Device for adjusting curvature radius of cylindrical mirror

A technology of cylindrical mirror and surface mirror, which is applied in the field of lasers, can solve the problems of reduced laser energy conversion efficiency, increased laser loss, difficult laser device adoption, etc., to achieve the effects of avoiding laser damage, maintaining stable operation, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

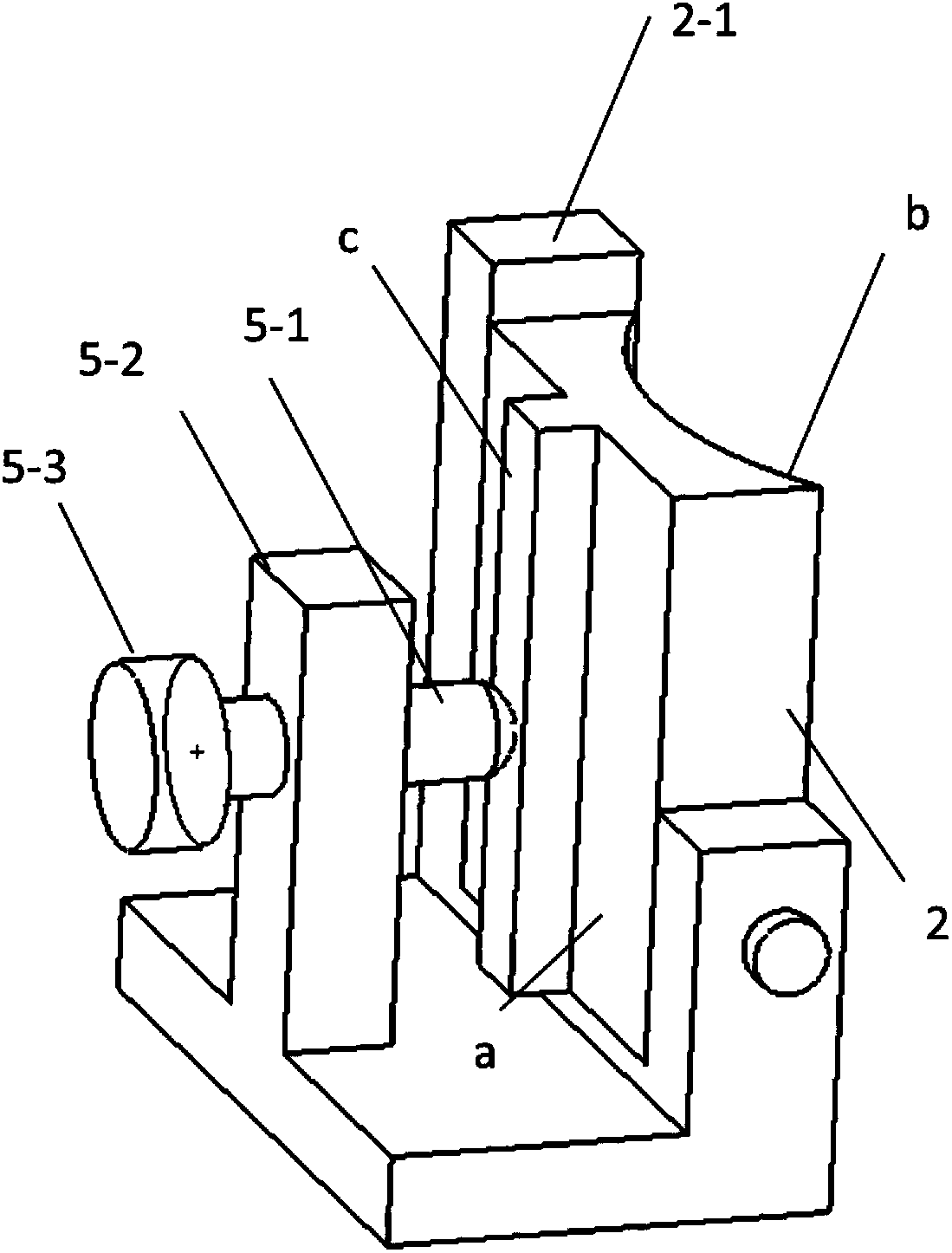

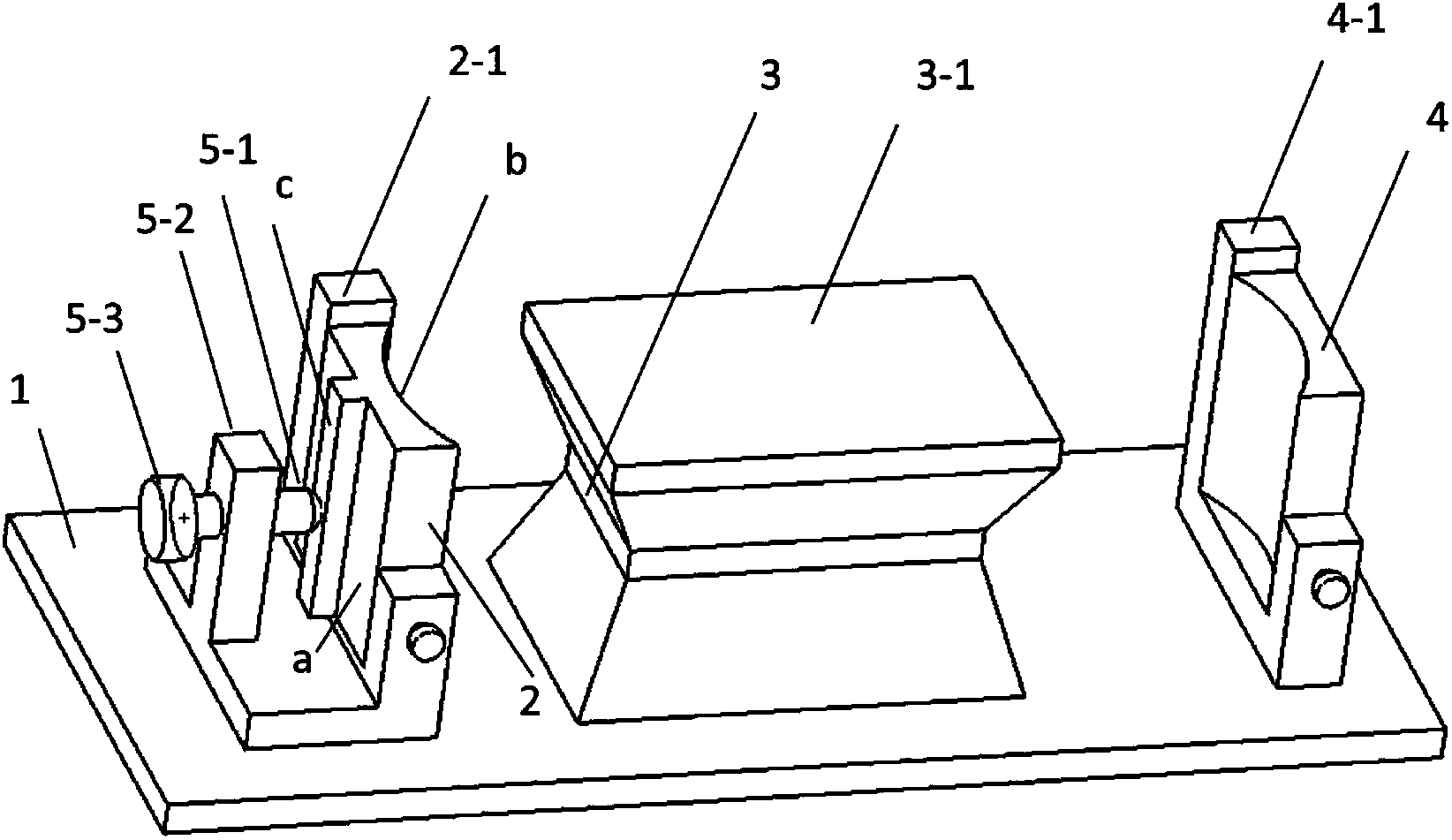

[0046] Such as figure 1 As shown, one end of the ejector rod 5-1 connected to the ejector rod drive unit 5-3 is provided with an external thread, and the ejector rod drive unit 5-3 is provided with an internal thread matching the external thread, and the ejector rod drive unit 5-3 is rotated It can promote telescopic movement of the push rod 5-1 in the horizontal direction. The ejector rod 5-1 of this embodiment runs through the ejector rod support 5-2, and the ejector rod 5-1 and the ejector rod support 5-2 are connected by threads.

