Laser cutting machine with focusing laser head

A technology of laser cutting machine and laser cutting head, which is applied in the direction of laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problem that optical fibers cannot cut thick plates, and achieve the effects of avoiding adverse effects, ensuring accuracy, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

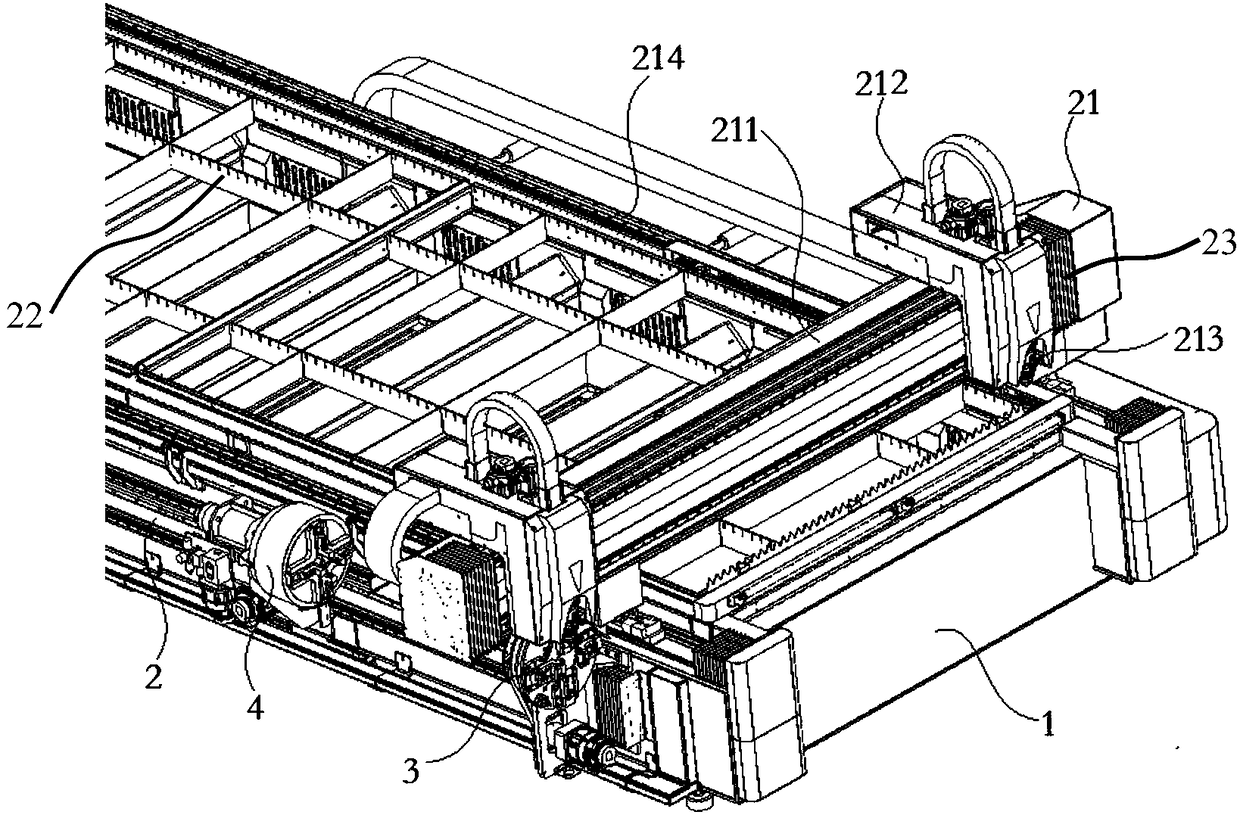

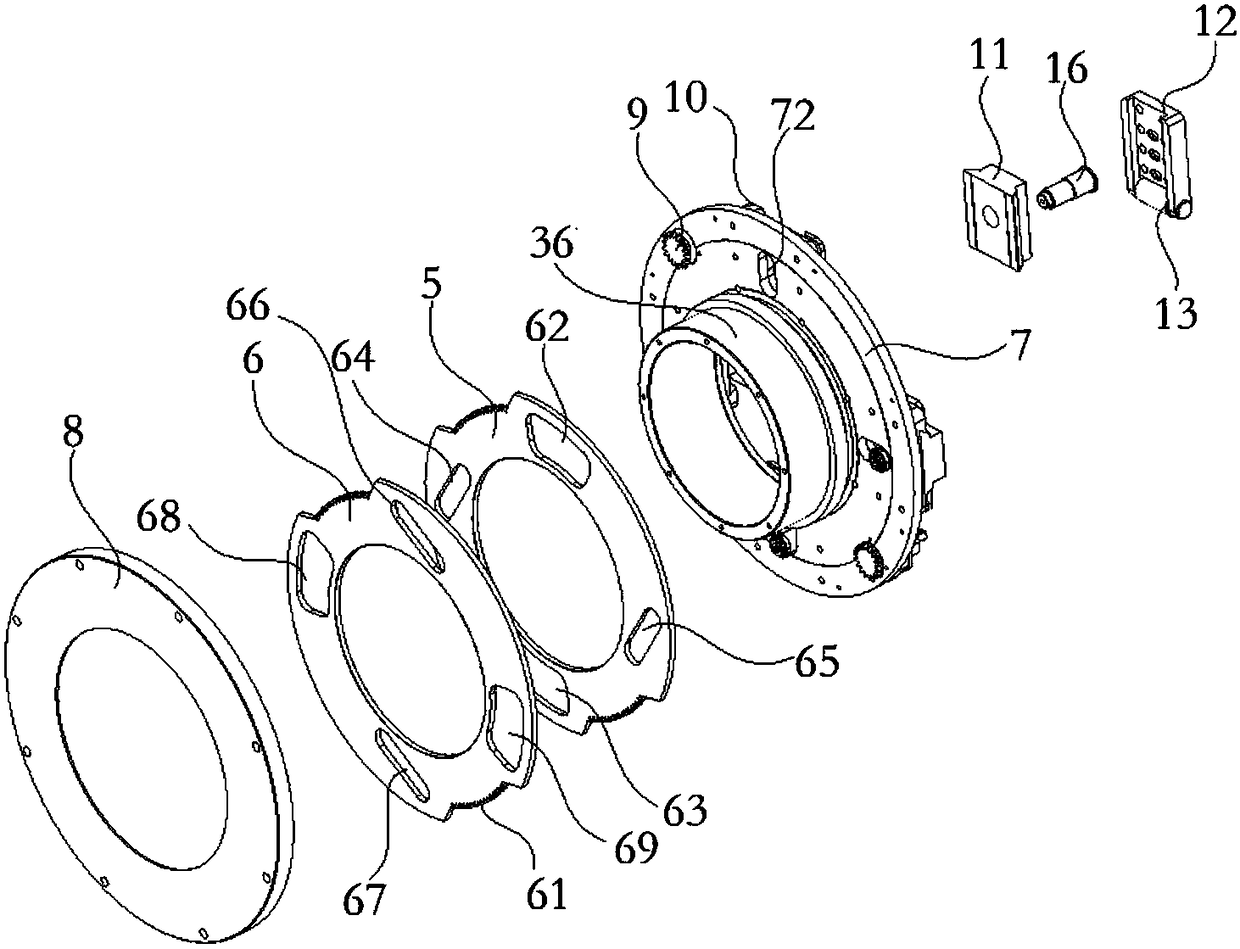

[0034] Embodiment 1: A laser cutting machine with an adjustable focus laser head, including a base 1, side guide rails 2 relatively arranged on both sides of the base 1, a front support mechanism 3, a rear rotation mechanism 4 and a cutting mechanism 21, the The cutting mechanism 21 is movably installed on the upper surface of the base 1, the rear rotating mechanism 4 is mounted on one side surface of the base 1 through the guide rail 2 and can move forward and backward along the guide rail, and the front supporting mechanism 3 is parallel to the rear rotating mechanism 4 set, installed at one end of the base 1;

