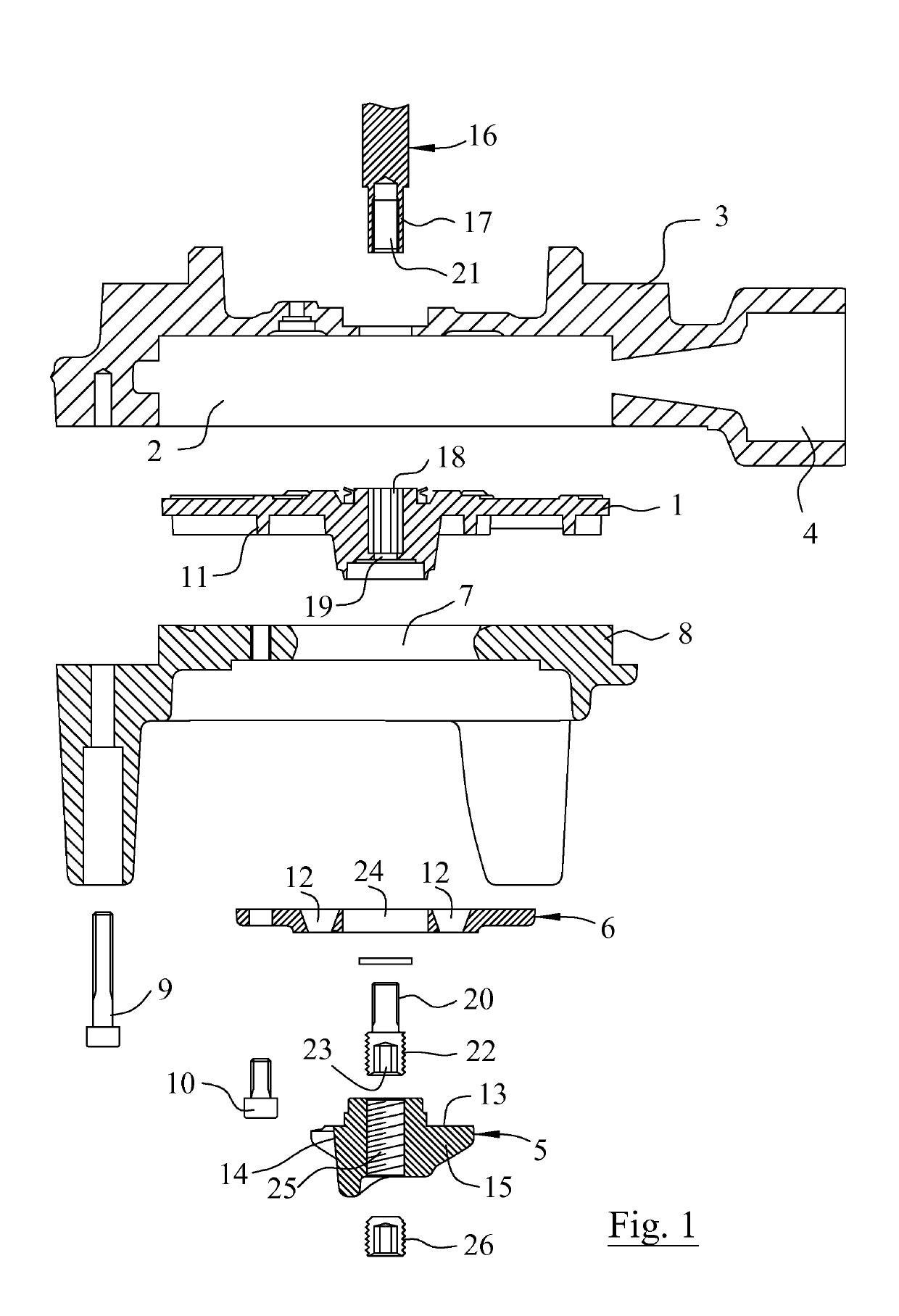

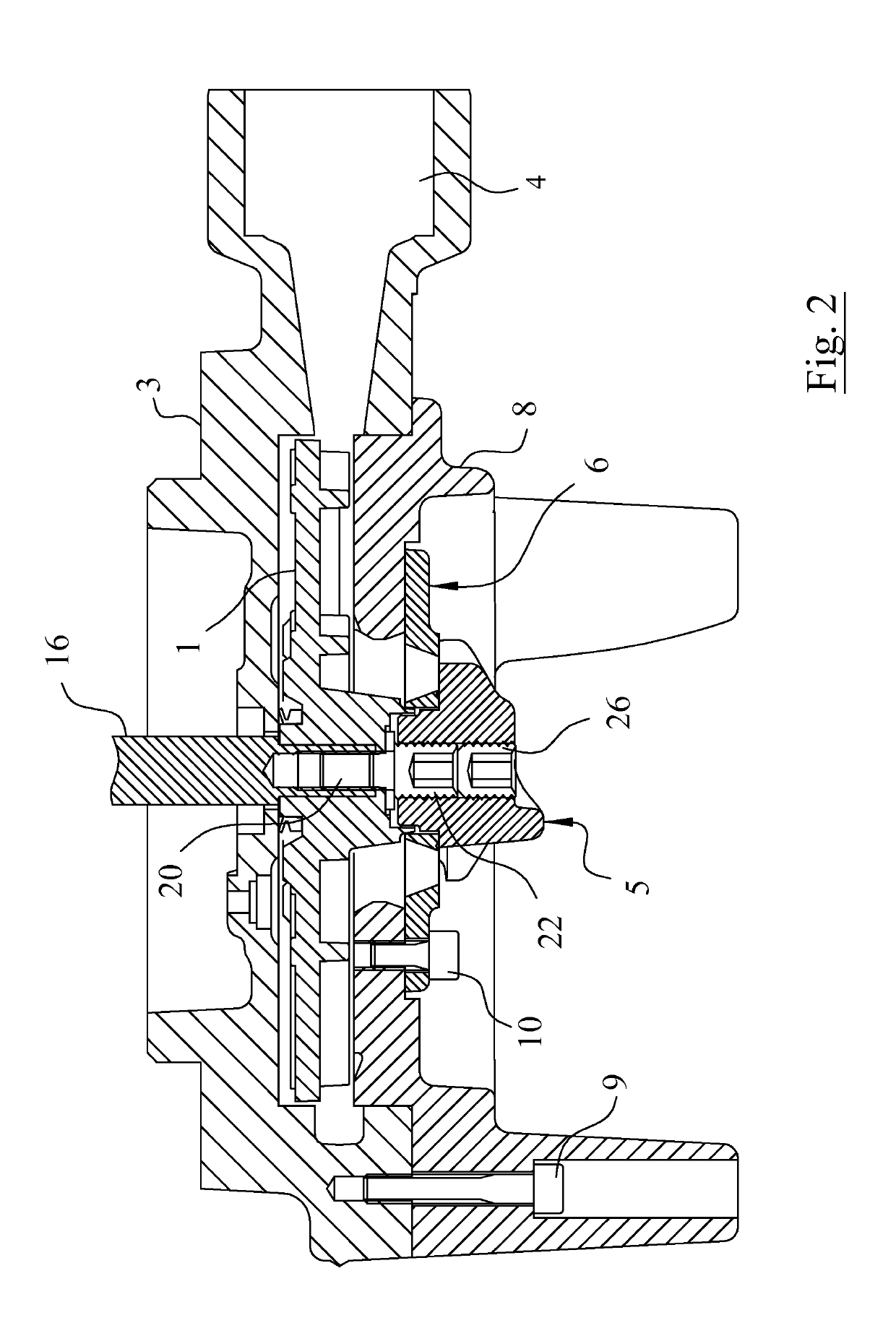

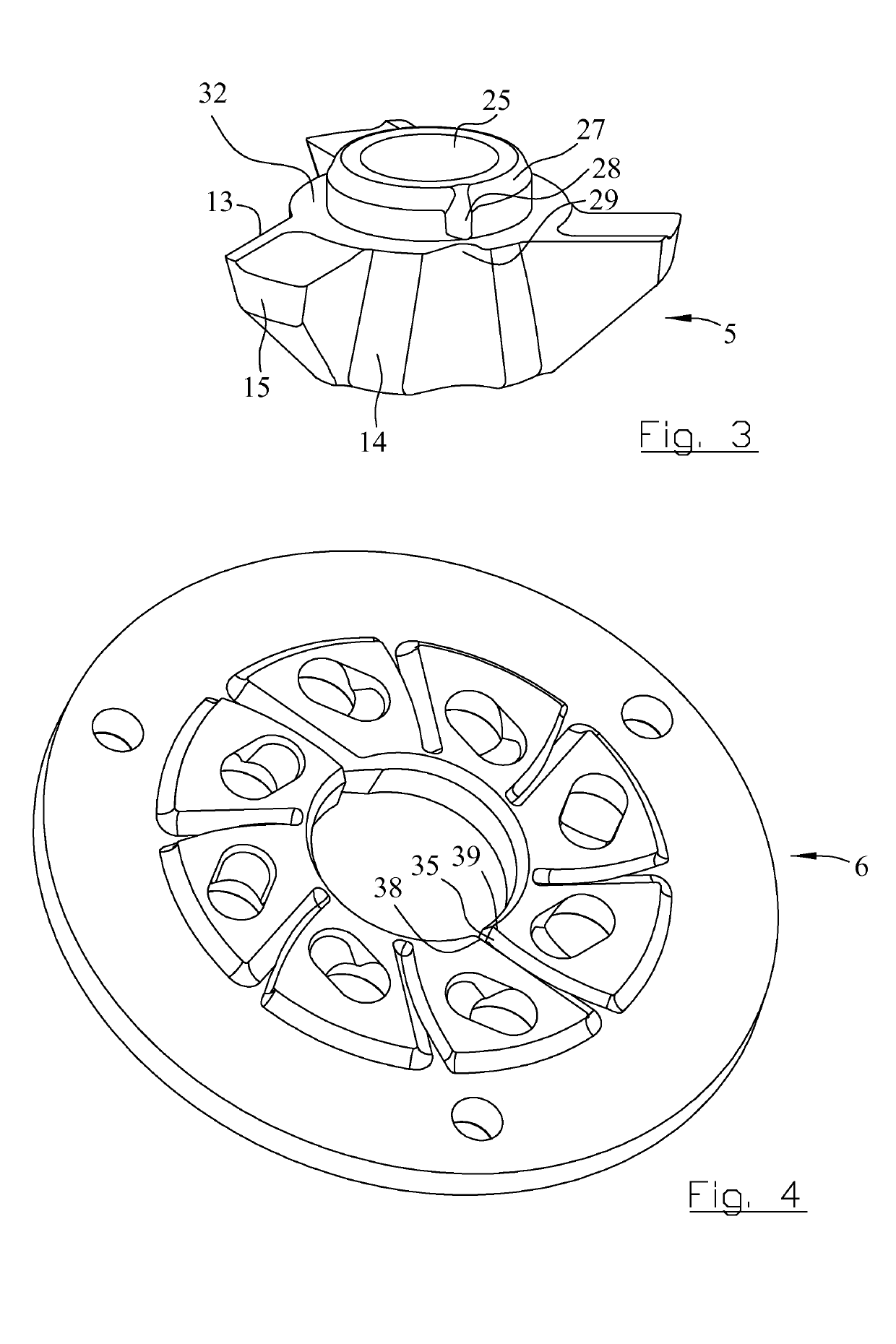

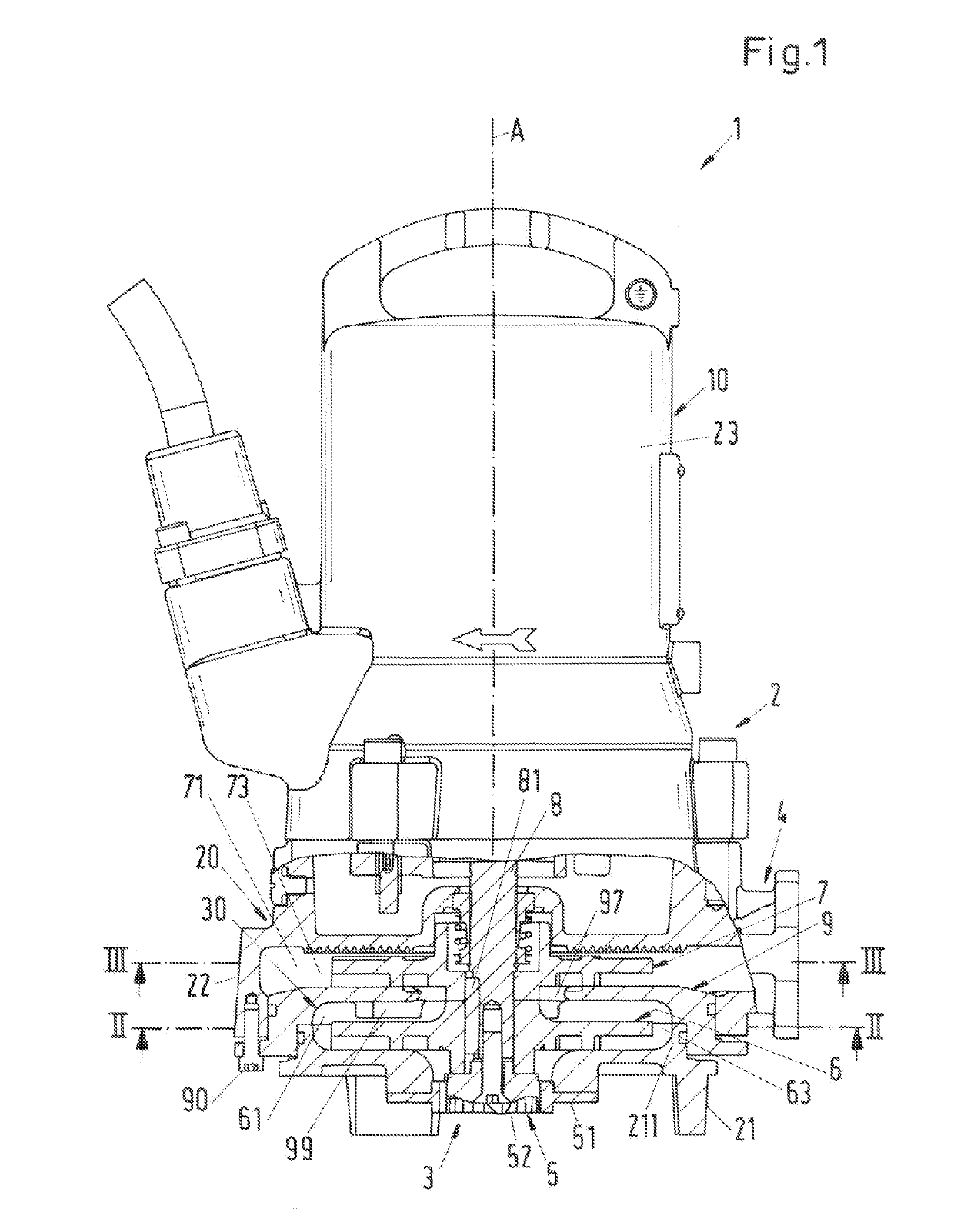

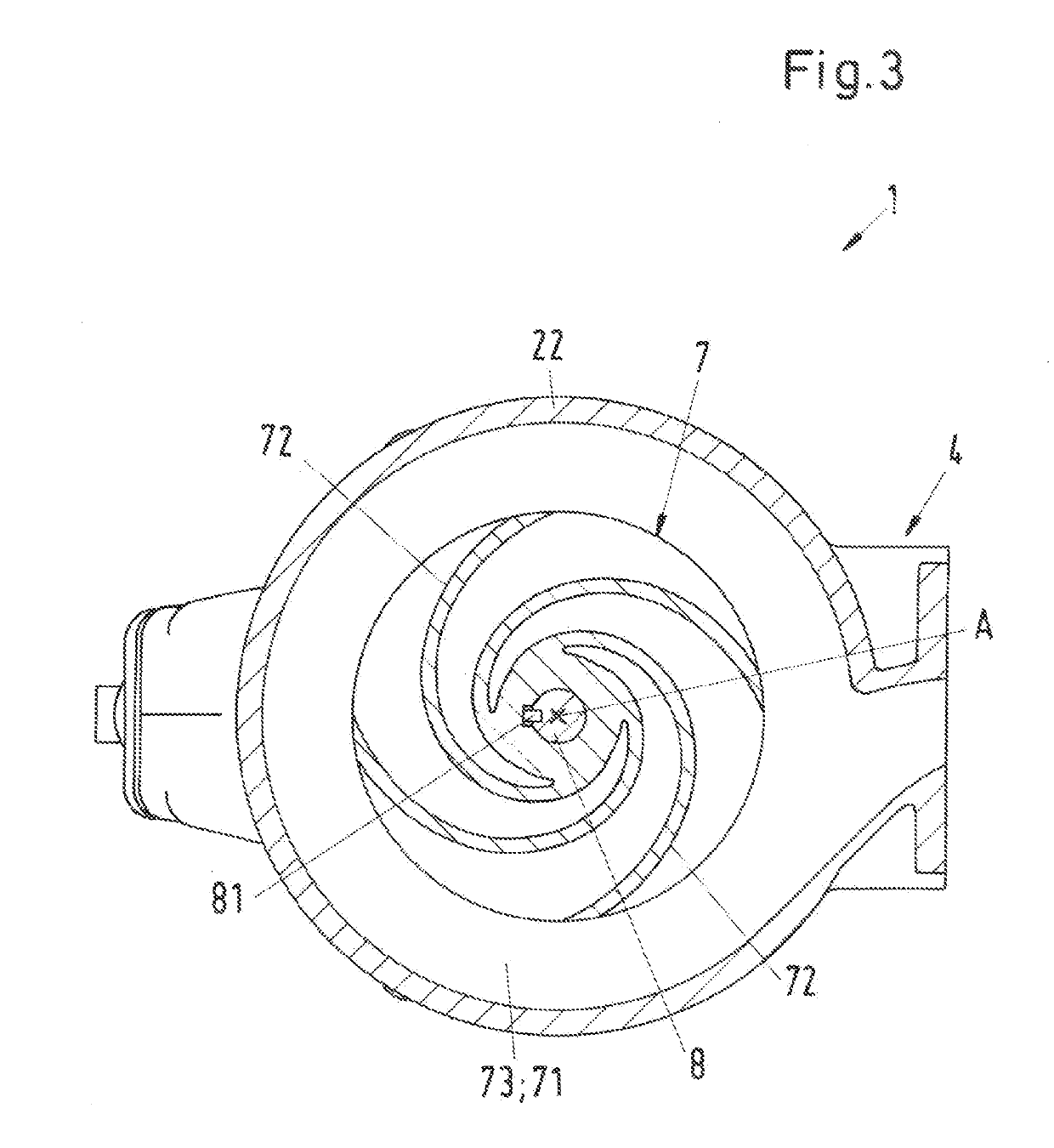

Cutter wheel, cutter disc as well as cutter assembly suitable for grinder pumps

ActiveUS11253866B2Increased operating lifeSolid matter is preventedSpecific fluid pumpsEngine manufactureSuction forceEngineering

