Fully-sealed environmentally-friendly recovery control system for tar residues in coal tar chemical industry

A control system and technology of tar residue, applied in coking ovens, petroleum industry, preparation of liquid hydrocarbon mixtures, etc., to achieve the effects of reducing production costs, smooth detection, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

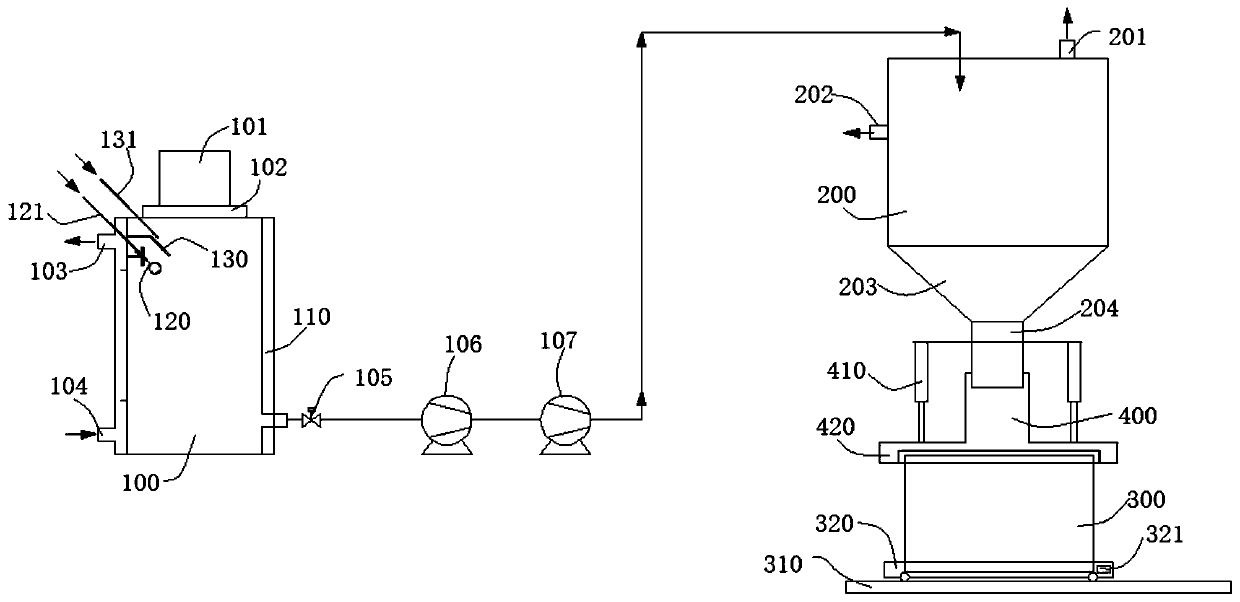

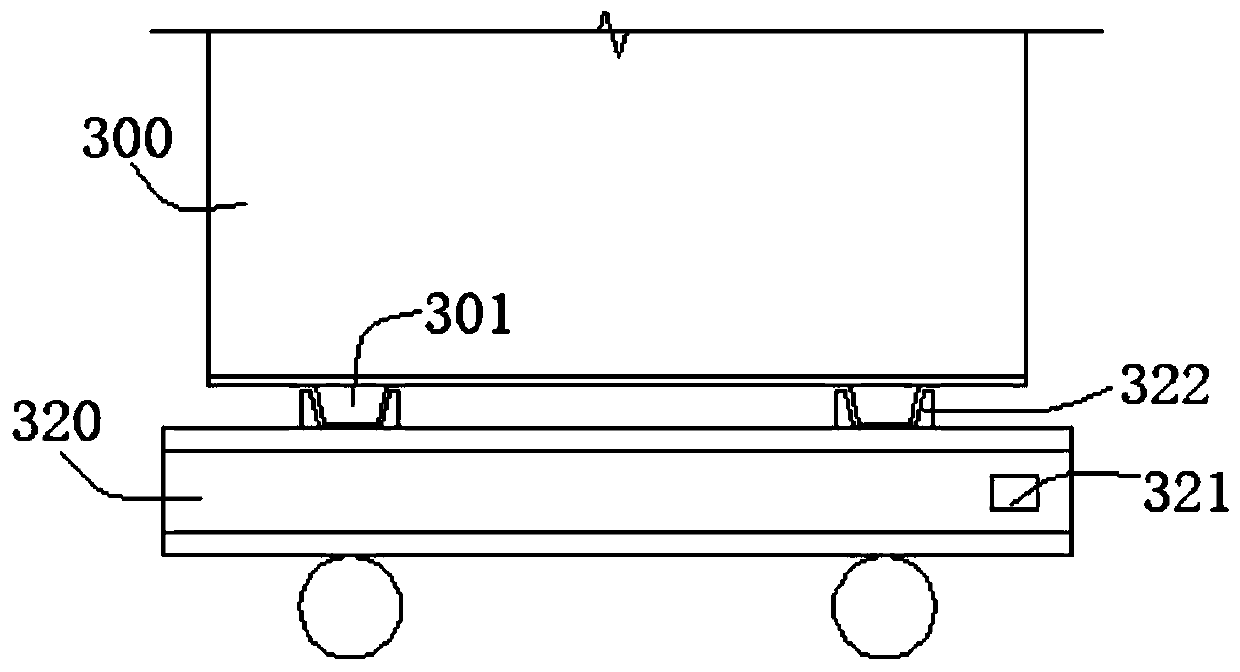

[0036] Such as figure 1 As shown, a fully sealed environmental protection recovery control system for coal coke tar slag in this embodiment includes an emulsifier 100, a two-phase separator 200 and a tar slag tank 300, wherein the emulsifier 100 is covered with a thermal insulation container 110, and The top and the bottom of the insulated container 110 are respectively provided with an insulated container liquid outlet 103 and an insulated container liquid inlet 104, and the top of the emulsifier 100 is provided with a feeding port 101; Sealed tube 102, the bottom of the emulsifier 100 is provided with an outlet, the outlet is connected to the two-phase separator 200 through a pipeline, the top of the two-phase separator 200 is provided with a waste gas outlet 201, and one side is provided with a discharge port 202, the two-phase separator There is a slag outlet 203 at the bottom of the 200, and the slag outlet 203 discharges the tar residue through the slag outlet pipe 204. ...

Embodiment 2

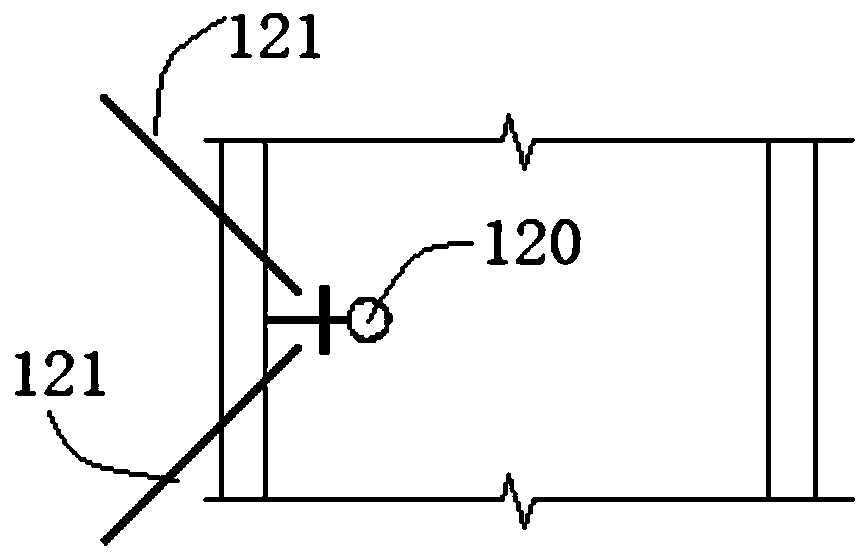

[0047] A fully sealed environment-friendly recovery control system for coal coke chemical tar residue in this embodiment is basically the same as in Embodiment 1. Furthermore, in this embodiment, the emulsifier 100 is also equipped with a device for cleaning and purging