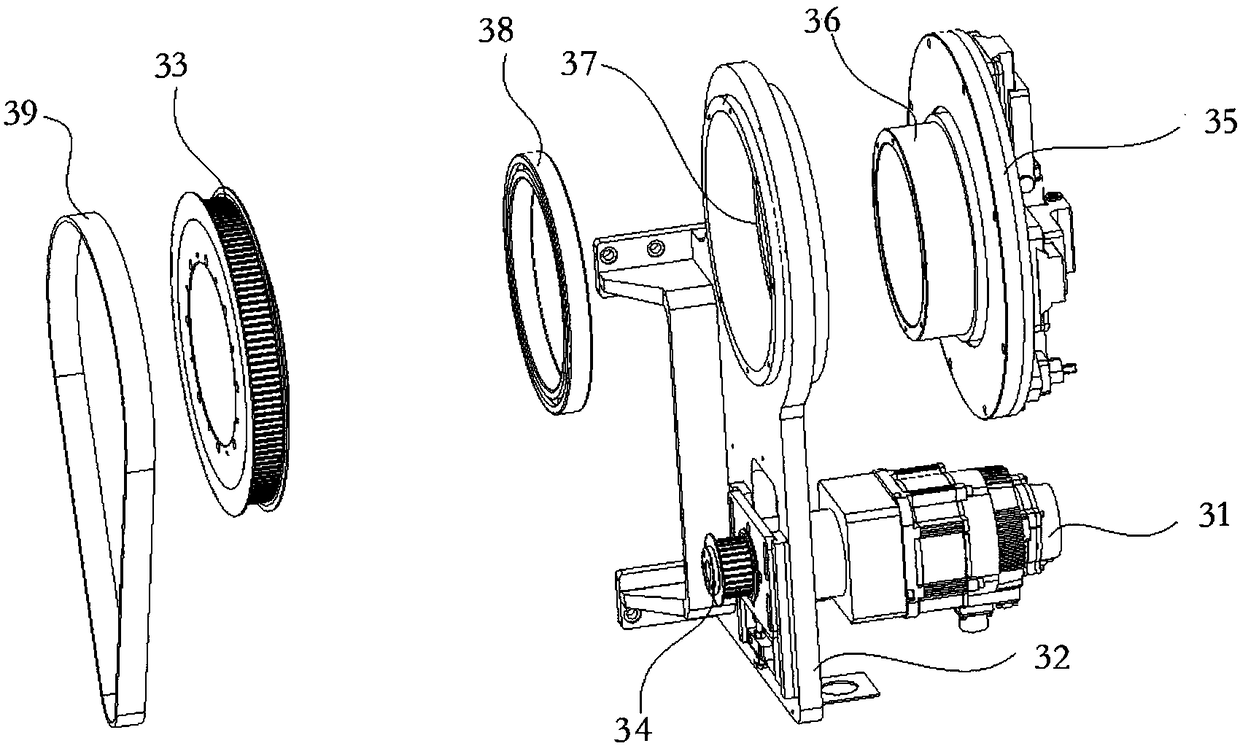

[0035] The front end support mechanism 3 further includes a motor 31, a support base 32, a large synchronous pulley 33, a small synchronous pulley 34 and a rotating disk 35, and the motor 31 and the small synchronous pulley 34 are respectively installed on both sides below the support base 32, The output shaft of this motor 31 passes through the support base 32 and i...

Embodiment 2

[0049] Embodiment 2: A laser cutting machine with an adjustable focus laser head, including a base 1, side guide rails 2 relatively arranged on both sides of the base 1, a front support mechanism 3, a rear rotation mechanism 4 and a cutting mechanism 21, the The cutting mechanism 21 is movably installed on the upper surface of the base 1, the rear rotating mechanism 4 is mounted on one side surface of the base 1 through the guide rail 2 and can move forward and backward along the guide rail, and the front supporting mechanism 3 is parallel to the rear rotating mechanism 4 set, installed at one end of the base 1;

[0050] The front end support mechanism 3 further includes a motor 31, a support base 32, a large synchronous pulley 33, a small synchronous pulley 34 and a rotating disk 35, and the motor 31 and the small synchronous pulley 34 are respectively installed on both sides below the support base 32, The output shaft of this motor 31 passes through the support base 32 and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com