Support moulding bed and linear forming method for setting up road steel bridge using same

A technology for supporting tires and steel bridges, applied in the field of steel structures, can solve the problems of inability to splicing highway steel bridge units, inability to mass-produce highway steel bridge units, and reduced performance and safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

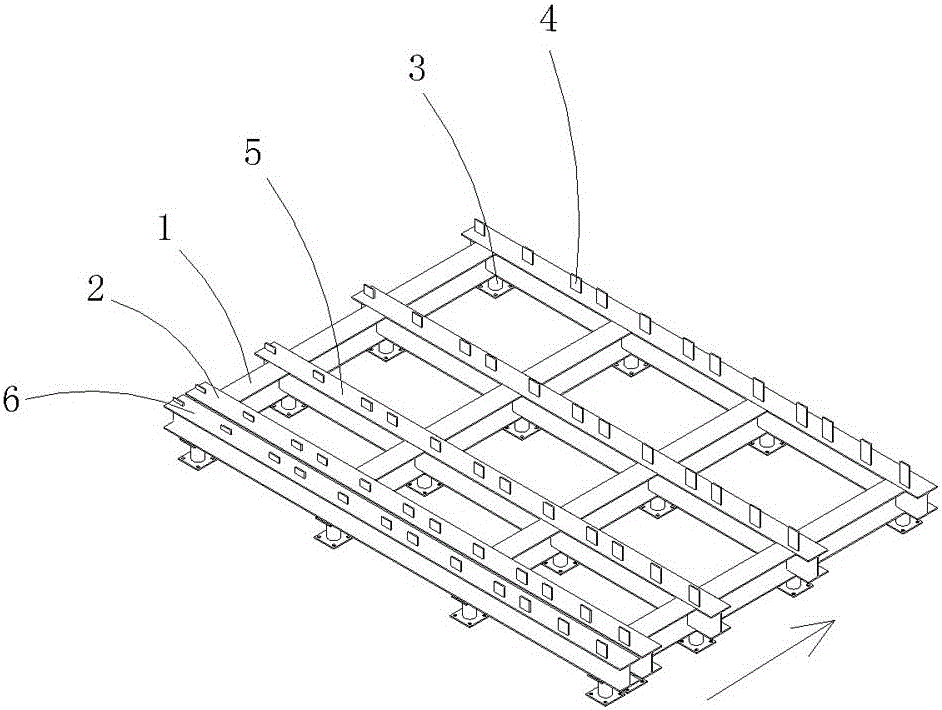

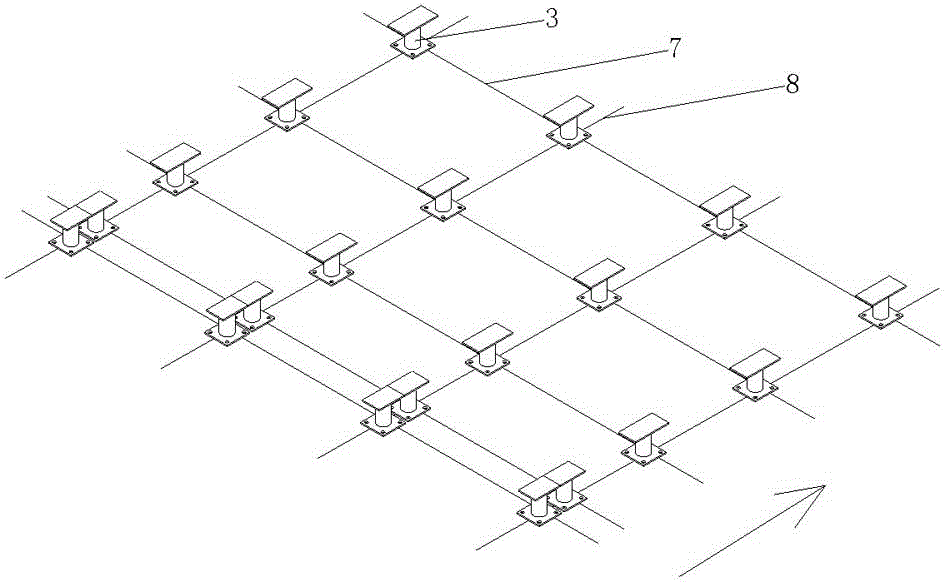

[0034] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Shown, a kind of highway steel bridge supports tire frame, comprises more than two longitudinal beams 1 and more than two transverse beams 2, two transverse beams 2 are fixed by two longitudinal beams 1, longitudinal beams 1 and transverse beams 2 The bottom of the joint is provided with a base 3, and the upper part of the transverse beam 2 is provided with evenly distributed tire mold control panels 4.

[0035] The two transverse beams 2 are provided with two intermediate transverse beams 5 that are mutually parallel and distributed in intervals, the longitudinal beams 1 have four, and the four longitudinal beams 4 are evenly distributed between the two transverse beams 2. The middle transverse beam 5 is spliced with four longitudinal beams 1;

[0036] The outer wall of the transverse beam 2 at one end is provided with a side transverse beam 6, and the base 3 is respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com