Continuous sludge pyrohydrolysis system and process capable of realizing efficient and sufficient pyrohydrolysis

A technology of thermal hydrolysis and sludge, which is applied in pyrolysis treatment of sludge, water/sludge/sewage treatment, multi-stage water treatment, etc. It can solve the problem of low thermal hydrolysis treatment efficiency of sludge and moisture content of dehydrated cake High, insufficient thermal hydrolysis and other problems, to achieve the effect of improving sludge treatment efficiency, increasing the degree of thermal hydrolysis, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

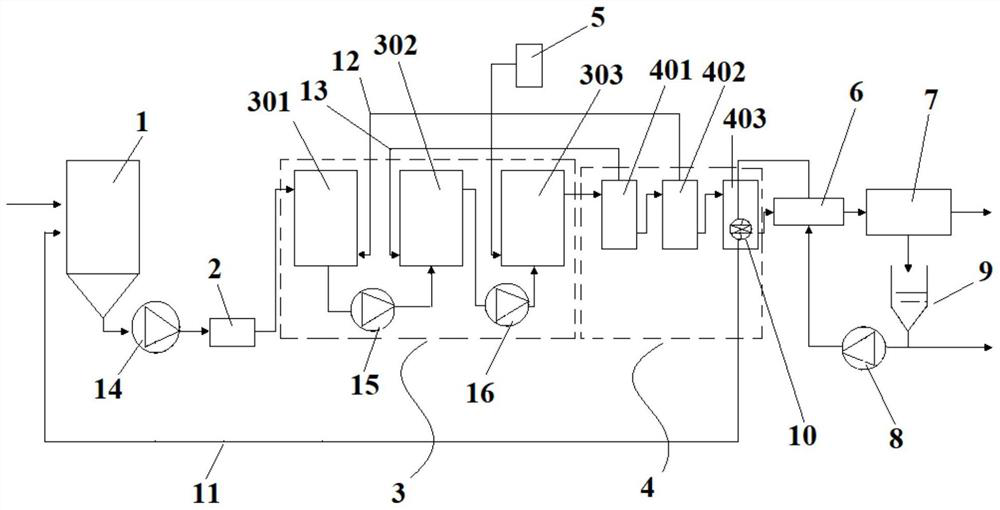

[0044] This embodiment provides a continuous sludge thermal hydrolysis system capable of efficient and sufficient thermal hydrolysis, such as figure 1 As shown, the system includes a sludge silo 1, the discharge port of the sludge silo 1 is connected with the grinding pump 2, and the grinding pump 2 is connected with the feed port of the slurry tank 301 in the step-by-step temperature boosting unit 3, The discharge port of the hydrolysis tank 303 in the step-by-step temperature boosting unit 3 is connected with the feed port of the multi-stage flash evaporation unit 4;

[0045] The step-by-step temperature boosting unit 3 includes a slurry tank 301, a preheating tank 302 and a hydrolysis tank 303 connected in sequence;

[0046] The multi-stage flash unit 4 includes a plurality of flash tanks connected in succession;

[0047] Hydrolysis tank 303 is also linked to each other with steam boiler 5;

[0048] The discharge port of the multi-stage flash evaporation unit 4 is connect...

Embodiment 2

[0054] This embodiment provides a continuous sludge thermal hydrolysis process capable of efficient and sufficient thermal hydrolysis, which adopts the continuous sludge thermal hydrolysis system capable of efficient and sufficient thermal hydrolysis given in Example 1;

[0055] In this process:

[0056] In the step-by-step temperature boosting unit 3, the temperature in the slurry tank 301 is increased to 85-90°C, and the pressure is normal pressure; the temperature in the preheating tank 302 is increased to 120-130°C, and the pressure is increased to 0.2MPa; the hydrolysis tank The temperature in 303 is increased to 180°C and the pressure is 1.0MPa.

[0057] In the step-by-step temperature boosting unit 3, the residence time of the sludge in the slurry tank 301, the preheating tank 302 and the hydrolysis tank 303 is 40 minutes.

[0058] The moisture content of the sludge in the sludge silo 1 is increased from 80% to 83%, the moisture content of the sludge in the slurry tank...

Embodiment 3

[0061] This embodiment provides a continuous sludge thermal hydrolysis process capable of efficient and sufficient thermal hydrolysis, which adopts the continuous sludge thermal hydrolysis system capable of efficient and sufficient thermal hydrolysis given in Example 1;

[0062] In this method, sludge with a water content of 80% is used as the thermal hydrolysis object, and the processing capacity is 2.5 tons per day, and the following steps are carried out:

[0063] Step 1, unload the sludge with a water content of 80% produced by sewage treatment into the sludge silo 1; start the centrifugal pump 9, and start the first screw pump 14, the second screw pump 15, the third screw pump 16 and the grinding pump at the same time 2;

[0064] Step 2, the centrifugal pump 9 heats part of the sludge press filtrate through the heat exchanger 6 and the triple flash heat exchanger 10 in the triple flash tank 403, and then enters the sludge silo 1 through the triple flash heat exchange tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com