the passive liquid level switch 120 The switch purge 121, as figure 1 As shown, the switch purger 121 is obliquely arranged on the side of the passive liquid level switch 120 , and its height gradually decreases along the direction of approaching the passive liquid level switch 120 . And if figure 2 As shown, switch purgers 121 are respectively provided on both sides of the passive liquid level switch 120, and at least one switch purger 121 is purged with ammonia water. Specifically, the two sides are symmetrically arranged and distributed at an angle of 90°. One side is purged with high-temperature steam, and the other side is purged with ammonia water, which can prevent the solidification of oil residue and...

Embodiment 3

[0049] A fully sealed environment-friendly recovery control system for coal coke chemical tar slag in this embodiment is basically the same as the above-mentioned embodiment. Furthermore, in this embodiment, a protective plate 130 is also provided in the emulsifier 100, and the protective plate 130 is covered in an airless above the source liquid level switch 120 , and the protective plate 130 gradually slopes downward along the direction away from the inner wall of the emulsifier 100 . Such as figure 1 As shown, the protection plate 130 can be set to be similar to an L shape, and its horizontal extension section is set above the passive liquid level switch 120, and then its end is gradually inclined downward, so as to facilitate the tar residue to slide down and prevent the tar residue from dripping and sticking. Attached to the passive liquid level switch 120; a protective plate purger 131 is arranged above the protective plate 130, and the protective plate purger 131 gradua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com