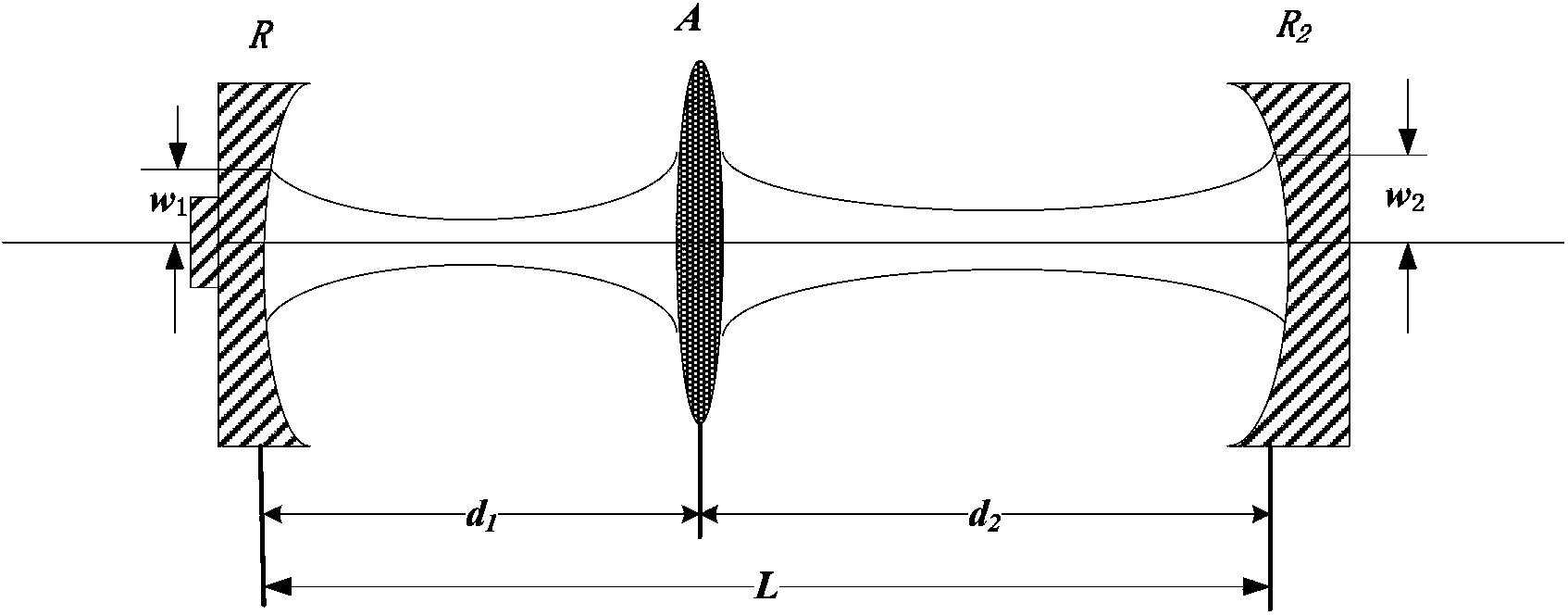

[0047] In this embodiment, the purpose of changing the radius of curvature R of the cylindrical mirror 2 is to change the force exerted by the ejector rod 5-1 on the outer surface a of the cylindrical mirror 2 by rotating the ejector rod driving unit 5-3. Such as figure 1 As shown, the minimum value of the change value Δx of the radius of curvature Δx of the cylindrical mirror 2 can be realized by manually adjusting the ejector rod drive unit ...

Embodiment 2

[0049] Such as Figure 4 , the ejector rod 5-1 is piezoelectric ceramic material, the ejector rod drive unit 5-3 is a piezoelectric ceramic power supply, the ejector rod 5-1 is connected to the ejector rod drive unit 5-3 through a cable, and the ejector rod support 5 in this embodiment The top of -2 has a card slot, and the ejector rod 5-1 is installed in the card slot, and the ejector rod 5-1 can move horizontally in the card slot. When there is no external voltage, the tip of the ejector rod 5-1 is in geometric contact with the pressure uniform distribution part c, and the voltage of the ejector rod drive unit 5-3 is adjusted to drive the ejector rod 5-1 to expand and contract, so that the ejector rod 5-1 acts on the column The force acting on the outer surface a of the mirror 2 changes, thereby achieving the purpose of changing the radius of curvature R of the inner surface b of the cylindrical mirror 2 .

[0050] Since the piezoelectric ceramic material can realize high-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com