Carrier tape feeder

一种送料器、载带的技术,应用在电气元件、金属加工设备、电气元件等方向,能够解决降低工作效率、作业时间加长、改变载带节距等问题,达到提高工作稳定性、次品发生率低、提高适应能力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be described in detail below.

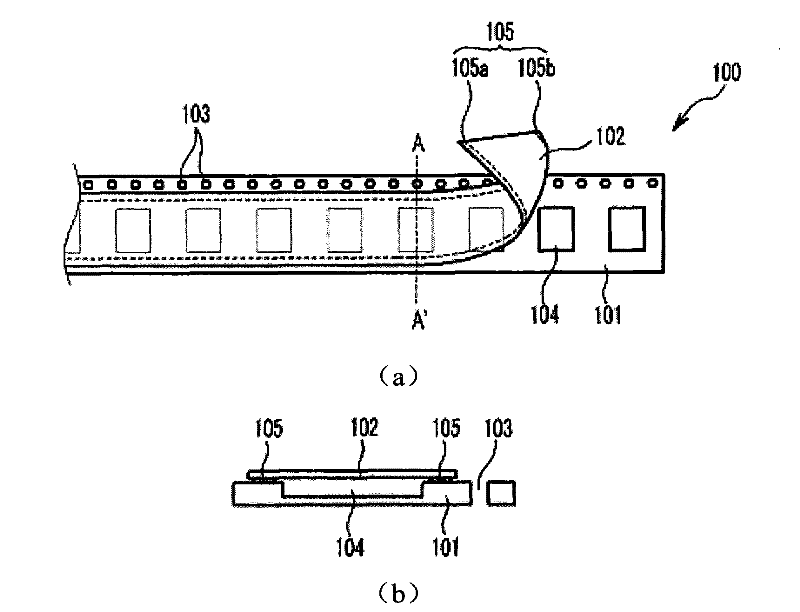

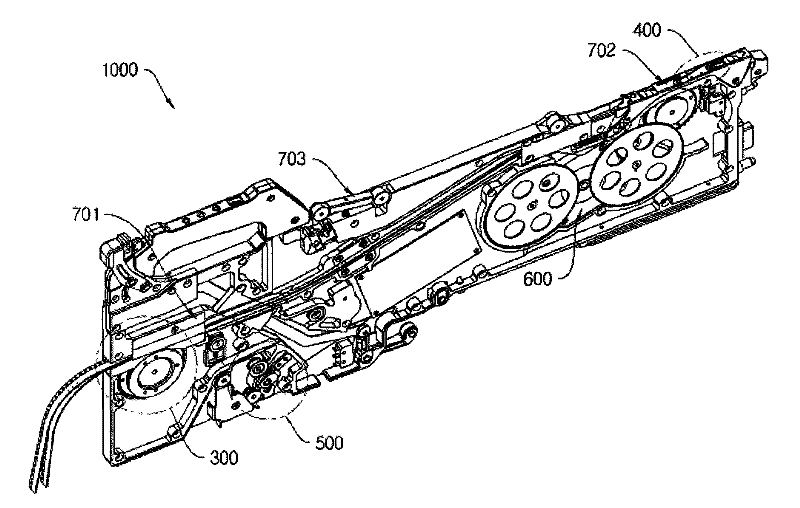

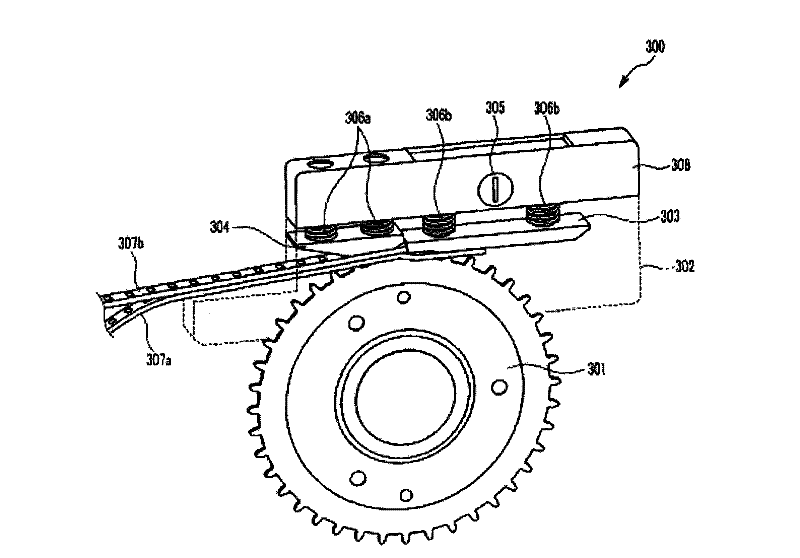

[0075] The carrier tape feeder of the present invention includes: a carrier tape loading part, a component pick-up part, and a drive part, wherein the part pick-up part includes: a knife edge part, which separates the base tape and the cover tape at the first joint part; the folding part, The folded portion is formed at intervals on the side of the blade portion, and the folded portion is formed by folding the cover tape separated from the blade portion along the length direction in a state combined with the second joint portion; a guide portion, which is laminated on the on the base tape, and extend obliquely from the blade portion and the folded portion to the outside of the carrier tape, to guide the upper and lower surfaces of the cover tape folded at the folded portion to turn over and be stacked on the base tape; wherein, the folded portion opposite to the blade portion Terminations of the sides extend abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com