Thermoplastic fluorine-containing fully aromatic polyimide powder and preparation method thereof

A polyimide powder, thermoplastic technology, applied in the field of thermoplastic fluorine-containing peraromatic polyimide powder and its preparation, can solve problems such as unpublished literature or patent reports, and achieve good application prospects and environmental friendliness , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

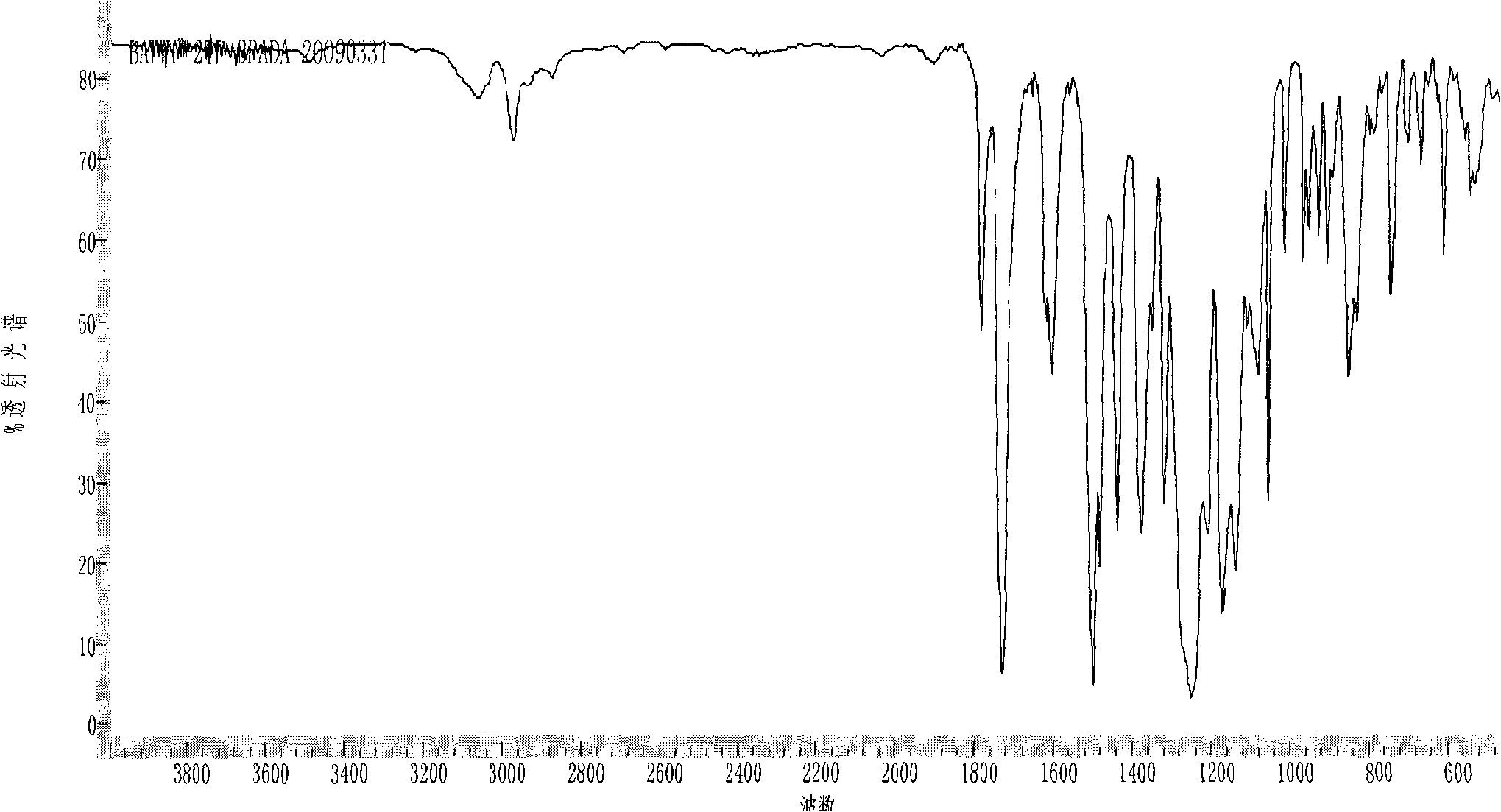

[0072] 65.4 grams (0.1 moles) of 2,2-bis[4-(2-trifluoromethyl-4-aminophenoxy)phenyl]hexafluoropropane (BAPFP-2TF), 52.0 grams (0.1 moles) of 2 , 2-bis[4-(3,4-dicarboxyphenoxy) phenyl] propane dianhydride (BPADA), 0.005 mole isoquinoline and 1308 gram o-cresol are put into