A machine tool spindle lubricating oil system with cooling function

A technology of machine tool spindle and lubricating oil, applied in manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of poor heat dissipation, insufficient lubrication, and inability to re-use, avoid rapid outflow, and facilitate installation. and the effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the invention but not to limit the scope of the invention.

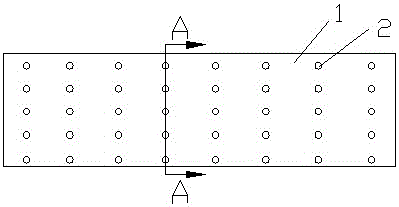

[0026] figure 1 It is a structural schematic diagram of the invention. It can be seen from the accompanying drawings that this kind of machine tool spindle lubricating oil system with cooling function includes a main shaft body, and the outer shaft body 6 of the main shaft is provided with several lubricating oil holes 2. The oil flows out from the lubricating oil hole 2 from the main shaft body and soaks into the surface of the main shaft body to lubricate the main shaft body.

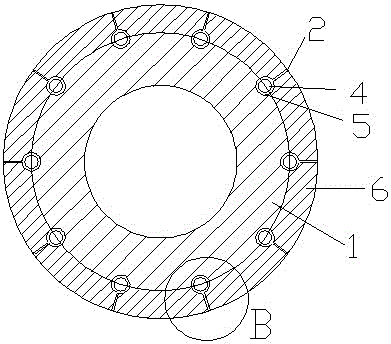

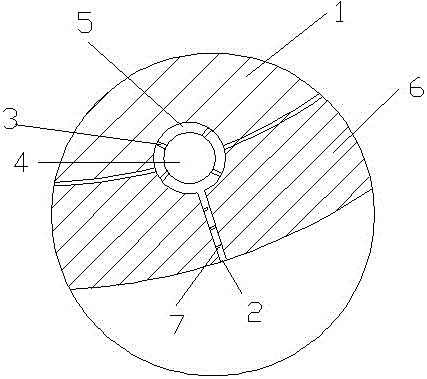

[0027] figure 2 yes figure 1 A-A sectional view in , combined with the accompanying drawings, it can be seen that the main shaft body includes a main shaft inner shaft body 1 and a main shaft outer shaft body 6, and the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com