A cutter assembly configured for a grinder pump and including a cutter wheel and a cutter disc that interact with each other. The cutter wheel includes a shaft portion that is configured to interact with a central hole of the cutter disc, a hub portion that is connected to the shaft portion and at least two main cutting edges that in the radial direction extend outwards from the hub portion and that are configured to interact with a set of cutting holes of the cutter disc. The shaft portion includes an axially extending cutting recess. The hub portion includes only one radially extending cutting recess. The cutter disc includes a suction side, a central hole that is configured to interact with the shaft portion of the cutter wheel and a set of cutting holes that open in the suction side radially outside the central hole.

Owner:XYLEM EURO GMBH

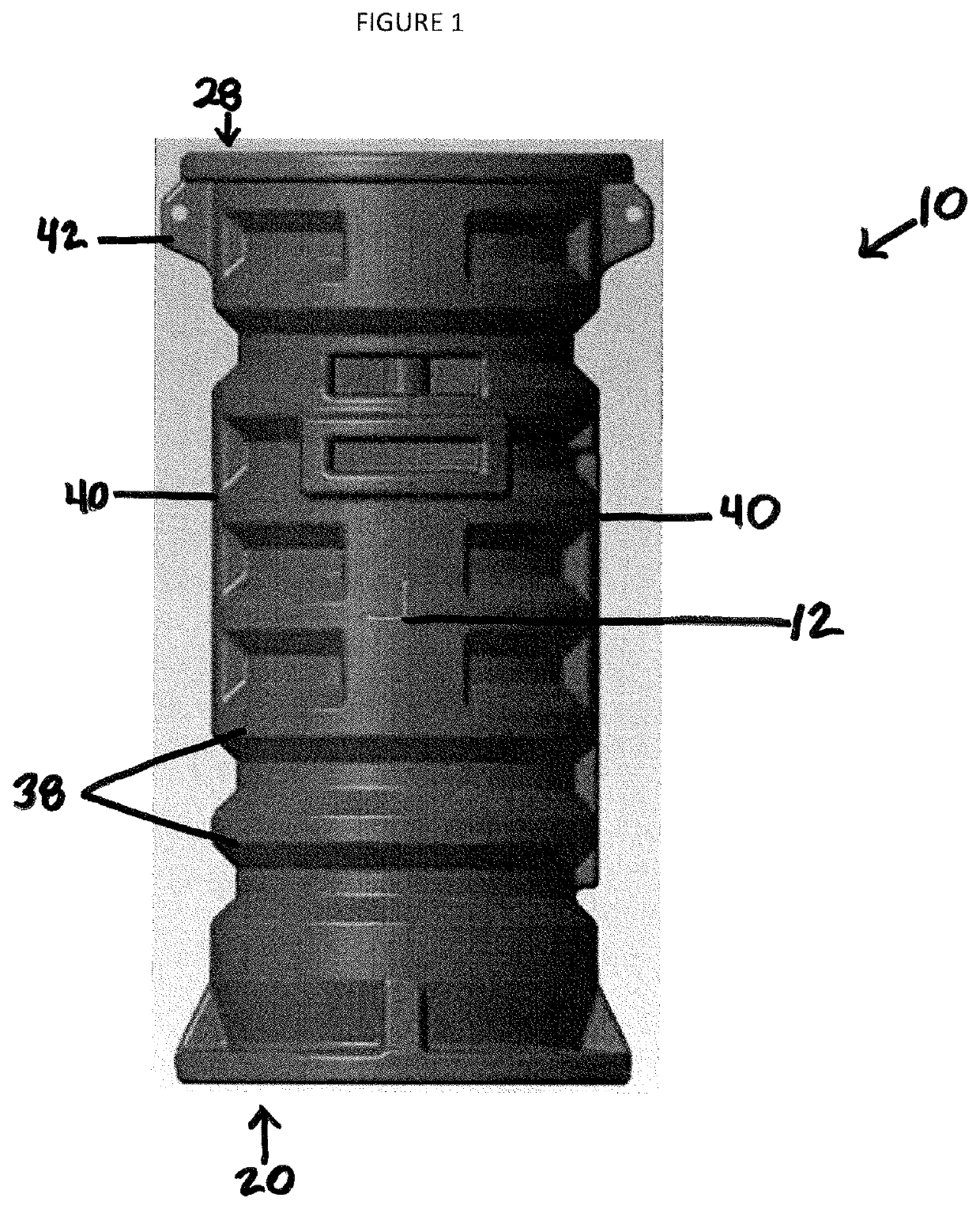

Grinder pump tank

InactiveUS20050205703A1Improves Structural IntegrityEasy to manufactureGas current separationSewerage structuresSewageStructural integrity

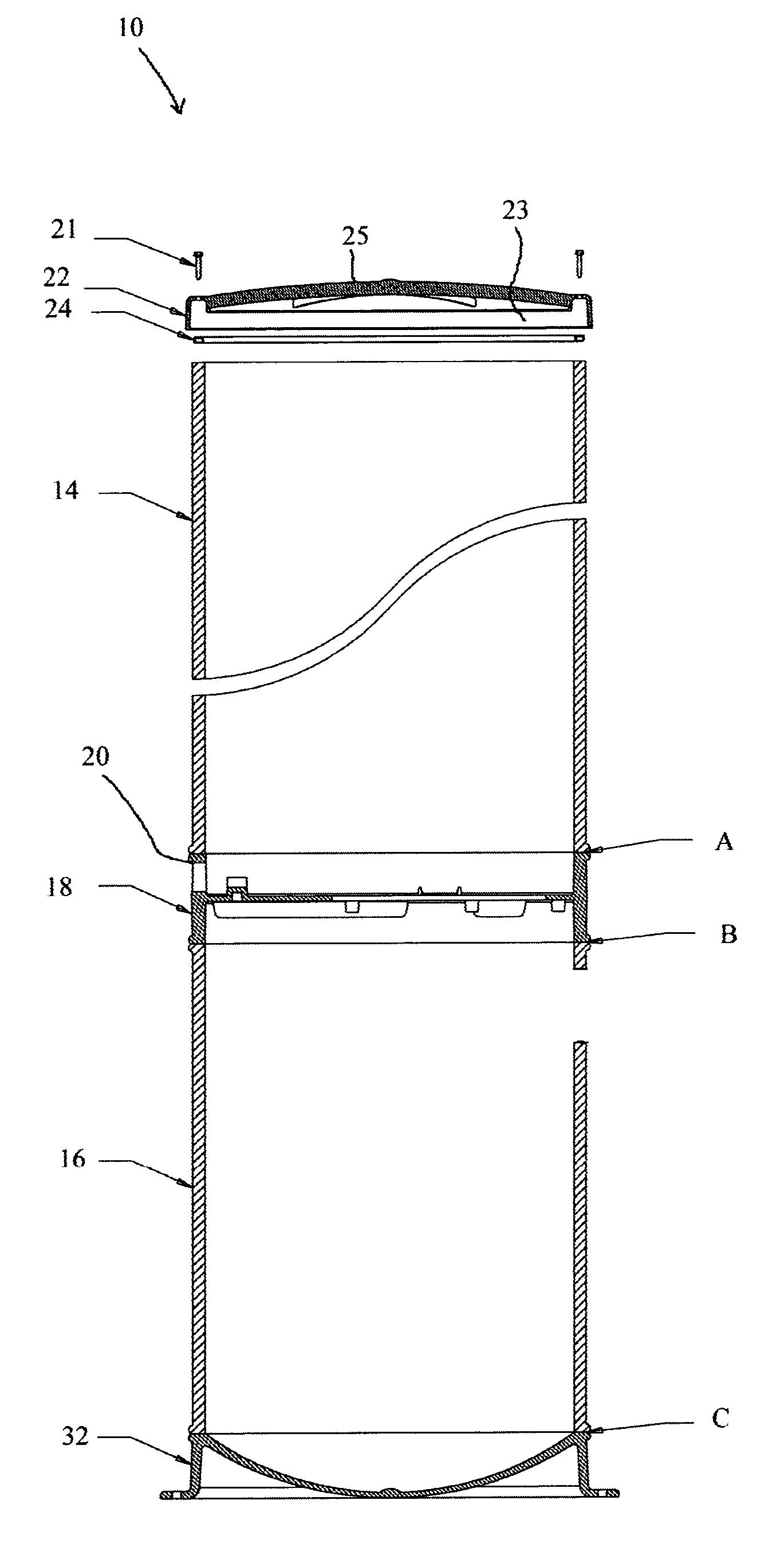

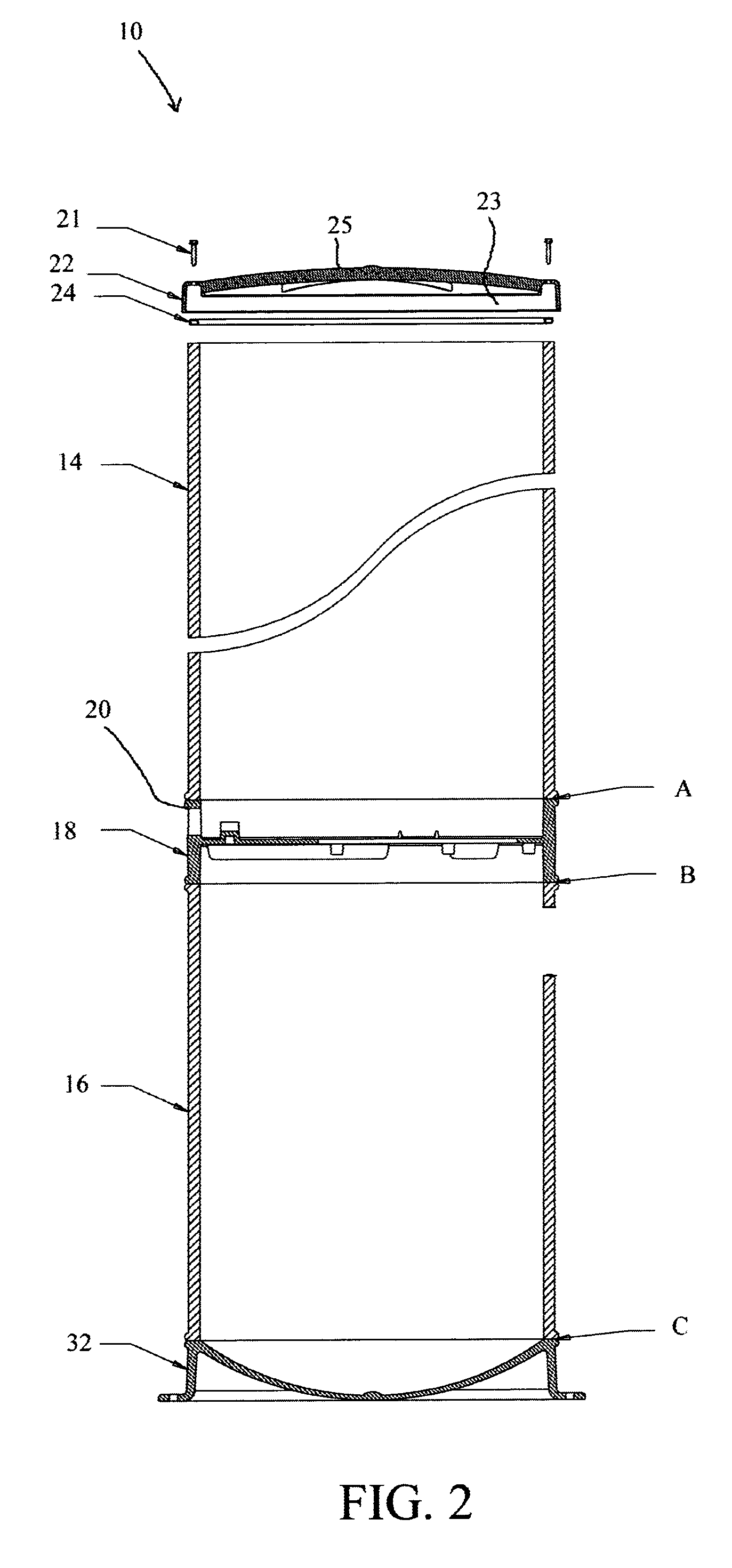

An improved sewage grinder pump tank inclusive of an upper tank portion formed as a cylindrical section of DR 32.5 HDPE, a lid assembly covering the upper tank portion, a lower tank portion similar to the upper tank portion, a pump platform section in communication with the upper tank portion and lower tank portion and forming a platform there between for mounting a grinder pump, and a base formed as a concave molded section for mating with the lower tank portion. The pump platform section is butt fused between the upper tank portion and the lower tank portion, and the base is butt fused to the open end of the lower tank portion. The butt fusion amalgamates the parts into one piece and avoids imperfections, thereby improving structural integrity. In addition, the grinder pump tank simplifies installation, and reduces cost.