reactor, stir, heat up to Within the temperature range of 100°C-180°C, after maintaining the reaction for 5 hours, pour it into 13080 grams of ethanol precipitant under high-speed stirring state while it is hot, and precipitate solid powder, filter, wash with ethanol 2-3 times, soak in acetone 5 hours, filter, wash with deionized water 2-3 times, dry, obtain 111.5 grams of BAPFP-2TF / BPADA-PI thermoplastic fluorine-containing fully aromatic polyimide white powder (theoretical amount 113.8 grams), yield is 98% , the glass transition temperature is 189.5°C, and its Fourier transform infrared spectrum (FTIR) is as follows figure 2 shown.

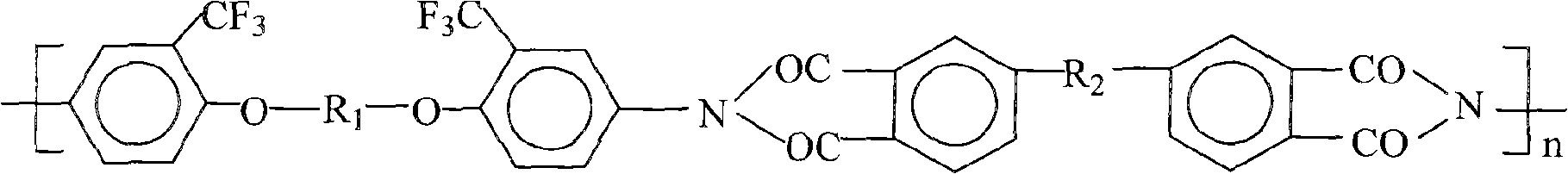

[0073] The molecular structural formula of BAPFP-2TF / BPADA-PI thermopla...

