Independent suspension mounting bracket structure

A technology for installing brackets and independent suspensions, applied in suspensions, elastic suspensions, substructures, etc., can solve the problems of heavy structure weight, high vehicle center of gravity, low frame integration, etc., and achieve high support rigidity and reliability Guarantee, ensure the effect of driving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] like Figure 16 As shown, the front end of the front suspension mounting frame structure 100 is welded to the front protective plate 300 of the engine hood of the car body, the side is connected to the wheel house plate 400, the rear longitudinal car body connecting beam outer plate is welded to the front wall of the car body 500, and the rear groove shape The inner panel is welded to the floor 600 grooved riser. Through the three-sided welding of front, side and rear, the frame structure and the car body form a good fit, so that the rigidity does not change sharply. The front and rear ends of the rear suspension mounting frame structure 200 are clamped and welded on the rear wheel house slant plate and the rear baffle plate 700 of the car body, and the middle groove opening is welded on the car body floor 600, so that the rear suspension frame structure is in harmony with the car body. The body forms a whole with good stiffness fit.

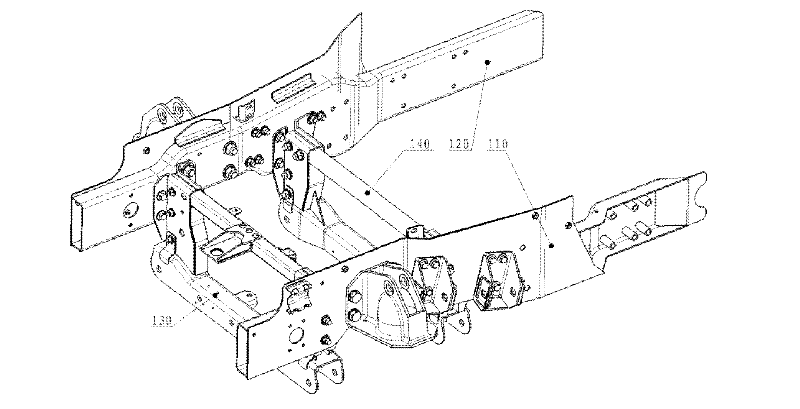

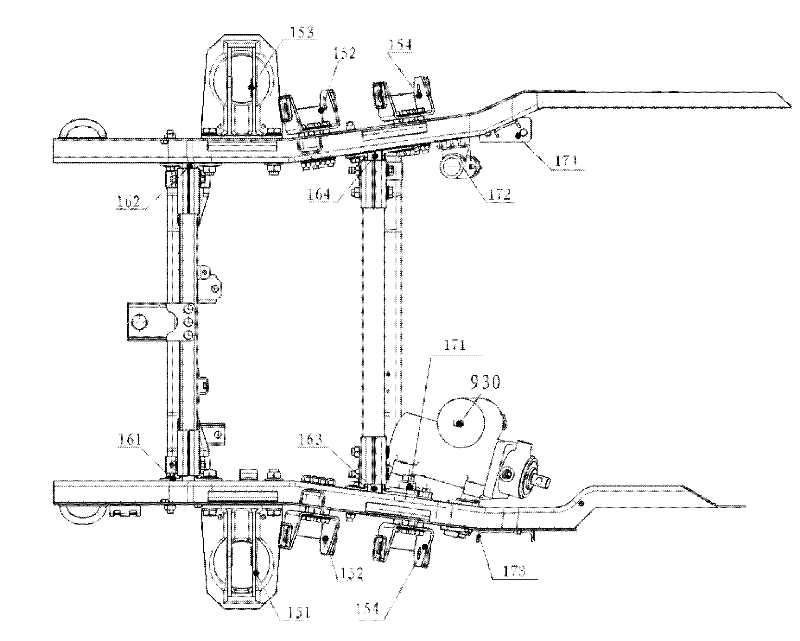

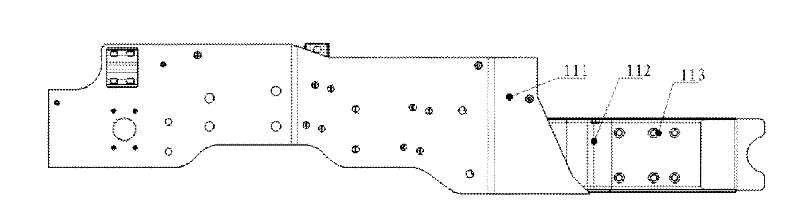

[0057] like Picture 1-1 , 1-2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com