Multi-stage raw medicine grinding system

A technology of raw medicine and grinding particles, which is applied in the directions of dissolving, grain processing, mixer, etc., can solve the problems of reduced grinding efficiency, low processing efficiency, high work intensity, etc., so as to reduce the specifications of grinding equipment, save costs, and improve grinding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

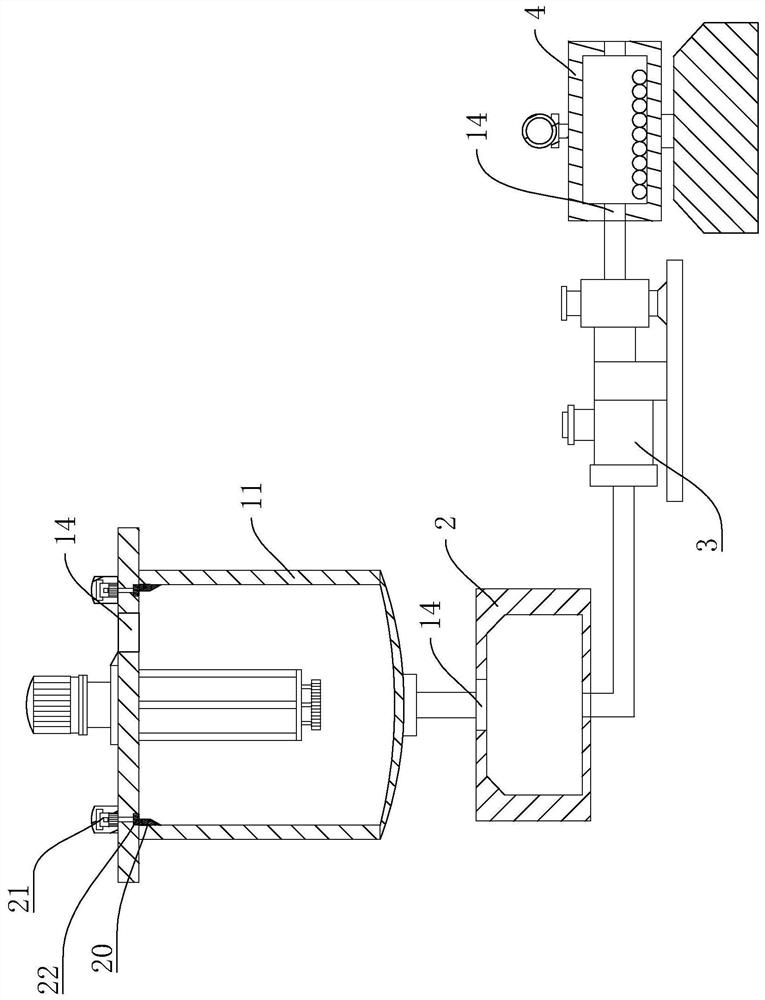

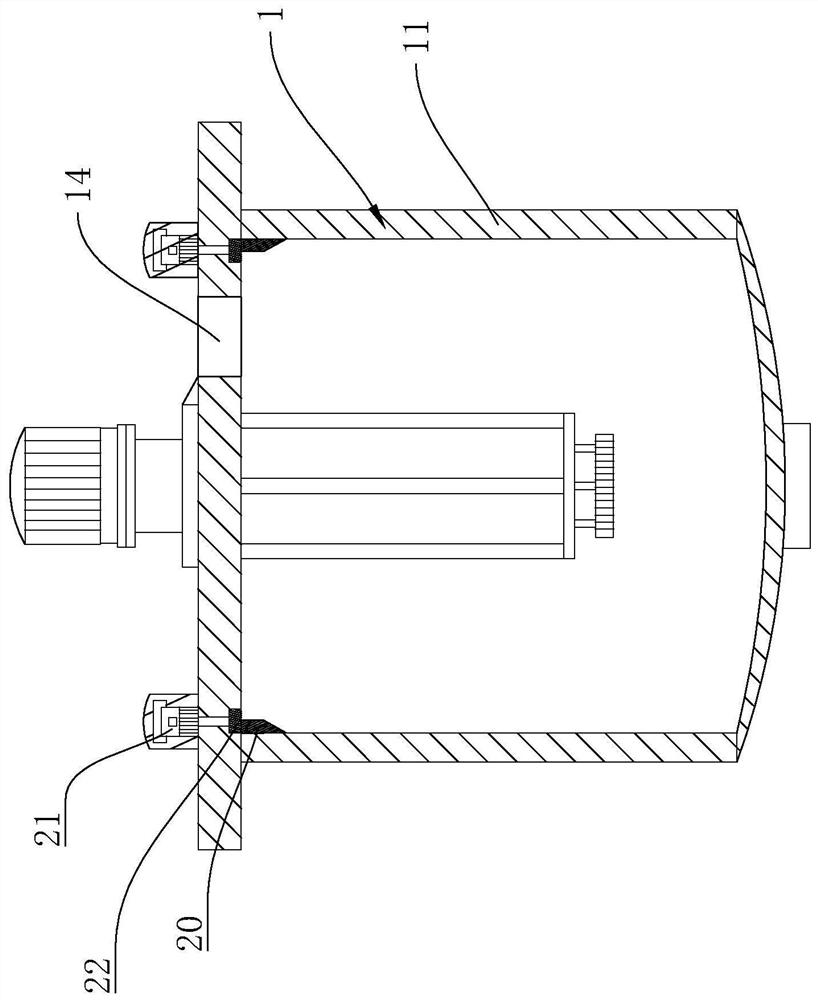

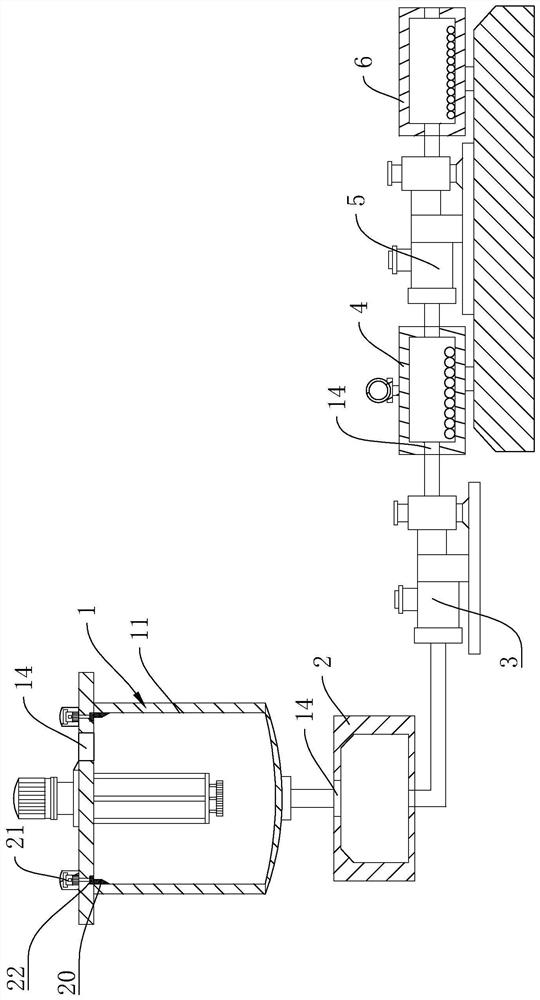

[0029] like figure 1 As shown, the multi-stage raw drug grinding system includes an emulsification kettle 1, a raw material temporary storage kettle 2, a grinding pump 3, and a ball mill 4, and the discharge port of the emulsification kettle 1 is communicated with the feed port 14 of the raw material temporary storage kettle 2 , the discharge port of the raw material temporary storage kettle 2 communicates with the feed port 14 of the grinding pump 3 , and the discharge port of the grinding pump 3 communicates with the feed port 14 of the ball mill 4 . There are multiple temporary raw material storage stills 2, and the grinding pump 3 and ball mill 4 correspond to the corresponding temporary raw material storage stills 2 respectively. The emulsification kettle 1 has a large specification, which can realize large-scale shearing and emulsification. In order to improve the grinding efficiency, one emulsification kettle 1 and corresponding multiple raw material temporary storage k...

Embodiment 2

[0039] like image 3As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in the multi-stage raw drug grinding system, the discharge port of the ball mill 4 is also provided with a secondary grinding pump 5, so The feed port 14 of the secondary grinding pump 5 is connected with the discharge port of the ball mill 4 . In order to further improve the grinding efficiency and facilitate the pumping of raw materials, a secondary grinding pump 5 is installed at the outlet of the ball mill 4 for grinding, so that the raw materials after ball milling by the ball mill 4 can be ground again. Described secondary grinding pump 5 rear is also provided with secondary ball mill 6, and the discharge port of described secondary grinding pump 5 is connected with the feed inlet 14 of secondary ball mill 6, and the secondary ball mill 6 that is provided with The abrasive particle size is smaller than that of the ball mill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com