Flexible-rigid combined board and terminal

A soft-rigid combination board and rigid technology, applied in the structural connection of printed circuits, circuit electrostatic discharge protection, circuit bendable/stretchable components, etc., can solve circuit structure damage, affect service life, and poor strength and other problems to achieve the effect of improving service life, enhancing assembly strength, and improving electrostatic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

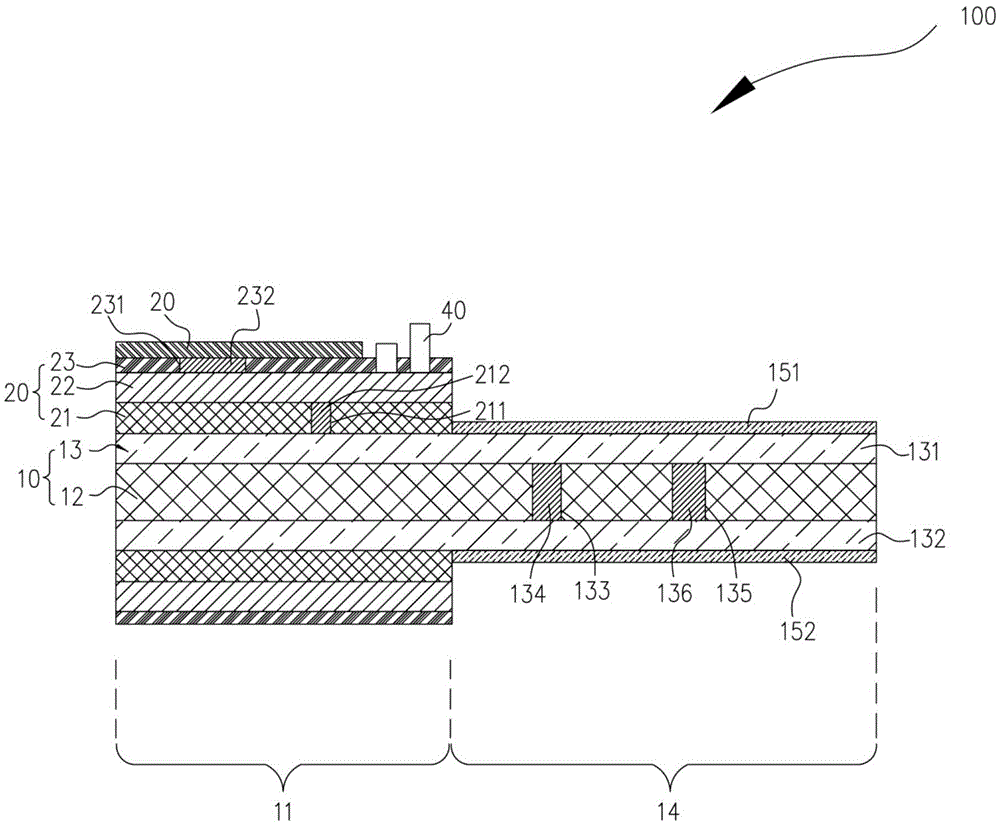

[0018] see figure 1 , the present invention provides a rigid-flex board 100 , the rigid-flex board 100 includes a flexible substrate 10 , a rigid substrate 20 and a steel sheet 30 . The flexible substrate 10 includes a first region 11, the rigid substrate 20 includes a hard insulating layer 21, a circuit layer 22 and a solder resist ink layer 23, the hard insulating layer 21 is fixed on the flexible substrate 10, and The orthographic projection area on the flexible substrate 10 coincides with the first region 11 . The circuit layer 22 is arranged on the hard insulating layer 21 , and the solder resist ink layer 23 covers the circuit layer 22 . The solder resist ink layer 23 is provided with at least one grounding via 231, and the grounding via 231 is provided with a ground c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com