Cutting and grinding pump

A technology for cutting discs and pump bodies, applied to pumps, pump components, non-variable pumps, etc., can solve problems such as poor cutting effect, low tool hardness, and large pump body inlet, so as to improve cutting effect and efficiency, improve Cutting effect, the effect of improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

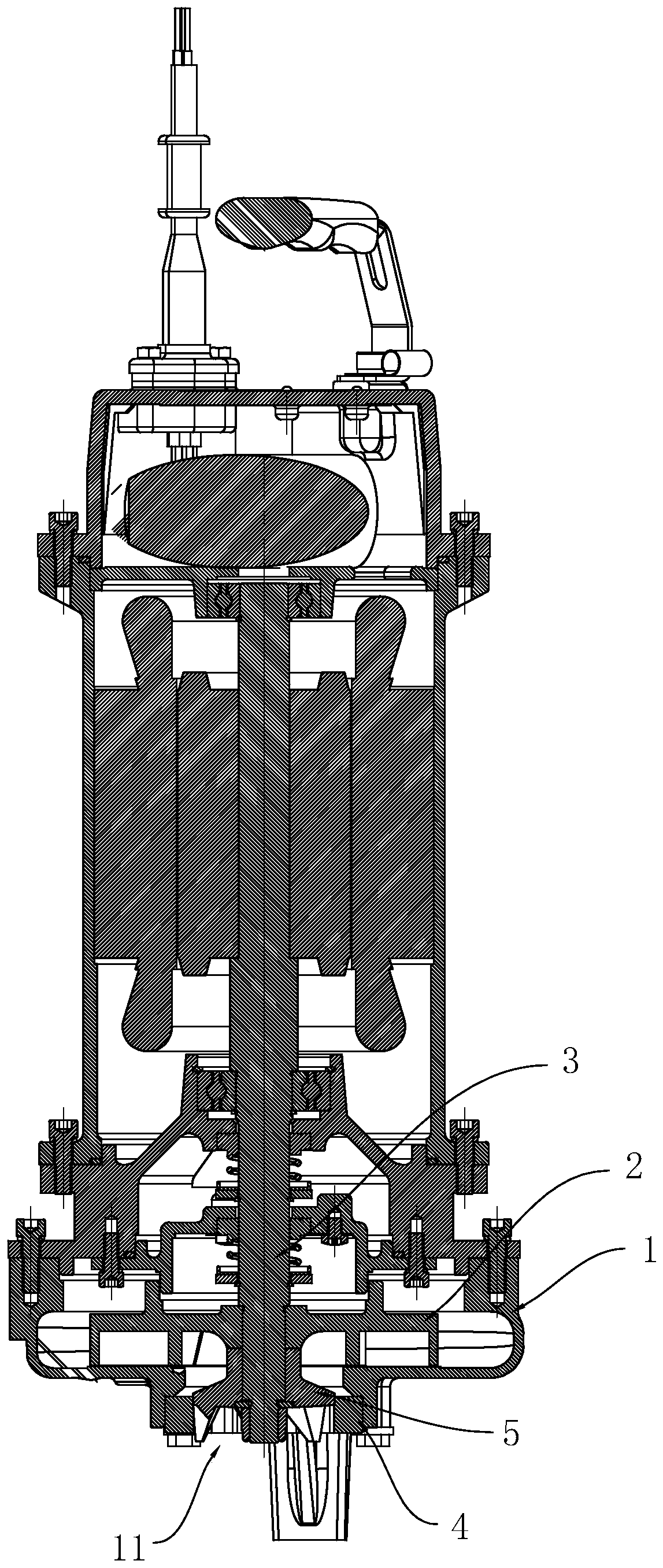

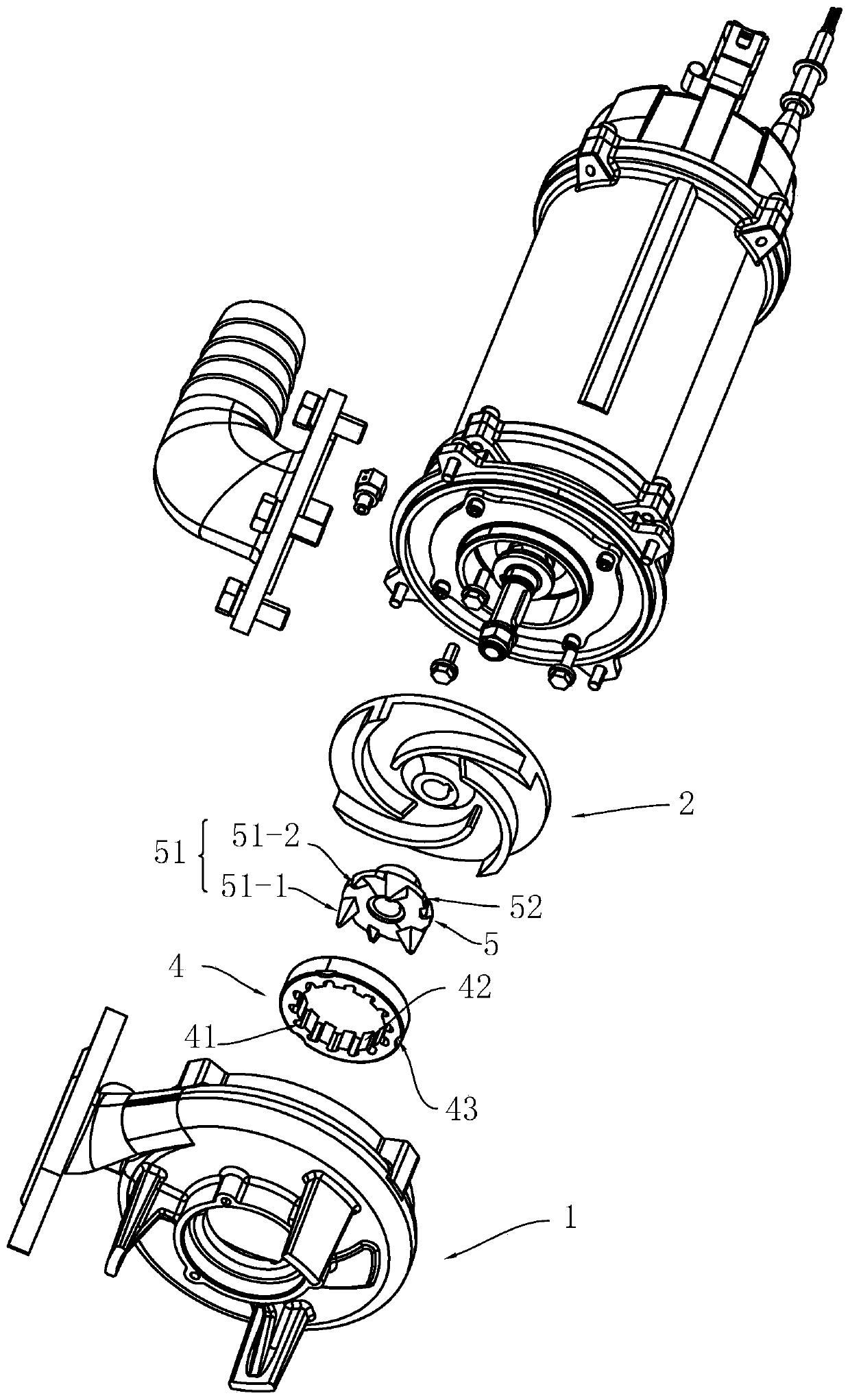

[0024] Example: such as Figure 1-10 As shown, the cutting and grinding pump includes a pump body 1 with a water inlet 11 and a water outlet, an impeller 2 matched with the flow passage of the pump body, and a pump shaft 3 that drives the impeller to rotate. The water inlet and outlet are connected to the flow passage. Cooperate.

