Cleaning equipment

A technology for cleaning equipment and equipment, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as reducing the exhaust effect, damage to workpieces, and hindering the flow of air inside the cleaning equipment, so as to reduce The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the cleaning equipment provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

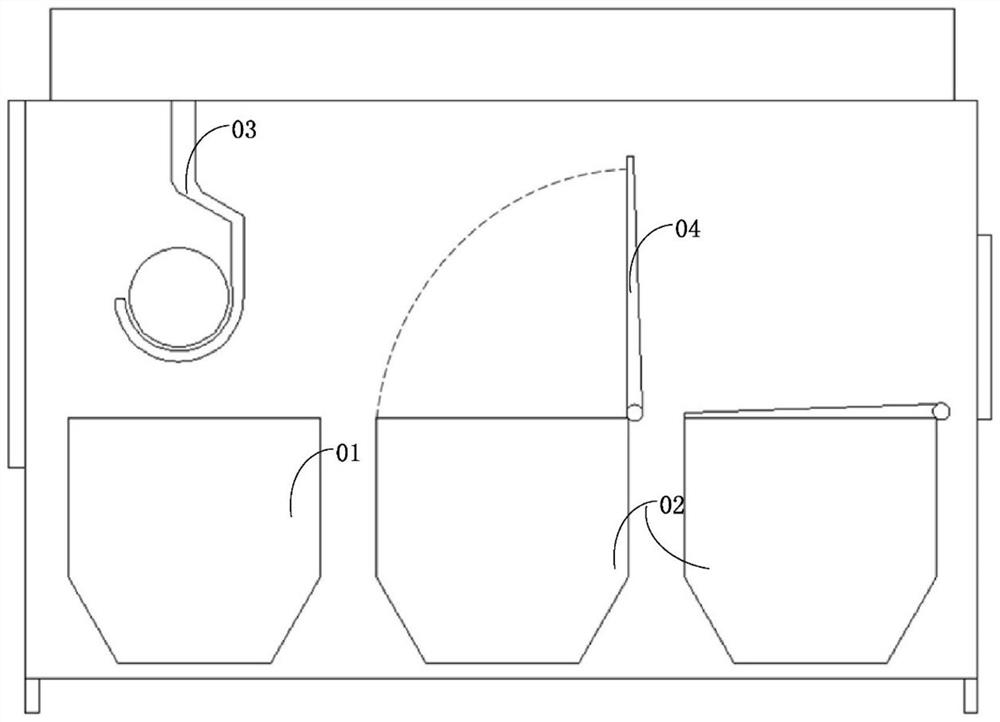

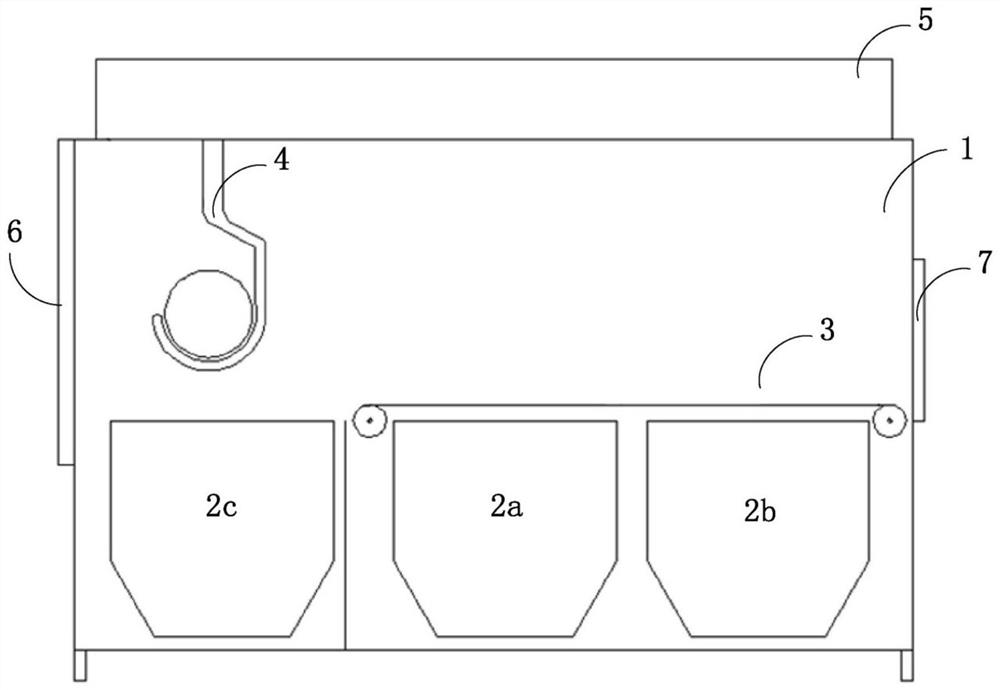

[0037] Please refer to figure 2 and image 3 , this embodiment provides a cleaning device, which includes a cavity 1 , a process tank 2 and an opening and closing device 3 . Wherein, the process tank 2 is arranged in the cavity 1, and is used for containing cleaning liquid. Specifically, the process tank 2 is, for example, an acid tank for containing acid liquid, and since the acid liquid is easy to volatilize, an opening and closing device 3 for controlling the opening and closing of the notch must be provided on the acid tank.

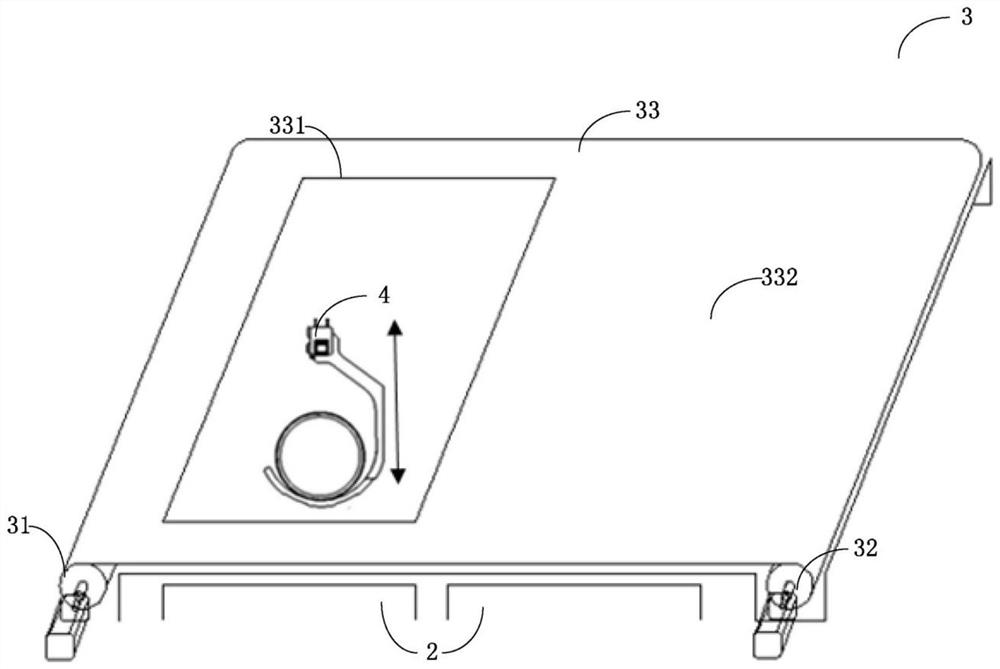

[0038] Such as image 3 As shown, the opening and closing device 3 includes a flexible film 33 , a first reel assembly 31 and a second reel assembly 32 . Wherein, the flexible film 33 cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com