Straw smashing inter-row collecting and covering no-tillage planter

一种秸秆粉碎、播种机的技术,应用在耕作机具、直到播种、肥料和播种设备等方向,能够解决作业顺畅性和播种质量无法保证、作业成本高、结构复杂等问题,达到满足多样化播种需求、作业集成度高、组配精简的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

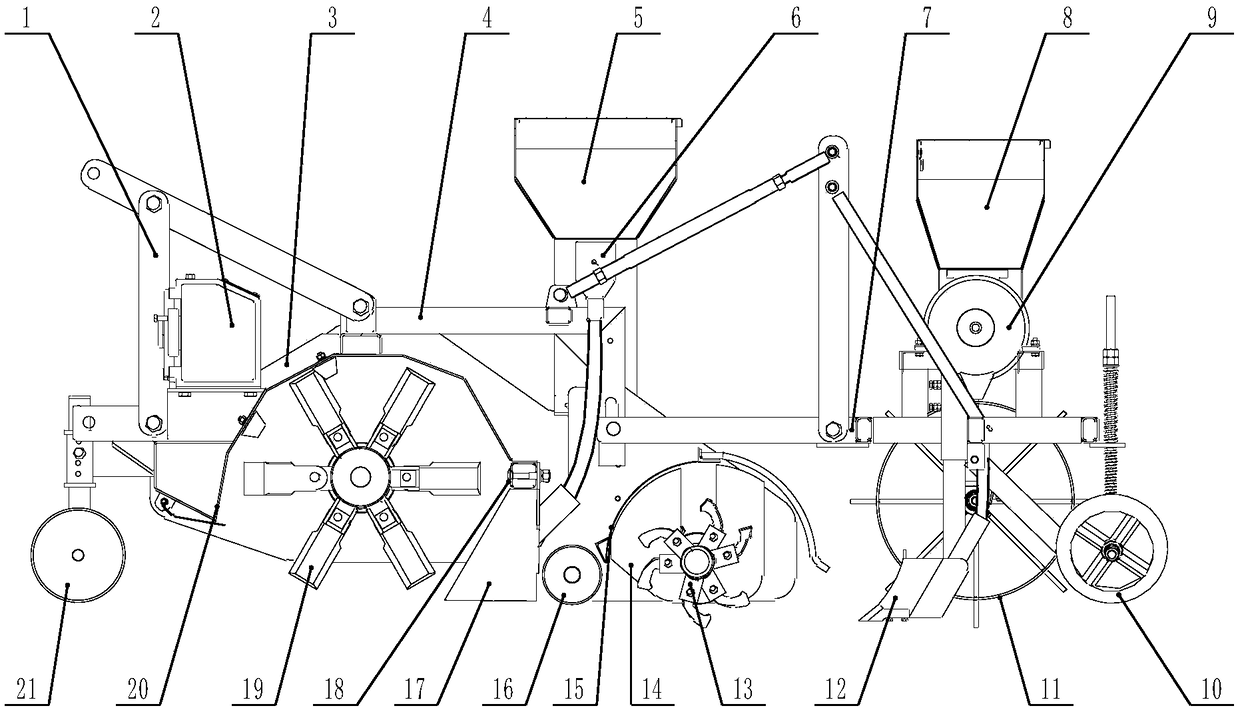

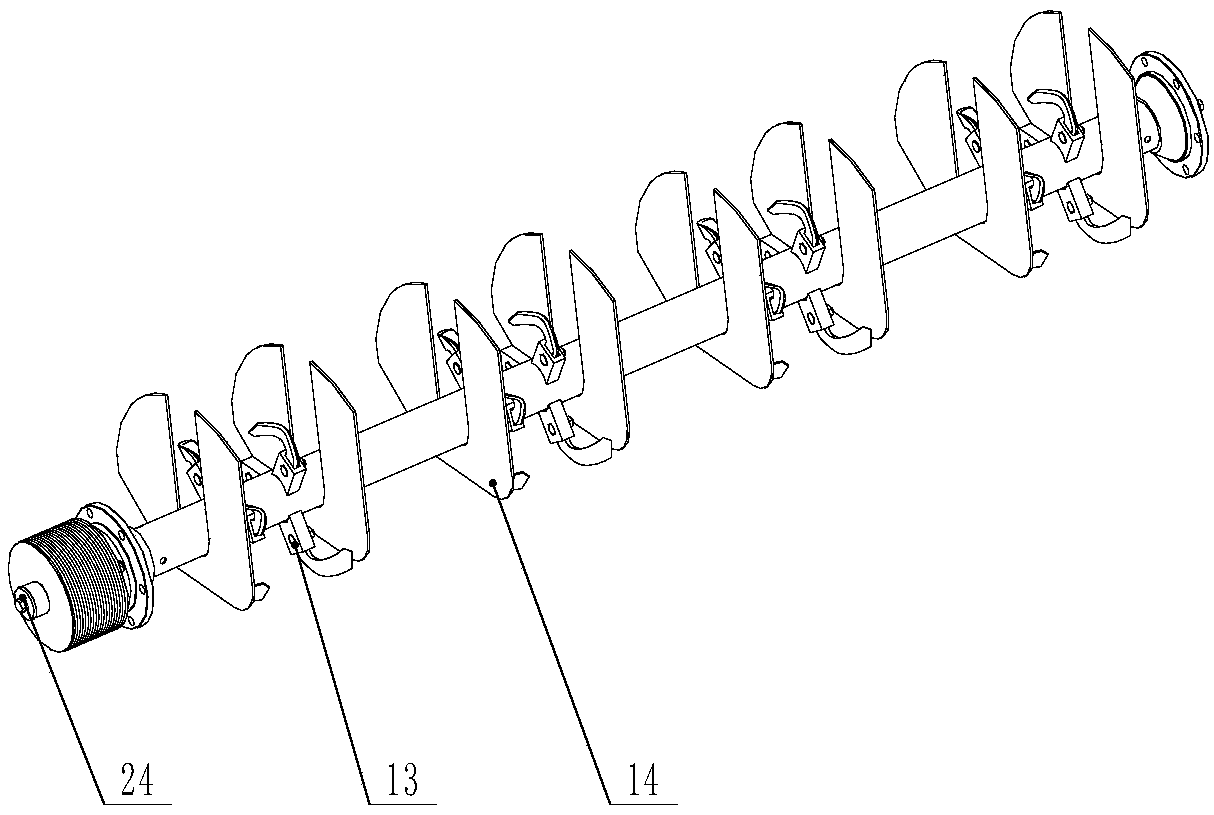

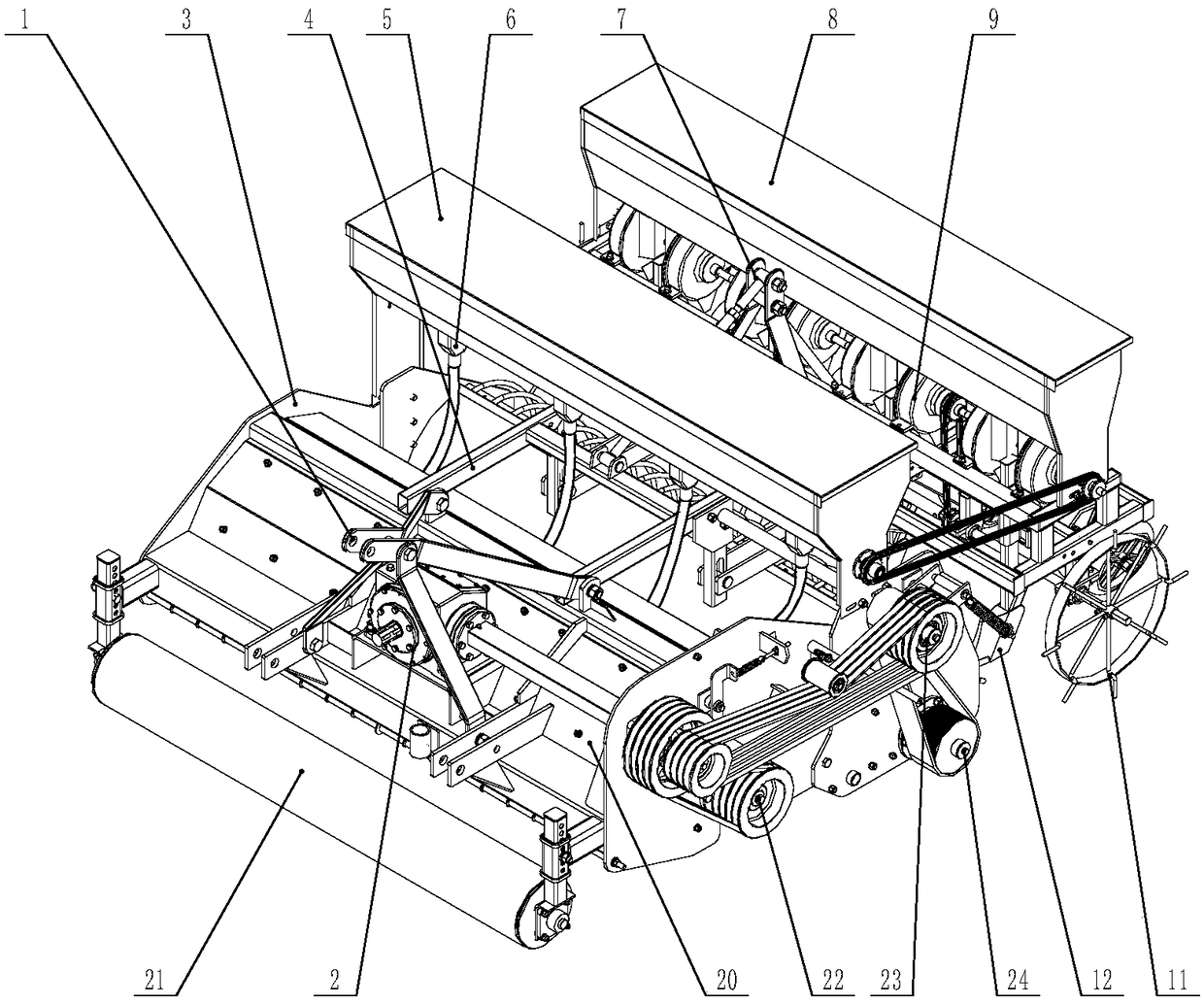

[0048] The structure of the present invention will be described in further detail below in conjunction with the drawings.

[0049] A no-tillage planter with straw crushing and mulching between rows, which is connected to a frame 3 by a suspension frame 1, and is successively arranged on the frame 3 from front to back: straw crushing device, diversion device, fertilizer device and ditching seeding device;

[0050] The straw crushing device: a straw crushing knife shaft 22 connected to the frame 3 horizontally, a number of straw crushing knives 19 are fixed circumferentially on the full length of the straw crushing knife shaft 22 without working space, and the straw crushing knife 19 is circumferentially fixed. A semicircular straw shredder cover 20 is arranged to the outside, and the tail of the straw shredder cover 20 is located at the horizontal position of the straw shredder shaft 22;

[0051] The diversion device: an adjusting beam 18 is provided at the tail of the straw shredder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com