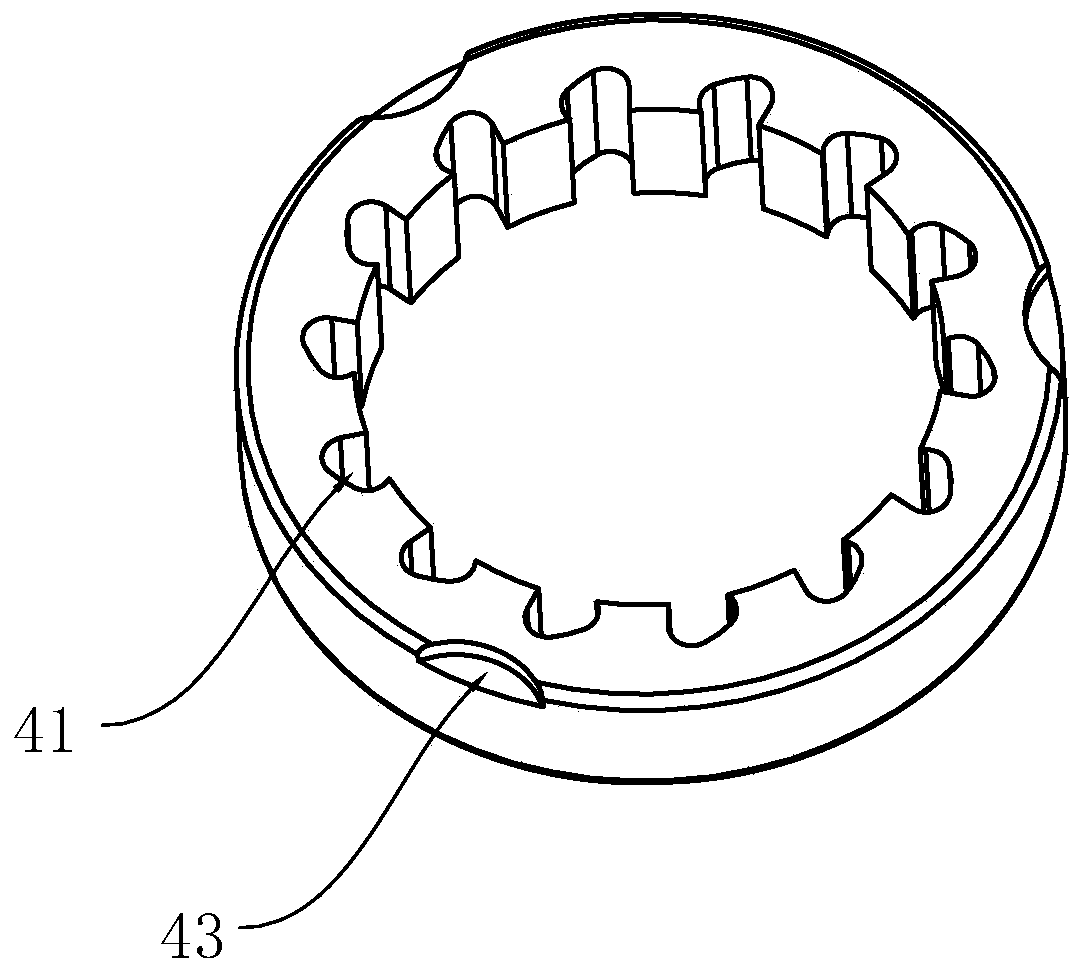

[0025] The cutting and grinding pump also includes a guide disc 4 matched with the water inlet 11 and a cutting disc 5 matched with the guide disc. The cutting disc 5 is arranged on the pump shaft 3. The guide disc 4 is in the shape of an annular disc, the inner ring wall of the guide disc is provided with a plurality of water inlet holes 41, the cutting disc is arranged in the inner cavity of the guide disc, and the edges of the cutting disc are evenly distributed A plurality of blade parts 51, the blade parts are matched with the inner ring wall 52 of the guide plate. A guide disc and a cutting disc are arranged at the water inlet of the pump body....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com