Embodiment 2

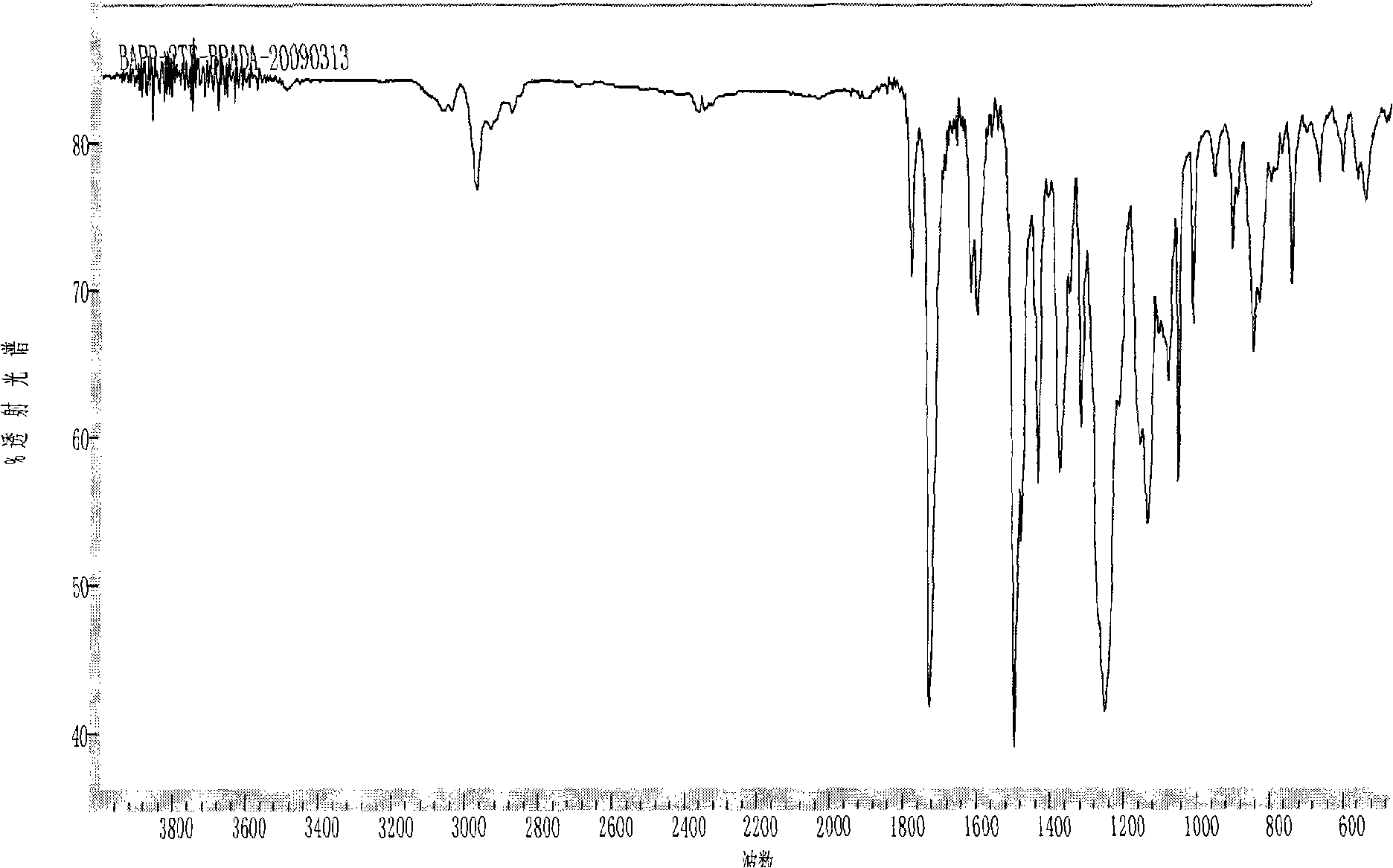

[0076] 54.7 grams (0.1 moles) of 2,2-bis[4-(2-trifluoromethyl-4-aminophenoxy)phenyl]propane (BAPP-2TF), 52.0 grams (0.1 moles) of 2,2 -Bis[4-(3,4-dicarboxyphenoxy)phenyl]propanedianhydride (BPADA), 0.001 mole of isoquinoline and 274 grams of o-cresol were put into the reaction kettle, stirred, and heated to 100°C Within the temperature range of -180°C, after maintaining the reaction for 10 hours, pour it into 1370 grams of methanol precipitant under high-speed stirring state while it is hot, and precipitate solid powder, filter, wash with isopropanol 2-3 times, soak in acetone 5 hours, filter, wash 2-3 times with deionized water, dry, obtain 102.1 grams of BAPP-2TF / BPADA-PI thermoplastic fluorine-containing fully aromatic polyimide white powder (theoretical amount 103.1 grams), yield is 99% , the glass transition temperature is 192.2°C, and its Fourier transform infrared spectrum (FTIR) is as follows image 3 shown.

[0077] The molecular structural formula of BAPP-2TF / BPADA...

Embodiment 3

[0080] 50.4 grams (0.1 moles) of 4,4'-bis(2-trifluoromethyl-4-aminophenoxy)biphenyl (DABP-2TF), 52.0 grams (0.1 moles) of 2,2-bis[4 -(3,4-dicarboxyphenoxy)phenyl]propane dianhydride (BPADA), 0.001 mole of isoquinoline, 0.009 mole of pyridine and 600 grams of o-cresol were put into the reaction kettle, stirred, and heated to 100°C In the temperature range of -180°C, after maintaining the reaction for 8 hours, pour it into 30,000 grams of isopropanol precipitant under high-speed stirring state while it is hot, and precipitate solid powder, filter, wash with isopropanol for 2-3 times, acetone soaked in medium for 5 hours, filtered, washed with deionized water for 2-3 times, and dried to obtain 93.8 grams of DABP-2TF / BPADA-PI thermoplastic fluorine-containing fully aromatic polyimide white powder (theoretical amount 98.8 grams), the yield is 95%, the glass transition temperature is 219.7 ° C, and its Fourier transform infrared spectrum (FTIR) is as follows Figure 4 shown.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com