Optically clear polycarbonate polyester compositions

一种聚碳酸酯、光学透明的技术,应用在热塑性树脂组合物领域,能够解决透明性降低、高扭矩、流动性低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

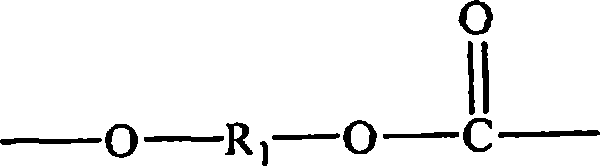

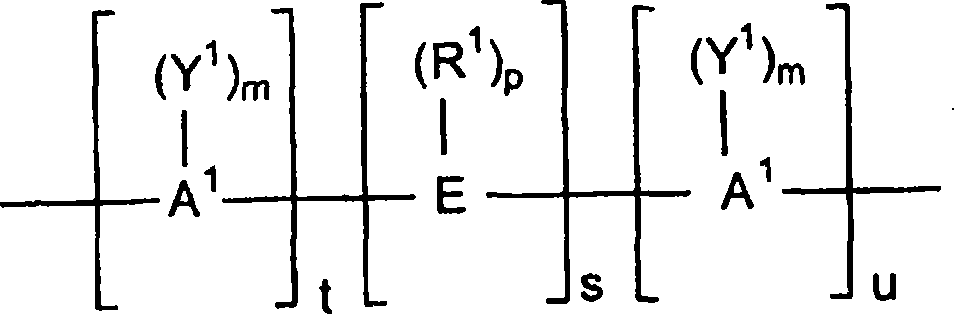

Method used

Image

Examples

Embodiment approach

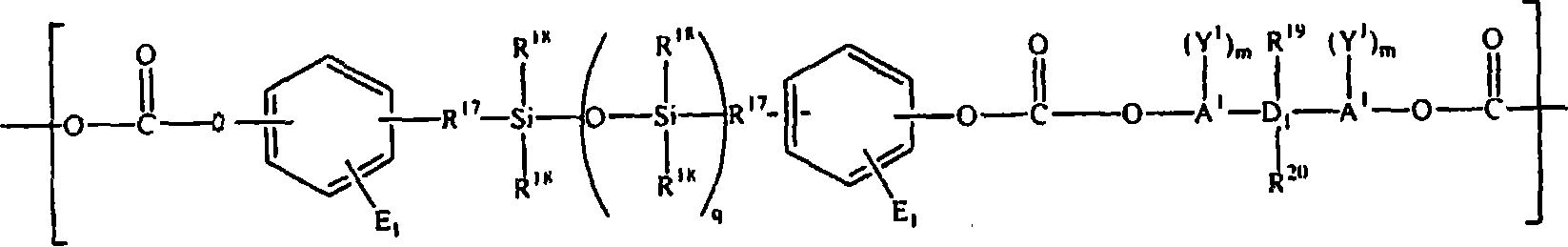

[0081] In one embodiment, the organopolysiloxane-polycarbonate block copolymer has structure XVIII:

[0082]

[0083] R 19 and R 20 The groups shown include aryl and haloaryl such as phenyl, chlorophenyl, xylyl, tolyl, etc.; aralkyl such as phenethyl, benzyl, etc.; aliphatic, haloaliphatic, and cyclic Aliphatic groups such as alkyl, cycloalkyl, haloalkyl, including methyl, ethyl, propyl, chlorobutyl, cyclohexyl, etc.; R 19 and R 20 can be the same group or any two or more of the aforementioned groups, while R 19 and R 20 Preferably methyl, R 17 Include the above R 19 and R 20 All groups included, except hydrogen, where R 17 It can also be the same group or any two or more of the aforementioned R 19 and R 20 groups, except hydrogen, and R 17 Methyl is preferred. except R 19 and R 20 All groups (except hydrogen) included, R 17 Also included are cyanoalkyl groups such as cyanoethyl, cyanobutyl, and the like. E. 1 The groups included in the definition are hydro...

Embodiment 1-5

[0112] Examples 1-5: In these examples, polycarbonate obtained from the General Electric Company as Lexan(R) polycarbonate resin was blended with PCCD obtained from Eastman Chemicals and various levels of silicon obtained from the General Electric Company were used. Oxyalkylene-modified polycarbonate and ABS 415 were used as impact modifiers. The thermoplastic resin composition was compounded on a WP25mm co-rotating twin-screw extruder at 270°C to obtain a granular composition. The mixing was carried out at a feed rate of about 15 kg / h and a screw speed of about 300 revolutions / minute. The pellets obtained were dried at 100°C for at least 4 hours before injection molding into ASTM / ISO test specimens on an 80 ton, 4 oz injection molding machine operating at about 280°C. The silicone-modified polycarbonate used here has a silicone content of 6% and ABS 415 has a rubber (butadiene) content of 50%. The ingredient amounts were chosen to maintain the same soft phase (silicone + ru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact toughness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com