Owner:STROHECKER JAMES R +1

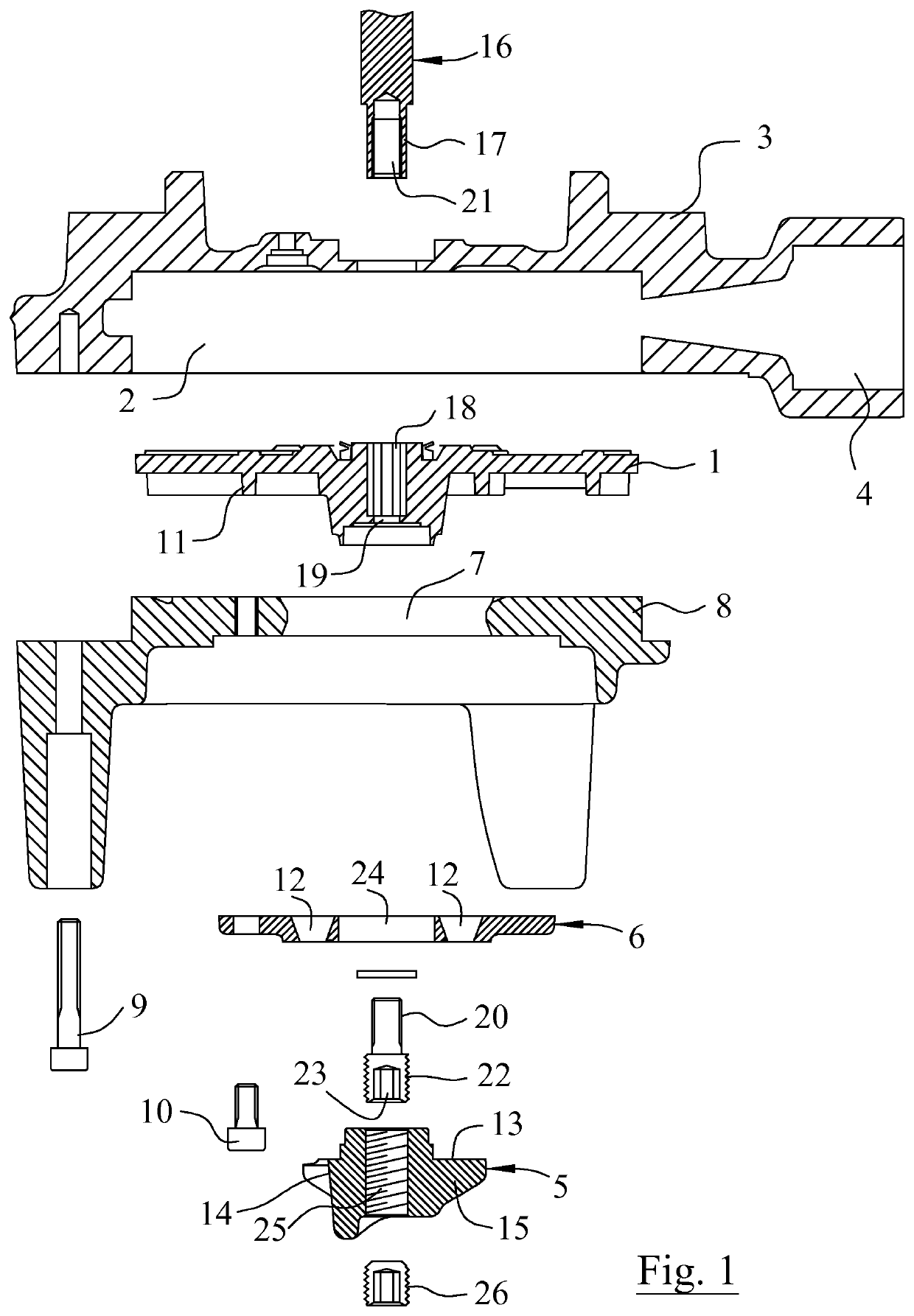

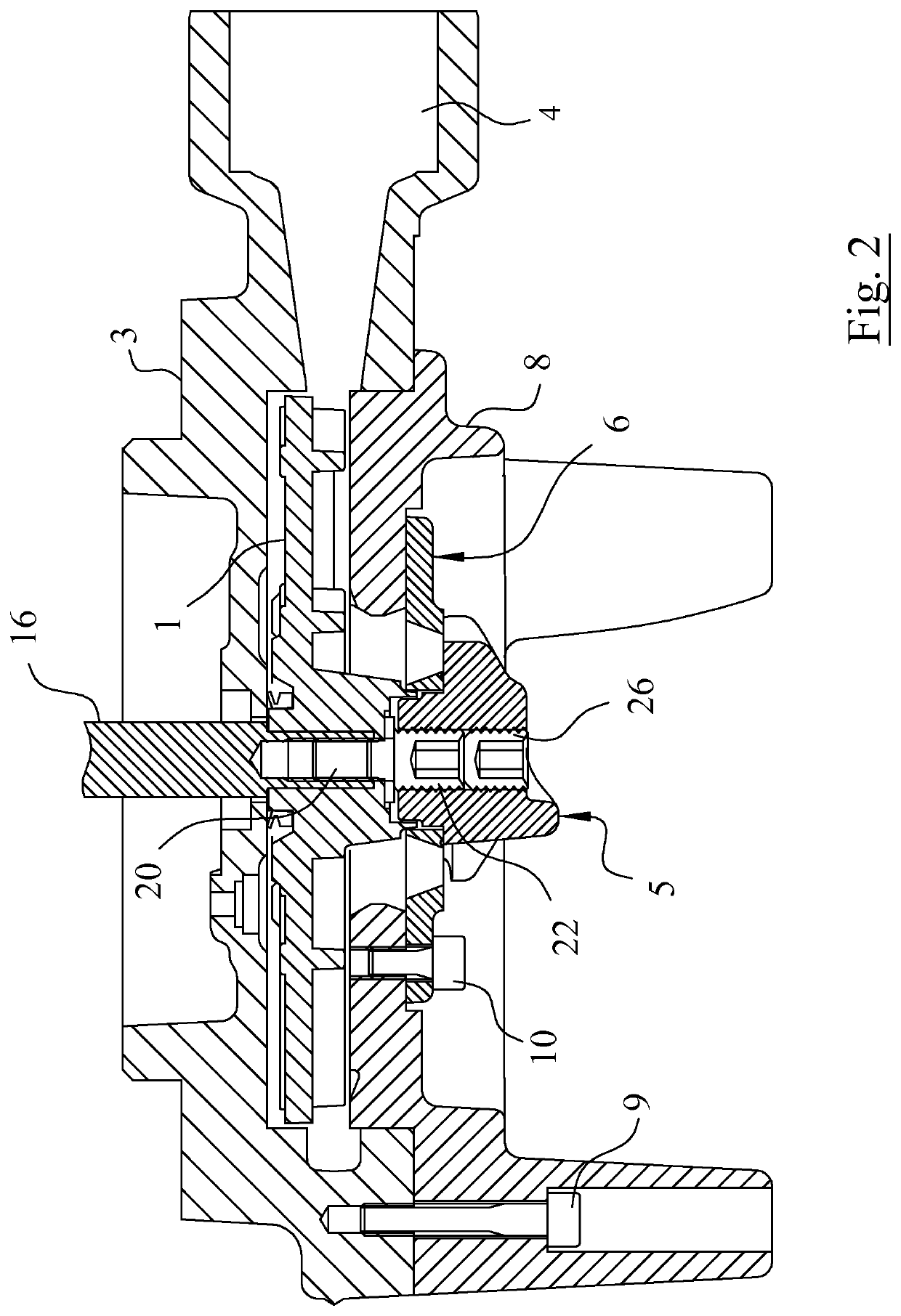

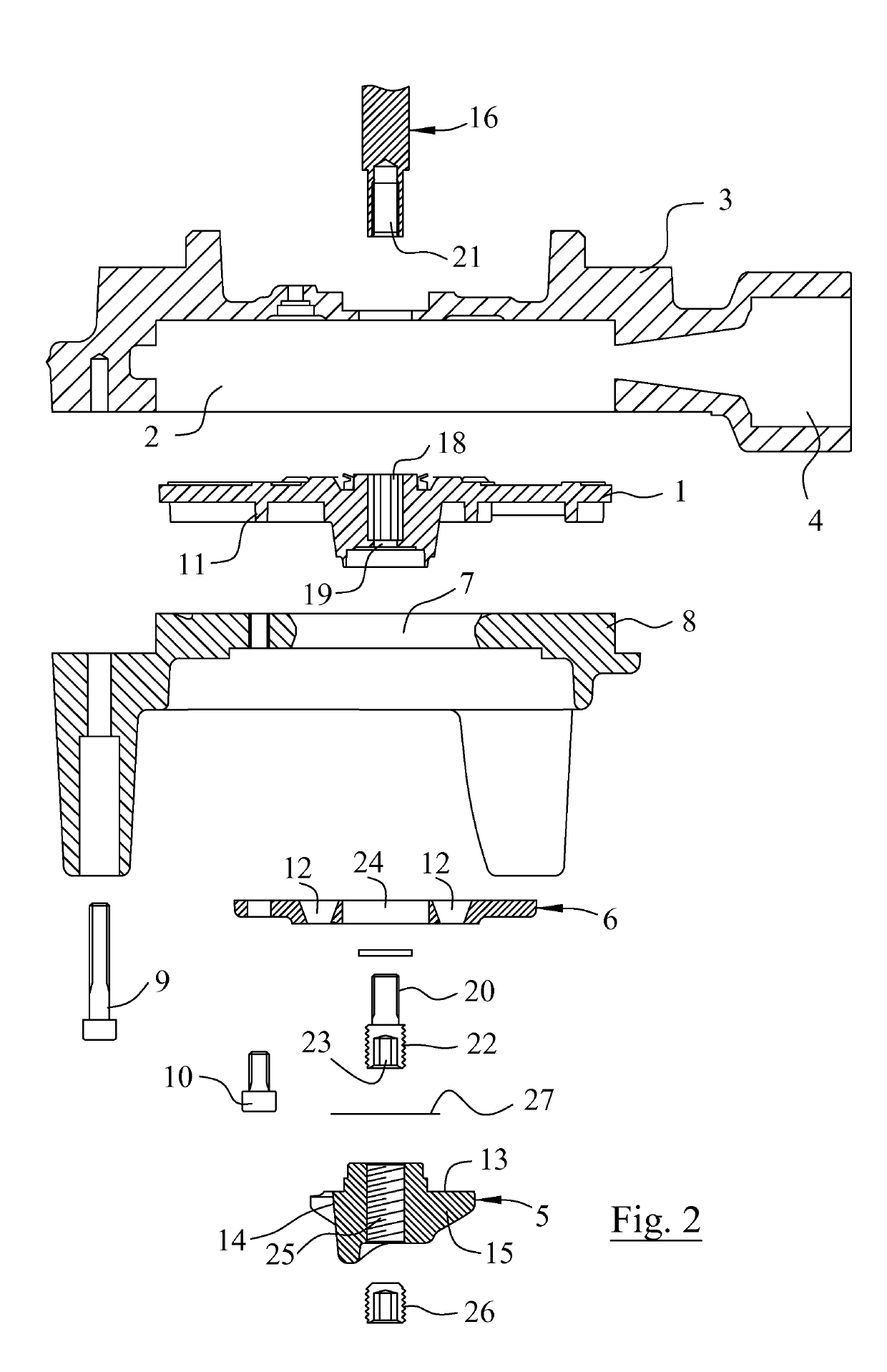

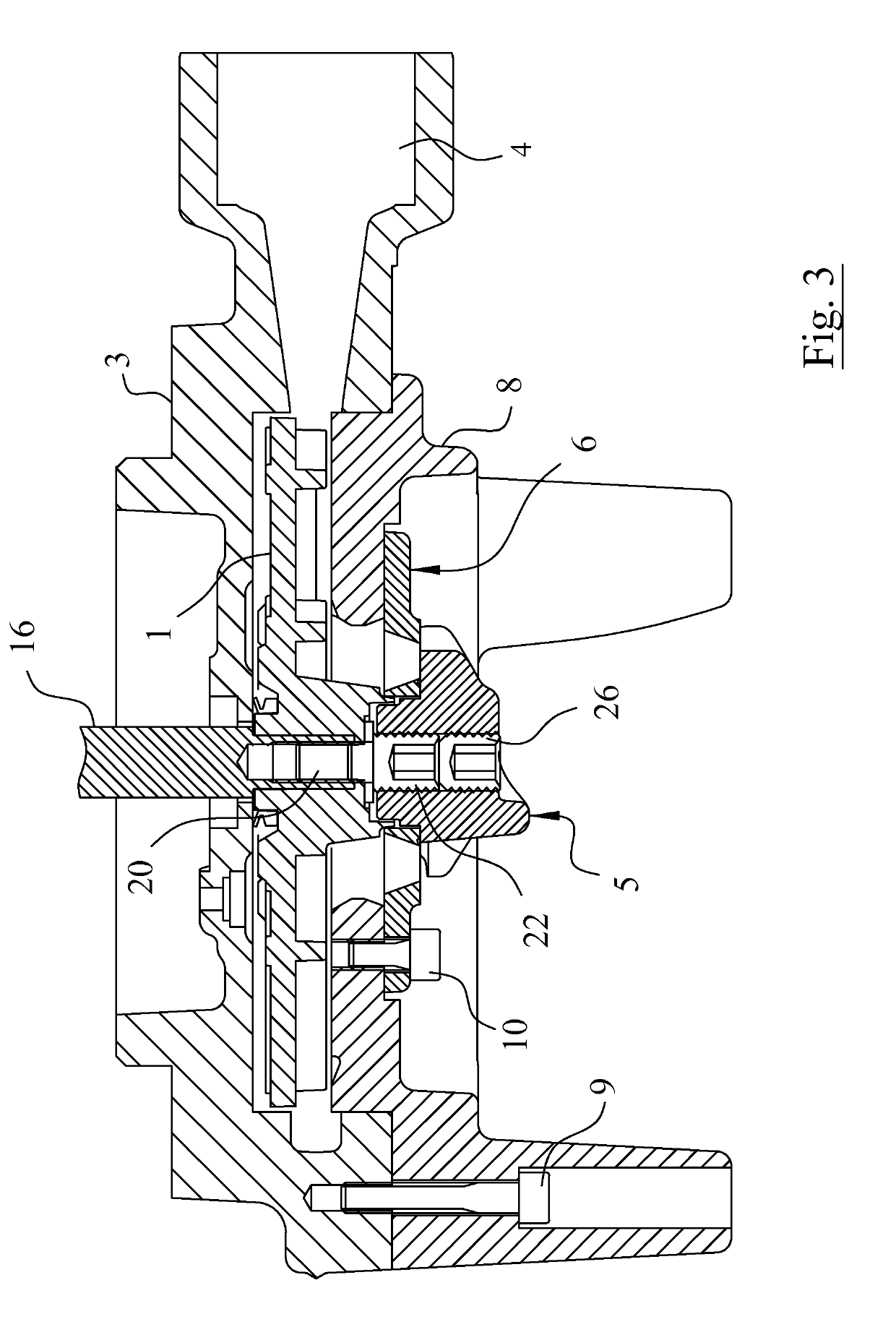

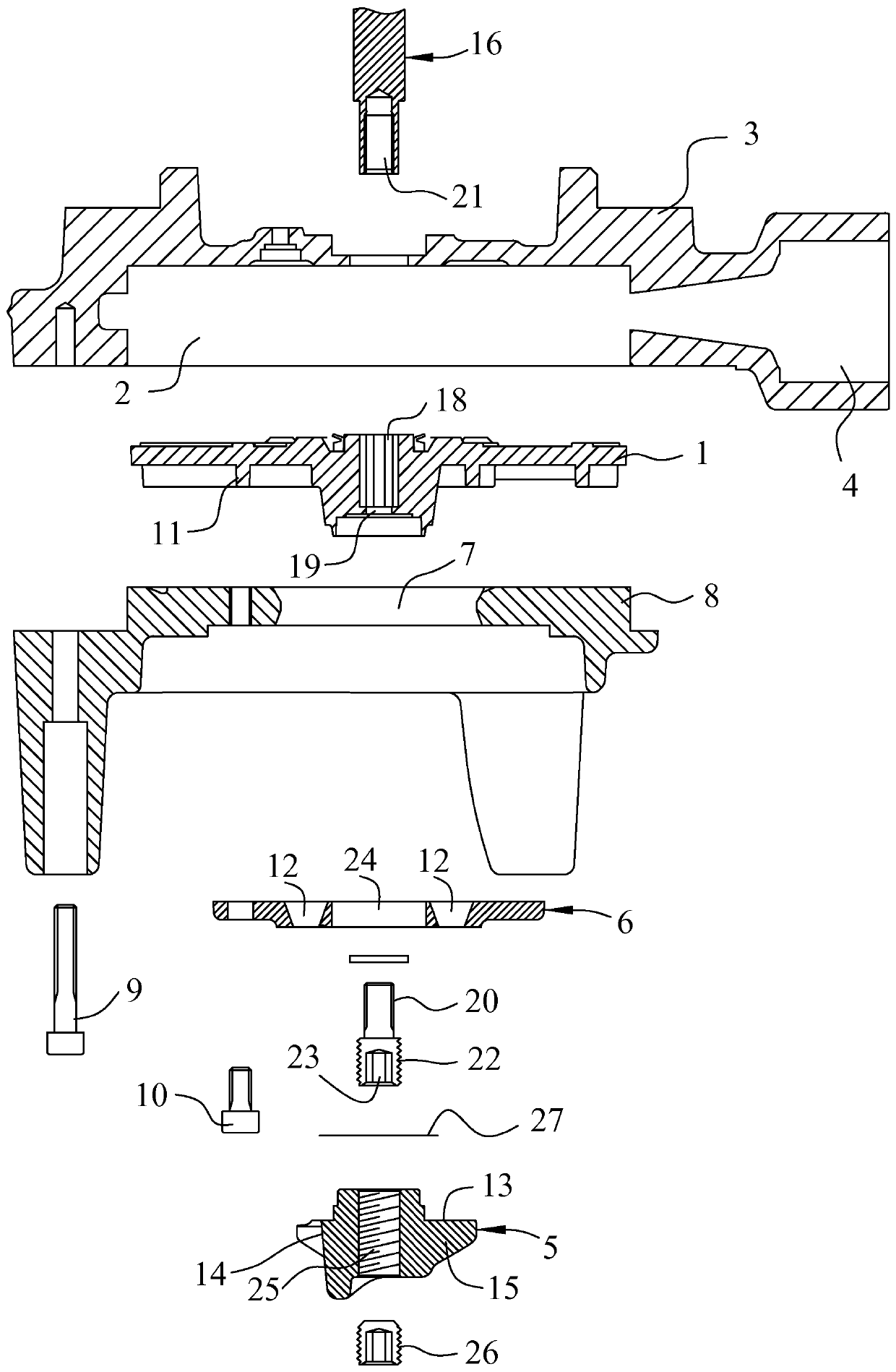

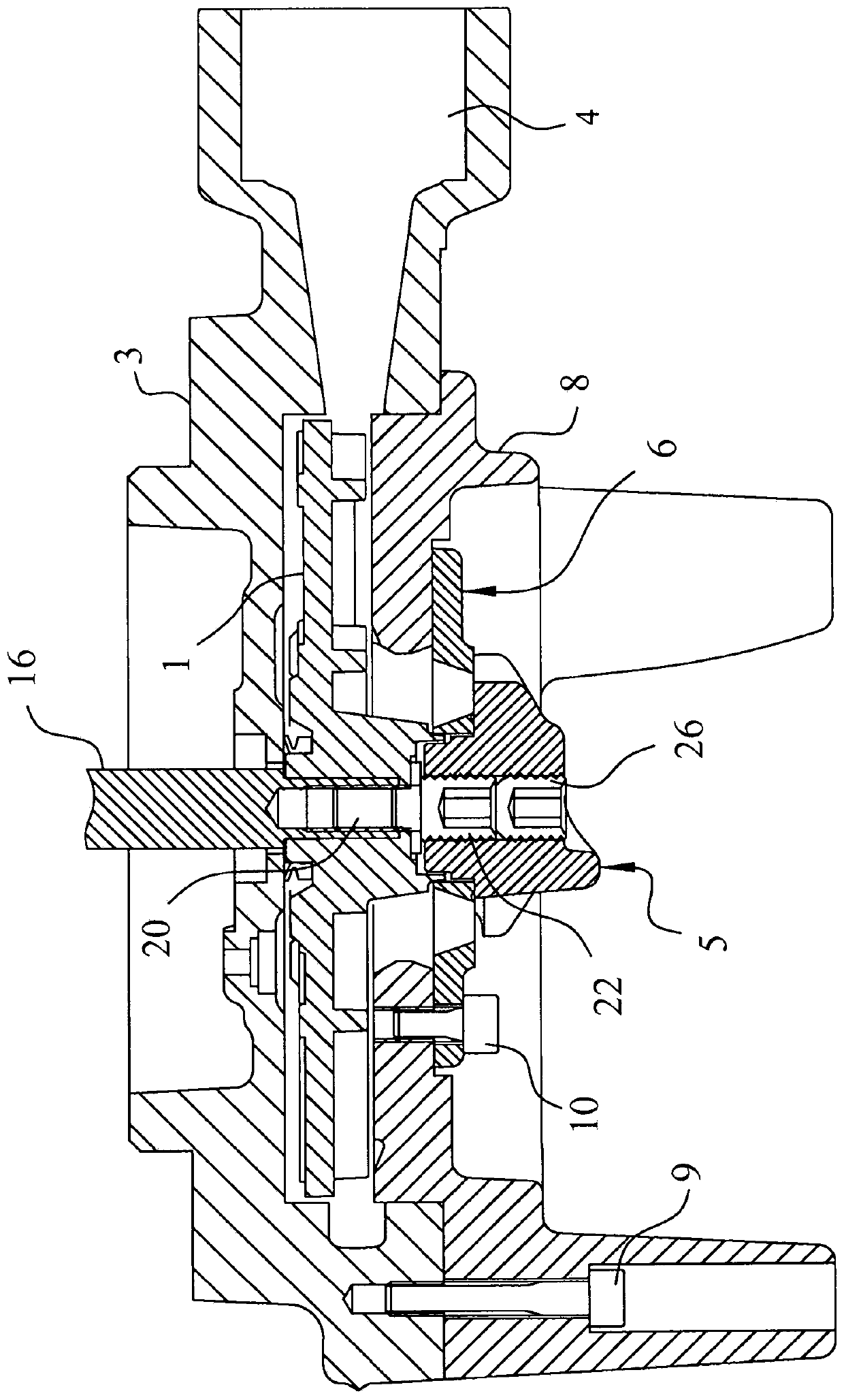

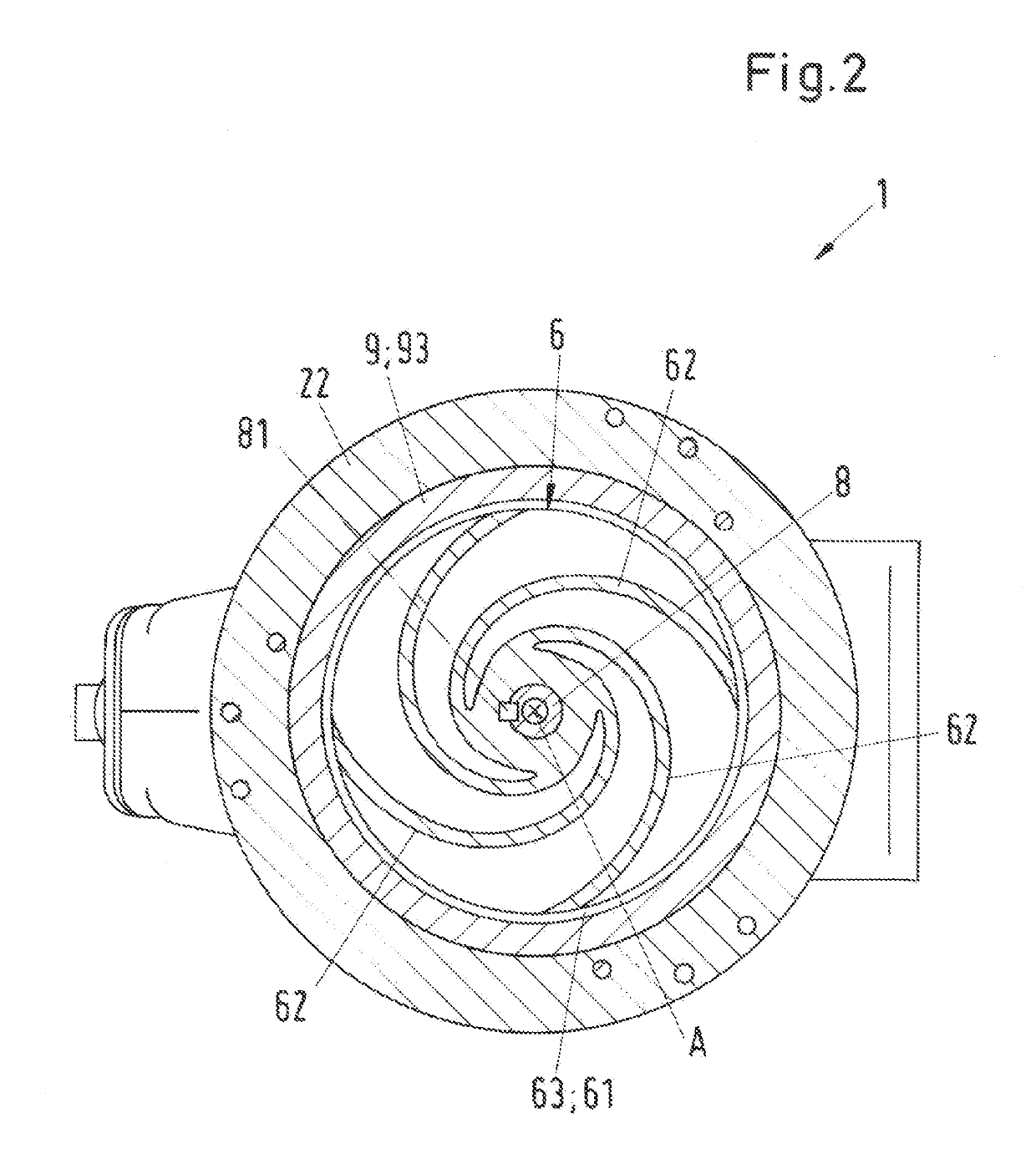

A method for providing an axial gap in a cutter assembly of a grinder pump, and a grinder pump comprising a shim configured for providing said axial gap

InactiveUS20190321827A1Easy to installEliminate riskSpecific fluid pumpsPump componentsDrive shaftPlastic materials

A method for providing an axial gap in a cutter assembly of a grinder pump in order to secure an operative shearing action at a shearing interface in the cutter assembly. A grinder pump includes a cutter wheel connected to and driven in rotation by a drive shaft. The cutter wheel includes a set of cutting edges, and a cutter disc stationary connected to a pump housing and having a central hole and a set of cutting holes. The drive shaft and the cutter wheel are interconnected via the central hole of the cutter disc, wherein the cutter wheel and the cutter disc constitute the cutter assembly. A shim, which has a thickness equal to or greater than 0.05 millimeters and equal to or less than 0.15 millimeters and that is manufactured from degradable paper or plastic material, is clamped between the cutter wheel and the cutter disc.

Owner:XYLEM EURO GMBH

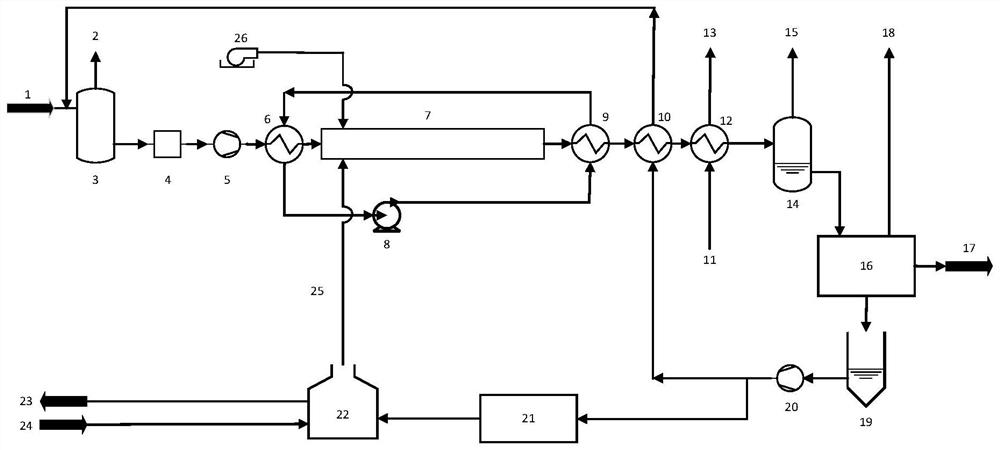

Anti-blocking continuous pyrohydrolysis system for sludge

ActiveCN109626784AGuaranteed economyLow costSludge treatment by oxidationSpecific water treatment objectivesPartial oxidationSludge

The invention discloses an anti-blocking continuous pyrohydrolysis system for sludge. Through coupling of a partial oxidation technology and intermediate medium backheating and the continuous pyrohydrolysis system, the problem that sludge in an anaerobic environment is subjected to high temperature carbonization and agglomeration is effectively solved, it is ensured that only clean fluid flows along the side of a heat exchanger shell to avoid frequent changing of the sludge conveying direction, a grinding pump breaks and grinds fed sludge to avoid aggregation and hardening of sludge particles,and the problem of system blockage is effectively avoided; heat of the system is utilized in a multi-gradient mode, a biogas production technology adopting anaerobic biochemistry is adopted, and liquid after pressing filtering is subjected to resource utilization; partial liquid after pressing filtering flows to the front sections of the technology to conduct viscosity reduction on sludge, usingof fresh softened waste is avoided, the thermal recycling efficiency of the system is improved, and resource consumption of the system is reduced; the economical performance of the system is effectively improved, the running stability of the continuous pyrohydrolysis system for sludge is enhanced, and promotion of large-scale application of the technology is facilitated.

