Processing technology of transparent ABS resin

A technology of ABS resin and processing technology, applied in the field of processing technology of transparent ABS resin, can solve the problems of large amount of three wastes, long process, complicated process, etc., and achieve the effect of low product odor, stable quality and short process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

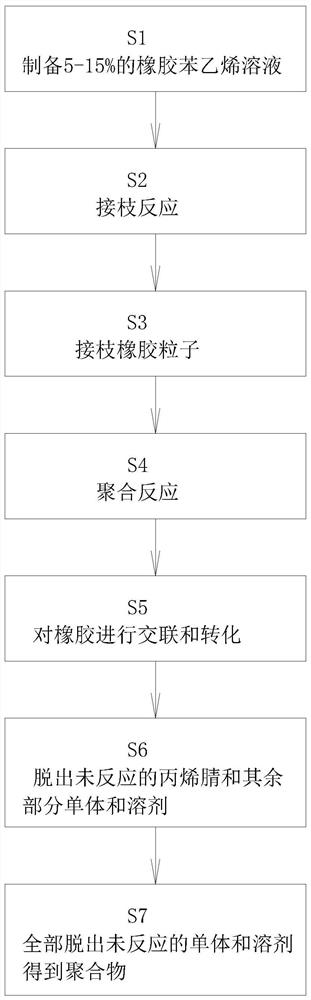

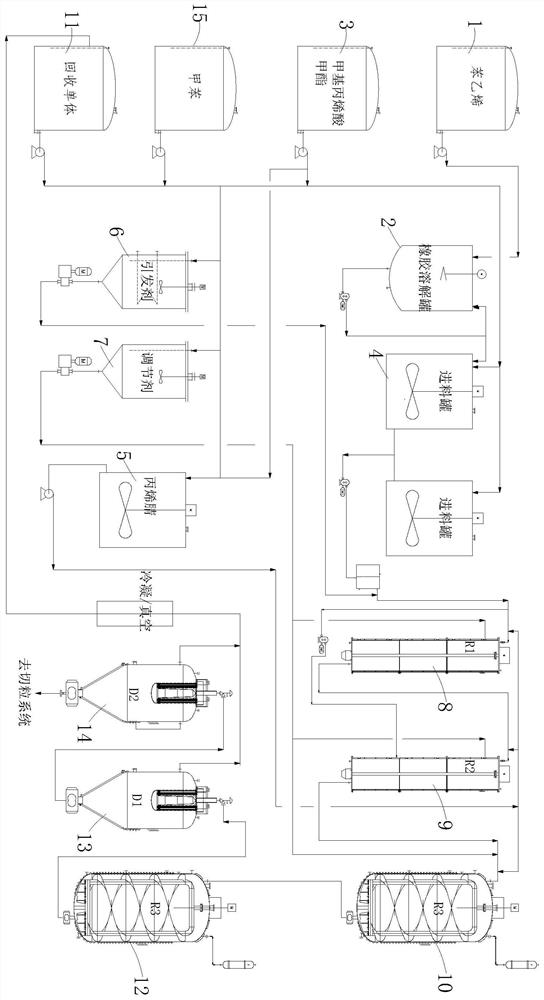

[0020] Such as figure 1 , figure 2 Shown, a kind of processing technique of transparent ABS resin comprises the steps:

[0021] S1. After the SBR rubber is pulverized, add the styrene in the styrene tank 1 into the rubber dissolving tank 2, stir and grind back through the grinding pump to make a rubber styrene solution with a content of 5-15%;

[0022] S2, rubber styrene solution, methyl methacrylate, initiator (diperoxy tert-butyl-cyclohexane), molecular weight regulator (n-dodecyl mercaptan) are continuously added to the first according to a certain ratio. In the reactor 8, control the temperature at 70-90°C and the stirring speed at 30-40rpm to carry out the grafting reaction;

[0023] Wherein, the rubber styrene solution is obtained by mixing and reacting SBR rubber particles in the rubber dissolving tank 2 with styrene, methyl methacrylate is supplied by the methyl methacrylate tank body 3, and the initiator is supplied by the initiator tank body 6, and the molecular w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com