Method for providing axial gap in cutter assembly of grinder pump, and grinder pump comprising shim configured for providing said axial gap

A technology of cutter assembly, axial clearance, applied to parts of pumping devices for elastic fluids, pump elements, water supply devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

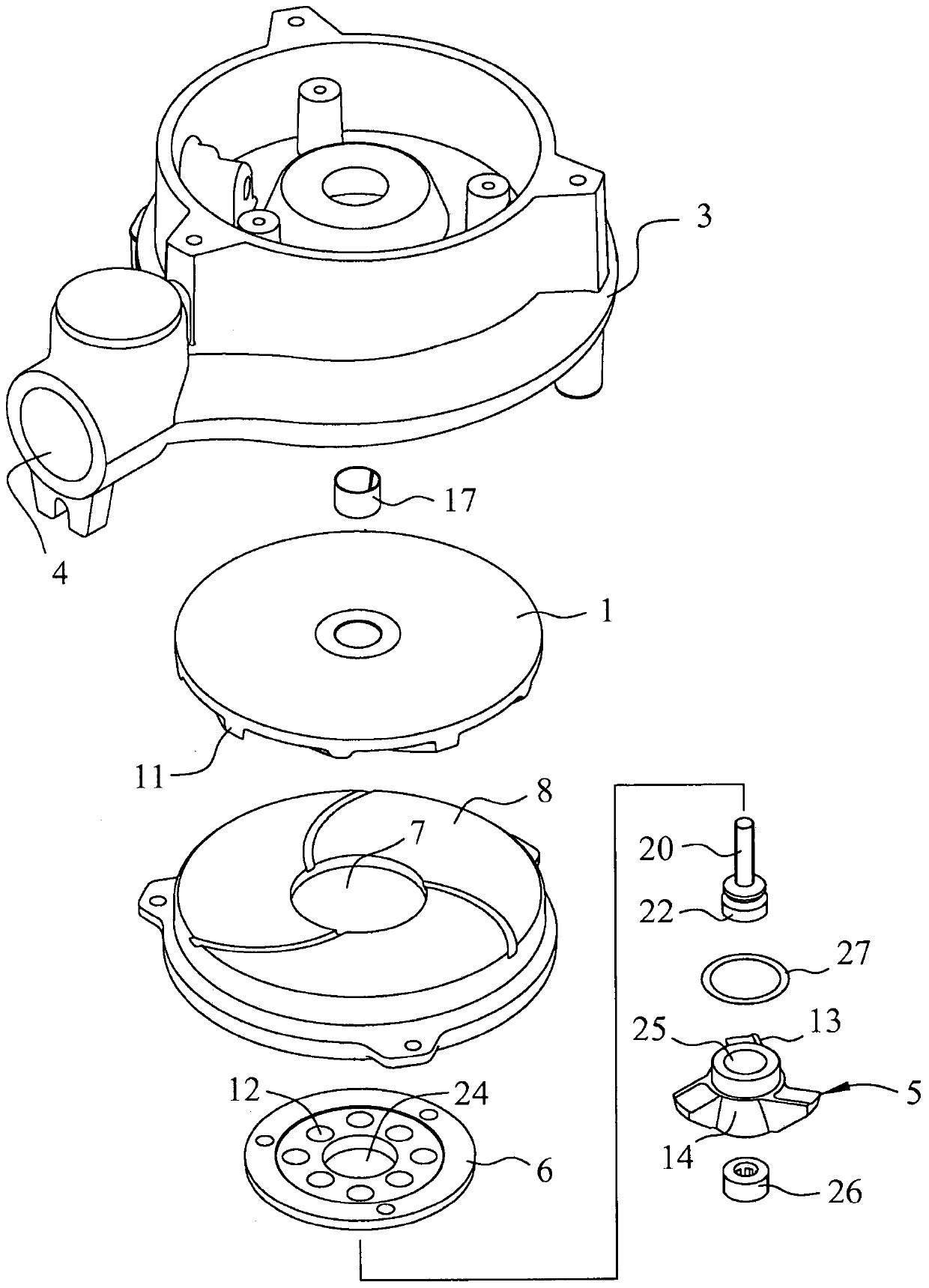

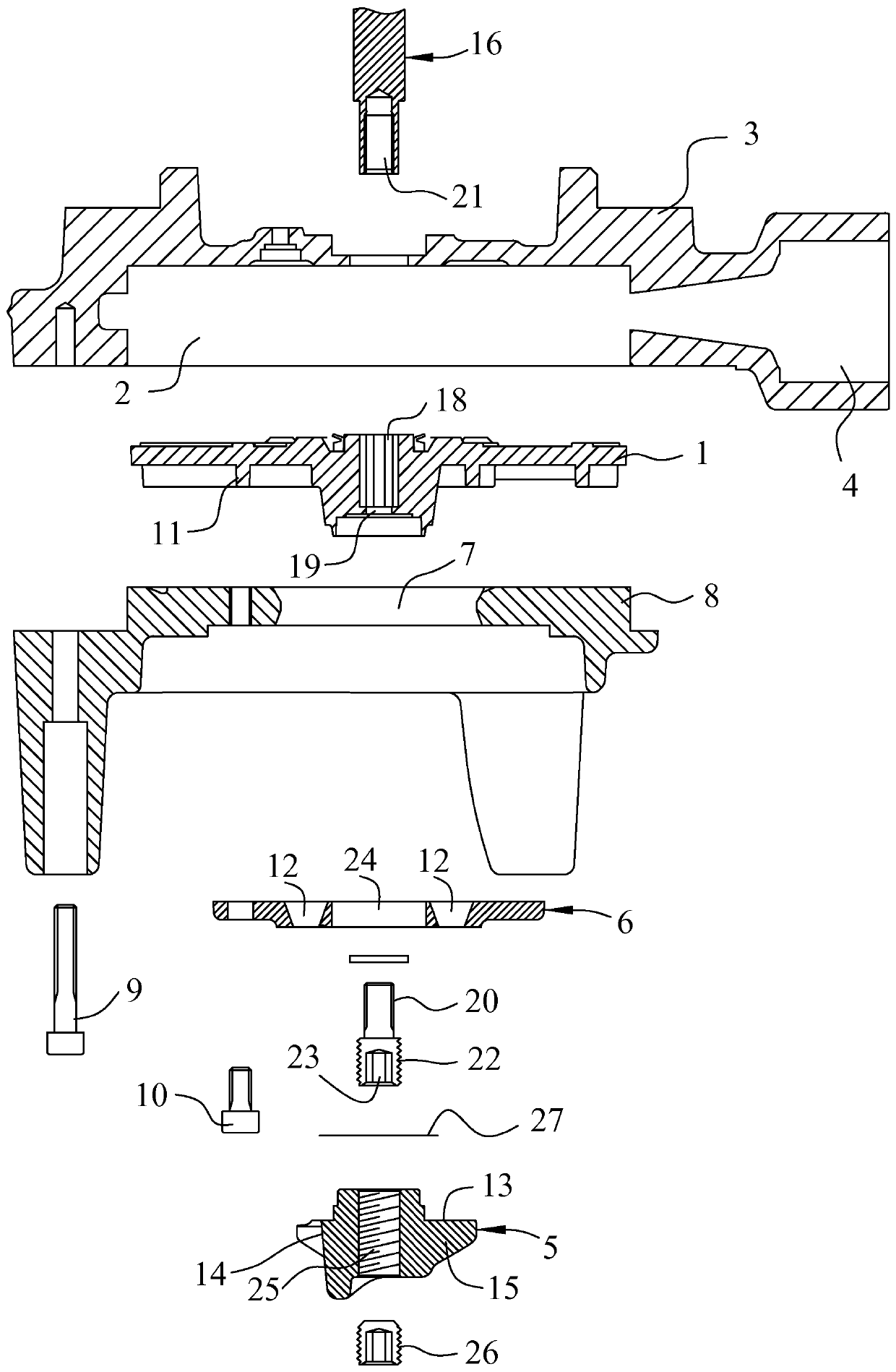

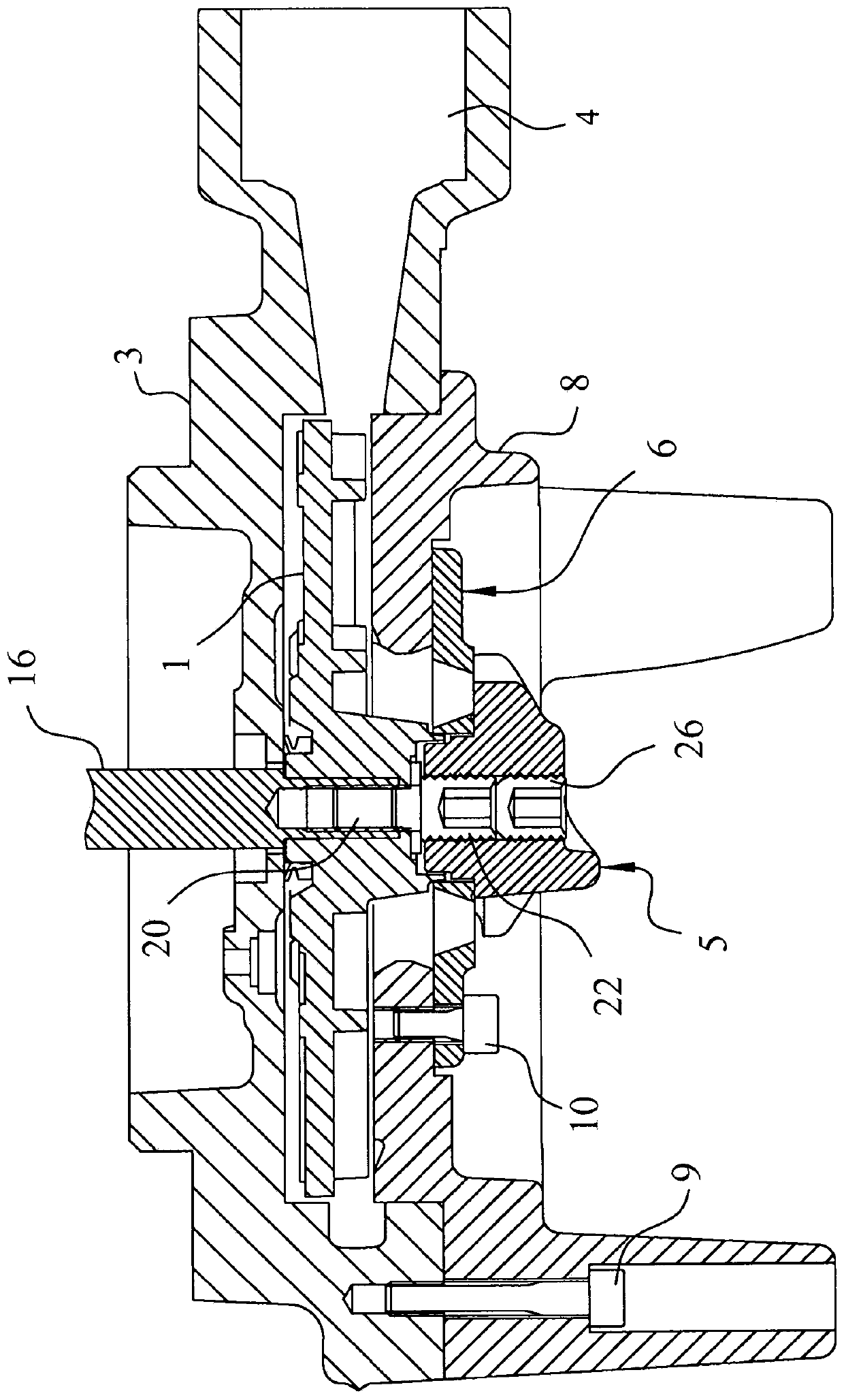

[0028] The invention relates in particular to a grinding pump which is arranged for pumping waste water containing solid matter. first reference Figure 1-3 .

[0029] A grinding pump (also called a chopping pump) comprises an impeller 1 journalled and driven in rotation in a pump chamber 2 defined by a pump housing 3 . The pump housing 3 has an axial inlet port on the suction / upstream side of the pump and a radial discharge port 4 on the pressure / downstream side of the pump for liquid delivery by the rotating impeller 1 during operation. The pump comprises a cutter wheel, indicated generally at 5, arranged coaxially with and co-rotating with the impeller 1 . In operation, the cutter wheel 5 rotates on the upstream side of a cutter disc (generally indicated at 6 ) which can be fixedly connected to the pump housing 3 . More precisely, the cutter disc 6 is fitted in covering relation to a central access opening 7 formed through a suction plate 8 which can be fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com