Owner:GUANGXI UNIV

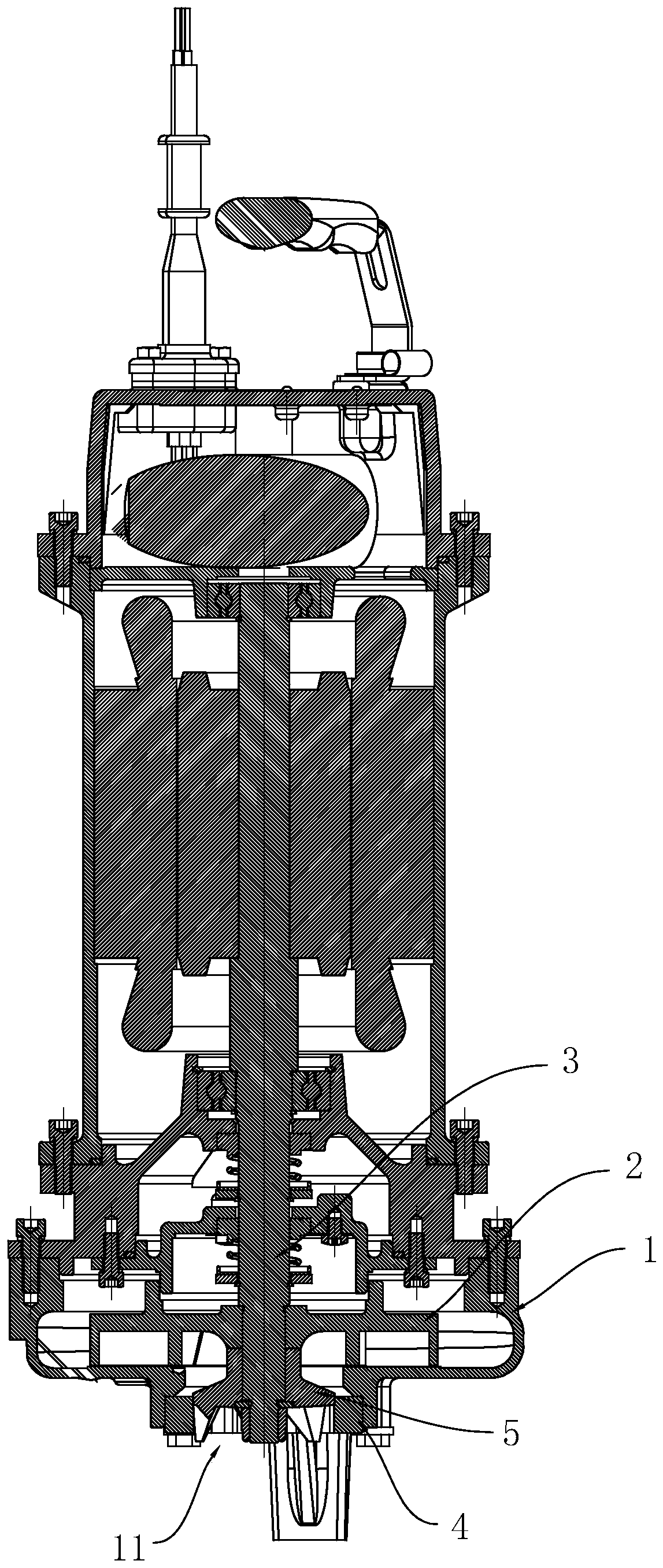

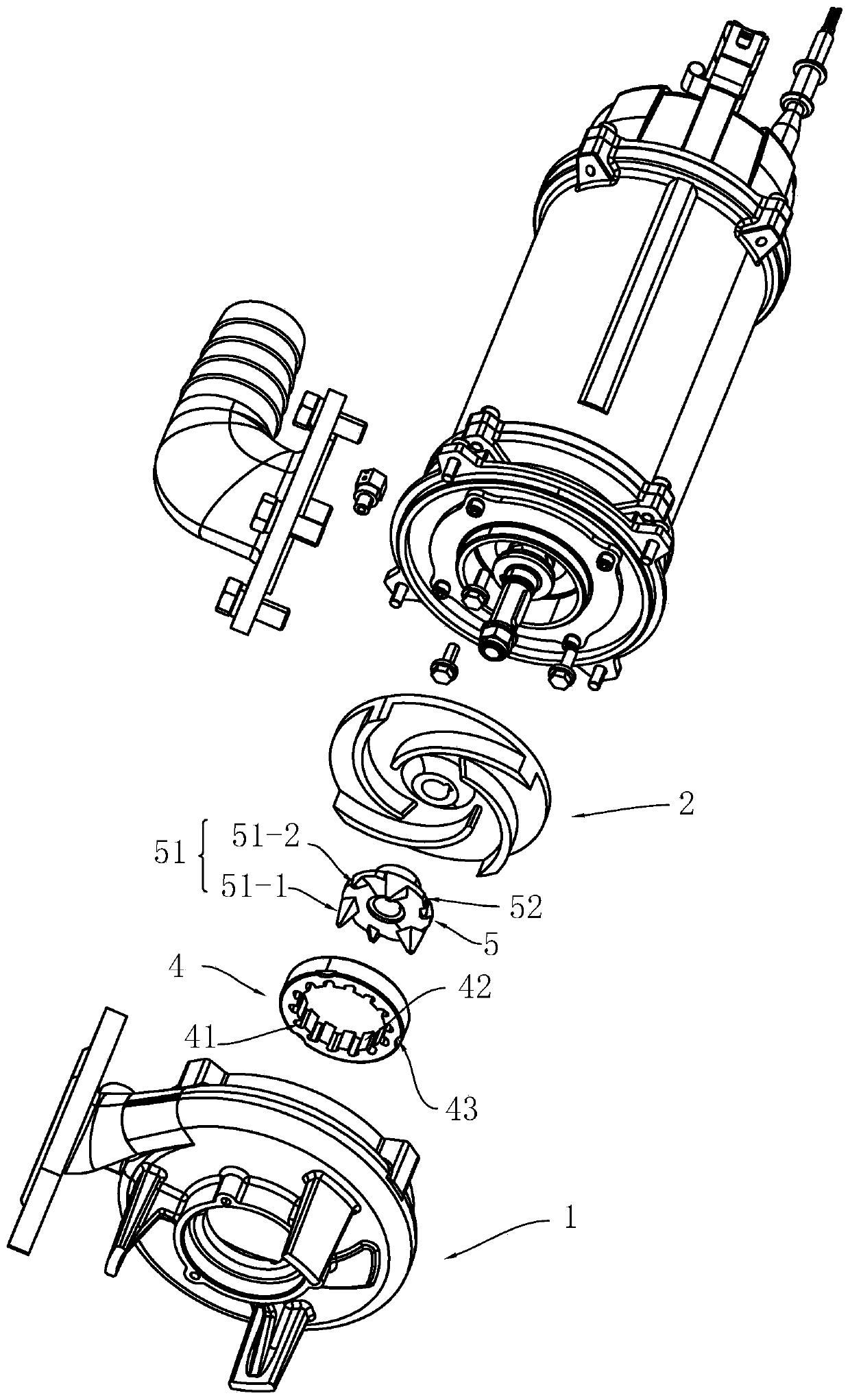

Method for providing axial gap in cutter assembly of grinder pump, and grinder pump comprising shim configured for providing said axial gap

InactiveCN110177948AWon't block the flowSpecific fluid pumpsPump componentsPlastic materialsDrive shaft

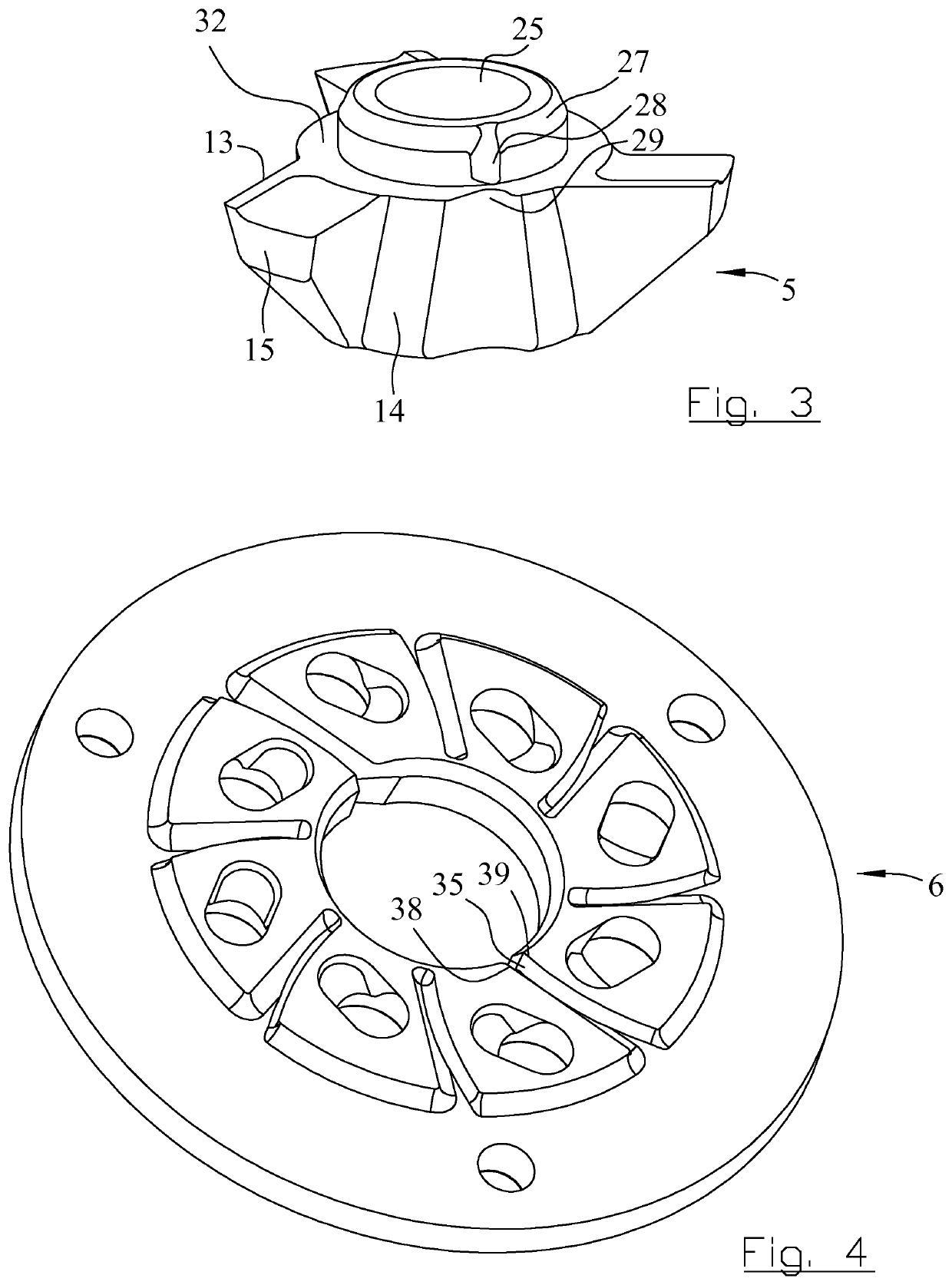

The invention relates to a method for providing an axial gap in a cutter assembly of a grinder pump in order to secure an operative shearing action at a shearing interface in said cutter assembly. Theinvention also relates to a grinder pump comprising a cutter wheel (5) connected to and driven in rotation by a drive shaft (16), the cutter wheel (5) comprising a set of cutting edges (13), and a cutter disc (6) stationary connected to a pump housing (3) and having a central hole (24) and a set of cutting holes (12), the drive shaft (16) and the cutter wheel (5) being interconnected via said central hole (24) of the cutter disc (6),wherein the cutter wheel (5) and the cutter disc (6) constitute said cutter assembly. The grinder pump is characterized in that a shim (27), that has a thicknessequal to or greater than 0,05 millimeters and equal to or less than 0,15 millimeters and that is manufactured from degradable paper or plastic material, is clamped between the cutter wheel (5) and thecutter disc (6), wherein the grinder pump further comprises a locking member (26) acting against the cutter wheel (5) and the drive shaft (16) and fixating the axial gap between the cutter wheel (5)and the cutter disc (6) provided by said shim (27), wherein the set of cutting holes (12) of the cutter disc (6) are located radially outside an imaginary circle that is concentric with an axial center axis of the grinder pump and that has a fourth diameter (D4),an outer diameter (Do) of the shim (27) being lesser than said fourth diameter (D4)of the imaginary circle of the cutter disc (6).

Owner:XYLEM EURO GMBH

Wastewater basin

A molded basin for use with a submersible sump, sewage or grinder pump. The molded construction of the basin permits design improvements to be incorporated into the basin including bolt down slots in a bottom flange of a bottom of the basin, a molded inner basin mounting surface for a float tree, a molded inner surface support mount to receive a bracket of a rail system used to raise and lower the pump within the basin, a disc that fits within the basin and is supported by a molded inner facing horizontal rib to create a wet / dry well and structural features present in a top surface of the basin and a cover for the basin to close said basin. Extension risers may be added to extend the height of the basin, wherein the extension risers contain many of the same structural features that are present in the basin.

Owner:ZOELLER PUMP

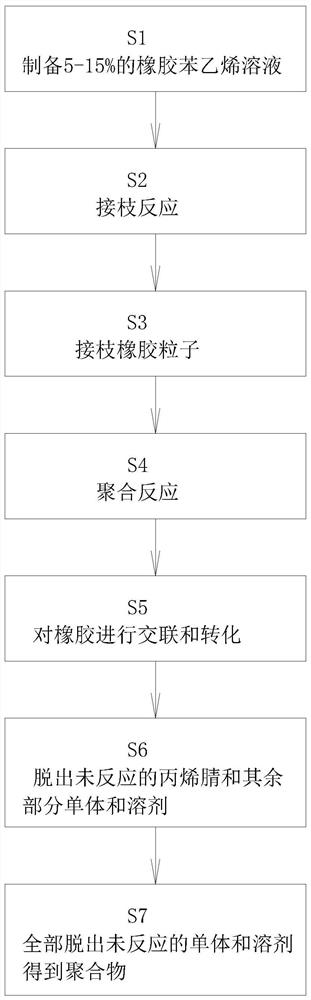

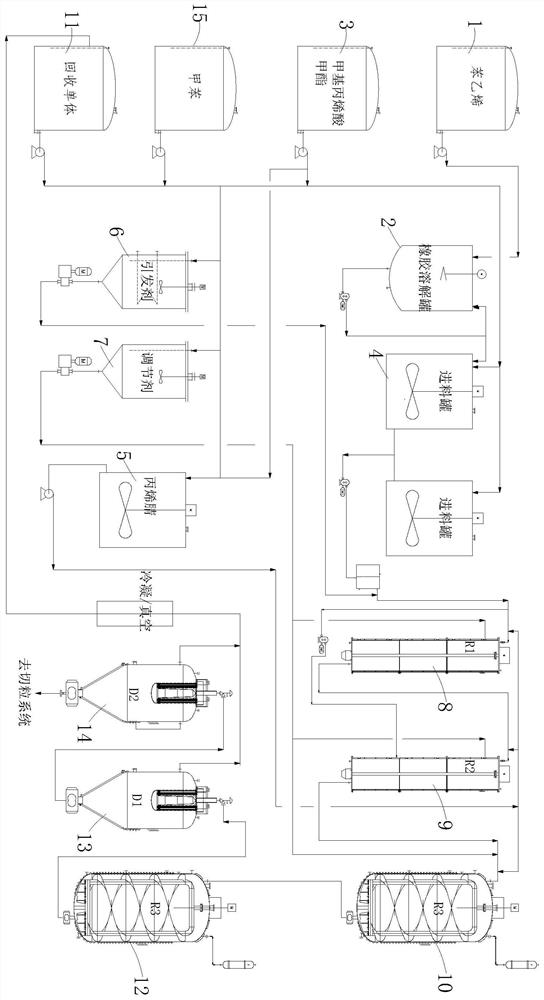

Processing technology of transparent ABS resin

The invention relates to a processing technology of transparent ABS resin. The processing technology comprises the following steps: S1, crushing SBR, adding the crushed SBR and styrene into a rubber dissolving tank, carrying out stirring, and carrying out reflux grinding by using a grinding pump to prepare a rubber styrene solution with a content of 5-15%; S2, continuously adding the rubber styrene solution, methyl methacrylate, an initiator and a molecular weight regulator into a first reactor according to a certain ratio, controlling a temperature to be 70-90 DEG C and a stirring speed to be30-40 rpm, and carrying out a grafting reaction; and S3, conveying polymerization liquid discharged from the first reactor to a second reactor through a gear pump, continuing the reaction, and controlling the reaction temperature to be 90-110 DEG C and the stirring speed to be 30-40 rpm so as to realize phase inversion of the polymerization liquid in the second reactor, thereby forming grafted rubber particles with particle sizes of 150-200 nm. Compared with a traditional emulsion grafting-blending technology, the bulk polymerization technology has the advantages of short flow, less three wastes, small product smell, stable quality and the like.

Owner:广西长科新材料有限公司

Cutter wheel, cutter disc as well as cutter assembly suitable for grinder pumps

ActiveUS20190321828A1Increased operating lifeAvoid cloggingSpecific fluid pumpsEngine manufactureEngineeringMechanical engineering

A cutter assembly configured for a grinder pump and including a cutter wheel and a cutter disc that interact with each other. The cutter wheel includes a shaft portion that is configured to interact with a central hole of the cutter disc, a hub portion that is connected to the shaft portion and at least two main cutting edges that in the radial direction extend outwards from the hub portion and that are configured to interact with a set of cutting holes of the cutter disc. The shaft portion includes an axially extending cutting recess. The hub portion includes only one radially extending cutting recess. The cutter disc includes a suction side, a central hole that is configured to interact with the shaft portion of the cutter wheel and a set of cutting holes that open in the suction side radially outside the central hole.

Owner:XYLEM EURO GMBH

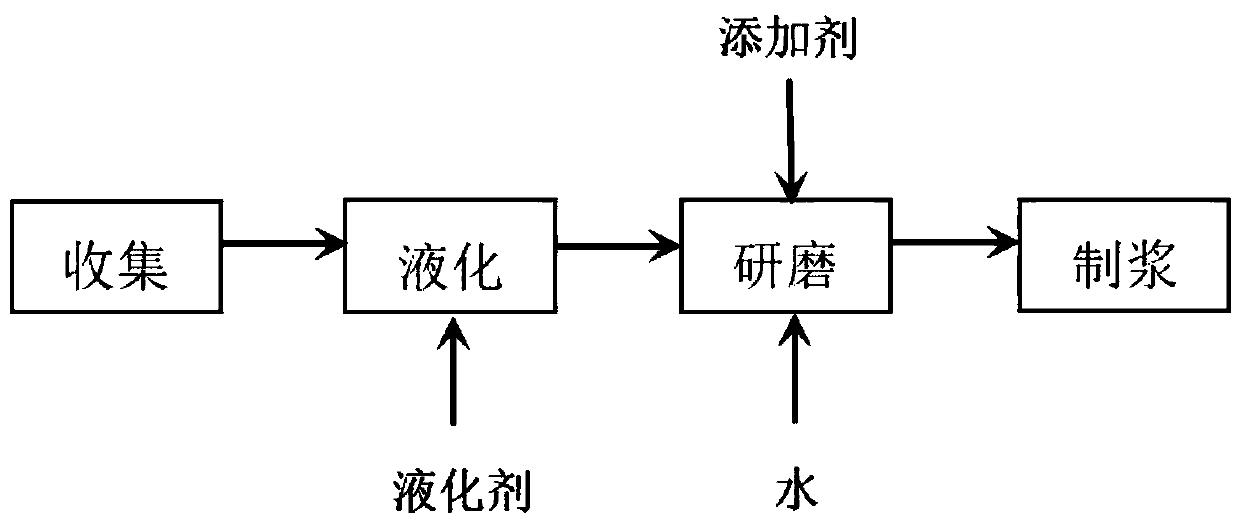

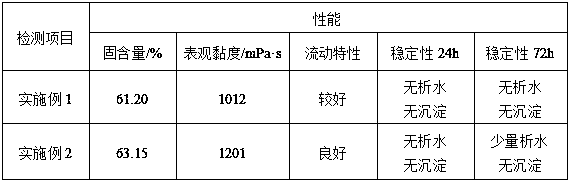

Hazardous waste tar residue resource utilization method

The invention discloses a hazardous waste tar residue resource utilization method, and belongs to the field of tar residue cyclic utilization. Tar residues are identified as hazardous wastes, and thehazardous waste tar residue resource utilization method comprises the following steps: 1, collection: collecting tar solid impurities deposited in tar by using existing tar residue separation equipment of a coking plant; 2, liquefaction: introducing a liquefying agent into the tar residue, and liquefying the tar residue by using a stirring paddle to achieve liquid flow characteristics; 3, grinding: feeding the tar residue with the liquid flow characteristics into a grinding pump for grinding by using a delivery pump, and adding water and a surfactant into the tar residue in the grinding process; and 4, pulping: strongly stirring the ground materials to obtain tar residue slurry. The tar residue slurry obtained by the method has stable, pumping and atomizing properties of liquid fuel, is convenient to load, unload, transport and store, and can be used for fuel combusted in a boiler or gasification raw materials of a gasification furnace. The method is low in cost, and the purpose of resource utilization of hazardous waste tar residues is achieved.

