An anti-clogging sludge continuous thermal hydrolysis system

A thermal hydrolysis and anti-clogging technology, applied in water/sludge/sewage treatment, sludge treatment, pyrolysis treatment of sludge, etc., can solve problems such as clogging, ensure economy, reduce consumption, and prevent sludge The effect of high temperature coking and hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

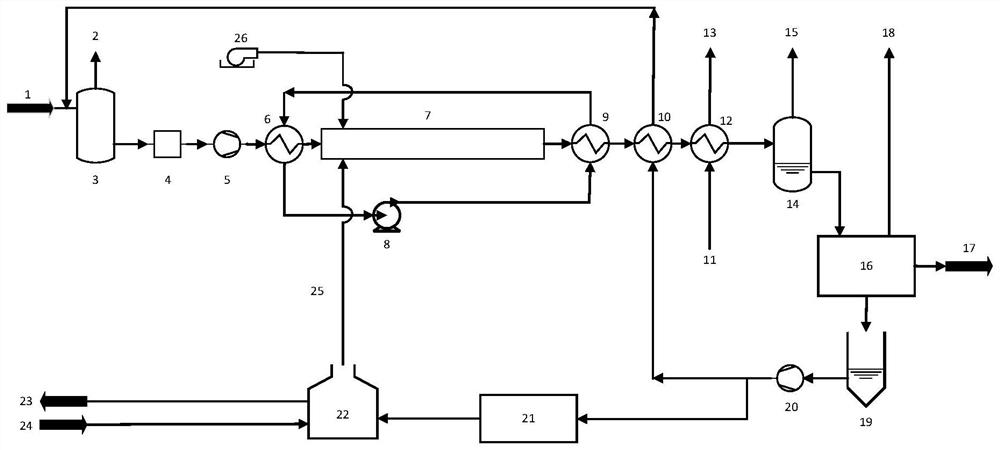

[0025] The structure of an anti-clogging sludge low-cost continuous thermal hydrolysis system is as follows: figure 1 As shown, the system consists of material sludge inlet 1, viscosity reduction tank exhaust port 2, viscosity reduction tank 3, grinding pump 4, screw pump 5, preheater 6, thermal hydrolysis reactor 7, intermediate medium circulation pump 8, Primary regenerator 9, secondary regenerator 10, cooling water inlet 11, cooler 12, cooling water outlet 13, gas-liquid separator 14, non-condensable gas exhaust port 15, automatic filter press system 16, dehydration sewage Sludge transportation 17, odor exhaust port 18, filtrate collection tank 19, centrifugal pump 20, anaerobic biochemical system 21, gas boiler 22, boiler exhaust 23, boiler water supply 24, boiler steam 25 and air compressor 26 The material sludge inlet 1 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com