Seaborne continuous blending device for fracturing fluid

A fracturing fluid and mixing technology, which is applied in the direction of mixers, dissolution, chemical instruments and methods, etc., can solve problems such as the inability to achieve continuous mixing, and achieve the effects of improving mixing efficiency, easy operation, and continuous mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

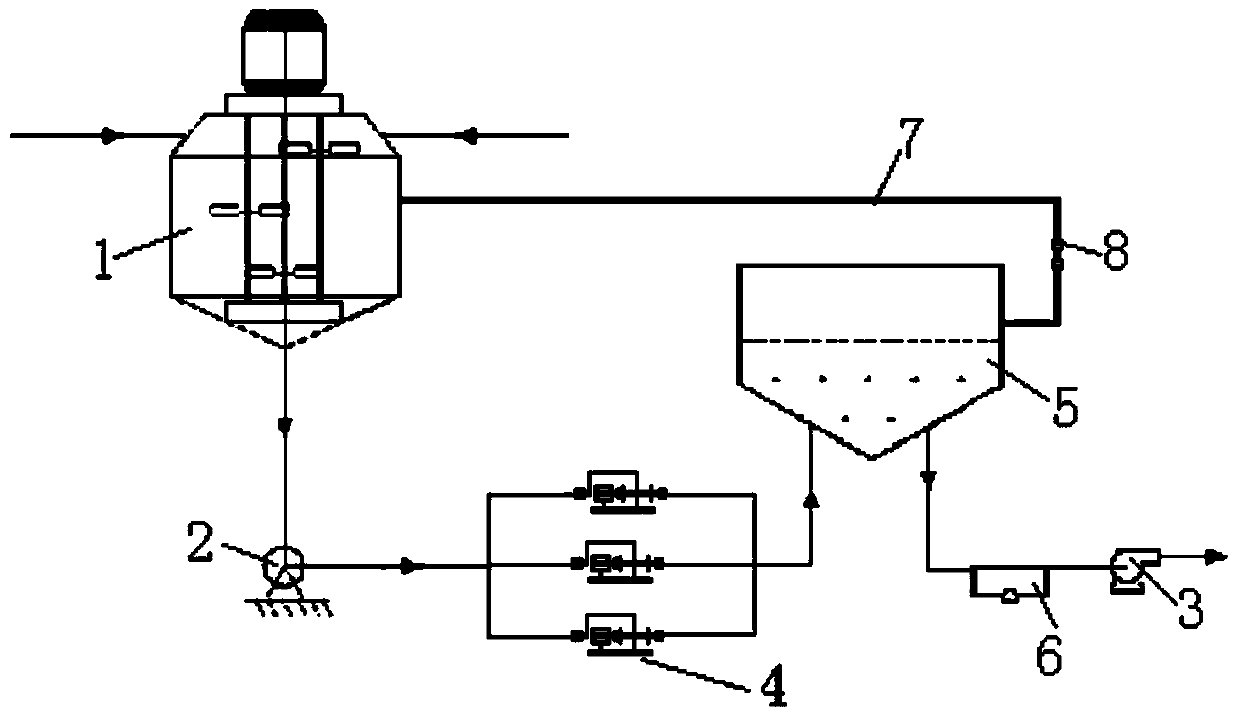

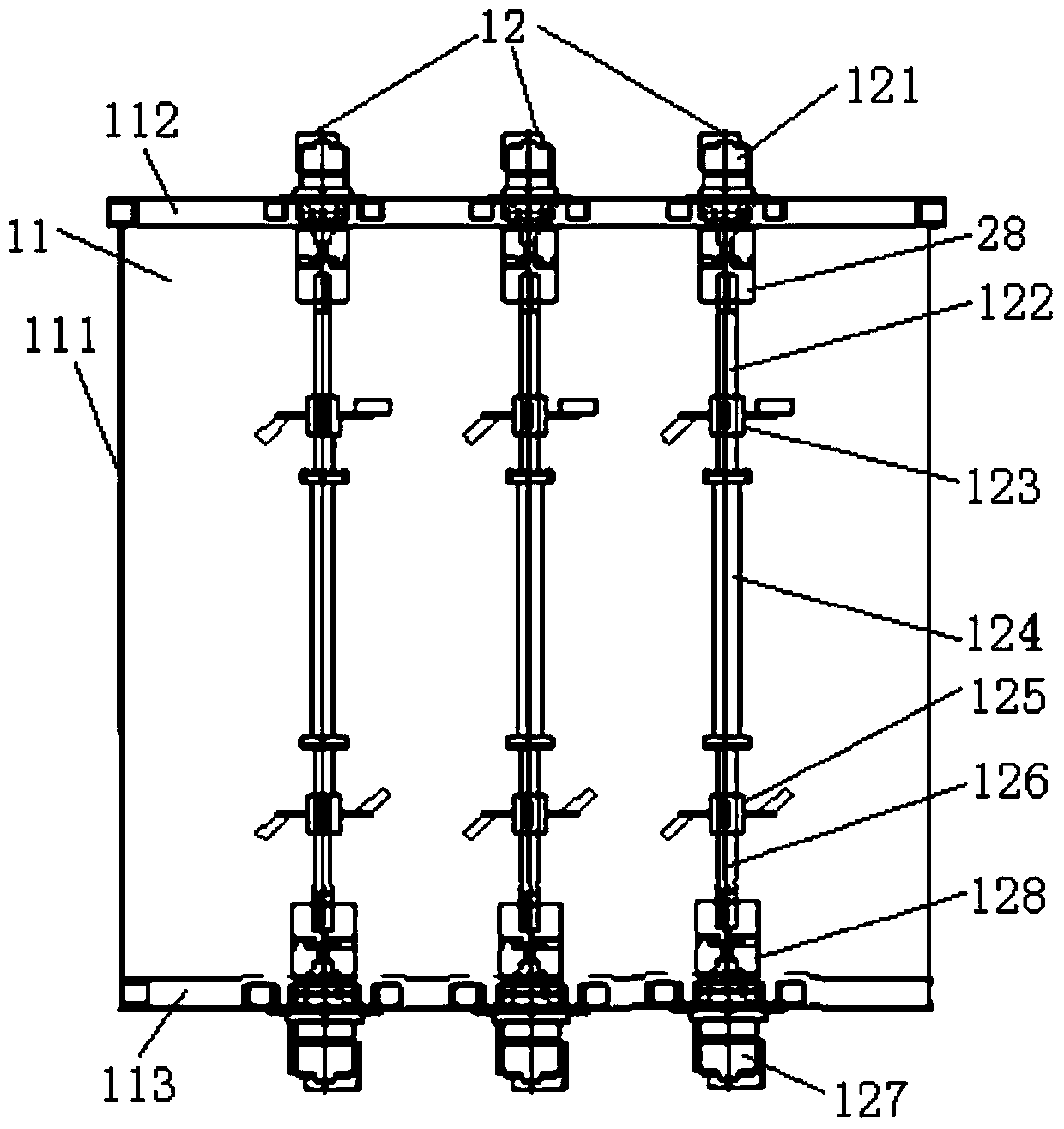

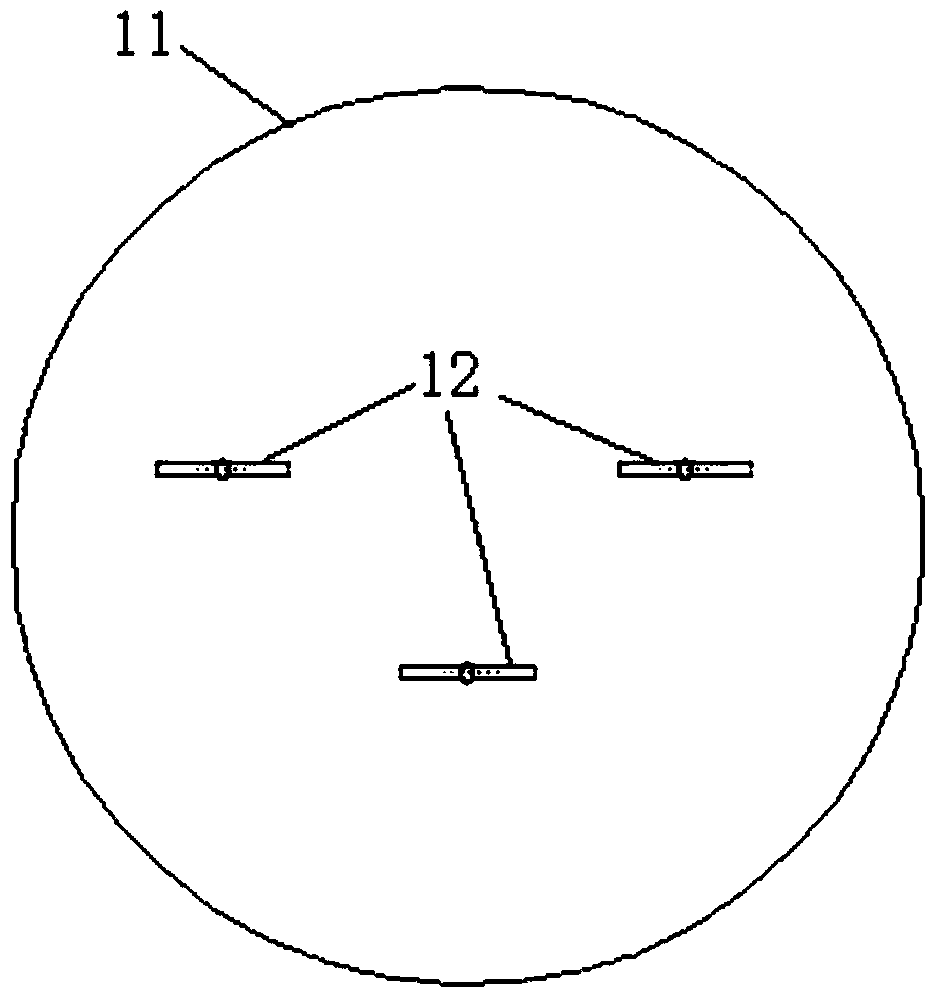

[0021] Such as figure 1 As shown, the offshore fracturing fluid continuous mixing device of the present invention includes a coaxial two-way stirring device 1, a first filling pump 2, a second filling pump 3, a multi-stage spiral grinding pump 4, and an air pressure multi-head jet mixing device 5 , a measuring device 6, a return line 7 and a solenoid valve 8. After the thickener and fracturing fluid are injected into the coaxial two-way stirring device 1 from the fracturing fluid inlet, the coaxial two-way stirring device 1 fully shears and stirs the thickener and fracturing fluid to obtain the thickener and fracturing fluid The mixture of thickener and fracturing fluid flows out from the outlet of the fracturing fluid and is injected into the first perfusion pump 2, and the first perfusion pump 2 pumps the mixture of thickener and fracturing fluid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com