Owner:LINHUAN COKING

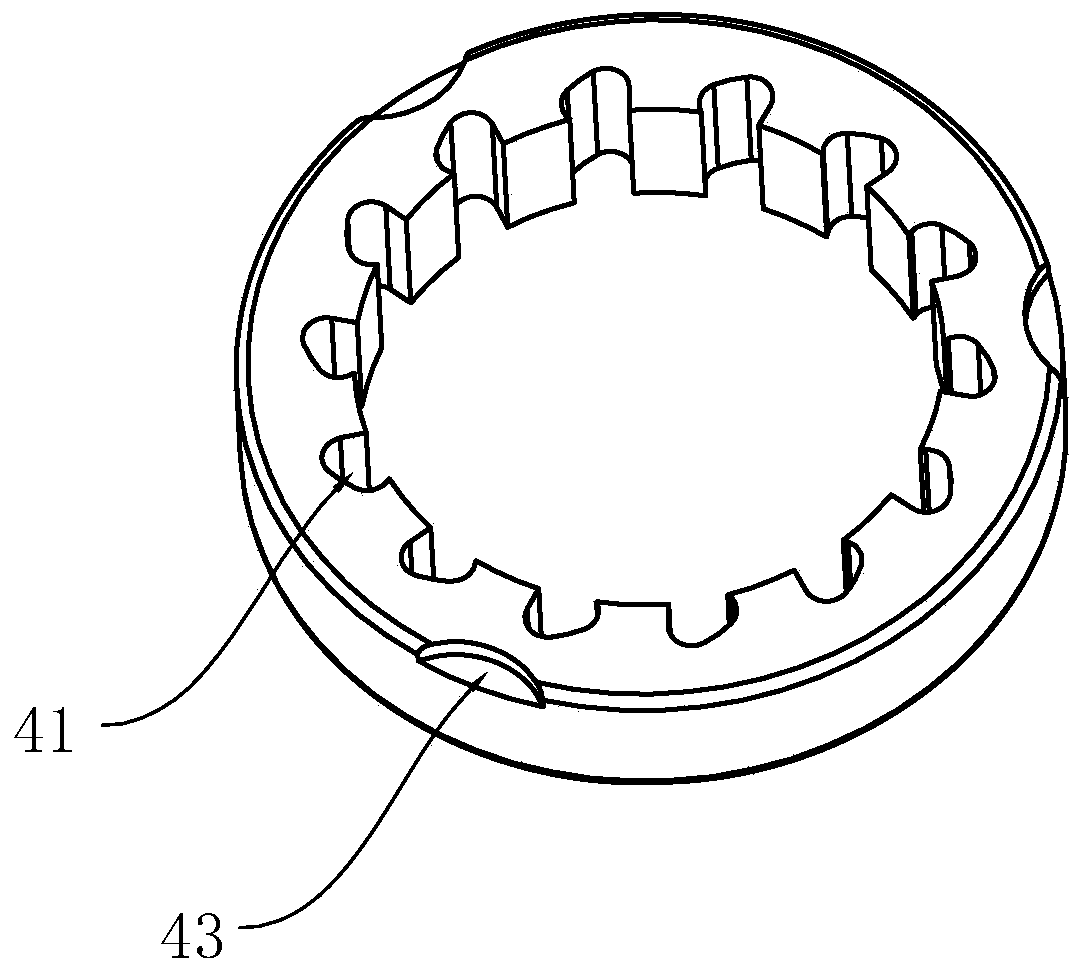

Cutting and grinding pump

InactiveCN110985400AEasy to gatherWith filter functionSpecific fluid pumpsPump componentsImpellerGrinder pump

The invention relates to a cutting and grinding pump. The cutting and grinding pump solves the problems existing in the prior art that the cutting effect is not very good and an impeller is prone to being stuck and the like. According to the adopted technical scheme, the cutting and grinding pump further includes a guide disk matched with a water inlet and a cutting disk matched with the guide disk, wherein the cutting disk is arranged on a pump shaft, and the guide disk is in the shape of an annular disk; a plurality of water inlet holes are formed in the inner ring wall of the guide disk, and the cutting disk is arranged in an inner cavity of the guide disk; and a plurality of blade parts are evenly distributed at the edge of the cutting disk, and the blade parts are matched with the inner ring wall of the guide disk. The cutting and grinding pump has the effects that the guide disk and the cutting disk are arranged at the water inlet of a pump body, the guide disk enables fluid to enter a flow path of the pump body through the water inlet holes, the guide disk and the cutting disk are matched to play a cutting effect and a filtering function to filter impurities, the effectiveness of cutting is improved, and the occurrence of blockage at the water inlet of the pump body is greatly reduced.

Owner:新界泵业(浙江)有限公司

Grinder pump and cutting assembly thereof

ActiveUS10364821B2High rate of wearShort lifeSpecific fluid pumpsPump componentsEngineeringMechanical engineering

Owner:LIBERTY PUMPS

Multi-stage raw medicine grinding system

PendingCN113019662ANo secondary shipping requiredHigh precisionMixing methodsTransportation and packagingProcess engineeringMechanical equipment

The invention relates to a multi-stage raw medicine grinding system, and belongs to the field of mechanical equipment. The problem of low grinding precision of a grinding system in the prior art is solved. The multi-stage raw medicine grinding system comprises an emulsifying kettle, a raw material temporary storage kettle, a grinding pump and a ball mill. A discharging outlet of the emulsifying kettle is communicated with a feeding inlet of the raw material temporary storage kettle, a discharging outlet of the raw material temporary storage kettle is communicated with a feeding inlet of the grinding pump, and a discharging outlet of the grinding pump is communicated with a feeding inlet of the ball mill. According to the multi-stage raw medicine grinding system, raw medicine is integrated from a material crushing stage to a fine grinding stage, and high-precision grinding can be achieved without secondary transportation. The grinding pump is used for pumping the raw materials, so that the grinding effect is also achieved in the pumping process, and the grinding efficiency is improved. The raw materials with high grinding requirements can be connected with a second-stage grinding pump and a second-stage ball mill so that multiple times of grinding can be realized without halting. The emulsifying kettle can be externally connected with the multiple raw material temporary storage kettles, multi-path simultaneous grinding is realized by means of one-time shearing, the specification of grinding equipment is lowered, and the cost is reduced.

Owner:安徽瑞然生物药肥科技有限公司

Solid organic waste treatment and separation system based on supercritical water oxidation technology

ActiveCN108941153BImprove continuous transmission and distribution capabilitiesAvoid depositionSolid waste disposalSalt depositSupercritical water oxidation

The invention discloses a solid-containing organic waste treatment and separation system based on supercritical water oxidation technology, including a solid-containing waste pretreatment module, a solid-containing waste preheating module, an oxidant supply module, a supercritical water oxidation module, and subsequent products Temperature and pressure reduction module, subsequent product online separation module. Through screw conveyors, crushers, vibrating screens, iron removers, grinding pumps and other devices, solid wastes are crushed, screened, and ground in multiple stages to meet the requirements of supercritical water oxidation feed. At the same time, by adding quartz sand to grind the sedimentary salt that may be generated in the system, the problems of salt deposition and blockage in heat exchangers, reactors and other equipment are avoided. For the gas-liquid-solid three-phase products after the reaction, a two-stage separation measure combining a three-phase separator and a liquid-solid two-phase separator is adopted. At the same time, the liquid phase separated by the liquid-solid separator is circulated and separated, which improves the liquid-solid separation. At the same time, the solid residue after the reaction can be used for brick making, ceramsite making and external sales, etc., which improves the system economy.

Owner:XI AN JIAOTONG UNIV

An anti-clogging sludge continuous thermal hydrolysis system

ActiveCN109626784BRealize step-by-step recyclingGuaranteed economySludge treatment by oxidationSpecific water treatment objectivesPartial oxidationSludge

The invention discloses an anti-clogging sludge continuous thermal hydrolysis system, which effectively solves the high-temperature carbonization and agglomeration of sludge in an anoxic environment by coupling partial oxidation technology and intermediate medium heat recovery to the continuous thermal hydrolysis system. Ensure that only clean fluid flows through the shell side of the heat exchanger, avoid frequent changes in the direction of sludge transport, and crush and grind the feed sludge through the grinding pump to prevent the sludge particles from agglomerating and compacting, effectively avoiding the problem of system blockage; at the same time, adopt Multi-level gradient utilization of system heat, and anaerobic biochemical biogas production technology, resource utilization of the filtrate, and at the same time, part of the filtrate is heat-exchanged and reflowed to reduce the viscosity of the sludge in the early stage, avoiding the use of fresh demineralized water, and improving the system While improving the efficiency of heat recycling, it reduces the consumption of system resources, effectively improves the economy of the system, and enhances the operation stability of the sludge continuous thermal hydrolysis system, which will help promote the large-scale application of this technology.

Owner:GUANGXI UNIV

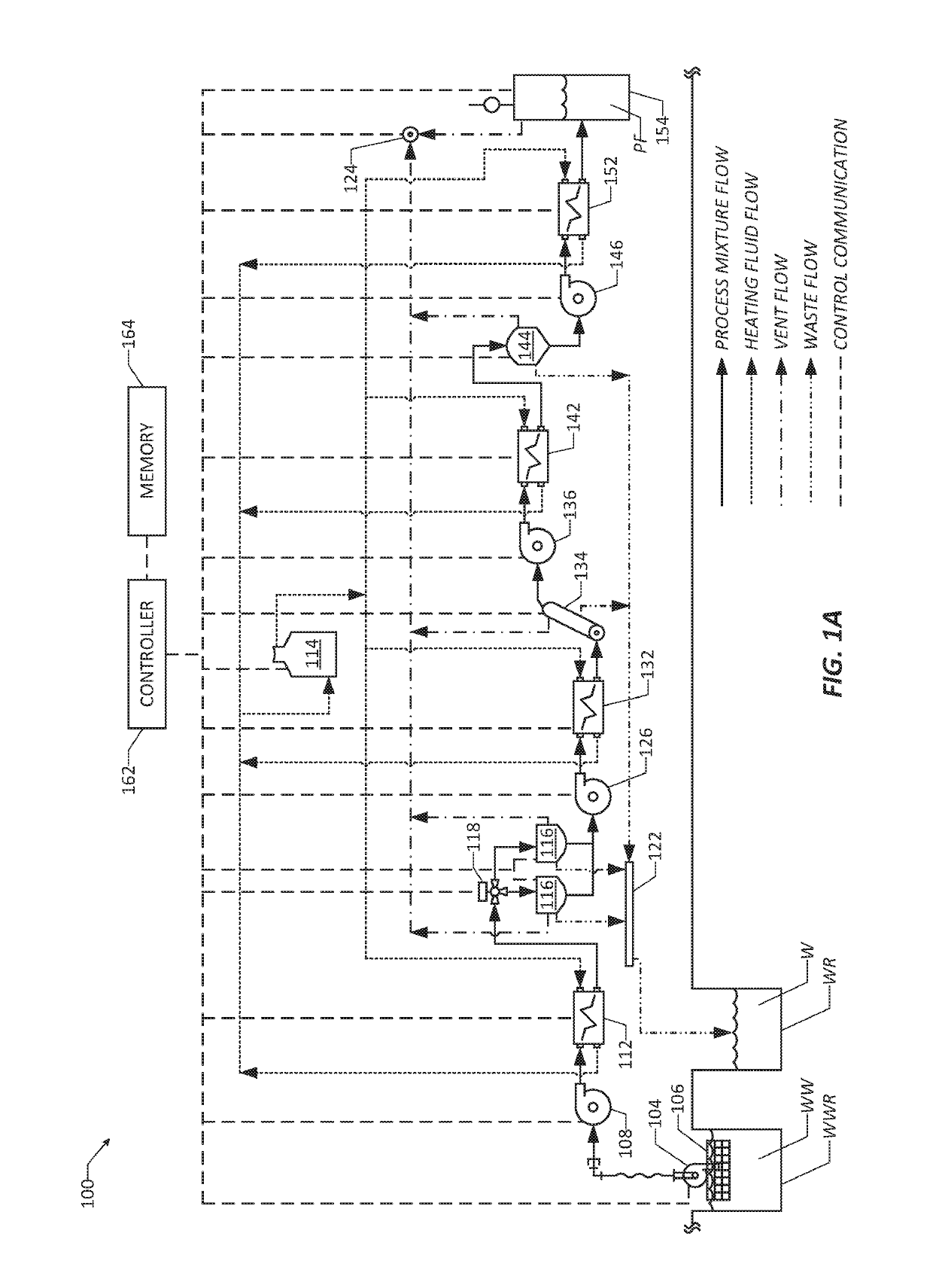

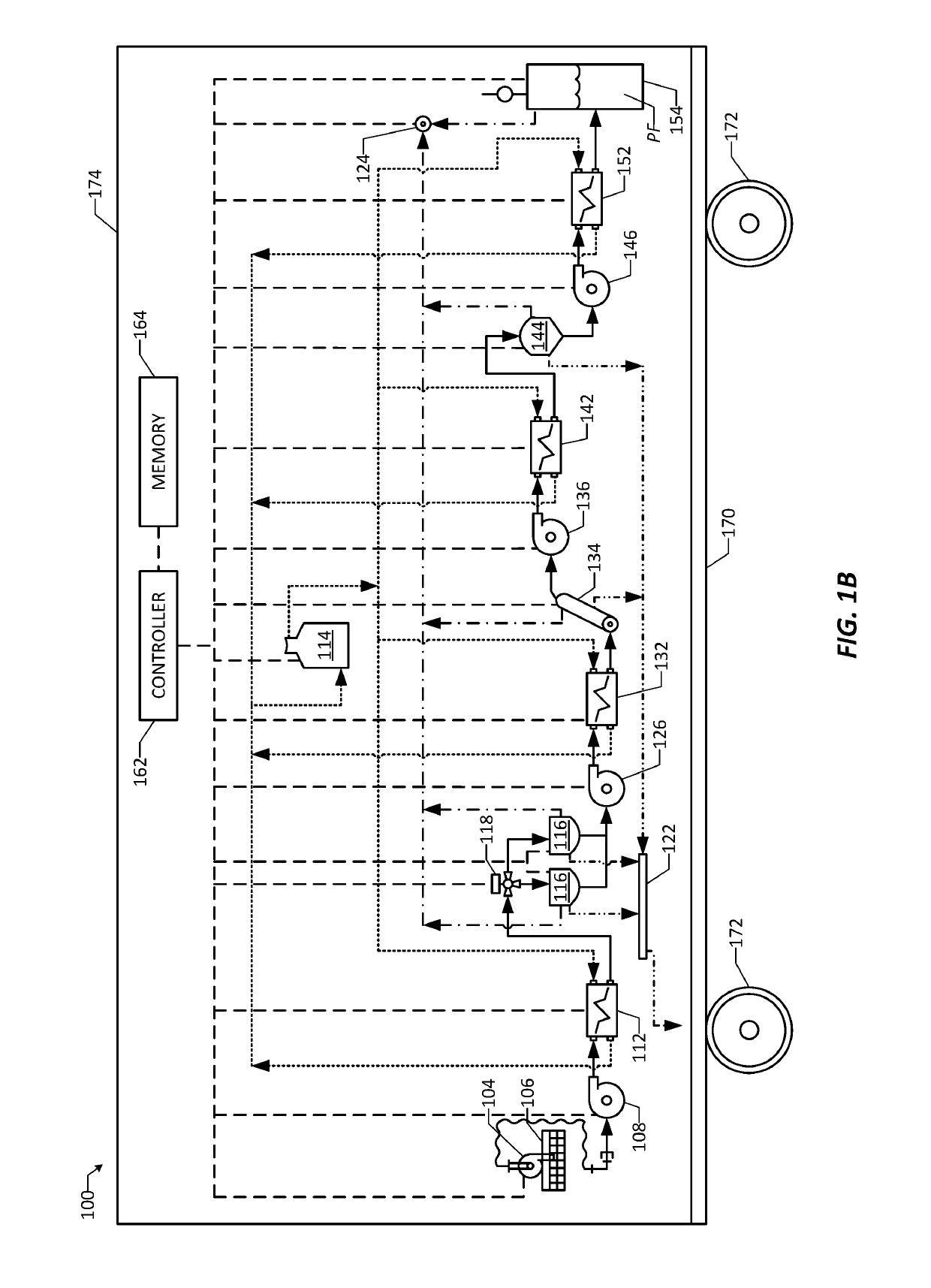

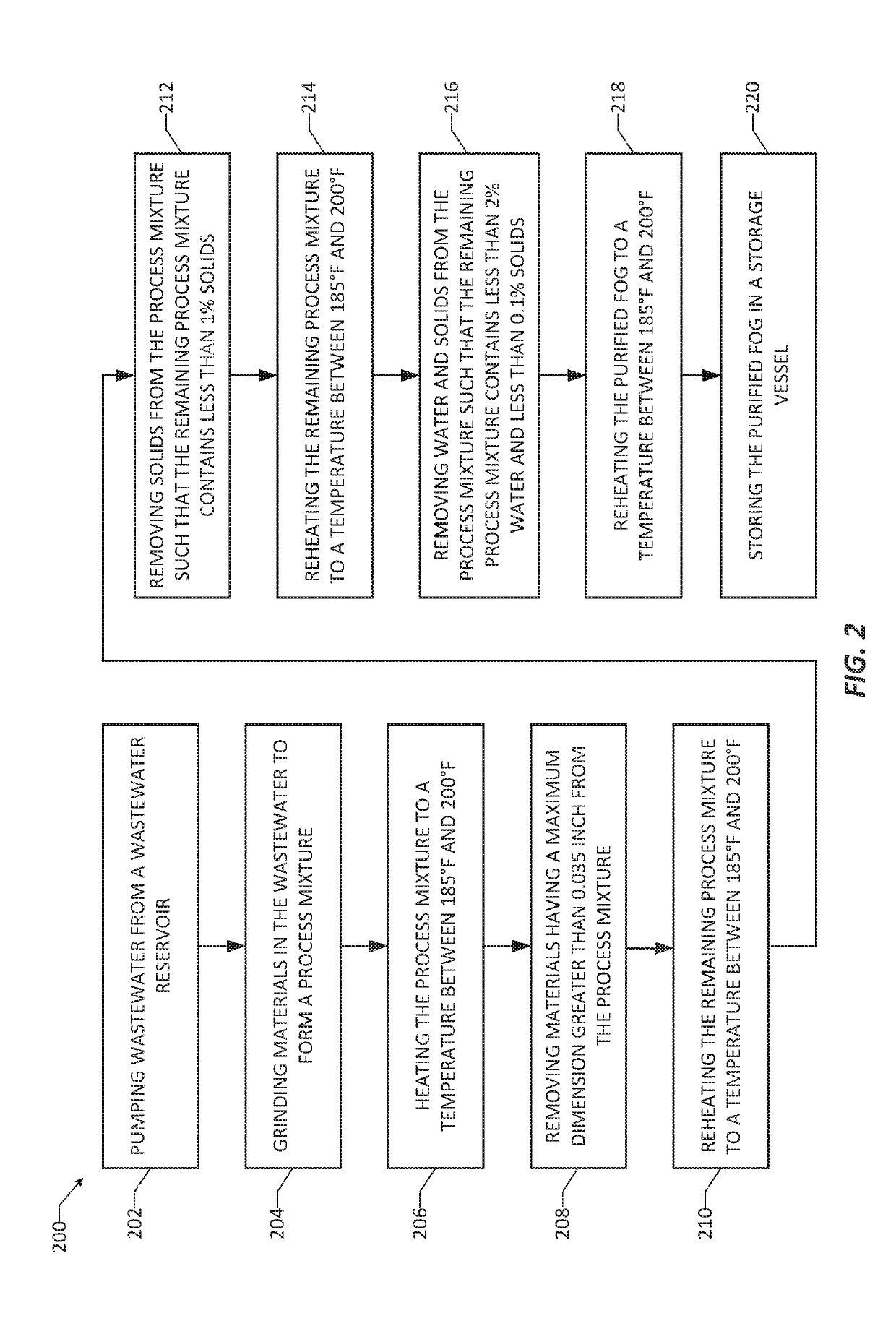

Systems and methods for purification of fats, oils, and grease from wastewater

ActiveUS10472592B1Simple compositionFatty oils/acids recovery from wasteBiofuelsOil and greaseCentrifuge

Embodiments of the present disclosure provide a system for purifying fats, oils, and grease from wastewater. The system may include a trash pump configured to pump the wastewater into the system, a grinder pump positioned downstream of the trash pump and configured to grind materials in the wastewater to form a process mixture, a plurality of heat exchangers positioned downstream of the grinder pump and configured to heat the process mixture, a shaker tray positioned downstream of the grinder pump and configured to remove solids from the process mixture, a decanter positioned downstream of the shaker tray and configured to remove solids from the process mixture, and a centrifuge positioned downstream of the decanter and configured to remove liquids and solids from the process mixture to form purified FOG.

Owner:SMISSON MATHIS ENERGY LLC

Biological waste management systems

Biological waste management systems are provided herein. A waste management system may include a waste shredder, an accumulator tank, a water supply, a digester tank, and a grinder pump. The accumulator tank may define an accumulation chamber downstream from the waste shredder to receive a shredded biologic waste or a decomposition agent. The water supply may be in fluid communication with the accumulator tank to provide a water flow to the accumulation chamber. The digester tank may define a digestion chamber in fluid communication with the accumulation chamber to receive a slurry mixture comprising the biologic waste and the decomposition agent. The grinder pump may be disposed in fluid communication with the accumulation chamber to grind the slurry mixture upstream from the digester tank.

Owner:ENVIROPURE SYST INC

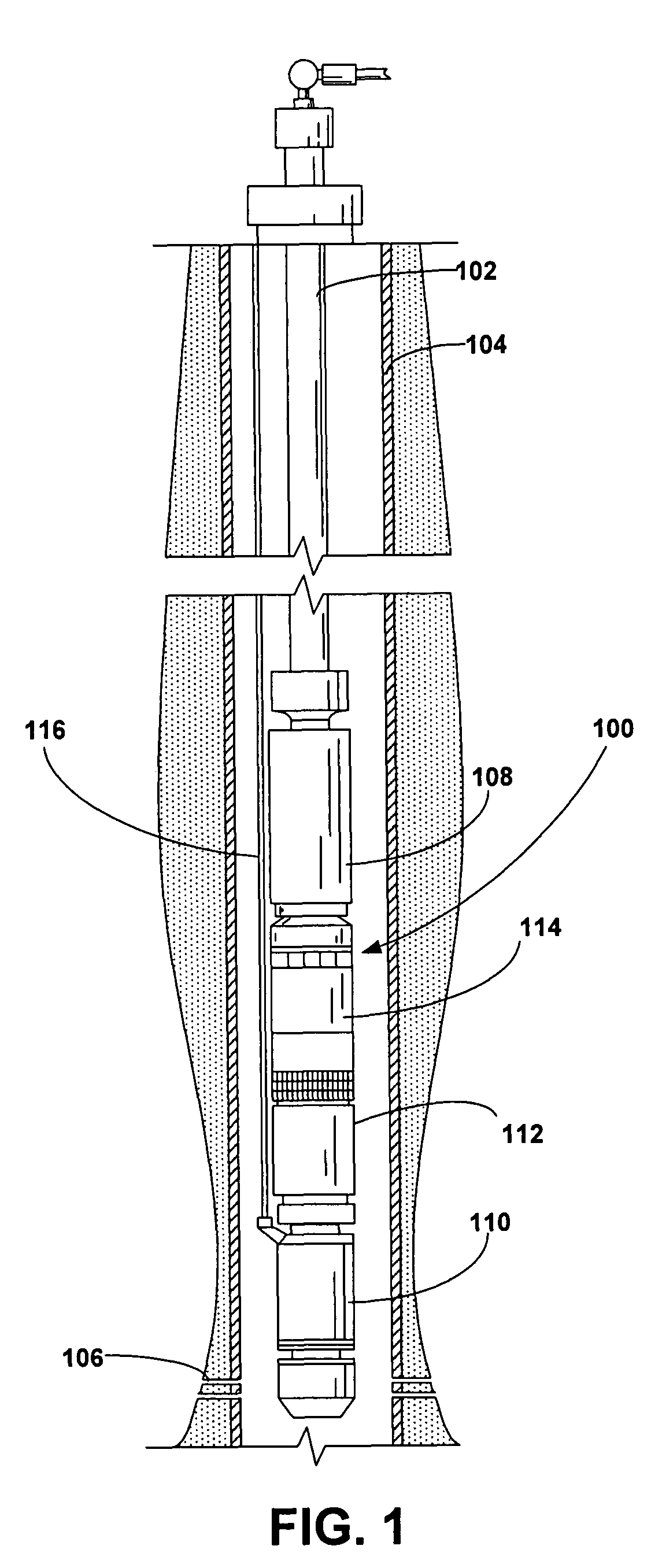

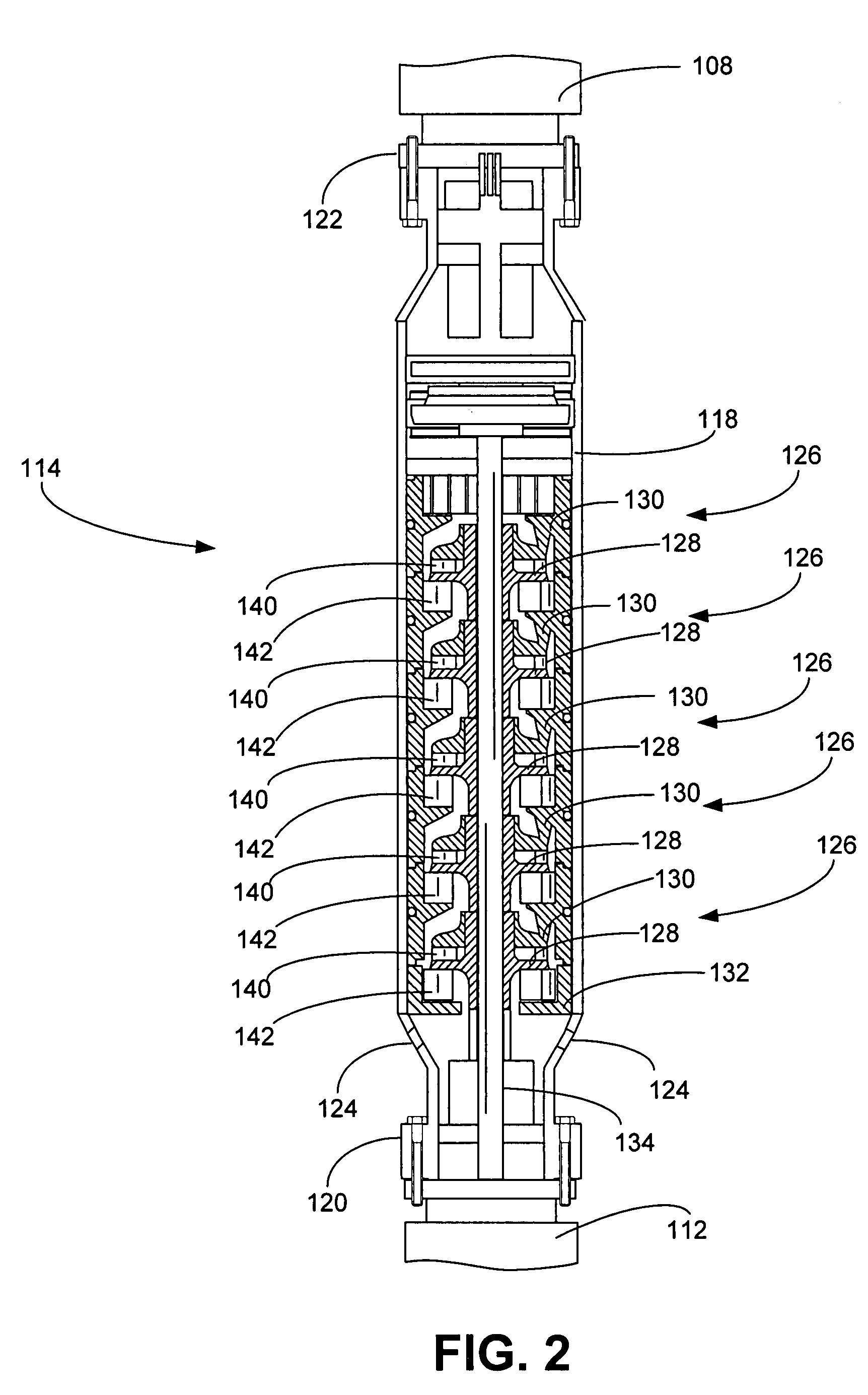

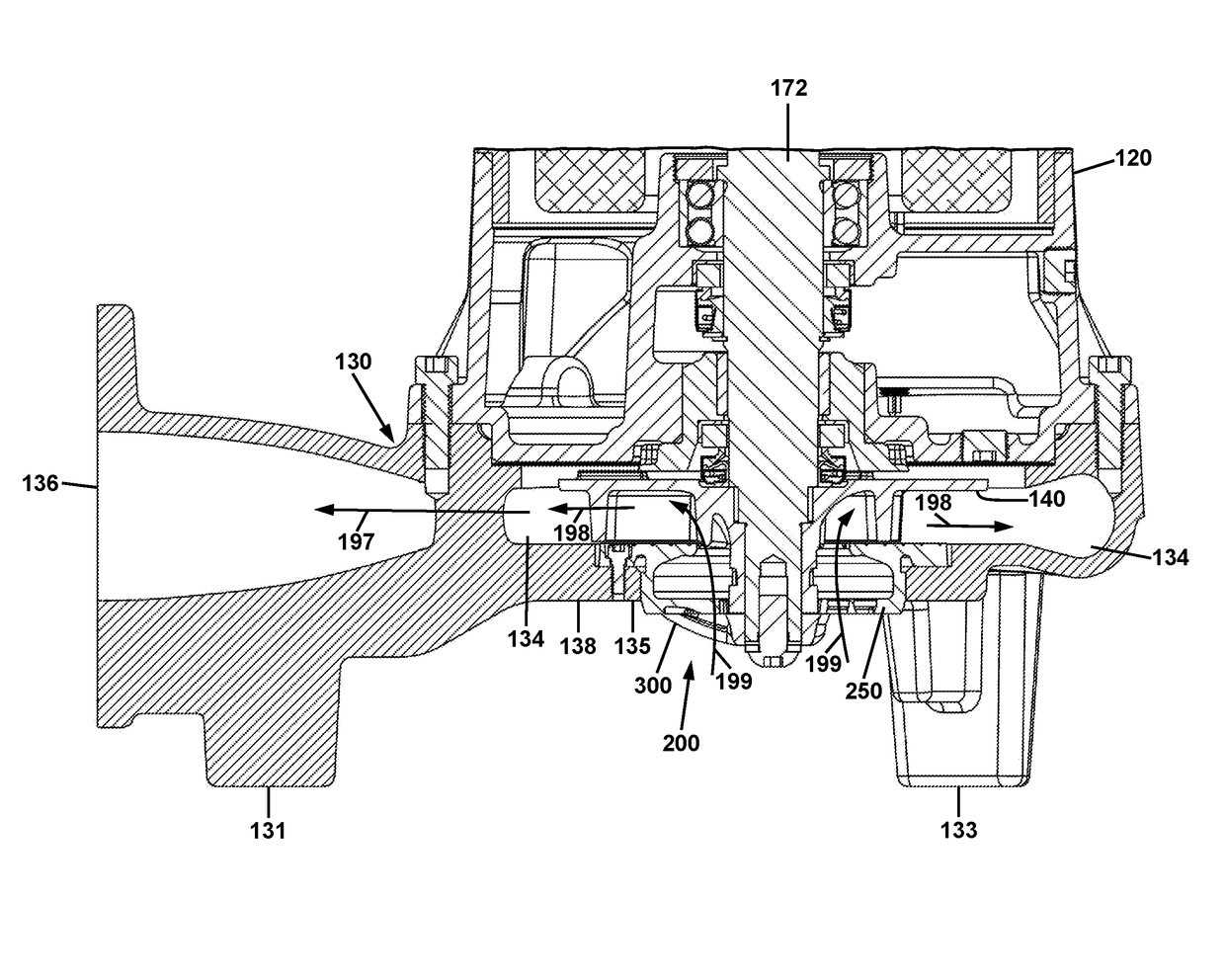

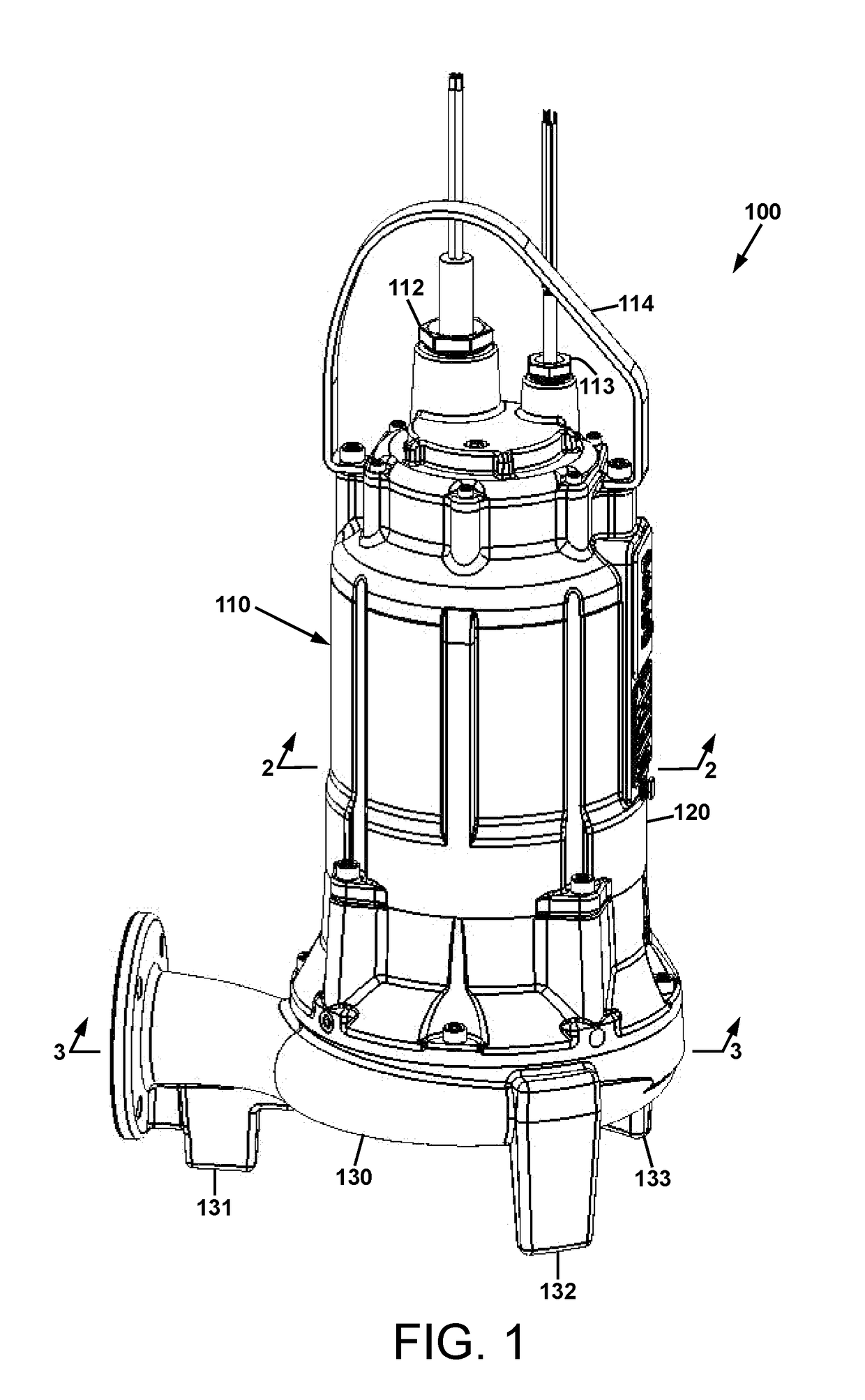

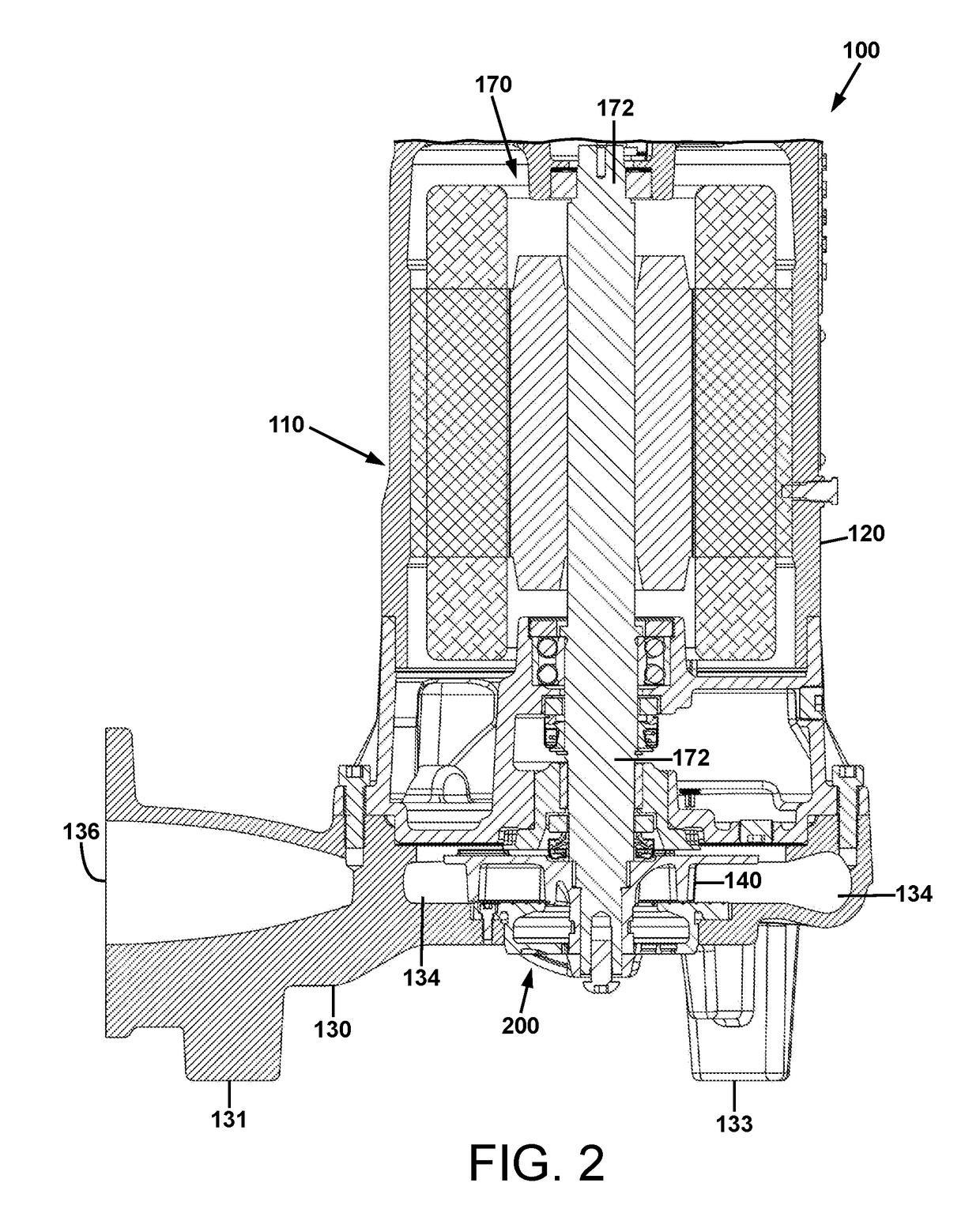

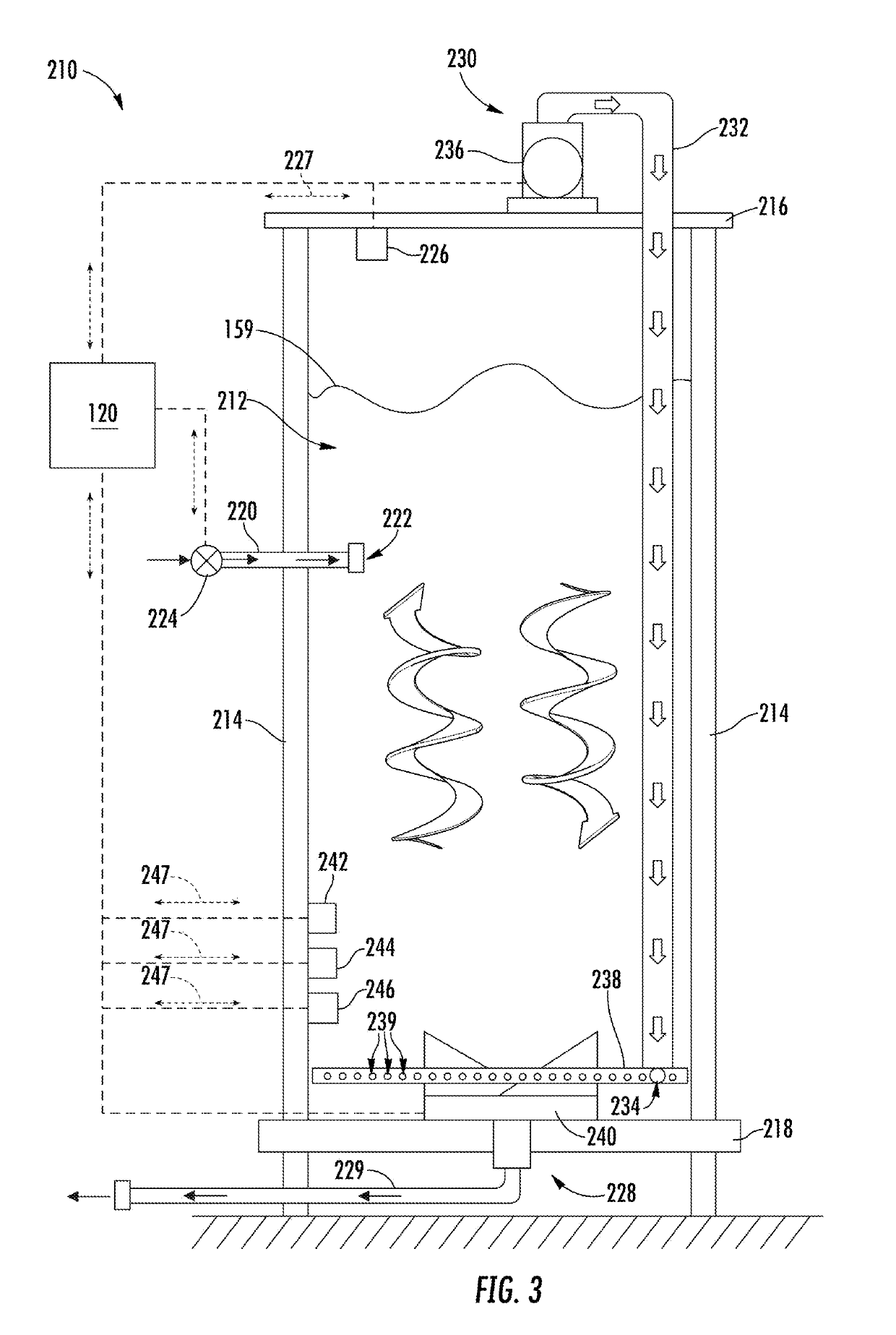

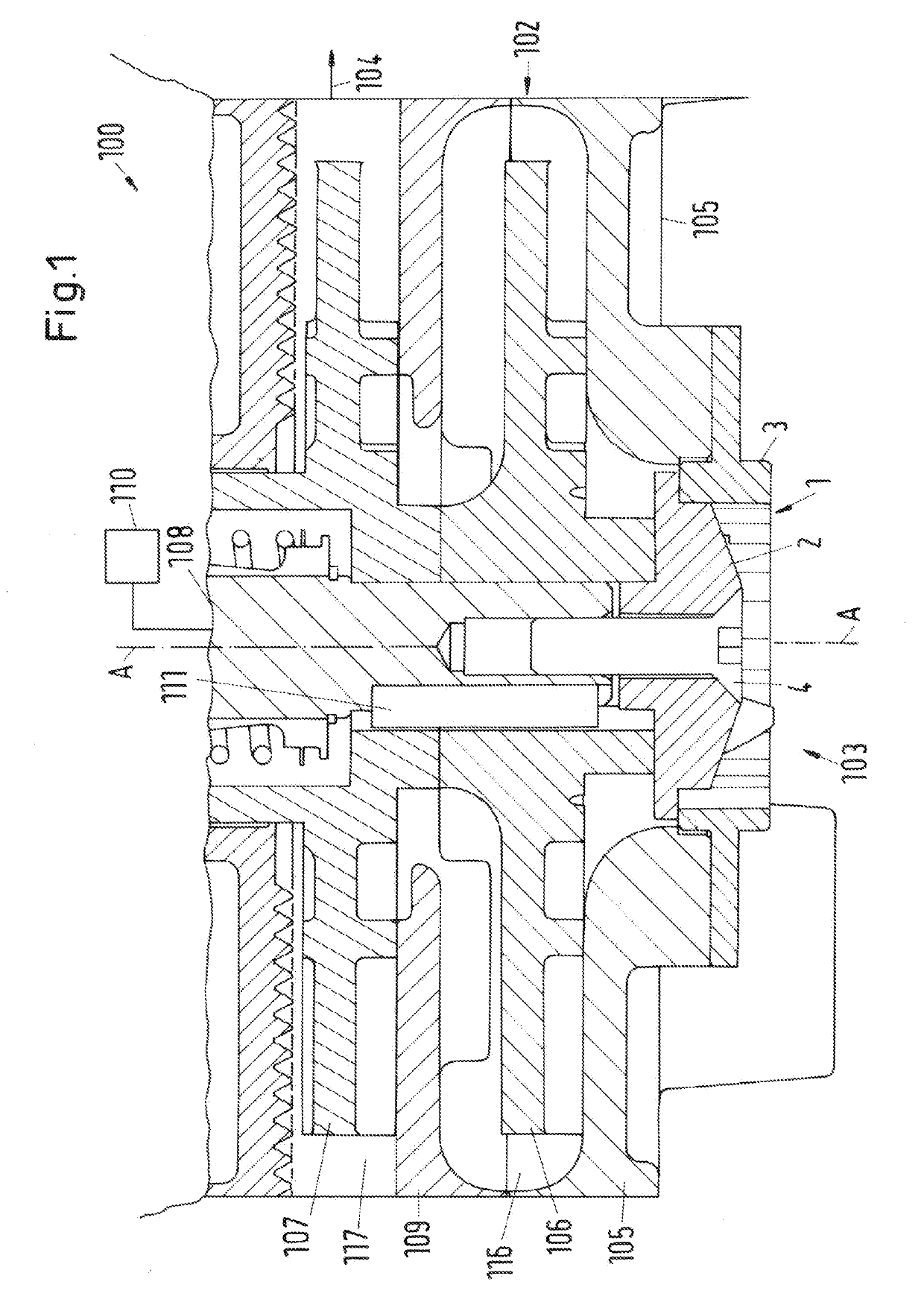

Multistage centrifugal grinder pump

ActiveUS20190264690A1Reduce riskThe process is compact and efficientSpecific fluid pumpsPump componentsImpellerSemi open

A multistage centrifugal grinder pump includes a grinder to grind a fluid, a first stage impeller, a second stage impeller, a stationary diffusor arranged between the first stage impeller and the second stage impeller to guide the fluid from the first stage impeller to the second stage impeller and a shaft to rotate the first stage impeller, the second stage impeller and the grinder. The first and second stage impellers in series and connected to the shaft in a torque-proof manner. The diffusor is a semi-open diffusor having a top wall, a radially outer annular side wall, and an open bottom side facing the first stage impeller, the top wall arranged adjacent the second stage impeller, the top wall having a central outlet opening surrounding the shaft, and the open bottom side extending beyond the first stage impeller with respect to a radial direction.

Owner:SULZER MANAGEMENT AG

Shredding assembly for a grinder pump and centrifugal grinder pump

ActiveUS20190170145A1Reduce cleaningFine shredding actionSpecific fluid pumpsEngine manufactureCentrifugal pumpGrinder pump

A shredding assembly for a grinder pump includes a stationary shredding ring mounted to an inlet of the pump, and a cutting device rotatable about an axial direction and fixed to a shaft of the pump. The shredding ring includes a top face, a bottom face, and a central opening extending from the top face to the bottom face and delimited in a radial direction by an inner periphery. Slots extending in the axial direction are formed in the inner periphery. The cutting device is positioned in the central opening of the shredding ring, and includes a front face and a back face. The front face includes a plurality of first cutting members extending in the axial direction and facing the slots. The back face includes a second cutting member projecting beyond the central opening with respect to the radial direction.

Owner:SULZER MANAGEMENT AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com